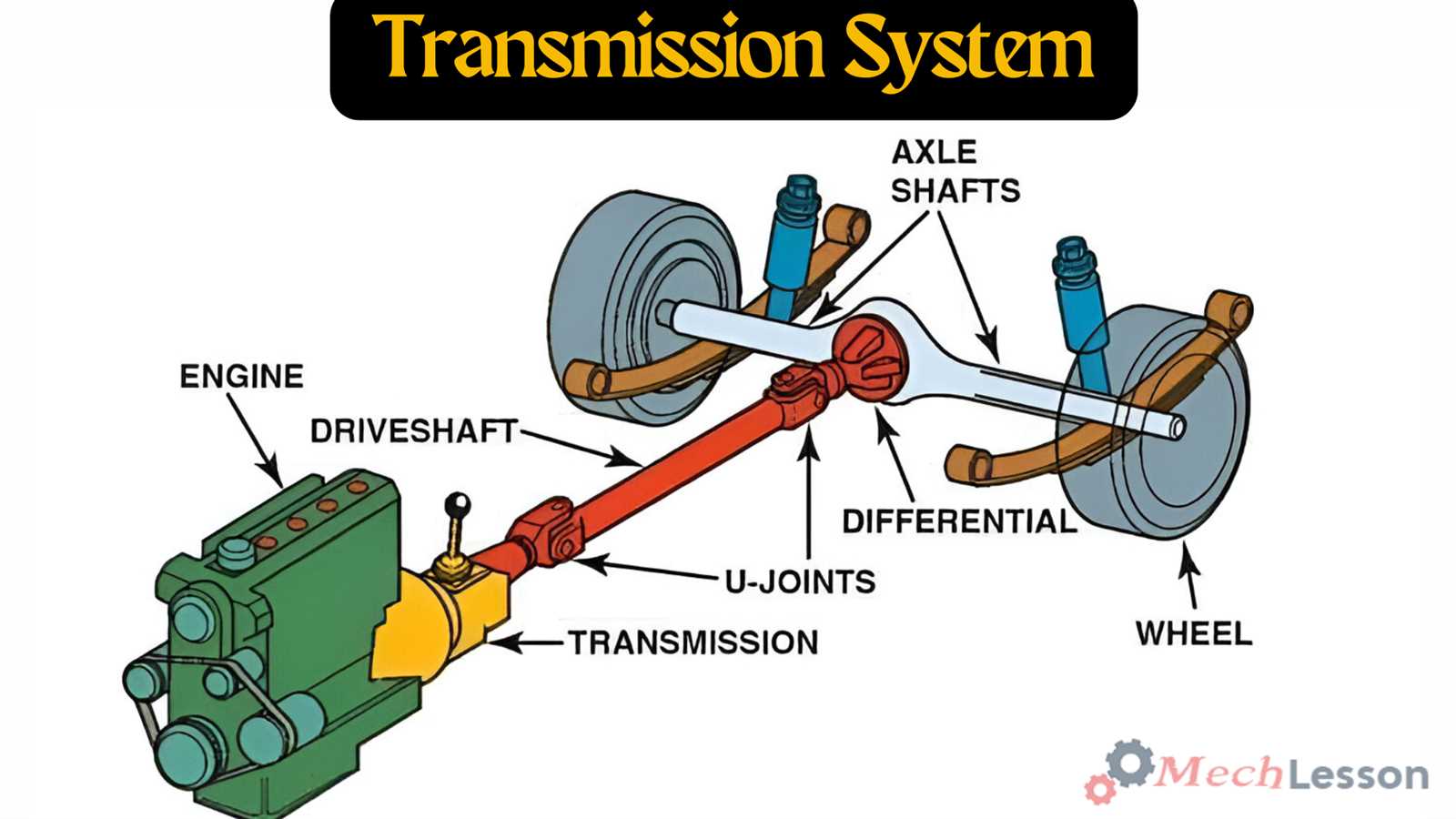

The intricacies of mechanical systems often hinge on the interplay between various elements that facilitate the transfer of energy. An effective representation of this flow is crucial for comprehending how motion and force are conveyed within a given setup. By analyzing these essential segments, one can grasp the fundamental workings that drive performance and efficiency.

In the realm of engineering, each section serves a specific purpose, contributing to the overall functionality of the mechanism. Whether it’s focusing on the conversion of rotational energy or managing the synchronization of moving parts, these components play an integral role in ensuring seamless operation. Delving into their characteristics reveals the underlying principles that govern their interactions.

Ultimately, a thorough understanding of these integral sections empowers engineers and designers to innovate and enhance performance across various applications. Emphasizing their unique functions allows for a deeper appreciation of the complex relationships that exist within mechanical systems.

