In the realm of mechanical equipment, comprehending the intricate relationships between various elements is essential. Each component plays a vital role in ensuring optimal performance and functionality. By exploring the layout and connections of these elements, users can gain valuable insights into maintenance and operational efficiency.

Illustrations of these connections provide a clear visual reference, making it easier to identify individual elements and their respective functions. This understanding not only aids in troubleshooting but also enhances the overall ability to manage the equipment effectively.

Whether for repairs or enhancements, having a solid grasp of how these components interact is crucial for anyone involved in the upkeep of machinery. With the right knowledge, users can navigate challenges with confidence and ensure longevity in their operations.

Power King Tractor Components Overview

This section provides a comprehensive look at the essential elements that make up a well-functioning machine in the agricultural sector. Understanding these components is crucial for effective maintenance and operation.

- Engine: The heart of the machinery, responsible for powering the entire system.

- Transmission: This system transfers power from the engine to the wheels, facilitating movement.

- Hydraulic System: This enables lifting and moving heavy loads, enhancing operational efficiency.

- Chassis: The framework that supports all other components, ensuring stability and durability.

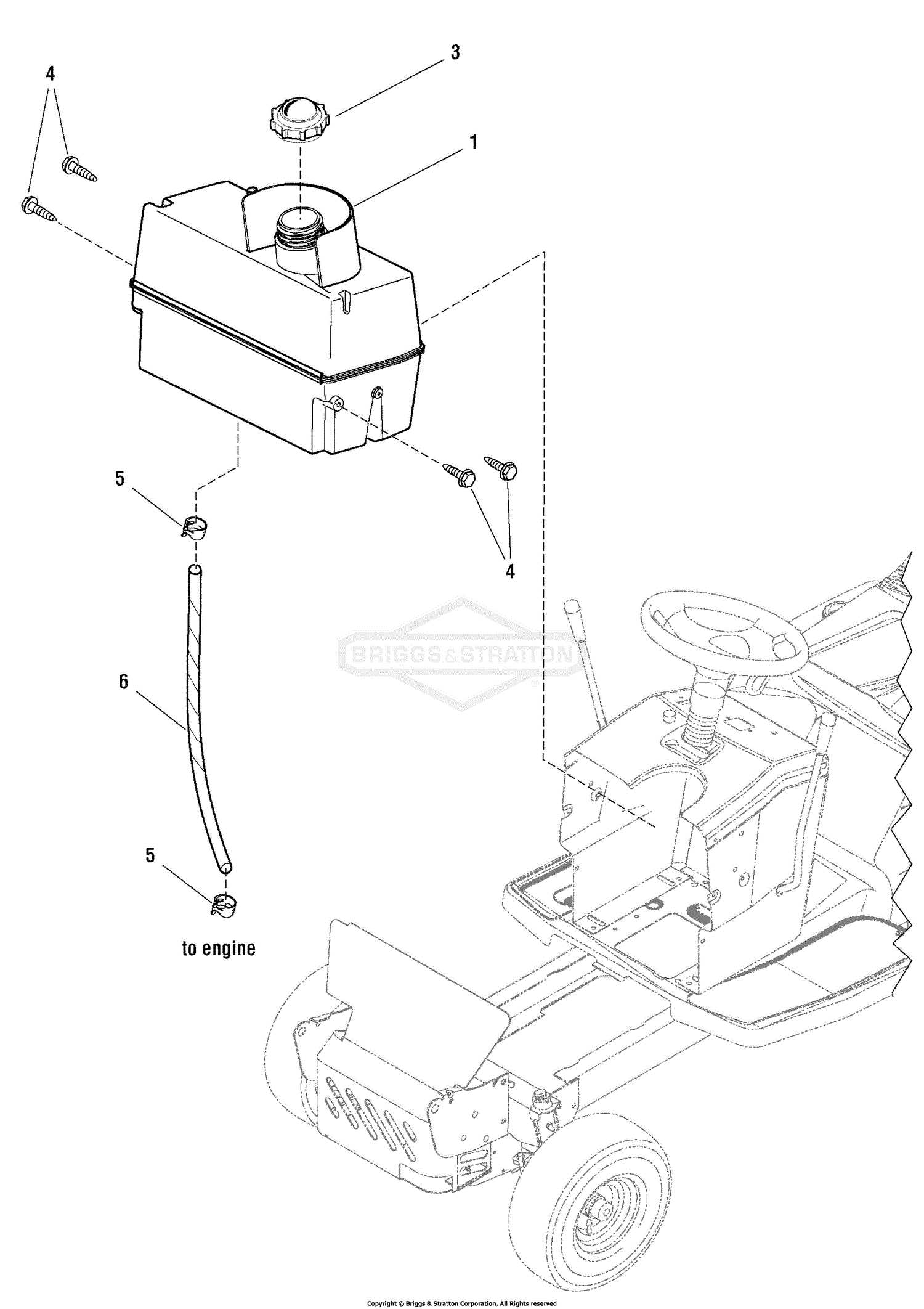

- Fuel System: This system stores and delivers energy, vital for continuous operation.

Each of these elements plays a significant role in the overall functionality and performance of the machine. Regular inspection and maintenance of these components contribute to the longevity and reliability of the equipment.

- Regularly check the engine oil levels to ensure optimal performance.

- Inspect the hydraulic system for leaks and proper fluid levels.

- Monitor the transmission fluid to prevent overheating and wear.

Key Features of Power King Models

This section explores the distinctive characteristics of specific models known for their reliability and efficiency. These features contribute to their popularity among users seeking robust machinery for various tasks.

Durability and Performance

Renowned for their sturdy construction, these models are designed to withstand demanding conditions. Their powerful engines ensure optimal performance, enabling them to tackle challenging tasks with ease.

User-Friendly Design

The intuitive layout and controls enhance usability, making operation straightforward for both novices and experienced users. This thoughtful design approach promotes comfort during extended use.

