When delving into the intricacies of mechanical assemblies, it becomes crucial to comprehend how various elements interact to achieve seamless functionality. This section will explore the essential components that form the backbone of these intricate systems, shedding light on their arrangement and significance in ensuring optimal performance.

The organization of these crucial elements is often represented visually, allowing for a clearer understanding of their connections and roles. By examining these illustrations, one can appreciate how each component contributes to the overall operation, highlighting the importance of precision in their design and implementation.

Furthermore, understanding these components aids not only in maintenance and troubleshooting but also in enhancing performance through informed modifications. This knowledge empowers individuals to make educated decisions regarding upgrades or repairs, ultimately leading to improved efficiency and longevity of the system.

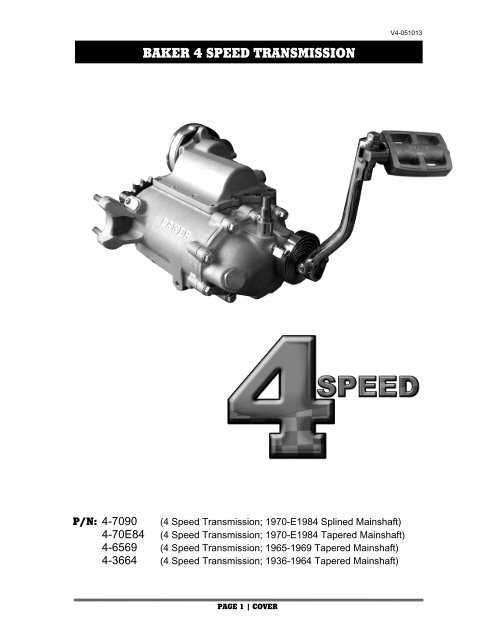

Key Components of Baker Transmission

The intricate workings of any mechanical system rely on various essential elements that collaborate seamlessly to ensure optimal performance. Understanding these critical components is vital for anyone interested in the functionality and maintenance of these systems.

Essential Elements

Each system comprises several significant components that serve distinct purposes. These elements work in harmony to facilitate smooth operation and enhance efficiency. A comprehensive grasp of these essential elements can significantly contribute to effective troubleshooting and maintenance.

Overview Table

| Component | Description |

|---|---|

| Gear Set | Responsible for transferring torque and speed between moving parts. |

| Fluid Pump | Ensures circulation of hydraulic fluid, vital for operation. |

| Filter | Removes contaminants from the fluid to maintain system integrity. |

| Control Valve | Regulates fluid flow and pressure to manage performance. |

Understanding Transmission Functionality

The mechanics behind a vehicle’s power delivery system are crucial for ensuring smooth operation and performance. This intricate network of components works harmoniously to manage the transfer of energy from the engine to the wheels, enabling efficient movement. By comprehending the principles at play, one can appreciate the importance of each element in maintaining optimal functionality.

Key Elements of this system include gears, clutches, and hydraulic mechanisms, each serving a specific role in facilitating the conversion of engine power. The interplay between these components determines how effectively power is harnessed and distributed, influencing acceleration, speed, and overall driving experience.

Maintenance of this assembly is vital for longevity and performance. Regular checks and timely replacements can prevent wear and tear, ensuring that the vehicle operates smoothly under various conditions. Understanding how these components function together helps in diagnosing issues and implementing solutions when problems arise.

Common Components Found in Baker Systems

In this section, we explore the fundamental elements frequently encountered within systems manufactured by Baker. These components play integral roles in ensuring the smooth operation and reliability of the transmission mechanisms. Understanding these foundational parts is essential for maintenance and troubleshooting purposes.

- Essential elements

- Primary components

- Key elements

- Crucial parts

- Central components

Each of these elements contributes uniquely to the overall functionality of the systems, emphasizing the importance of their proper integration and maintenance. By recognizing these core components, technicians and operators can effectively manage and optimize Baker systems, ensuring longevity and performance.

