Exploring the intricate mechanisms within automotive systems reveals a combination of essential elements that work together to ensure smooth and efficient operation. A deep dive into the architecture of these systems allows enthusiasts and professionals to appreciate the balance between function and form, highlighting the role that each component plays in overall performance.

Whether you’re maintaining, repairing, or simply seeking to learn more about the mechanical interplay, identifying key segments within the vehicle’s core system is crucial. Recognizing how each element contributes to the broader mechanism can help diagnose issues and optimize functionality. This guide aims to break down the essentials, providing insight into the arrangement of vital components for better understanding and practical application.

In this section, we will explore the layout and connections of various elements, shedding light on their purpose and how they work together to create a reliable and efficient system. By understanding the structure of these components, you can ensure the longevity and performance of the system while addressing any potential issues with confidence.

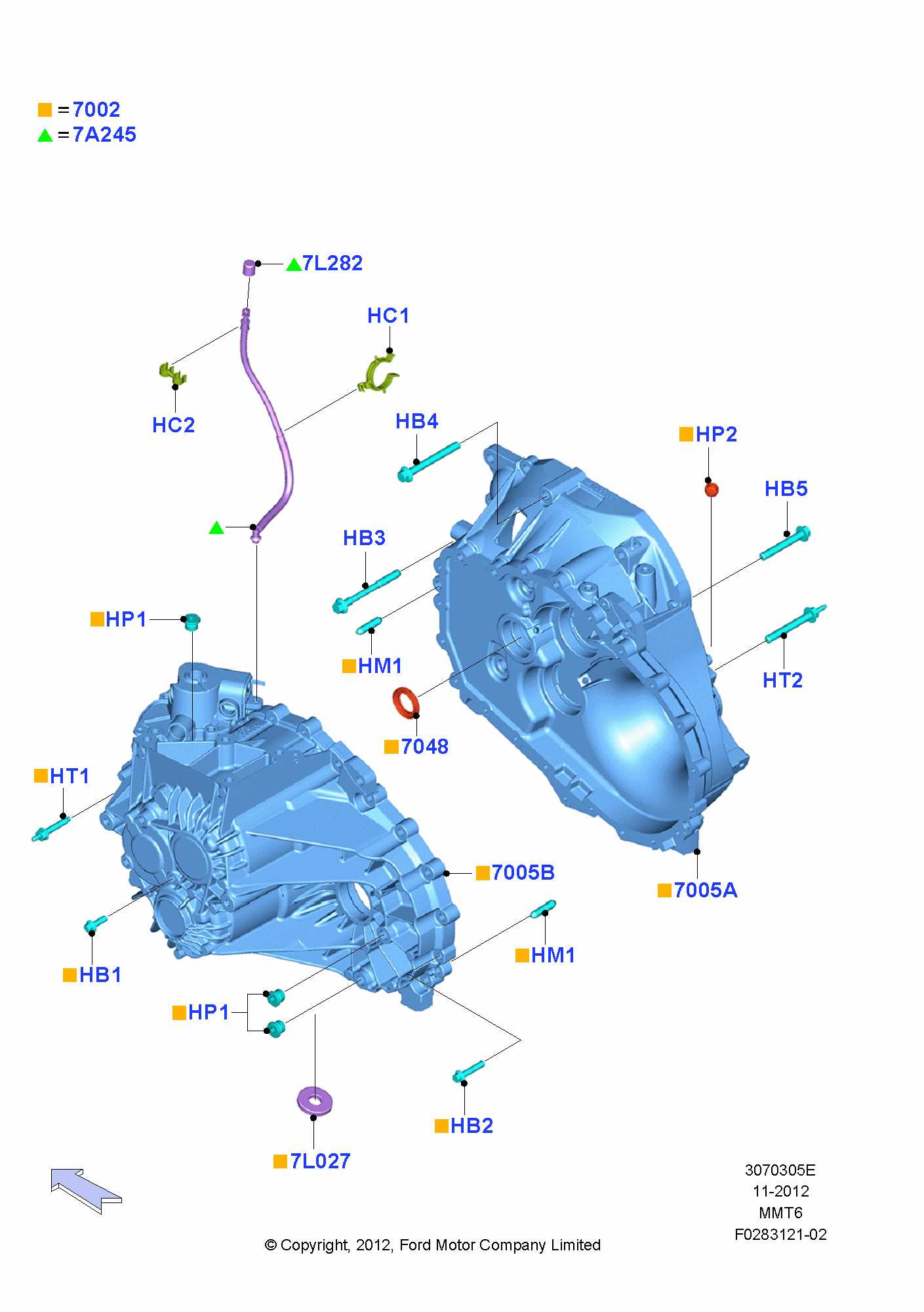

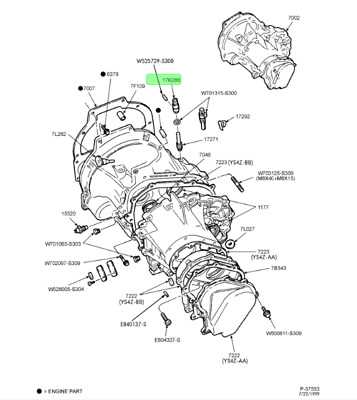

Ford Transmission System Overview

The system responsible for controlling power distribution plays a crucial role in vehicle performance, influencing the way energy from the engine is directed to the wheels. It ensures smooth operation, contributing to overall driving efficiency and responsiveness. Understanding its components and their functions provides insight into how a vehicle adapts to different driving conditions.

Main Components of the System

