The intricate mechanisms that enable vehicles to navigate challenging terrains are essential for off-road enthusiasts and professionals alike. A comprehensive grasp of the various elements involved in these systems can significantly enhance performance and maintenance practices. By exploring the intricacies of these assemblies, one can ensure optimal functionality and longevity of the vehicle.

In the following sections, we will delve into the individual elements that play a crucial role in this driving system. Each component serves a specific purpose, contributing to the overall efficiency and effectiveness of the vehicle’s capabilities. Understanding how these parts interact will provide valuable insights for those looking to upgrade or troubleshoot their machinery.

Whether you are a seasoned mechanic or a novice enthusiast, familiarizing yourself with the layout and operation of these components can empower you to make informed decisions. From identifying wear and tear to executing repairs, a clear understanding of these essential elements will ultimately lead to enhanced performance on and off the road.

Np241 Transfer Case Overview

This section provides a comprehensive look at a critical component of many four-wheel-drive systems, focusing on its functions, structure, and significance in enhancing vehicle performance.

Functionality

The primary role of this assembly is to manage power distribution between the front and rear axles, allowing for improved traction and stability. Key functionalities include:

- Power splitting for optimized driving conditions

- Facilitating low-range gearing for challenging terrains

- Enabling shifting between two-wheel and four-wheel drive

Components

Understanding the main elements of this mechanism is essential for maintenance and repairs. Key components include:

- Input shaft

- Output shafts

- Planetary gears

- Shift linkage

- Seals and gaskets

Each part plays a vital role in ensuring the smooth operation of the entire assembly, contributing to the vehicle’s overall efficiency and capability.

Understanding Transfer Case Functionality

The mechanism in question plays a crucial role in distributing power from the engine to the wheels, ensuring optimal traction and performance across various terrains. This component allows vehicles to adapt seamlessly to changing driving conditions, enhancing stability and control.

Key functions of this system include:

| Function | Description |

|---|---|

| Power Distribution | Evenly channels engine power to the front and rear axles. |

| Gear Selection | Enables drivers to switch between high and low gear ratios for different driving scenarios. |

| Traction Control | Helps maintain grip by adjusting power delivery based on wheel slip conditions. |

| Durability | Constructed to withstand the rigors of off-road and challenging environments. |

Understanding these functions provides insight into how this essential mechanism enhances vehicle capability and driver experience.