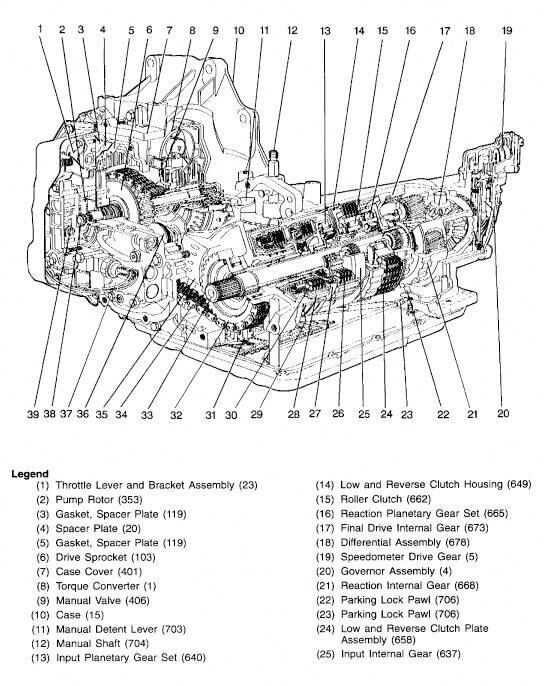

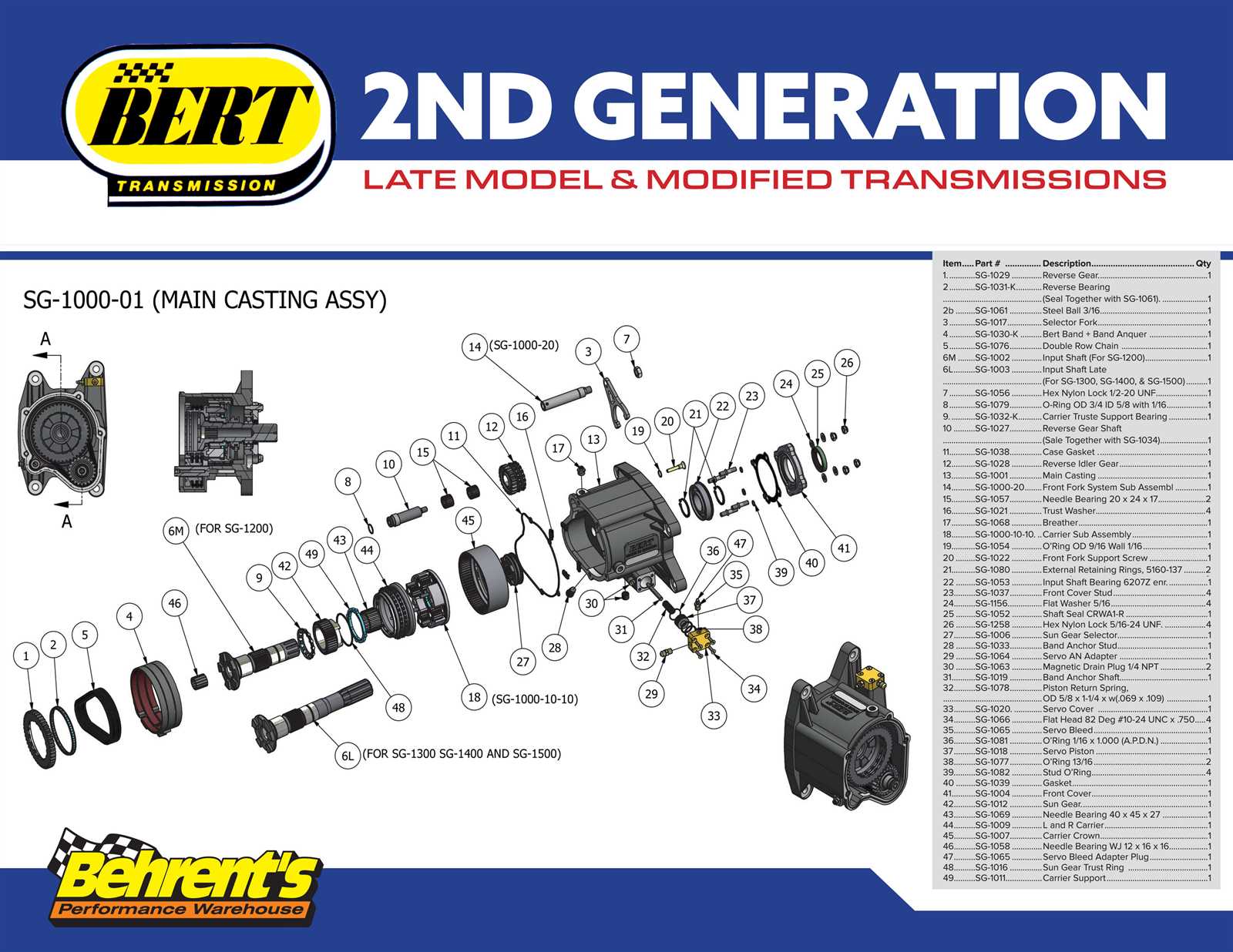

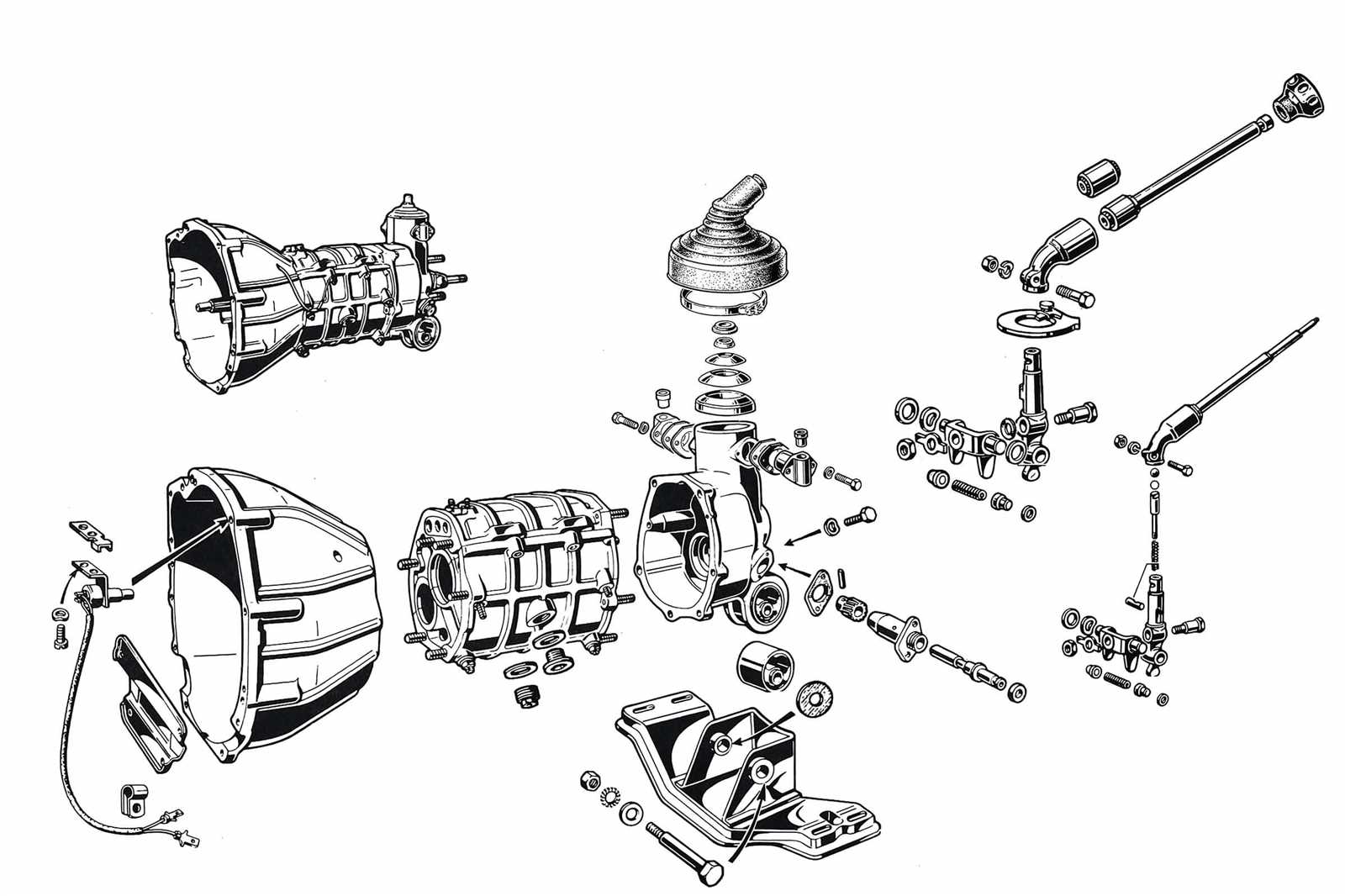

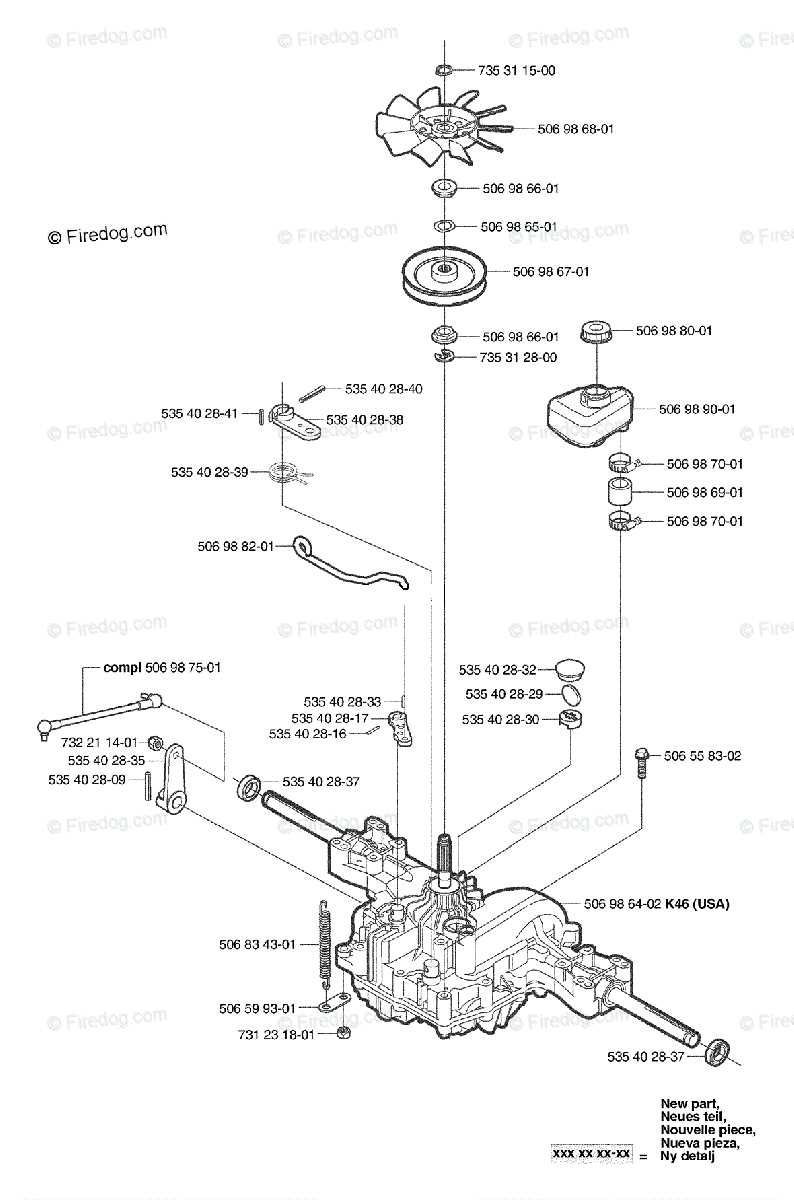

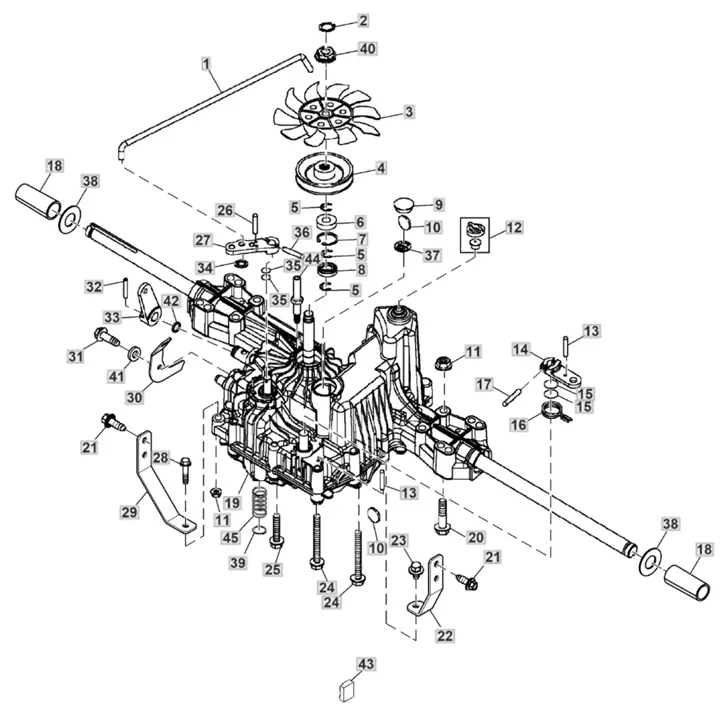

Understanding Transmission Diagrams

Comprehending the visual representation of complex systems is essential for analyzing their functionality. This section will explore the various elements that contribute to the overall picture, highlighting how they interact to convey crucial information.

- Symbols: Different shapes and icons are utilized to represent specific components, facilitating easier interpretation.

- Connections: Lines indicate relationships and pathways between elements, illustrating the flow of information or energy.

- Labels: Clear annotations provide context, ensuring that each part is easily identifiable and understood.

By breaking down these components, one can delve deeper into the mechanics at play and appreciate the ultimate design and functionality of the entire system.