Key elements include devices that regulate power flow, gear mechanisms that adjust speed and torque, and control units that ensure seamless interaction between various parts. Each of these works together to ensure the optimal balance between power output and fuel consumption.

Performance and Efficiency

This system is designed to offer improved handling, adapting to various terrain and driving styles. Its efficiency is enhanced by modern technology, allowing for smoother gear shifts and a more dynamic driving experience. The overall goal is to create a balance between performance and energy use, making it an essential component of any vehicle.

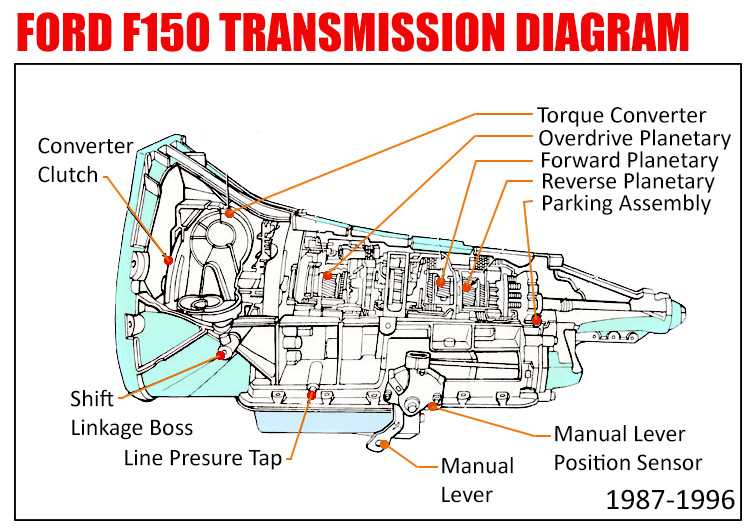

Key Components of Ford Automatic Transmissions

Modern automotive gear systems are composed of a variety of crucial elements that work together to ensure smooth operation and efficiency. These systems rely on several key mechanisms to shift gears automatically and adapt to changing driving conditions.

One of the essential mechanisms in such gearboxes is the torque converter, which transfers engine power to the system while allowing a fluid connection to provide smoother transitions. Another vital part is the planetary gear set, responsible for adjusting speed ratios and ensuring optimal performance across different driving modes.

The hydraulic control unit plays a critical role in regulating the pressure needed for shifting between different stages, using valves and sensors to manage fluid distribution. Clutches and bands, on the other hand, engage and disengage various gears, helping to control movement and prevent unnecessary slippage.

Finally, electronic control systems have become an integral aspect, coordinating the entire process with real-time data from the engine and driving conditions. This integration of mechanical and electronic components ensures reliability, smooth operation, and fuel efficiency.