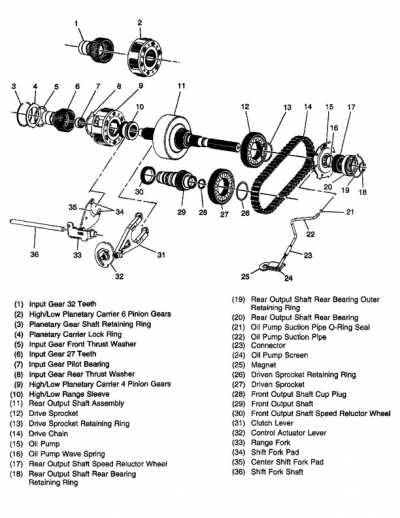

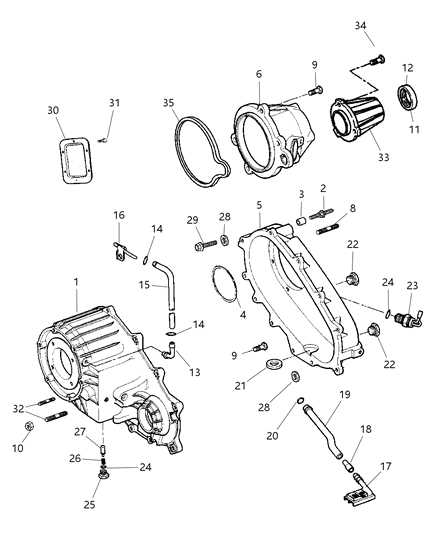

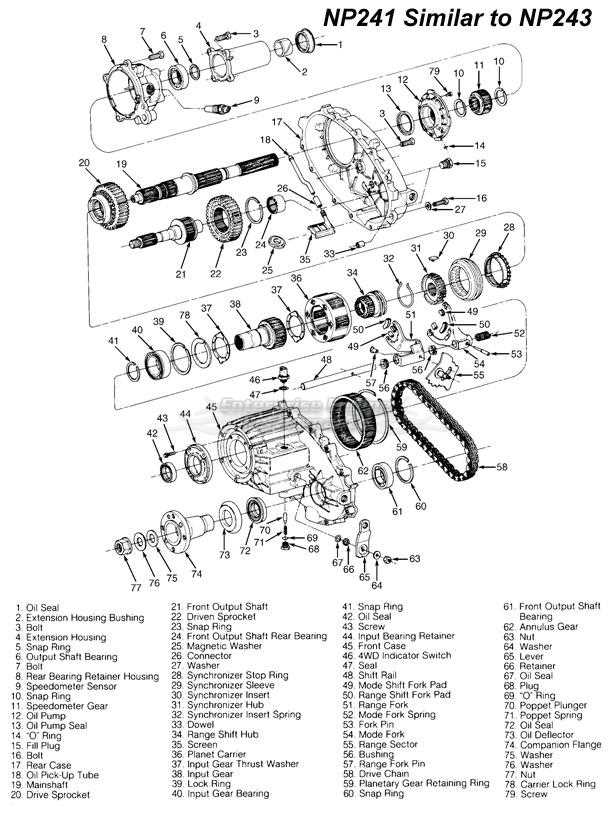

Main Components of Np241

The mechanism in question is composed of several key elements that work together to ensure optimal functionality and performance. Each part plays a vital role in the overall system, contributing to its reliability and efficiency during operation.

Key Elements

Housing: This robust structure encases the internal mechanisms, providing protection and stability under various conditions.

Gear Set: This assembly is crucial for power distribution, allowing for smooth transitions between different driving modes.

Control Mechanisms

Shift Linkage: This component facilitates the selection of modes, enabling the driver to adjust settings based on terrain and driving needs.

Fluid System: The lubrication system ensures that all moving parts operate seamlessly, reducing wear and tear over time.

Benefits of Upgrading Parts

Enhancing components in your vehicle can lead to significant improvements in performance, reliability, and longevity. Upgrades can optimize functionality, increase efficiency, and elevate overall driving experience. Understanding the advantages of these enhancements is crucial for any enthusiast or owner.

Improved Performance

- Increased power delivery

- Enhanced torque response

- Better fuel efficiency

Increased Durability

- Longer lifespan of upgraded elements

- Resistance to wear and tear

- Better handling of extreme conditions

Investing in better-quality components can ultimately lead to a more enjoyable and reliable driving experience.

Common Issues with Np241

Many users encounter a range of challenges with this particular system, which can lead to performance issues and operational difficulties. Understanding these common problems can help in maintaining functionality and enhancing longevity.

- Fluid Leaks: One of the most prevalent issues is leaking fluid, which can occur due to worn seals or gaskets. Regular inspection is essential to identify and address leaks promptly.

- Noise: Unusual sounds, such as grinding or clunking, often indicate internal wear or damage. Identifying the source of the noise is crucial for timely repairs.

- Engagement Problems: Difficulty in shifting between modes may arise from worn linkage or internal components. This can lead to an inability to switch effectively between settings.

- Overheating: Excessive heat can cause serious damage, often stemming from low fluid levels or improper use. Monitoring temperature is vital for preventing overheating.

- Vibration: Excessive vibration during operation may signal issues with alignment or balance. Addressing these concerns early can prevent further damage.

Addressing these common issues proactively can greatly enhance the reliability and performance of the system, ensuring smoother operation and extending its lifespan.