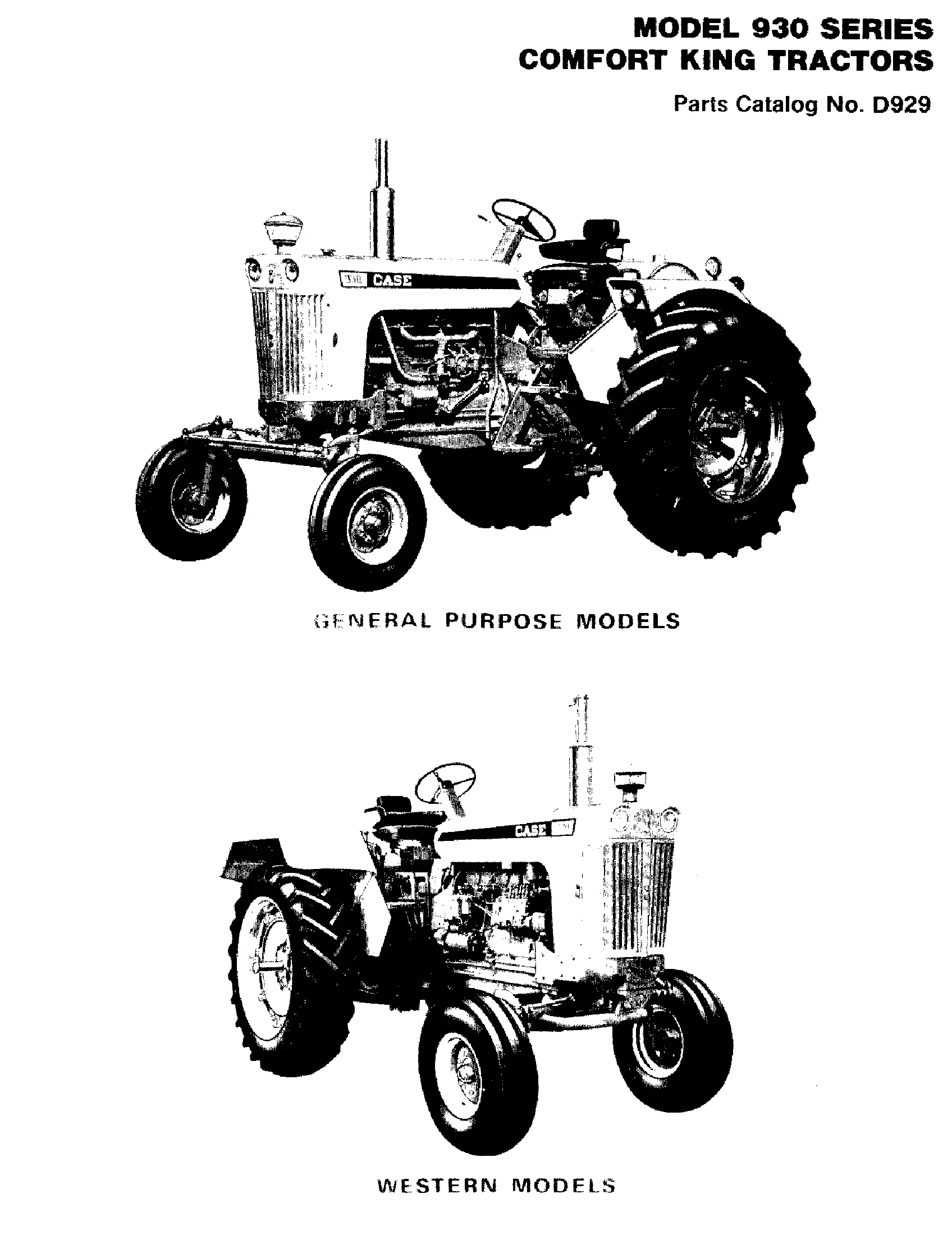

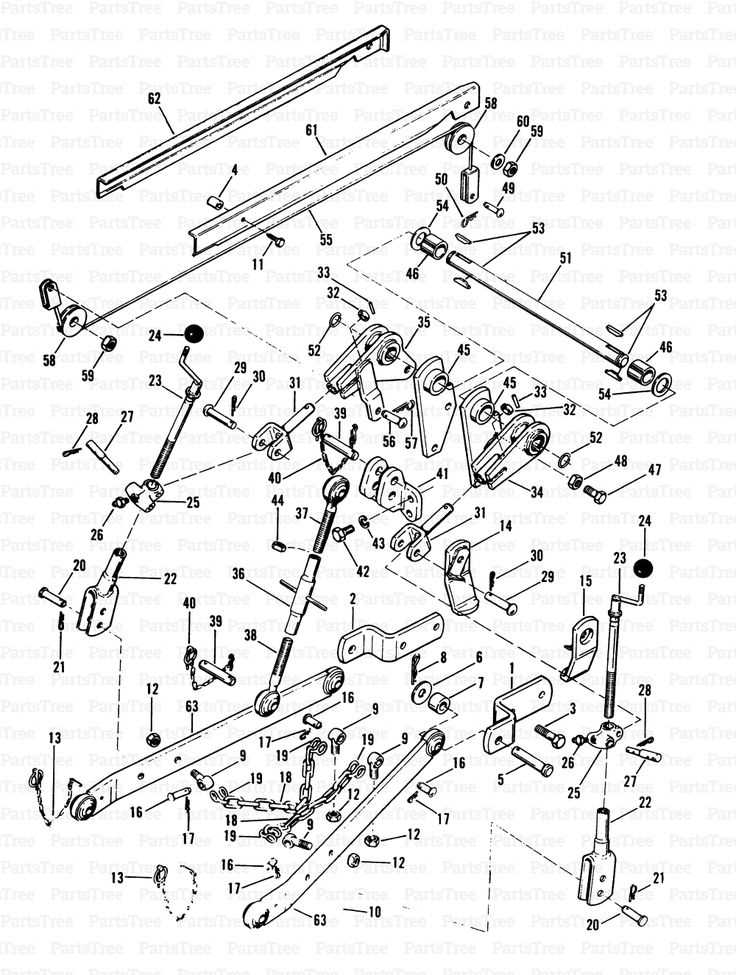

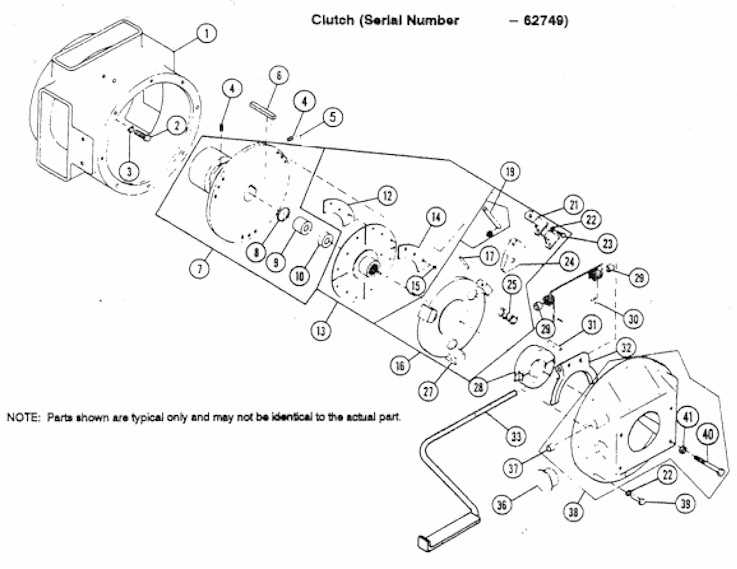

Understanding the Parts Diagram

This section explores the visual representation of various components essential for a specific machinery type. By interpreting this illustration, users can enhance their knowledge about the key elements that contribute to optimal performance and maintenance.

Key Components Overview

The following table highlights the fundamental elements featured in the illustration, providing clarity on their functions and relevance:

| Component | Description |

|---|---|

| Frame | The structural foundation supporting all other elements. |

| Engine | The powerhouse that drives the entire mechanism. |

| Transmission | Facilitates the transfer of power to various parts. |

| Wheels | Enable movement across different terrains. |

Importance of Understanding

Grasping the arrangement and functionality of these components is crucial for effective troubleshooting and routine upkeep. Familiarity with the layout empowers users to identify potential issues and enhance operational efficiency.

Essential Components of the Tractor

The machinery consists of various crucial elements that work together to ensure optimal performance. Understanding these components helps in maintenance and enhances efficiency.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulic System | Enables various operations through fluid pressure. |