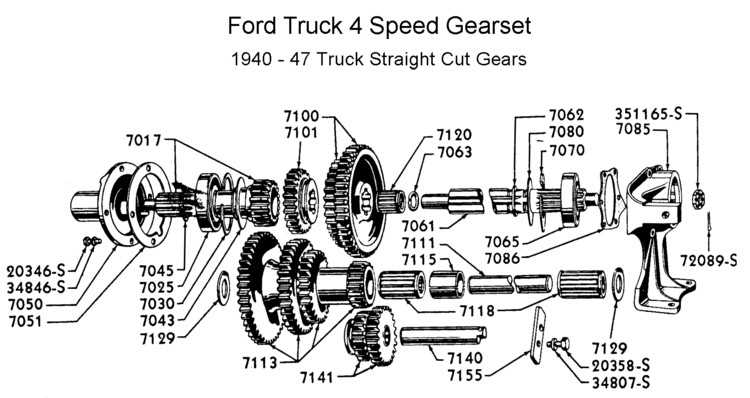

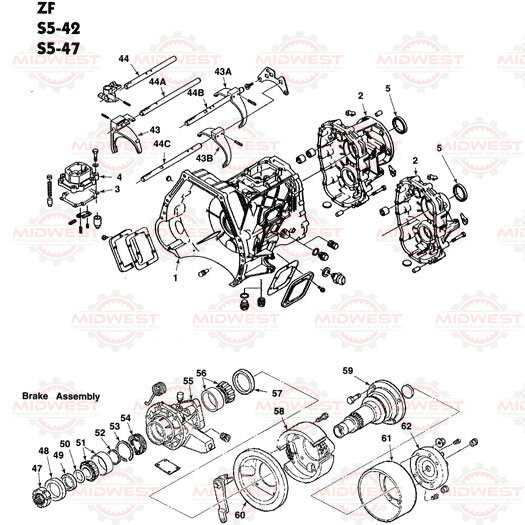

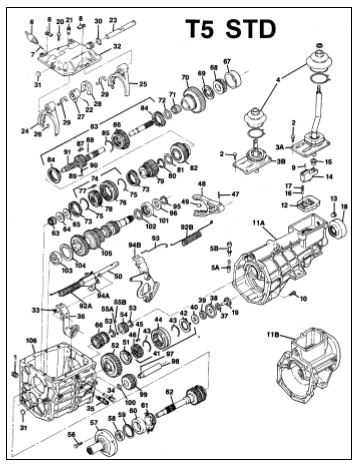

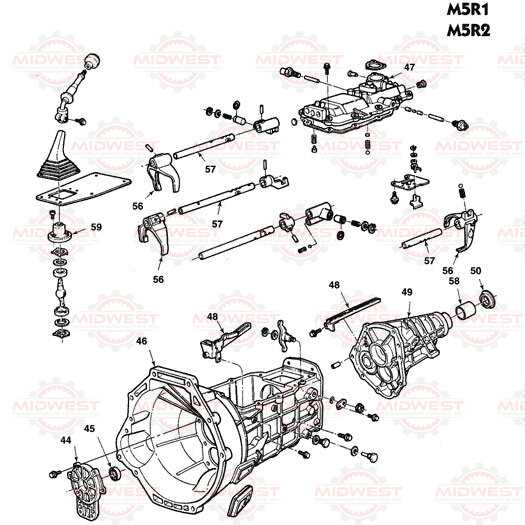

Identifying Parts in Manual Transmission Models

Manual driving systems are composed of several essential components that work together to deliver power and control. Understanding the key elements involved helps in maintaining and diagnosing mechanical systems. Each part plays a crucial role in ensuring smooth gear shifting and vehicle performance.

Main Components Overview

The heart of the manual driving system includes multiple elements responsible for handling power distribution and torque management. These include key components that manage motion, synchronization, and the engagement of gears. Each of these elements must be in proper working condition to ensure reliability and efficiency.

Key Elements Breakdown

| Component | Function |

|---|---|

| Clutch Assembly | Disconnects and reconnects the engine power for smooth shifting. |

| Gearbox | Houses the gear sets and synchronizes their movement during operation. |

| Shift Forks | Directly engage with the gears to facilitate shifting between speeds. |

| Synchronizers | Ensure smooth engagement of gears by matching rotational speeds. |

| Input Shaft | Transfers power from the engine to the internal components of the system. |