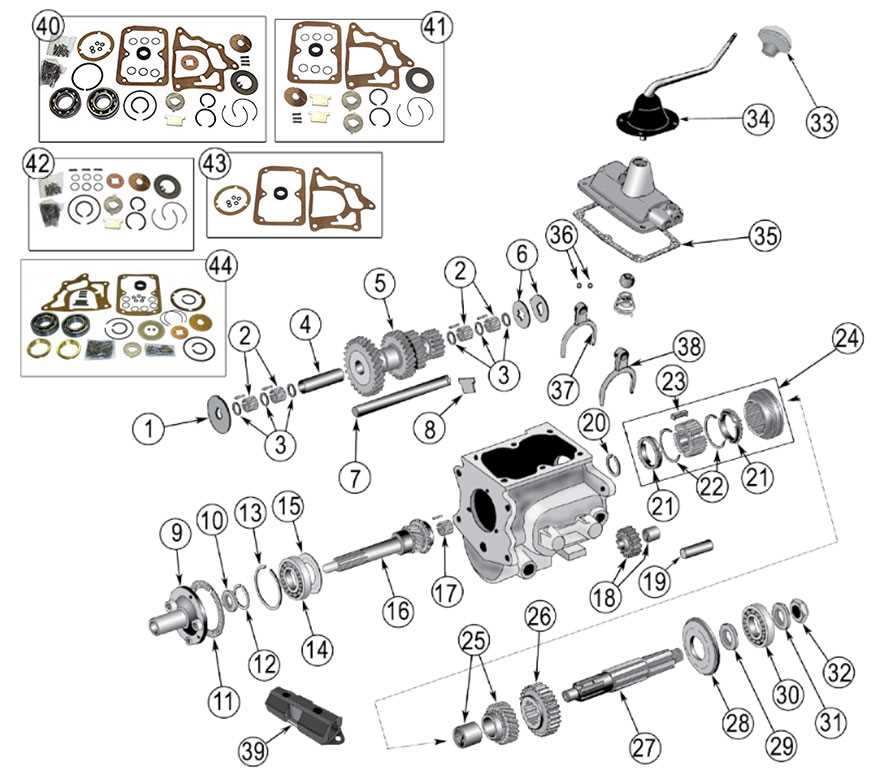

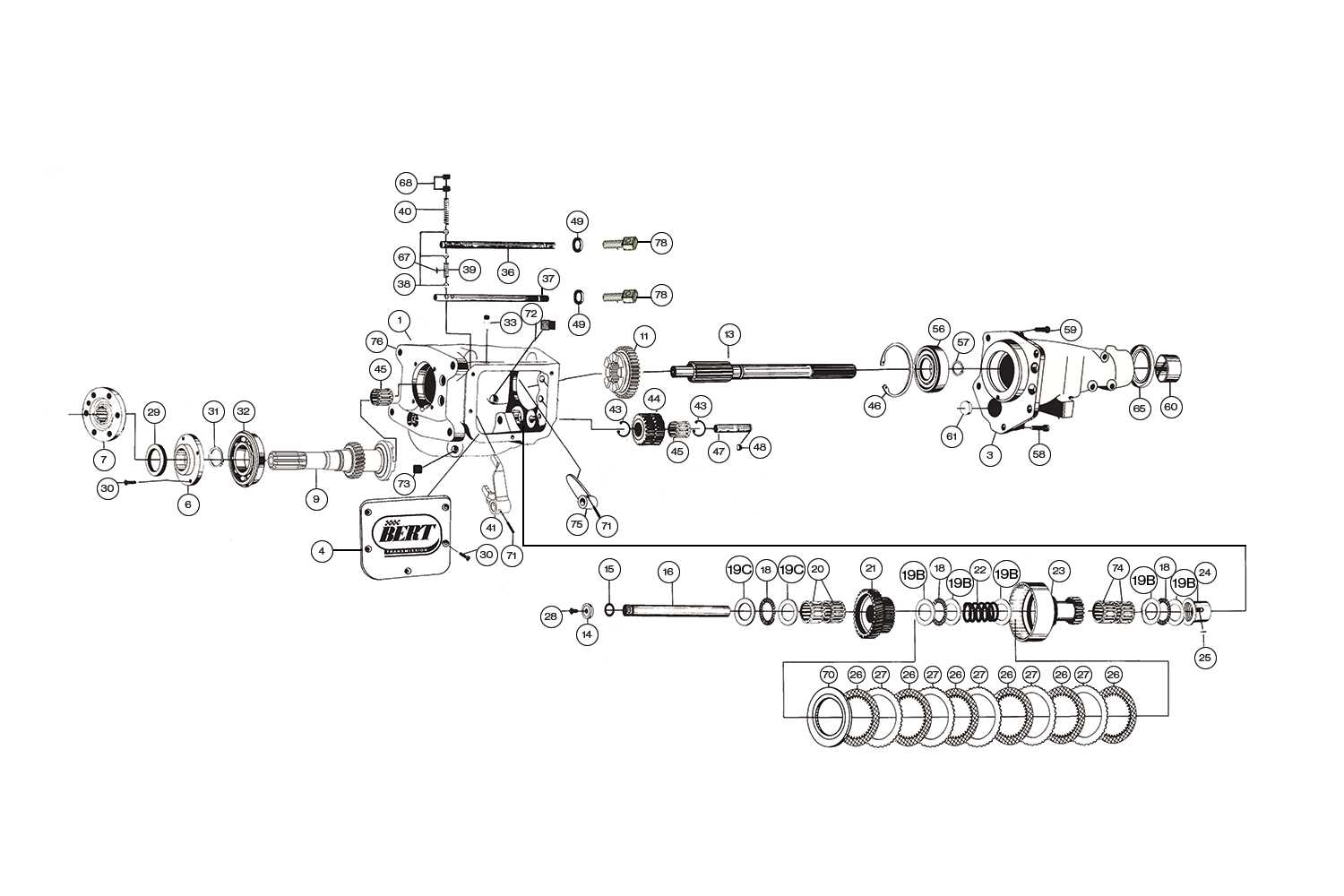

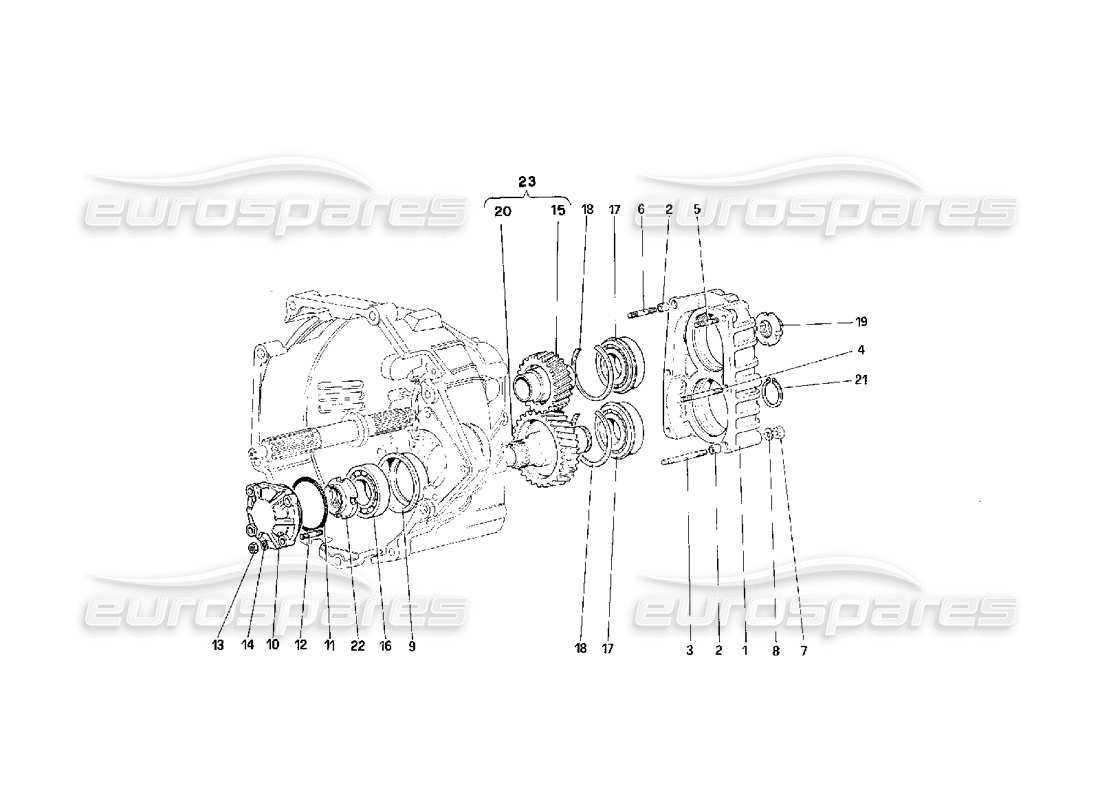

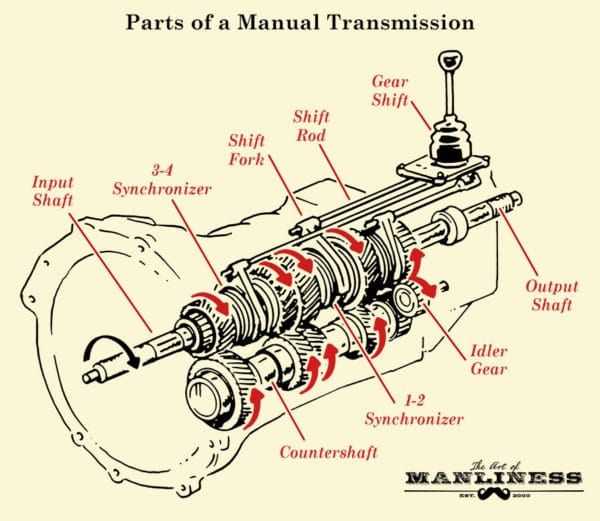

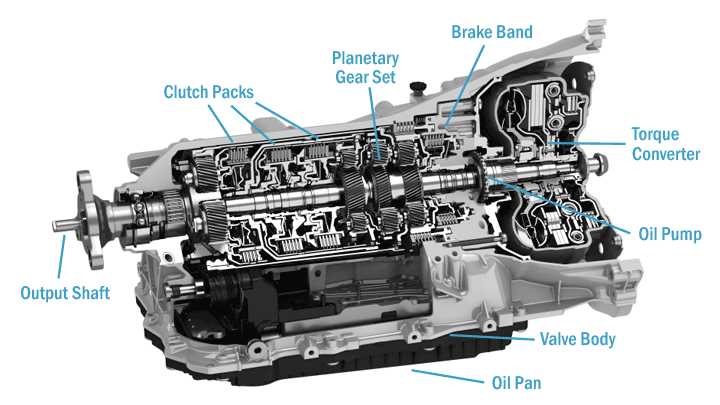

Key Components Explained

Understanding the essential elements involved in a system’s functionality is crucial for grasping its overall operation. Each component plays a significant role, contributing to the seamless interaction and efficiency of the entire mechanism. This section delves into the primary elements that ensure optimal performance and reliability.

1. Gearbox: The gearbox is vital for adjusting the speed and torque generated by the engine. By changing gear ratios, it allows for efficient power distribution, enabling smooth transitions between different driving conditions.