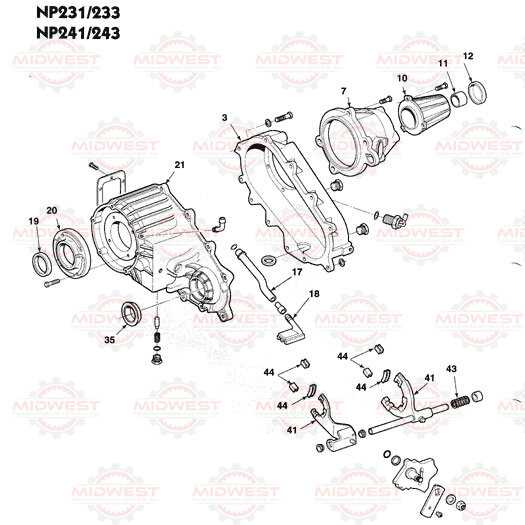

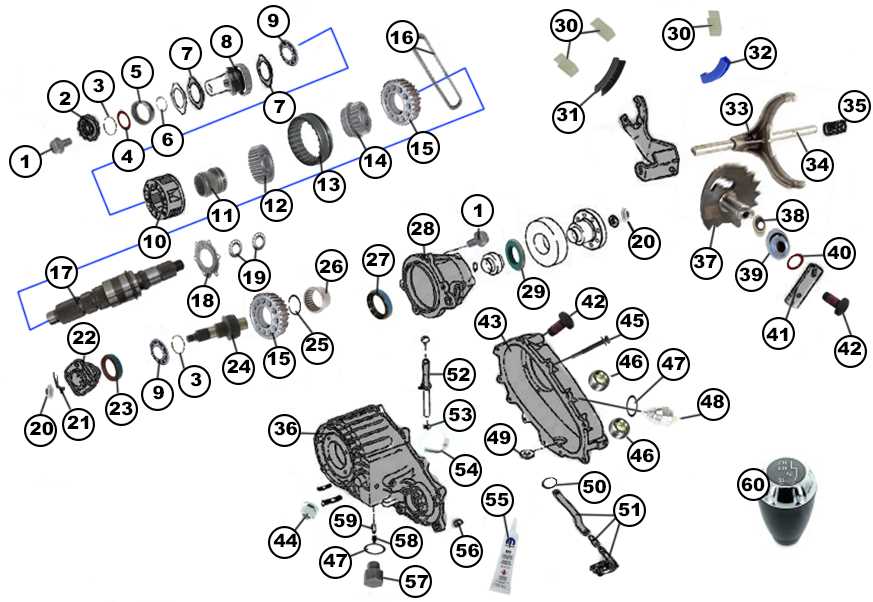

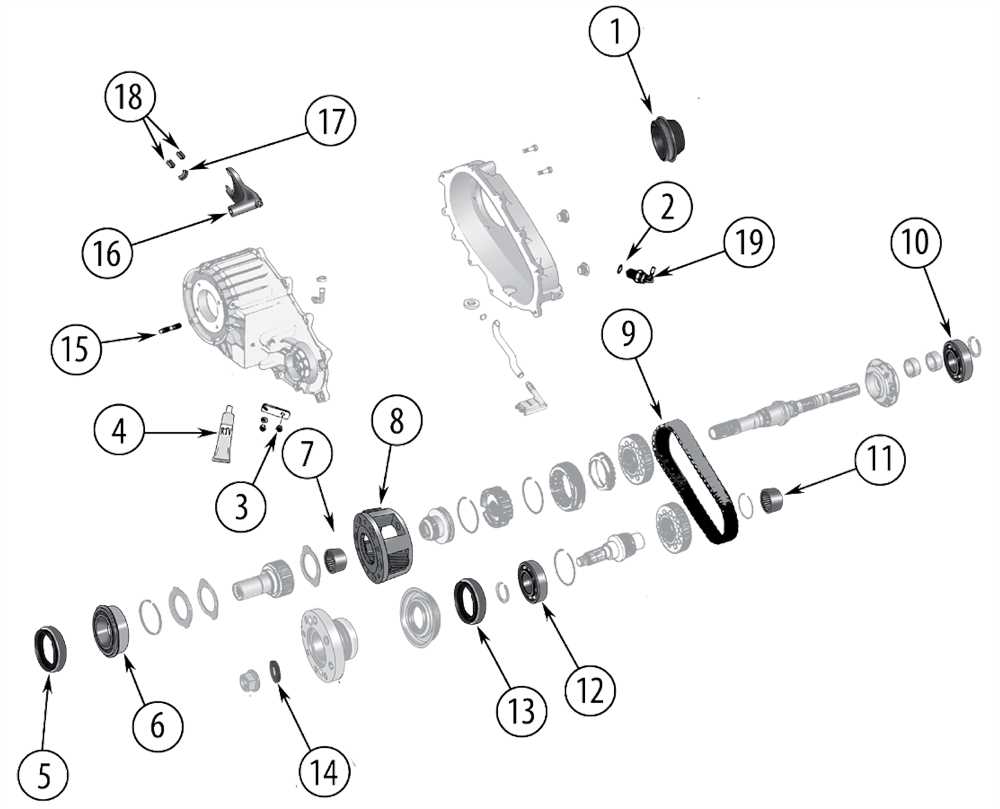

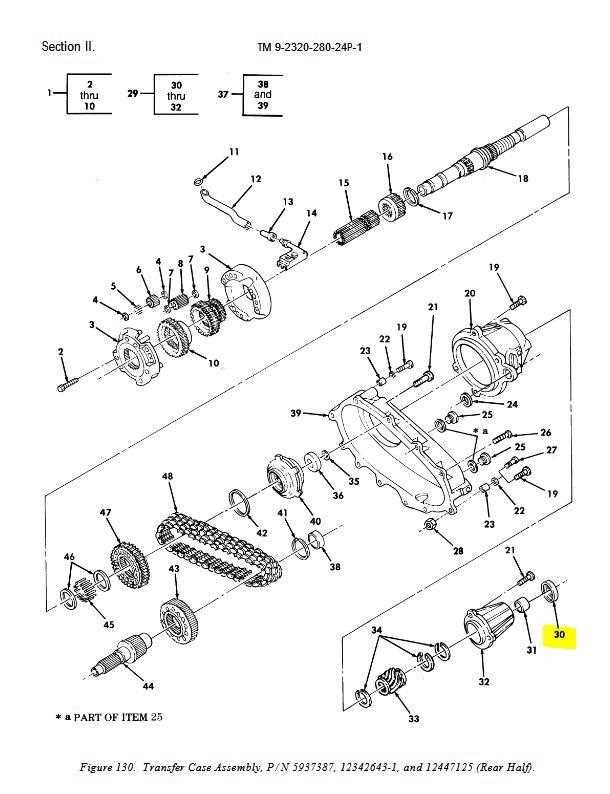

Parts Diagram Explanation

Understanding the layout of components in a mechanical assembly is crucial for effective maintenance and troubleshooting. A visual representation serves as a roadmap, guiding users through various elements and their interrelations. This structured overview aids in recognizing how each segment contributes to the overall functionality.

Key Elements typically include labels for each component, which help in identifying their specific roles. This clarity allows users to pinpoint where issues may arise and facilitates easier replacements or repairs. By comprehensively mapping out the structure, one can appreciate the intricate connections and the importance of each individual piece.

Maintenance and Repair tasks become significantly more manageable when armed with such illustrations. They not only provide insights into the assembly but also enhance one’s understanding of operational mechanics. As a result, users can approach projects with greater confidence, ensuring a thorough and effective resolution to any complications encountered.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your vehicle’s crucial components requires regular attention and care. Implementing a few straightforward practices can significantly enhance performance and durability, minimizing the likelihood of costly repairs. Following a routine maintenance schedule will help keep your machinery running smoothly and efficiently.