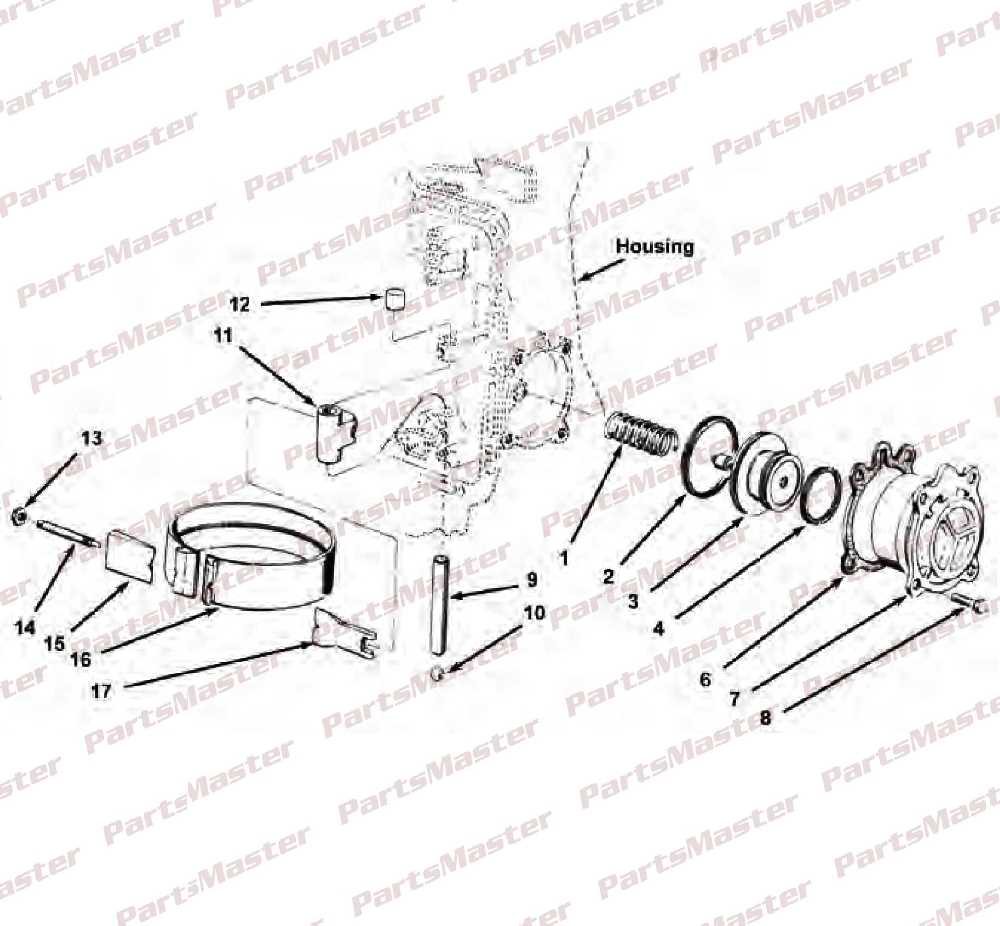

Torque Converter Functionality and Diagram

The torque converter is a critical element that helps transfer energy efficiently within a vehicle’s drive system. By acting as a fluid coupling, it allows smooth acceleration and power transmission between the engine and the rest of the drivetrain. This mechanism is especially important in automating the engagement process, ensuring seamless operation during varying driving conditions.

Main Components of the Torque Converter

- Impeller: This part rotates with the engine and drives fluid towards the turbine.

- Turbine: The turbine receives the fluid and transfers rotational power further along the drivetrain.

- Stator: Positioned between the impeller and turbine, the stator redirects fluid flow to enhance torque multiplication.

- Lock-Up Clutch: Engages under certain conditions to provide a direct mechanical link, improving fuel efficiency.

How the Torque Converter Works

- As the engine runs, the impeller pushes fluid into the turbine, initiating rotation.

- The turbine spins and transfers torque to the drivetrain, propelling the vehicle forward.

- The stator redirects fluid to maximize efficiency, especially at lower speeds.

- At higher speeds, the lock-up clutch engages, providing a direct mechanical connection for improved efficiency.

How Transmission Gears Operate in Ford Vehicles

Understanding how gear systems work in vehicles is essential for smooth driving and effective power management. Gears are responsible for transferring energy from the engine to the wheels, allowing a car to move at various speeds while optimizing fuel efficiency. Their coordination ensures that the engine runs at an optimal pace, regardless of driving conditions.

Gear Mechanisms and Shifting Process

At the core of gear systems lies the interaction between different sized wheels, often referred to as ratios. When a driver selects a new speed setting, the corresponding mechanisms engage, altering the rotation pace and torque. This change helps the vehicle maintain stability and speed, whether accelerating on highways or climbing steep inclines.

Synchronization and Precision

One of the key aspects of modern driving systems is the synchronization between gears. Precision components ensure that shifts happen smoothly without damaging the internal machinery. This not only improves the longevity of the system but also provides a seamless driving experience by reducing unnecessary strain on the vehicle’s engine.

Clutch System Role in Transmission Performance

The clutch mechanism is a vital component in facilitating smooth engagement and disengagement of power between the engine and the drivetrain. This system plays a critical role in enabling seamless gear shifts, ensuring optimal performance under varying driving conditions. By managing torque transfer, it helps maintain control over vehicle acceleration and deceleration, directly impacting overall driving experience.