2. Clutch: The clutch serves as a critical interface, enabling the driver to engage or disengage the engine from the wheels. This component facilitates smooth starts and stops while allowing for gear changes without damaging the system.

3. Drive Shaft: The drive shaft transmits power from the gearbox to the wheels. Its design is essential for maintaining the integrity of power transfer, ensuring that energy flows effectively throughout the system.

4. Differential: The differential allows for variations in wheel speed during turns, improving handling and stability. It plays a key role in distributing power to the wheels while accommodating their differing rotation rates.

5. Synchronizers: Synchronizers aid in the smooth engagement of gears, preventing clashes during shifts. This component is crucial for maintaining the longevity of the system and enhancing the overall driving experience.

Each of these elements interacts intricately, forming a cohesive unit that enhances functionality and performance. A thorough understanding of these key components empowers users to appreciate the complexities of the system and facilitates informed decision-making when it comes to maintenance and upgrades.

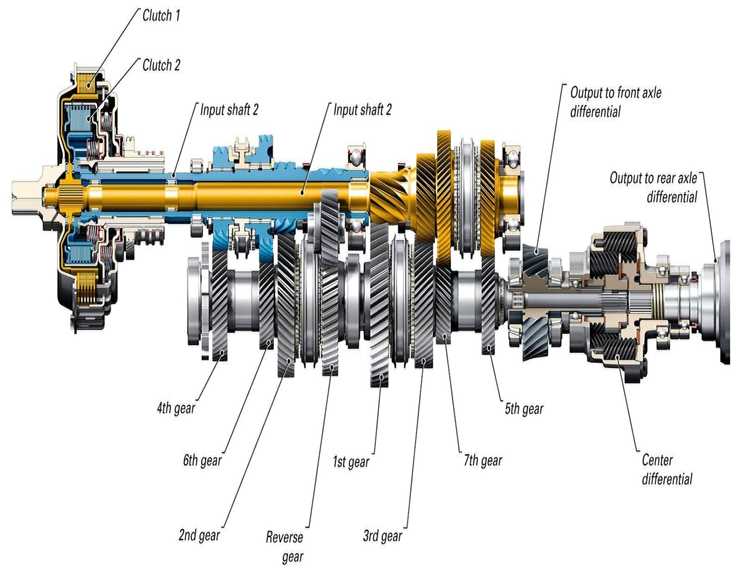

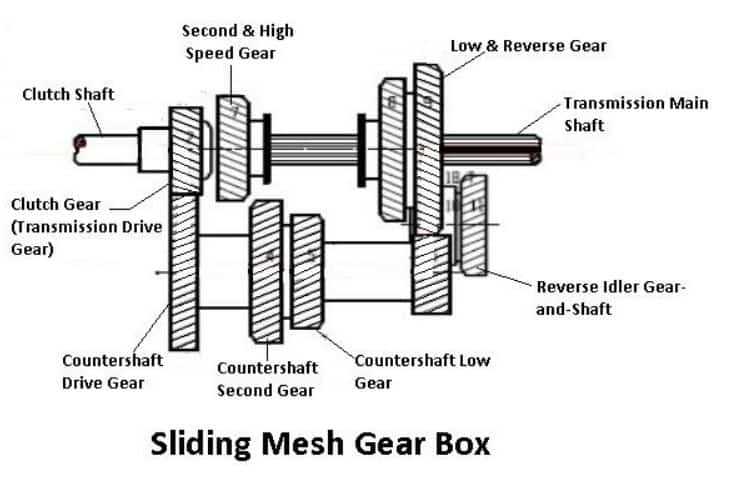

Function of Gears in Transmission

Gears play a crucial role in the mechanics of power transfer, facilitating the conversion of motion and torque within various machines. Their design and arrangement allow for the manipulation of speed and force, making them essential for optimizing performance in numerous applications.