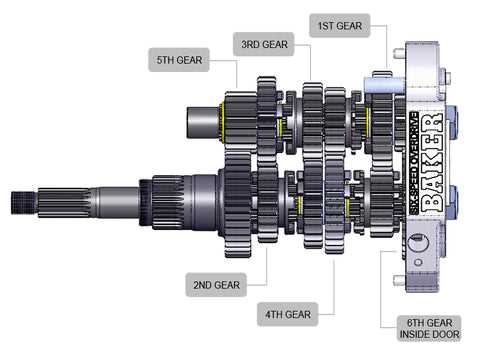

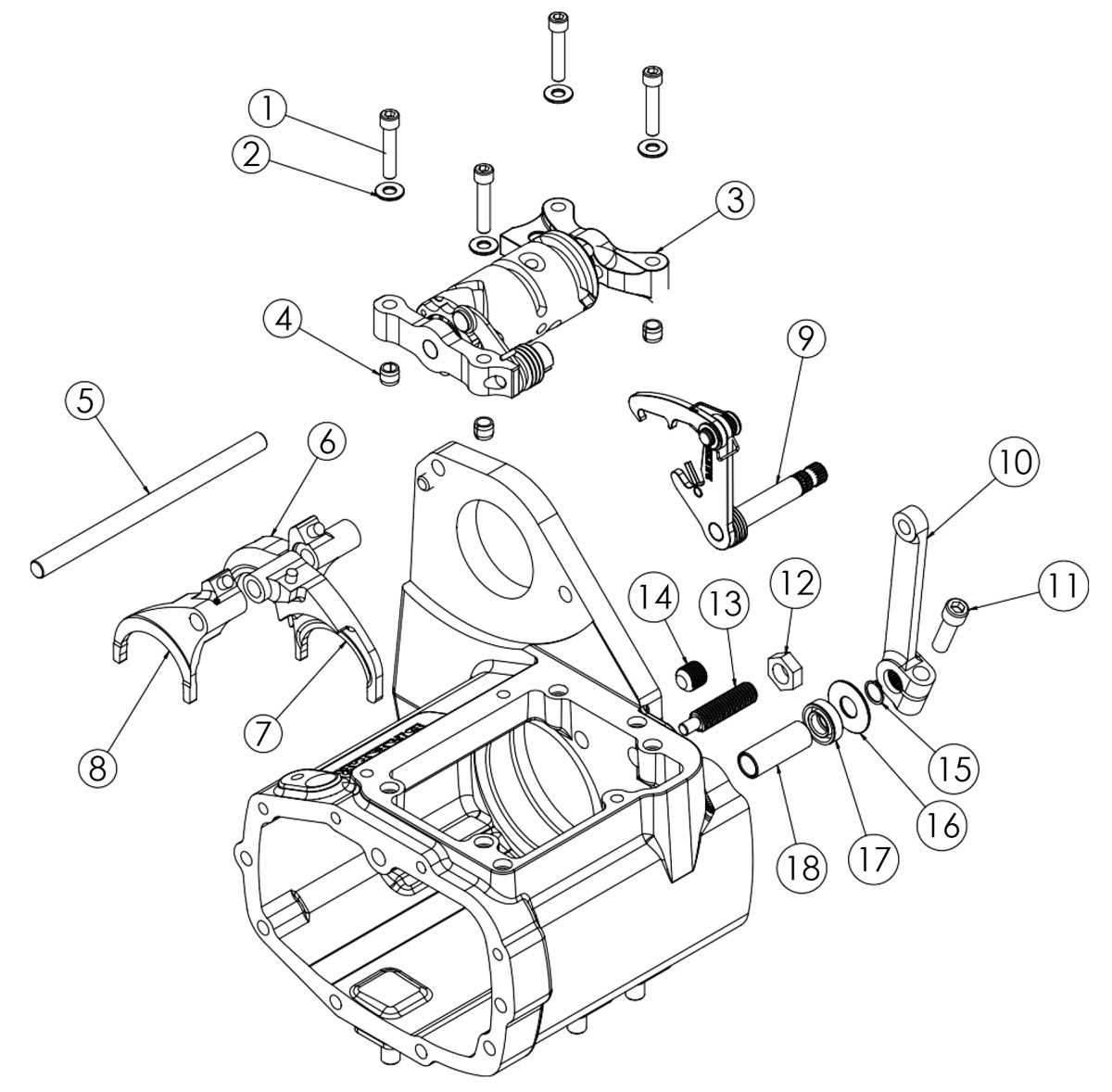

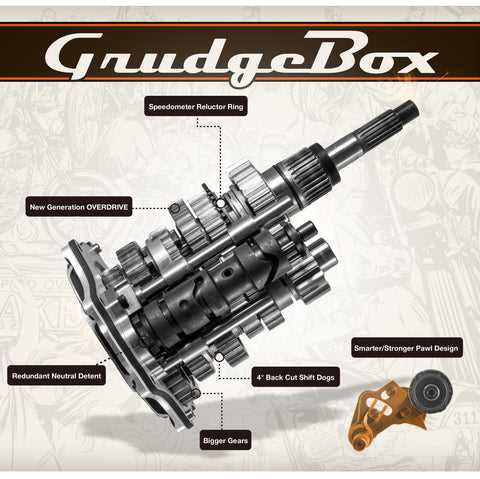

Transmission Assembly Diagram Explained

This section delves into the intricate assembly layout of a vehicle’s power delivery system. Understanding this schematic is essential for comprehending how different components interact to facilitate optimal functionality. Each element plays a pivotal role in ensuring smooth operation, and recognizing their arrangement can enhance maintenance and troubleshooting efforts.

| Component | Description |

|---|---|

| Housing | The outer shell that contains and protects the internal mechanisms. |

| Input Shaft | The shaft that transmits power from the engine to the assembly. |

| Gear Set | A collection of gears that adjusts torque and speed based on vehicle demands. |

| Output Shaft | The shaft that delivers power to the wheels, enabling movement. |

| Control Mechanism | The system that allows the driver to select different operational modes. |

Importance of Each Component

Understanding the significance of every individual part within a transmission system is crucial for maintaining optimal performance and reliability. Each element plays a pivotal role in ensuring smooth operation and longevity, contributing uniquely to the overall functionality. Recognizing the importance of these components not only enhances comprehension but also aids in effective troubleshooting and maintenance.

Diagnosing Transmission Issues

Identifying problems in vehicle shifting mechanisms is crucial for ensuring optimal performance and longevity. Various symptoms can indicate underlying malfunctions, ranging from unusual noises to performance degradation. By recognizing these signs early, you can prevent more extensive damage and costly repairs.

Unusual Noises: Listen for grinding, whining, or clunking sounds when the vehicle shifts gears. These noises may suggest worn components or insufficient lubrication within the system.

Slipping Gears: If the vehicle unexpectedly changes gears or hesitates during acceleration, it may point to internal issues. This can often indicate that the mechanism is struggling to maintain engagement.

Fluid Leaks: Inspect for any fluid leaking under the vehicle. Transmission fluid is typically red or brown, and any leaks should be addressed promptly to avoid severe complications.

Delayed Engagement: A noticeable delay when shifting from park to drive can signal a malfunction. This could result from low fluid levels or internal wear.

By systematically evaluating these indicators, you can effectively diagnose issues and take appropriate action, ensuring your vehicle operates smoothly.

Maintenance Tips for Baker Parts

Regular upkeep is essential for ensuring optimal performance and longevity of mechanical components. Implementing effective maintenance strategies can prevent issues and enhance efficiency. This section offers practical advice on how to care for these crucial elements in your system.

Routine Inspections

Consistent evaluations of the mechanisms are vital. Check for any signs of wear, leaks, or unusual noises during operation. Early detection of potential problems can save time and resources in the long run.

Lubrication Practices

Proper lubrication is crucial for reducing friction and preventing damage. Use the recommended types of lubricants and adhere to suggested intervals for application. Ensuring that all moving parts are well-lubricated will significantly improve their functionality and lifespan.

Parts Replacement Guide

Maintaining optimal performance in your vehicle involves timely substitutions of various components. Understanding when and how to replace these elements is essential for ensuring reliability and longevity. This guide provides a structured approach to identify, source, and install replacements, thereby enhancing your ride’s efficiency.

Identifying Worn Components

Before initiating the replacement process, it’s crucial to recognize the signs of wear. Look for unusual noises, leaks, or decreased performance, which may indicate that certain elements need attention. Regular inspections can help pinpoint issues early, preventing further damage and costly repairs.

Installation Tips

When replacing any component, ensure you have the appropriate tools and follow manufacturer instructions closely. If you’re uncertain, consulting a professional can save time and prevent mistakes. Always test the functionality of new elements after installation to confirm that they are working as intended.

Upgrades for Enhanced Performance

Improving the efficiency and responsiveness of your vehicle can significantly enhance your overall driving experience. Various modifications can be made to elevate performance, focusing on increasing power delivery, optimizing functionality, and enhancing durability. This section explores key enhancements that can transform how your machine operates.

Performance Enhancements

One effective way to boost performance is by upgrading to high-quality components that ensure smoother operation. Utilizing advanced materials and designs can reduce friction and wear, leading to a more reliable system. Additionally, enhancing the cooling mechanisms can prevent overheating, allowing for sustained high performance.

Maintenance Tips

Regular maintenance is crucial to achieving optimal functionality. Checking and replacing worn elements can prevent potential issues and prolong the lifespan of your equipment. Utilizing premium lubricants can also significantly reduce wear and tear, ensuring that all components function harmoniously.

| Upgrade Type | Benefits |

|---|---|

| High-Performance Components | Increased power delivery and efficiency |

| Cooling System Enhancements | Prevents overheating and maintains optimal temperature |

| Quality Lubricants | Reduces friction and prolongs component life |

| Regular Maintenance | Ensures reliability and optimal performance |

Best Practices for Installation

Ensuring a successful setup requires careful attention to detail and adherence to established guidelines. Proper execution of the installation process can greatly enhance performance and longevity. Below are some key practices to follow during the installation phase.

Preparation Steps

- Gather all necessary tools and components before starting.

- Review the manufacturer’s instructions thoroughly.

- Clean the workspace to prevent contamination of parts.

- Ensure you have adequate lighting to see clearly during installation.

Installation Techniques

- Follow a systematic approach, completing one step at a time.

- Utilize torque specifications as recommended to avoid over-tightening.

- Inspect each component for any signs of damage before installation.

- Connect all parts securely, checking for any misalignments.

By adhering to these best practices, the installation process will not only be more efficient but also more effective, leading to improved functionality.

Frequently Asked Questions

In this section, we address common inquiries that arise regarding the components and visual representations associated with Baker transmissions. Here, we provide answers to commonly posed questions regarding these mechanical elements and their illustrated depictions.