Functionality and Design

The primary function of the clutch is to connect and disconnect the engine’s power from the wheels. When the driver presses the pedal, the clutch disengages, allowing the gears to shift without interference from the engine’s force. This design minimizes wear and tear on the gears and synchronizers, promoting longevity and efficiency. Additionally, advancements in clutch technology have led to designs that offer better grip and reduced slippage, further enhancing performance.

Impact on Driving Dynamics

A well-functioning clutch system contributes significantly to vehicle handling and responsiveness. It enables precise control during acceleration and braking, allowing drivers to maneuver effectively in various environments. Poor clutch performance can lead to slippage, difficulty in shifting gears, and overall diminished driving pleasure. Therefore, regular maintenance and timely replacements are essential to ensure that the system operates at peak efficiency.

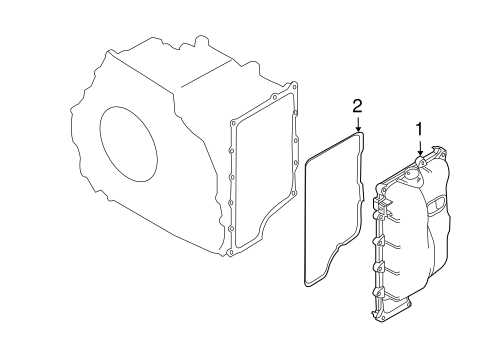

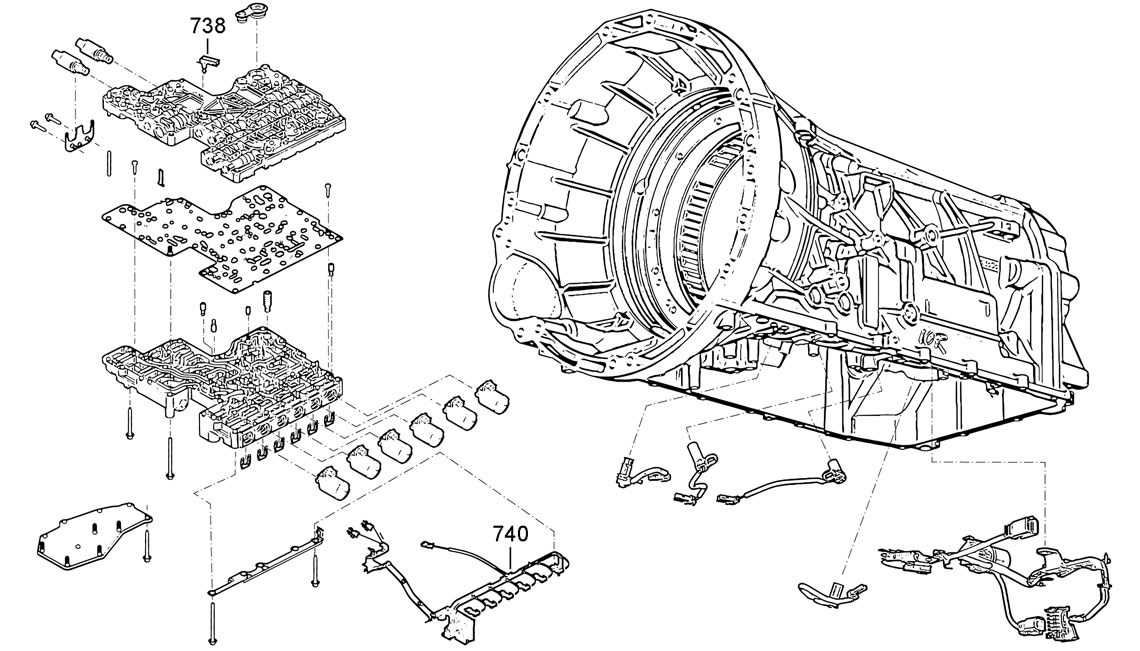

Valve Body and Its Contribution to Shifting

The valve body is a critical component in any automotive gearbox system, playing a pivotal role in controlling the flow of hydraulic fluid. It orchestrates the operation of various elements within the mechanism, ensuring smooth and precise gear changes. This section delves into the significance of the valve body and how it impacts the overall performance and efficiency of gear shifting.

Functionality of the Valve Body

The valve body houses a series of valves that direct hydraulic pressure to various clutches and bands, enabling them to engage or disengage as needed. By managing this pressure, it allows for seamless transitions between gears, enhancing the driving experience. The valve body is designed to respond quickly to changes in driving conditions, ensuring optimal performance under various circumstances.