By engaging with one another, gears enable different rotational speeds, allowing an engine or motor to operate efficiently across a range of conditions. This interaction not only adjusts the velocity but also enhances the overall capability of the system, ensuring that the desired output is achieved with precision.

The ratio between interlocking gears determines how force is transmitted. For instance, when a smaller gear drives a larger one, the speed increases while the torque decreases, and vice versa. This versatility makes gears indispensable for various tasks, from simple machines to complex vehicles.

In addition to modifying speed and torque, gears contribute to the smooth operation of mechanisms, reducing friction and wear. This functionality ensures longevity and reliability, critical factors in both industrial machinery and everyday devices.

Role of Clutch Mechanisms

The clutch mechanism serves a pivotal function in facilitating the smooth operation of vehicles, allowing for controlled power transfer between the engine and the drivetrain. This system is essential for engaging and disengaging motion, enabling seamless acceleration and deceleration.

Primarily, the mechanism allows the driver to change gears without damaging the internal components, enhancing overall performance. It works by creating a connection or separation between rotating elements, which is vital during gear shifts.

Additionally, it aids in preventing stalling and provides the ability to manage engine power efficiently. This control contributes significantly to vehicle maneuverability, especially in complex driving situations.

In essence, the functionality of clutch systems is integral to the driving experience, ensuring reliability and responsiveness on the road.

Importance of Shafts and Bearings

Shafts and bearings play a crucial role in the functionality and efficiency of mechanical systems. They facilitate movement, reduce friction, and ensure that energy is transmitted effectively from one component to another. Understanding their significance can enhance performance and longevity in various applications.

Functionality of Shafts

Shafts serve as the backbone of rotating machinery. They are responsible for transferring torque and rotational motion between different elements. This seamless transfer is vital for optimal operation.

Role of Bearings

Bearings minimize friction between moving parts, allowing for smoother operation and reducing wear and tear. Their design and material choices significantly impact the efficiency and reliability of mechanical systems.