Regular inspections are vital. Checking for any signs of wear, leaks, or unusual noises can prevent minor issues from escalating. Cleanliness is equally important; removing dirt and debris can prevent buildup that may lead to mechanical failure. Additionally, timely fluid changes are essential, as they help maintain optimal operation and reduce friction between moving elements.

It’s also wise to adhere to manufacturer recommendations for servicing intervals and specifications. Using high-quality lubricants and components tailored to your model can make a substantial difference in performance. Lastly, driving habits play a significant role; gentle acceleration and braking can alleviate unnecessary stress on mechanical systems, contributing to longevity.

Replacing Np241 Components

When it comes to maintaining the functionality of your vehicle’s drivetrain, replacing worn or damaged elements is essential for optimal performance. Addressing these components promptly not only enhances reliability but also ensures safety during operation.

Identifying Issues: Start by thoroughly inspecting the assembly for signs of wear or malfunction. Look for leaks, unusual noises, or difficulty in shifting.

Gathering Tools: Before beginning the replacement process, ensure you have the necessary tools at hand. A complete toolkit will facilitate a smoother experience and help avoid delays.

Disassembly: Carefully disassemble the unit, taking care to keep track of all components. Documenting the order of removal can be invaluable during reassembly.

Component Replacement: When replacing any elements, opt for high-quality parts to guarantee longevity. Following manufacturer specifications is crucial for compatibility and performance.

Reassembly: Once new components are in place, reassemble the unit methodically. Double-check each step to ensure everything is secure and correctly aligned.