Common Issues and Maintenance

Regular maintenance of the valve body is essential for preserving its functionality. Common issues include wear and tear, which can lead to delayed shifting or erratic behavior. It is advisable to check for leaks and perform fluid changes as part of routine service to maintain the integrity of the hydraulic system.

| Issue | Symptoms | Solutions |

|---|---|---|

| Wear and Tear | Delayed shifting, harsh engagement | Replace or rebuild valve body |

| Fluid Leaks | Low fluid levels, slipping | Repair seals, replace damaged components |

| Clogged Valves | Inconsistent shifting, overheating | Clean or replace valve components |

Ford Transmission Fluid Pathway Analysis

This section delves into the intricacies of the fluid routing system within a vehicle’s gear mechanism. Understanding the flow of hydraulic fluid is essential for maintaining optimal performance and ensuring longevity. This analysis highlights the components involved in the circulation of fluid, illustrating their interconnected roles in facilitating smooth operation.

Fluid Flow Mechanism

The fluid pathway serves as a crucial element in the functionality of the gear system. It facilitates the transfer of hydraulic pressure, which is vital for engaging gears and enabling smooth shifts. The pathway typically comprises various components that work together seamlessly, ensuring the system operates efficiently.

Key Components and Their Functions

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure to initiate fluid movement. |

| Valves | Regulate the flow of fluid to different sections of the system. |

| Cooler | Maintains optimal fluid temperature by dissipating excess heat. |

| Filter | Removes contaminants from the fluid, ensuring system cleanliness. |

| Reservoir | Holds excess fluid and allows for expansion and contraction. |

By analyzing these components, we can appreciate the complexity of fluid dynamics within the mechanical assembly. Proper maintenance and timely inspections are vital to prevent issues that could arise from fluid mismanagement.

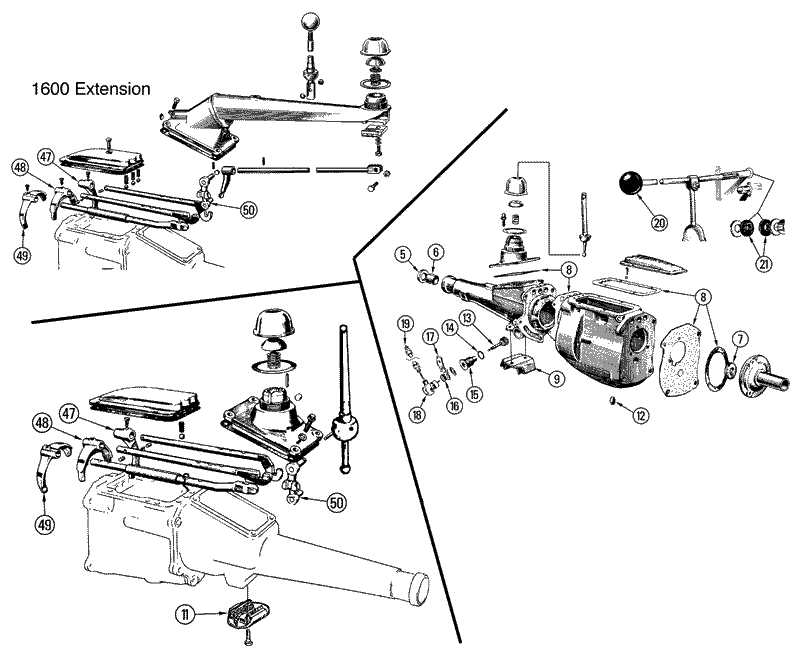

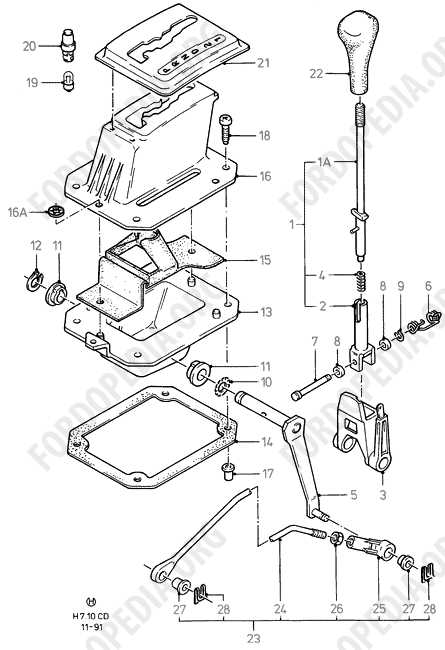

Shifter Mechanism: Parts and Functions

The shifter mechanism plays a crucial role in vehicle operation, allowing drivers to select various drive modes. This system is designed to translate driver inputs into precise movements, ensuring smooth gear changes and optimal vehicle performance. Understanding its components and their roles can enhance your knowledge of automotive functionality.

Key Components

- Shifter Lever: The primary control used by the driver to select the desired gear.

- Linkage: A series of rods and cables that connect the shifter lever to the internal mechanisms.

- Gate: A housing structure that guides the shifter lever through its various positions.

- Detent Mechanism: Provides tactile feedback to the driver, ensuring accurate gear selection.

- Indicator: A visual display that shows the current gear selection to the driver.

Functions of the Shifter Mechanism

- Facilitates the transition between different drive modes such as park, reverse, neutral, and drive.

- Ensures that the appropriate gear is engaged, allowing for effective acceleration and deceleration.

- Provides feedback to the driver, confirming that the desired selection has been achieved.

- Integrates safety features to prevent accidental shifting into inappropriate gears.

Transmission Control Module Overview

The control module plays a crucial role in managing the performance and functionality of the shifting system within vehicles. It acts as the brain of the system, ensuring optimal operation through various input signals and commands. This section provides an overview of its importance, components, and operational principles.

Functions of the Control Module

This essential unit monitors and regulates multiple factors to maintain efficient functionality. It interprets data from various sensors and executes commands accordingly to achieve seamless gear changes. By doing so, it enhances overall performance and driving experience.

Key Components

| Component | Description |

|---|---|

| Input Sensors | Devices that gather data regarding speed, throttle position, and other parameters. |

| Control Unit | The central processing unit that analyzes input data and determines the appropriate responses. |

| Output Actuators | Components responsible for executing the control module’s commands by adjusting the shifting mechanism. |

| Wiring Harness | A collection of cables connecting the control unit to other vehicle systems for data exchange. |