| Chassis | The frame that supports all other components. |

| Wheels | Provides mobility and stability on various terrains. |

Maintenance Tips for Power King

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular attention can prevent minor issues from escalating into significant problems, ensuring reliable operation over time.

Regular Inspections: Conduct frequent checks to identify wear and tear. Look for signs of damage or deterioration that may require immediate attention.

Fluid Levels: Ensure that all essential fluids, such as oil and coolant, are maintained at appropriate levels. Regularly change these fluids to promote efficient functioning.

Cleaning: Keep the exterior and interior free from debris and dirt. This not only enhances the appearance but also helps in preventing rust and corrosion.

Component Checks: Examine belts, hoses, and filters for signs of wear. Replace any components that show signs of damage to avoid operational disruptions.

Consult the Manual: Refer to the manufacturer’s guidelines for specific maintenance recommendations tailored to your equipment. Following these suggestions can greatly enhance performance.

Common Issues with Power King Parts

When it comes to the components of heavy machinery, several challenges can arise that may impact performance and longevity. Understanding these issues is essential for maintaining operational efficiency and ensuring smooth functionality.

Wear and Tear: Over time, frequent use can lead to deterioration in various components. Regular inspections are crucial to identify signs of damage before they escalate.

Improper Installation: Many complications stem from incorrect assembly of parts. Following manufacturer guidelines can help mitigate risks associated with misalignment and poor fit.

Compatibility Concerns: Using non-standard components can lead to performance issues. Always verify that replacements are suitable for your specific machinery model.

Maintenance Neglect: Failing to adhere to routine maintenance schedules can exacerbate existing issues, leading to more significant problems and costly repairs. Keeping a diligent maintenance log can prove beneficial.

Environmental Factors: External conditions, such as moisture and dust, can affect the integrity of components. Implementing protective measures can help prolong their lifespan.

Replacement Part Options Available

When maintaining machinery, understanding the various alternatives for components is crucial. These options not only enhance performance but also ensure longevity and reliability. Exploring the range of available choices can greatly benefit users seeking to optimize their equipment.

Types of Alternatives

- Aftermarket Components: These are produced by third-party manufacturers and often provide cost-effective solutions without compromising quality.

- OEM Selections: Original equipment manufacturer options are designed to meet specific standards and compatibility requirements, ensuring seamless integration.