Final Checks: After reassembly, conduct a thorough inspection and test the system. Ensure that everything operates smoothly before taking your vehicle on the road.

Aftermarket Parts vs. OEM

When it comes to enhancing vehicle performance, enthusiasts often face a choice between two main categories of components. Understanding the differences between these options is crucial for making informed decisions that affect both reliability and budget. Each category has its unique advantages and potential drawbacks that can significantly influence the overall driving experience.

Original Equipment Manufacturer (OEM) components are produced by the same company that made the original components for the vehicle. These items are typically designed to meet specific factory standards, ensuring compatibility and reliability. Many drivers appreciate the peace of mind that comes with using OEM parts, as they are generally backed by warranties and are known for their durability.

On the other hand, aftermarket components offer a range of alternatives that might provide enhanced performance or better pricing. These items are manufactured by third-party companies and can vary widely in quality and compatibility. While some aftermarket options may exceed OEM standards, others might not deliver the same level of reliability. It’s essential for consumers to research and choose reputable brands to ensure they get the best value.

Ultimately, the choice between OEM and aftermarket solutions depends on individual priorities, whether it’s maintaining authenticity, enhancing performance, or balancing cost-effectiveness. By weighing these factors, vehicle owners can make decisions that align with their specific needs and preferences.

How to Identify Np241 Parts

Understanding the components of a specific assembly is crucial for effective maintenance and repair. This section provides insights on recognizing the individual elements that comprise this essential mechanism, facilitating easier troubleshooting and replacement.

To accurately identify the components, follow these steps:

- Visual Inspection:

Begin with a thorough visual examination. Familiarize yourself with the overall structure and layout.

- Consult Documentation:

Utilize manuals or guides that offer detailed illustrations. These resources can help you match what you see with the corresponding names and functions.

- Check for Part Numbers:

Look for any markings or labels on the components. Often, part numbers are inscribed on the surface, allowing for easy identification.

- Use Online Resources:

Leverage online forums, videos, and databases where enthusiasts share their knowledge. This can provide additional context and visuals.

- Seek Professional Help:

If unsure, consider consulting with a technician. Their expertise can offer clarity and ensure proper identification.

By following these guidelines, you can effectively recognize the individual elements of your assembly, ensuring optimal performance and longevity.

Installation Process for Np241

Setting up this particular component involves several crucial steps to ensure proper functionality and longevity. Attention to detail during the assembly process can significantly affect the overall performance of your vehicle. Understanding the key procedures and best practices is essential for a successful installation.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Consult the manual specific to your model to familiarize yourself with the specifications. Clear the work area to ensure a safe and efficient environment. It is also advisable to wear protective gear to prevent injuries during the installation.

Installation Procedure

Start by positioning the unit correctly within the designated area. Ensure all connections align appropriately. Fasten each component securely to avoid any future complications. After completing the assembly, double-check all connections and tighten fasteners to the recommended torque specifications. Once everything is secure, conduct a thorough inspection before testing the system to confirm proper operation.

Impact on Vehicle Performance

The configuration of a vehicle’s drivetrain significantly influences its overall functionality and responsiveness. Properly functioning components ensure optimal power distribution and enhance maneuverability in various terrains.

Key factors affecting performance include:

- Power Delivery: Efficient transfer of power leads to improved acceleration and handling.

- Durability: High-quality materials and design increase the lifespan of the drivetrain, reducing maintenance costs.

- Fuel Efficiency: Well-aligned systems can enhance fuel economy by minimizing energy loss.

Understanding these aspects can help drivers appreciate the ultimate impact of drivetrain systems on their vehicles’ capabilities, especially in challenging driving conditions.

Resources for Further Learning

Exploring additional materials is essential for deepening your understanding of mechanical components and their functionalities. Various platforms provide insights, tutorials, and detailed guides that can enhance your knowledge base.

Online Platforms

| Resource | Description |

|---|---|

| YouTube | A vast collection of instructional videos covering assembly and maintenance techniques. |

| Forums | Online communities where enthusiasts share experiences and advice on troubleshooting and upgrades. |

Books and Manuals

Books and service manuals provide in-depth technical information and diagrams, ideal for both beginners and seasoned professionals. Seek out titles that focus on automotive mechanics and repair to gain comprehensive insights.