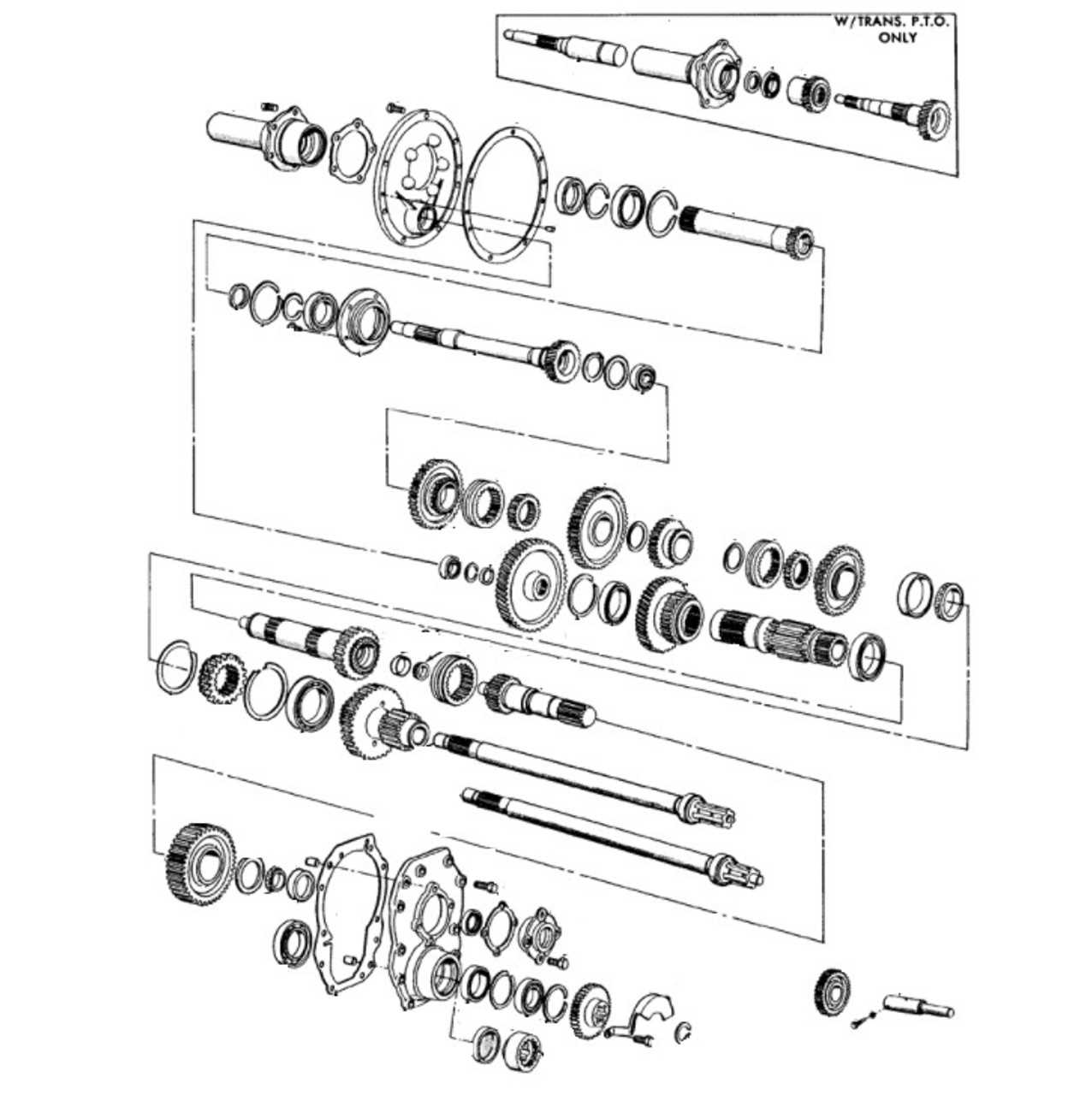

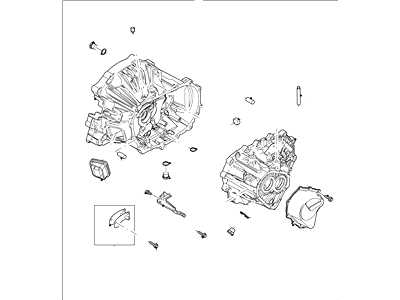

Input and Output Shafts in Ford Transmissions

The functioning of any automotive system relies significantly on its internal components, particularly those involved in power transfer. Among these critical elements are the input and output shafts, which play a vital role in facilitating the flow of energy from the engine to the wheels. Understanding their design and purpose can enhance the knowledge of vehicle mechanics and contribute to effective maintenance practices.

Input Shafts serve as the primary conduit for engine power. When the engine operates, rotational force is transmitted through the input shaft, enabling the vehicle’s drivetrain to engage. This component is designed to withstand high levels of torque and stress, ensuring that the power is efficiently directed toward the necessary systems. The construction and material choices for input shafts are crucial for durability and performance.

On the other hand, the output Shafts are responsible for transferring the power generated by the input shaft to the wheels. These shafts are engineered to ensure smooth delivery of torque while minimizing vibrations and losses in energy. The connection between the output shaft and the wheels is essential for translating the engine’s power into movement, making it a critical component for vehicle operation.

Both input and output shafts are integral to a vehicle’s performance, impacting acceleration, handling, and overall efficiency. Regular inspection and maintenance of these components can prevent costly repairs and enhance the longevity of the entire system. By understanding the roles of these shafts, vehicle owners can better appreciate the intricate workings of their machines.

Transmission Cooling System Components

The efficiency of any vehicle’s power delivery system is significantly influenced by its cooling mechanism. A well-designed cooling arrangement is crucial for maintaining optimal operating temperatures, which in turn enhances performance and prolongs component lifespan. Understanding the essential elements that contribute to this system is vital for effective maintenance and repair.

Cooling Radiator: This is a fundamental element that dissipates heat generated during operation. It allows the fluid to flow through cooling fins, where heat is released into the atmosphere, ensuring that the system operates within safe temperature limits.

Fluid Pump: A robust pump circulates the cooling fluid throughout the system. Its reliability is essential, as it ensures consistent flow and pressure, allowing for efficient heat exchange.

Hoses and Fittings: These components facilitate the transfer of fluid between different parts of the cooling system. High-quality hoses and secure fittings are crucial to prevent leaks and ensure effective fluid circulation.

Thermostat: This device regulates fluid temperature by controlling its flow within the cooling system. By opening and closing at predetermined temperatures, it ensures that the fluid remains at optimal levels for effective cooling.

Cooling Fan: The fan enhances airflow through the radiator, particularly during low-speed operations or idling. Its role in maintaining airflow is vital for preventing overheating during extended use.

Understanding these critical components aids in recognizing potential issues and implementing effective solutions, thereby ensuring the longevity and efficiency of the vehicle’s overall operation.