| Component | Function | Benefits |

|---|---|---|

| Shafts | Transmit torque | Enhanced power efficiency |

| Bearings | Reduce friction | Increased lifespan of components |

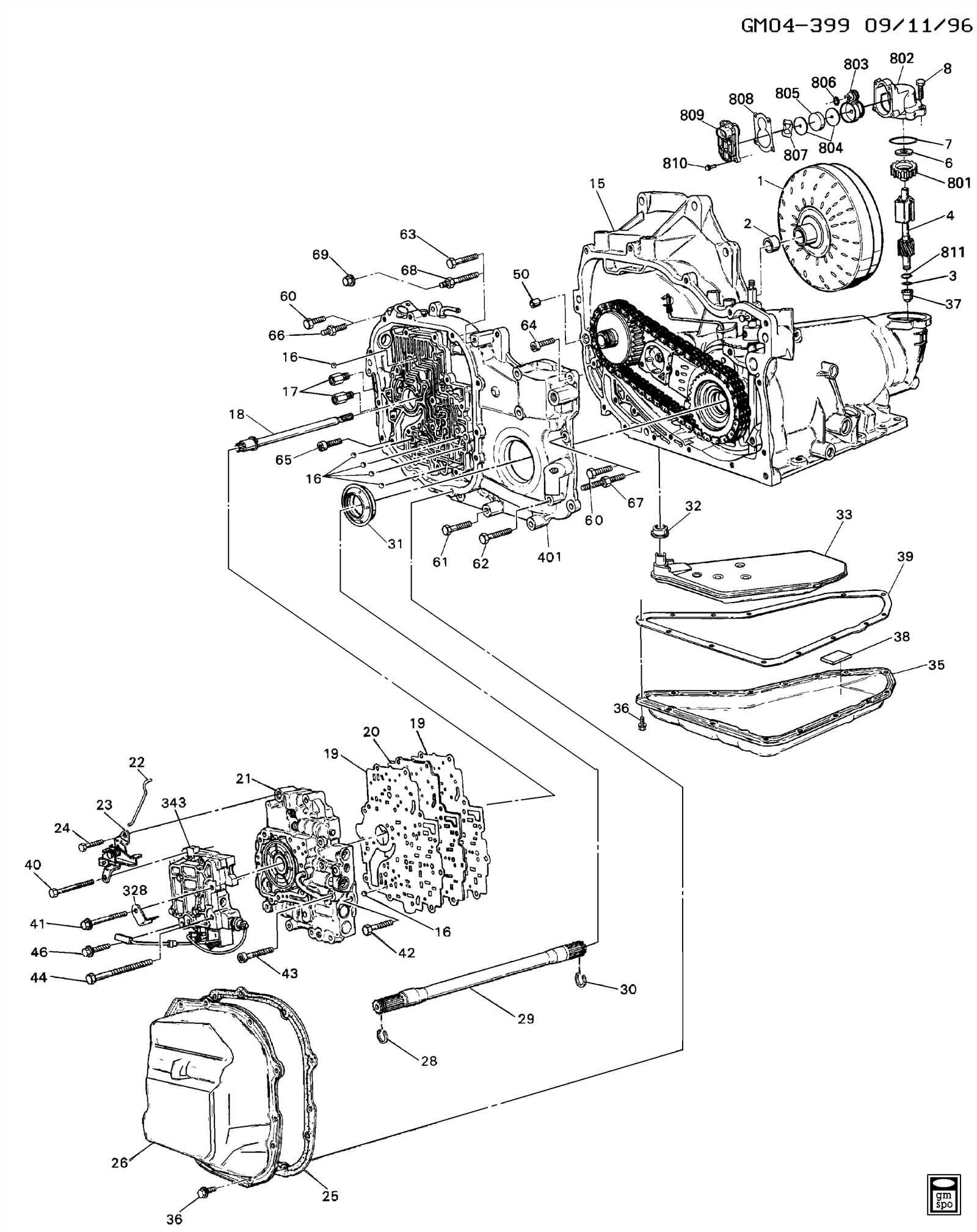

Fluid Dynamics in Transmissions

The behavior of fluids in mechanical systems plays a crucial role in optimizing efficiency and performance. Understanding how these substances interact within various components allows for improved design and functionality. This section explores the principles governing fluid movement and its impact on overall operation.

Key Concepts of Fluid Movement

- Viscosity: The measure of a fluid’s resistance to flow.

- Pressure: The force exerted by the fluid per unit area.

- Flow Rate: The volume of fluid passing through a section per unit time.

Importance of Fluid Dynamics

- Enhances cooling efficiency in systems.

- Reduces wear and tear on mechanical parts.

- Improves energy transfer and system responsiveness.

Types of Transmission Systems

Understanding the various mechanisms that facilitate the transfer of power is crucial for enhancing vehicle performance. Each system serves distinct purposes and operates under different principles, affecting efficiency, speed, and adaptability.

Manual Systems: These rely on driver engagement for gear selection, offering a direct connection between the engine and wheels. They provide greater control and responsiveness, appealing to enthusiasts seeking a dynamic driving experience.

Automatic Systems: Designed for convenience, these systems shift gears based on speed and load without driver input. They enhance ease of use, particularly in urban settings, allowing focus on the road rather than gear changes.

Continuously Variable Systems (CVT): This type offers seamless acceleration without distinct gear shifts, optimizing engine performance across varying speeds. CVTs promote fuel efficiency by maintaining optimal engine RPM.

Dual-Clutch Systems: Combining the benefits of manual and automatic mechanisms, these utilize two clutches for rapid gear shifts. They provide a sporty feel while ensuring smooth transitions, ideal for high-performance vehicles.

Hybrid Systems: Integrating traditional and electric power sources, these systems offer versatility and reduced emissions. They adapt to driving conditions, enhancing overall efficiency and performance.

Common Transmission Diagram Symbols

Understanding the various symbols used in technical illustrations is essential for effectively interpreting the relationships and functions within a system. These representations simplify complex concepts, allowing for clearer communication among engineers and technicians.

Key Symbols and Their Meanings

Each symbol carries specific information about the components and their interactions. For instance, a circle may indicate a motor, while arrows often denote the direction of movement or flow. Recognizing these visual cues can enhance comprehension and facilitate troubleshooting.

Importance of Standardization

The use of standardized symbols ensures consistency across different documentation and industries. This uniformity not only aids in understanding but also helps in training new professionals, making it easier to delve into complex systems and achieve ultimate efficiency.

Reading a Transmission Schematic

Understanding a schematic is essential for effective troubleshooting and analysis of mechanical systems. It serves as a visual representation, detailing the flow and interaction of components, enabling one to grasp the underlying mechanics at play.

Key Elements to Consider

When interpreting these visuals, focus on symbols, lines, and notations. Each symbol represents a specific component, while lines indicate the connections and flow of energy or power.

Common Symbols and Their Meanings

| Symbol | Description |

|---|---|

| Circle | Represents a component or junction point. |

| Arrow | Indicates direction of flow or movement. |

| Dashed Line | Denotes a conditional connection or alternative path. |

Applications in Automotive Engineering

In the realm of automotive design and functionality, the intricate systems that facilitate vehicle movement and control play a crucial role. These mechanisms ensure efficiency, safety, and performance, directly impacting the driving experience. Understanding the various components involved allows engineers to optimize designs and innovate solutions tailored to modern demands.

Efficiency and Performance Optimization

One of the primary applications in automotive engineering is the enhancement of efficiency and performance. By analyzing the interrelationships between different mechanisms, engineers can create systems that reduce energy consumption while maximizing power output. For example, advancements in materials and technology have led to lighter and stronger elements, which contribute to improved fuel economy and overall vehicle dynamics.

Safety Enhancements

Another significant area is the development of safety features. The integration of advanced mechanisms helps in creating systems that react promptly to various driving conditions. Adaptive braking and stability control are examples where precise coordination between components ensures that vehicles respond effectively to driver inputs, enhancing overall safety. As technology evolves, the focus on creating resilient and responsive systems continues to grow, aiming to minimize risks on the road.

Challenges in Transmission Design

The process of creating efficient systems for power transfer is fraught with complexities that engineers must navigate. These challenges arise from the need to balance performance, reliability, and cost while adapting to various operational conditions.

Technological Limitations

One of the primary hurdles involves the constraints of current technologies. The pursuit of innovative solutions often leads to unforeseen issues, such as material fatigue and energy loss. Engineers must continuously delve into advancements in materials and components to enhance efficiency.

Environmental Considerations

Additionally, environmental factors significantly impact design choices. Variations in temperature, humidity, and external loads necessitate robust solutions that can withstand diverse conditions. