The intricate assembly of an automatic gearbox plays a vital role in the overall functionality of a vehicle. Each element within this system is meticulously designed to work in harmony, ensuring smooth transitions between different speeds and optimal power delivery. A comprehensive overview of these components can greatly enhance one’s knowledge of automotive mechanics.

In this section, we will explore various elements that contribute to the seamless operation of an automatic gearbox. By examining the relationships between each component, one can appreciate the engineering prowess involved in crafting a reliable and efficient system. Whether you are a seasoned mechanic or a curious enthusiast, understanding these components is essential for anyone interested in the world of automotive technology.

Moreover, having a clear visual representation of these elements can serve as a valuable reference for maintenance and repairs. It allows for a deeper understanding of how each piece functions individually and collectively. This knowledge can empower you to troubleshoot issues effectively, ensuring that your vehicle remains in peak condition.

The operation of an automotive gear system is essential for the efficient transfer of power from the engine to the wheels. This complex mechanism enables the vehicle to adapt to varying speeds and driving conditions, ensuring optimal performance. Understanding the components and their interactions is crucial for grasping how power is effectively transmitted throughout the vehicle.

The main elements involved in this process include the hydraulic pump, valve body, clutches, and planetary gears. Each of these parts plays a vital role in managing power flow and ensuring smooth shifts between different gear ratios.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates fluid pressure necessary for operation. |