- Rebuilt Units: Reconditioned parts offer a sustainable choice, giving new life to existing components while maintaining functionality.

Considerations for Selection

- Compatibility: Ensure the chosen alternative fits the specific machinery model.

- Quality Assurance: Verify that the components meet industry standards for durability and performance.

- Cost-Effectiveness: Evaluate the long-term value against the initial investment to determine the best option.

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will simplify the process, enabling users to quickly interpret various symbols and connections. Familiarity with the layout and terminology will enhance troubleshooting skills and improve overall efficiency.

Step 1: Begin by identifying the key features indicated on the visual guide. Each element corresponds to specific functionalities, aiding in comprehension.

Step 2: Pay attention to the legend or key, which typically clarifies the meaning of different symbols. This information is crucial for accurate interpretation.

Step 3: Trace the connections between elements. Understanding how each component interacts will provide insight into the system’s overall operation.

Step 4: Regular practice with various representations will build confidence and expertise in recognizing patterns and functionalities.

Assembly and Disassembly Guide

This section provides essential guidance for effectively putting together and taking apart machinery components. Understanding the proper sequence and techniques is crucial for maintaining optimal functionality and ensuring safety during the process.

Preparation Steps

Before starting, gather all necessary tools and equipment. Ensure that the workspace is clean and organized to facilitate smooth operations. Familiarize yourself with the individual components to streamline the assembly or disassembly.

Assembly Process

Begin by carefully aligning all parts according to the designated configuration. Utilize appropriate fasteners and ensure they are tightened securely, yet not excessively. Regularly check your progress to maintain accuracy and prevent potential issues during operation.

Tools Needed for Repairs

When undertaking maintenance on agricultural machinery, having the right tools is essential for efficient and effective repairs. A well-equipped toolkit ensures that tasks can be completed smoothly, reducing downtime and improving productivity.

- Wrenches: Various sizes are crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different screws.

- Pliers: Useful for gripping and twisting components.

- Socket set: Provides the versatility needed for various fasteners.

- Jack stands: Important for safely lifting heavy machinery during repairs.

- Safety gear: Gloves and goggles protect against injury while working.

Having these essential tools readily available will facilitate smoother repair processes, ensuring that machinery remains in optimal condition.

Safety Precautions During Maintenance

Ensuring safety during upkeep activities is essential for preventing accidents and injuries. Proper precautions should be taken to create a secure environment for all individuals involved in the maintenance process.

First, always wear appropriate protective gear, including gloves, goggles, and sturdy footwear, to shield against potential hazards. Second, ensure that the working area is clean and organized to minimize risks of slips or falls. Regularly check that all tools and equipment are in good condition, as faulty items can lead to unexpected accidents.

Additionally, it is crucial to follow manufacturer guidelines and safety protocols during any maintenance procedure. Make sure to disconnect power sources and allow components to cool down before starting any work. Lastly, communicating clearly with team members about ongoing tasks can enhance overall safety.

Where to Buy Genuine Parts

Finding authentic components for your machinery is essential for optimal performance and longevity. Various sources offer high-quality replacements that ensure compatibility and reliability. When seeking these items, consider reputable retailers and official distributors who specialize in specific equipment.

Online Platforms: Numerous websites focus on selling authentic replacements, providing detailed catalogs and customer support. Look for platforms that offer guarantees and customer reviews to ensure reliability.

Local Dealerships: Authorized dealers often stock genuine components, providing personalized assistance. Visiting a local shop can also help you gain insights into compatible options for your machinery.

Manufacturer Websites: Directly checking the manufacturer’s website is a reliable approach. They typically offer a comprehensive list of available items and can guide you to trusted suppliers.

Trade Shows and Expos: Attending industry events can connect you with manufacturers and distributors, often showcasing the latest products and special offers.

Resources for Power King Owners

For enthusiasts of these versatile machines, accessing quality information and support is essential. Numerous platforms offer valuable resources tailored to the needs of owners. These can include forums, manuals, and dedicated websites that provide guidance on maintenance and repairs.

Online communities are particularly beneficial, allowing users to share experiences, troubleshoot issues, and exchange tips. Additionally, many retailers specialize in offering accessories and components, ensuring that users can easily find what they need to keep their equipment in top condition.