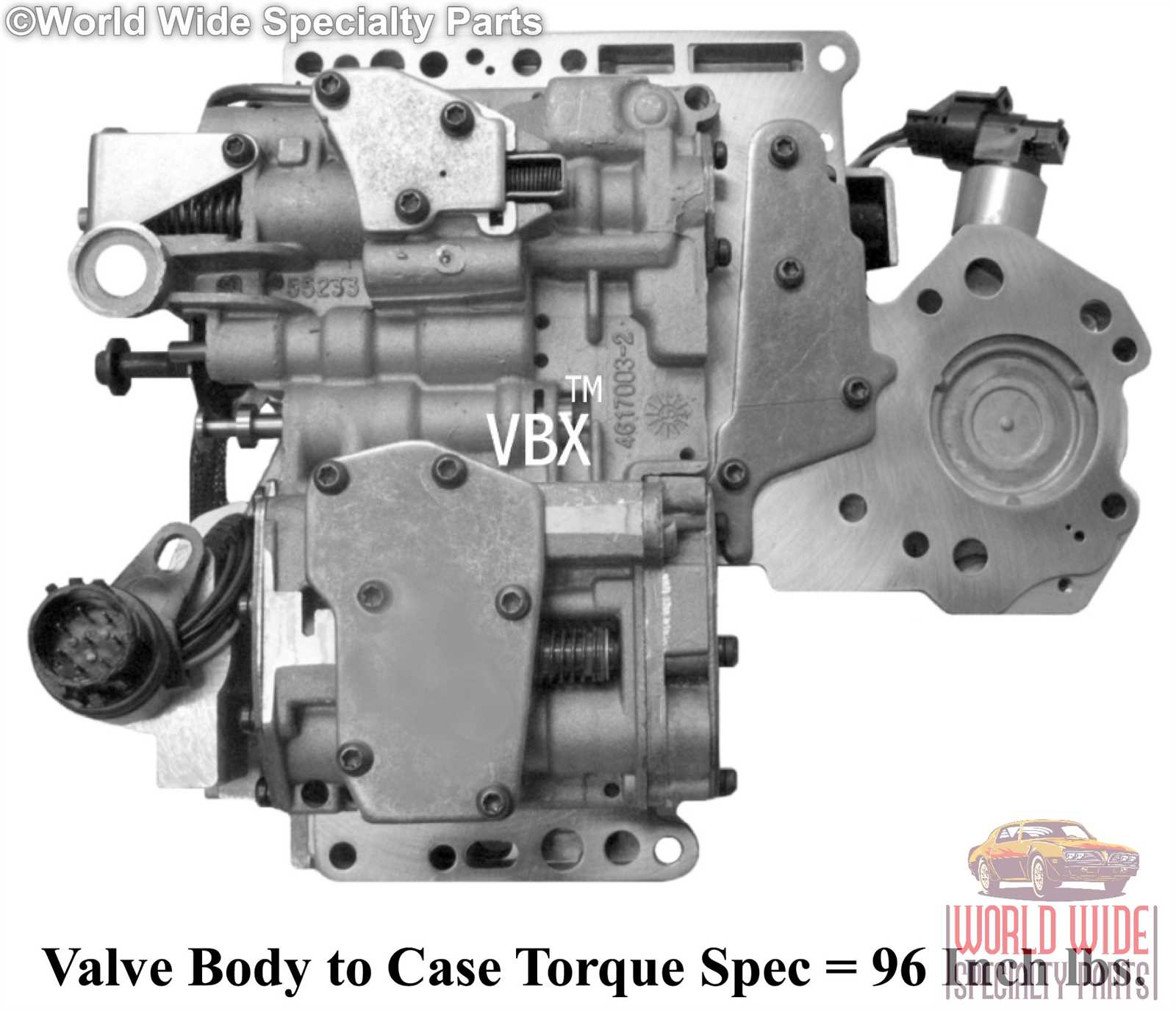

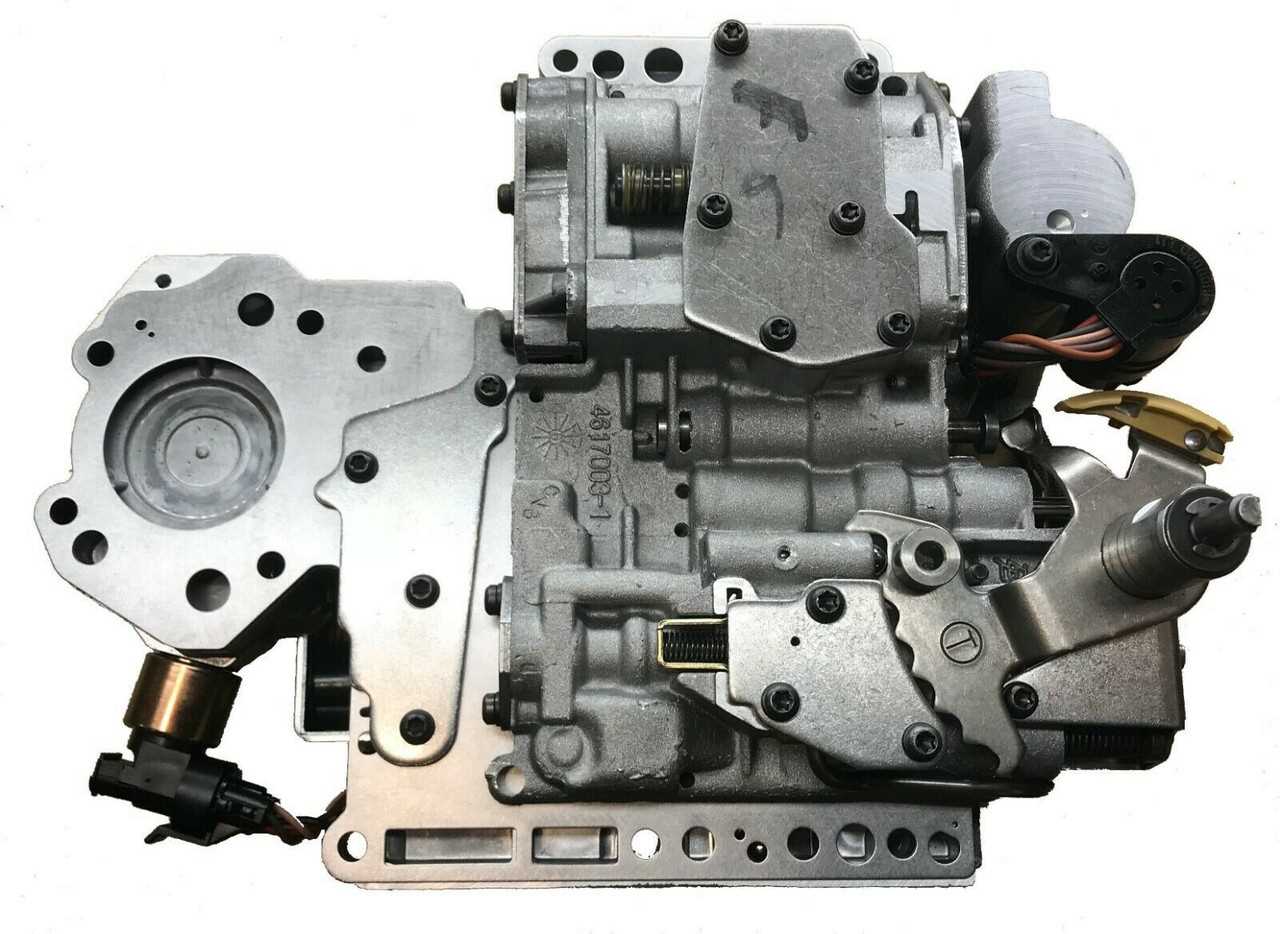

| Valve Body | Controls fluid direction and regulates gear shifts. |

| Clutches | Engage and disengage different gear sets. |

| Planetary Gears | Provide various gear ratios for power distribution. |

Through the coordinated actions of these components, the system allows for seamless acceleration and deceleration, adapting to the driver’s demands and enhancing the overall driving experience.

Common Issues and Solutions

In the realm of automatic gear systems, certain problems frequently arise, leading to performance difficulties. Recognizing these common challenges can facilitate timely repairs and enhance the overall longevity of the unit.

- Slipping Gears:

This occurs when the system unexpectedly changes gears or fails to engage properly. It often results from low fluid levels or internal wear. Regularly checking fluid levels and performing timely maintenance can help mitigate this issue.

- Delayed Engagement:

A noticeable lag when shifting into gear can indicate underlying problems. This may be attributed to hydraulic issues or worn components. Ensuring proper fluid levels and replacing old filters can alleviate this situation.

- Overheating:

Excessive heat can cause significant damage to the system. It typically results from low fluid levels or restricted airflow. Keeping the cooling system clean and monitoring fluid levels is crucial to prevent overheating.

- Noisy Operation:

Unusual sounds during operation can signal various issues, from low fluid to internal damage. Identifying the source of the noise early can prevent costly repairs. Regular inspections and fluid changes are recommended to maintain smooth operation.

Addressing these common concerns proactively will ensure better performance and reliability. Regular maintenance and timely interventions are key to keeping the unit in optimal condition.

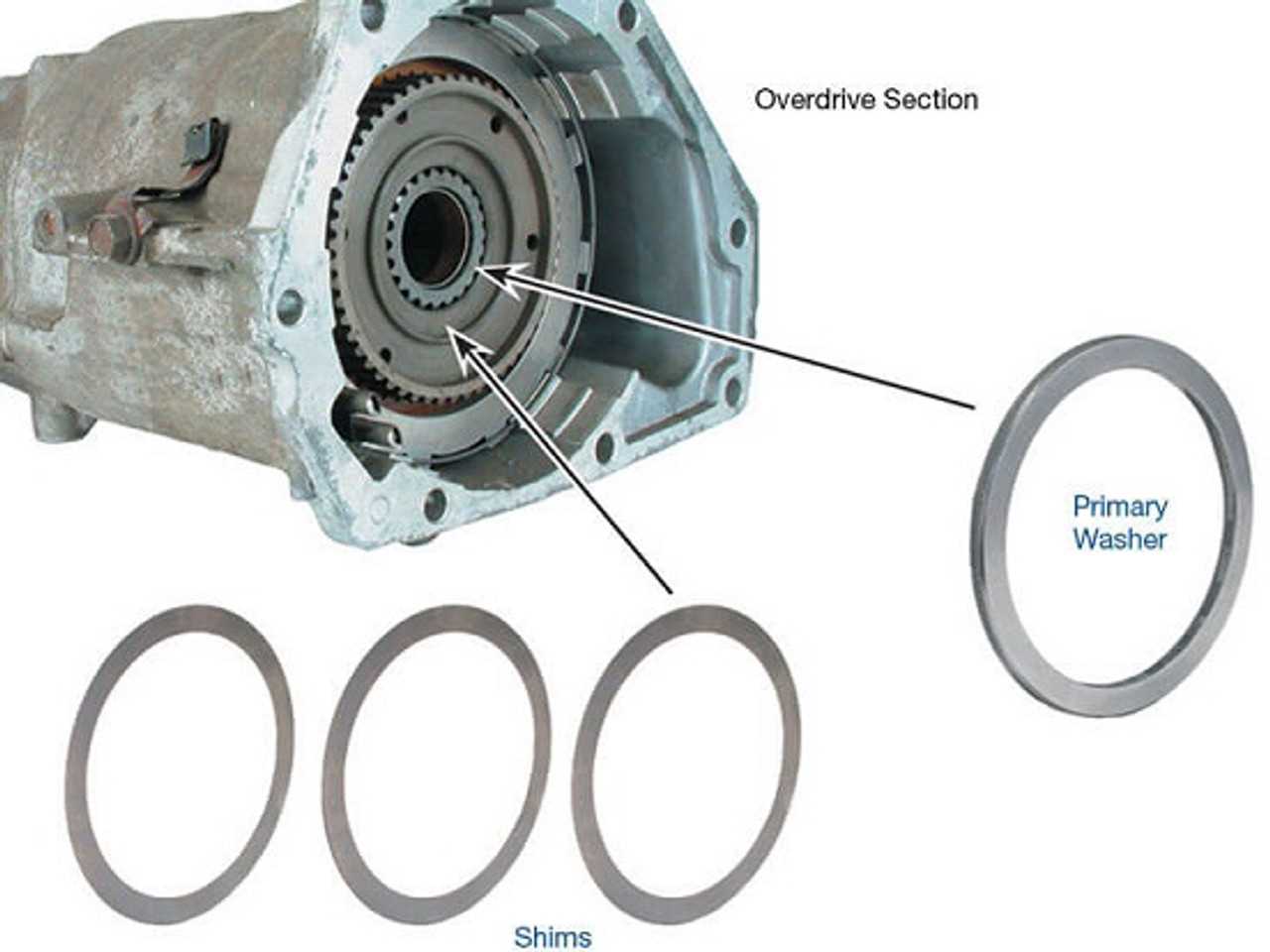

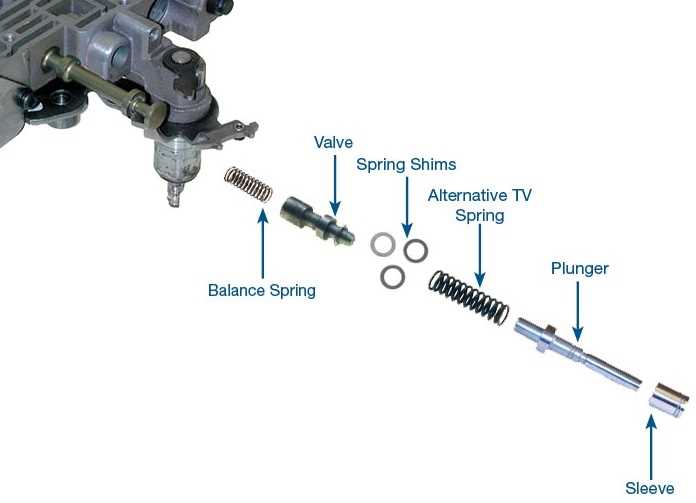

Parts Identification Guide

This section aims to provide a comprehensive overview of essential components utilized within a specific automotive assembly. Recognizing these elements is crucial for effective maintenance and repair procedures. By familiarizing oneself with the various elements and their functions, one can ensure optimal performance and longevity of the system.

Understanding the terminology and classifications associated with these components is the first step toward achieving proficiency in handling repairs. Each component plays a vital role, contributing to the overall functionality of the assembly. Proper identification and knowledge of these elements will aid in diagnosing issues and selecting suitable replacements when necessary.

For those involved in servicing or rebuilding this specific assembly, a detailed understanding of each component’s role and location is invaluable. Familiarity with these components enhances the ability to perform tasks efficiently and effectively, ensuring that the system operates at its best.

Through this guide, we encourage readers to engage with the content actively, allowing for better comprehension and practical application of the information presented.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your vehicle’s internal systems requires regular attention and care. By implementing simple yet effective maintenance practices, you can enhance performance and reduce the risk of premature failures.

Regular Fluid Changes: Consistently checking and replacing fluids is crucial. Clean and high-quality fluids help to minimize wear and tear on components, promoting smoother operation.

Monitor Temperature Levels: Overheating can lead to severe damage. Keep an eye on temperature gauges and ensure the cooling system is functioning properly to avoid overheating issues.

Inspect Seals and Gaskets: Regularly examining seals and gaskets for wear or leaks is essential. Replacing damaged seals can prevent fluid loss and maintain optimal functionality.

Timely Repairs: Addressing minor issues promptly can prevent them from escalating into major problems. Pay attention to unusual noises or changes in performance, and consult a professional if needed.

Clean External Components: Dirt and debris can accumulate, leading to inefficient operation. Regularly clean external components to ensure they function effectively and to prevent unnecessary strain.

Follow Manufacturer Recommendations: Adhering to the maintenance schedule provided by the manufacturer ensures that all necessary checks and services are performed, helping to prolong the life of your vehicle’s systems.

Parts Replacement Process

Replacing components in a vehicle’s drive system is essential for maintaining optimal performance and longevity. Understanding the procedure can greatly assist in ensuring that each element is fitted correctly and functions as intended. This guide outlines the steps involved in the effective substitution of crucial elements within the assembly.

Initial Assessment: Before beginning the replacement, it’s vital to assess the current condition of the system. Identify any faulty components by conducting a thorough inspection. Look for signs of wear, damage, or malfunction that may require attention.

Gather Necessary Tools: Equip yourself with the appropriate tools needed for the task. This typically includes wrenches, sockets, and any specialized equipment required for the specific components being replaced. Having everything prepared in advance can streamline the process.

Careful Disassembly: Start by carefully disassembling the relevant sections of the system. Take your time to avoid causing additional damage. Document the arrangement of components to aid in reassembly. It can be helpful to take photographs or notes during this stage.

Replacement of Components: Once the faulty elements have been removed, proceed with installing the new ones. Ensure each piece is aligned correctly and secured firmly. Follow any manufacturer specifications to guarantee proper fitment and functionality.

Final Checks: After the new components are in place, conduct a final inspection to confirm that everything is installed correctly. Reassemble any removed sections and ensure that all fasteners are tightened. A thorough check will help prevent future issues.

Testing: Finally, perform a test run to ensure that the system operates smoothly. Listen for any unusual sounds and monitor for any signs of leaks or irregular behavior. Proper testing is crucial for verifying that the replacement process has been successful.

Tools Needed for Repair

When undertaking a repair project involving automatic gear systems, having the right tools is essential for ensuring efficiency and precision. The following items are crucial for disassembly, inspection, and reassembly tasks, helping to maintain optimal functionality.

Basic Hand Tools: A set of standard hand tools, including wrenches, sockets, and screwdrivers, is vital for removing components and securing them back in place. Having a range of sizes will accommodate various fasteners.

Torque Wrench: This tool is important for applying the correct amount of force when tightening bolts and nuts, preventing damage to the components.

Fluid Pump: To manage and replace lubricants effectively, a fluid pump will help in transferring fluids without spillage, ensuring a clean workspace.

Seal Puller: This specialized tool is designed to remove seals and gaskets without damaging surrounding areas, which is essential for maintaining integrity during repairs.

Diagnostic Equipment: Utilizing electronic diagnostic tools can aid in identifying issues within the system. These devices read error codes and provide insights into the performance of the assembly.

By equipping yourself with these essential tools, you will be well-prepared to handle repairs effectively, ensuring that your automatic system operates smoothly once reassembled.

Aftermarket Parts vs. OEM

When it comes to enhancing vehicle performance, enthusiasts often face a critical decision between aftermarket components and original equipment manufacturer (OEM) options. Each choice has its unique advantages and drawbacks, making it essential to understand how they differ to make an informed decision.

Quality and Reliability

OEM components are crafted to meet the manufacturer’s exact specifications, ensuring a high level of reliability and compatibility. In contrast, aftermarket alternatives may vary widely in quality. While some may exceed OEM standards, others could fall short, potentially leading to performance issues.

Cost Considerations

Generally, aftermarket options are more budget-friendly compared to their OEM counterparts. This can make them an attractive choice for those looking to save money. However, it is vital to consider the long-term implications, as lower initial costs might result in higher expenses due to repairs or replacements if the quality is lacking.

Cost Considerations

When evaluating the expenses associated with an automatic gearbox, it is crucial to consider various financial factors that contribute to the overall investment. Understanding these elements can help vehicle owners make informed decisions regarding repairs or upgrades.

Factors Affecting Costs

- Repair Services: The choice between DIY repairs and professional services can significantly impact expenses. Hiring a skilled mechanic may incur higher costs, while self-repair could save money but requires knowledge and tools.

- Quality of Components: Utilizing high-quality or OEM components may lead to increased upfront costs but can enhance longevity and performance, ultimately saving money in the long run.

- Labor Rates: The geographic location and the reputation of the service provider can affect labor costs. Rates may vary significantly between urban and rural areas.

Budgeting Tips

- Research and compare prices for both parts and services to ensure competitive rates.

- Consider investing in preventative maintenance to avoid costly repairs in the future.

- Seek out warranties or service agreements that cover future repairs, providing additional peace of mind.

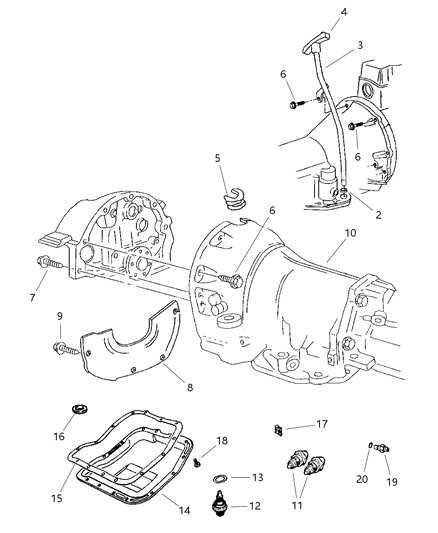

Transmission Diagram Visuals

Visual representations of mechanical components play a crucial role in understanding their functions and interactions. These illustrations serve as valuable tools for both novice and experienced technicians, facilitating a clearer grasp of complex assemblies. By examining these graphics, one can gain insights into the arrangement and operational dynamics of various elements within a drive mechanism.

Understanding Component Layouts

The layout of individual components within the assembly provides essential information about their roles. Each element is strategically positioned to ensure optimal performance. Recognizing how these pieces fit together enhances troubleshooting capabilities and aids in the efficient repair or maintenance of the system.

Visual Learning Benefits

Utilizing graphical representations allows for better retention of information. When individuals can visualize the relationships between components, they are more likely to recall their functions and locations. This approach not only simplifies learning but also encourages a deeper appreciation for the engineering behind such systems.

Resources for Further Learning

For those interested in deepening their understanding of automotive systems, there are various avenues available to enhance knowledge and skills. Engaging with comprehensive materials can provide valuable insights into the intricate components that facilitate vehicle performance.

Online Courses: Numerous platforms offer courses specifically tailored to automotive mechanics and engineering principles. These programs often feature expert instructors who guide learners through complex subjects, ensuring a solid grasp of fundamental concepts.

Books and Manuals: A wealth of literature exists that covers the fundamentals and advanced aspects of vehicle mechanisms. Look for resources that focus on mechanical engineering or automotive repair to gain a well-rounded perspective.

Forums and Communities: Joining online communities dedicated to automotive enthusiasts can foster collaboration and knowledge sharing. Engaging in discussions with fellow learners can yield practical advice and tips from those with hands-on experience.

YouTube Channels: Many content creators specialize in automotive repair and diagnostics. Video tutorials can visually demonstrate techniques and problem-solving methods, making complex ideas more accessible.

Workshops and Hands-On Training: Participating in local workshops or training sessions provides an excellent opportunity for practical learning. Hands-on experience under the guidance of seasoned professionals can significantly enhance understanding and skill proficiency.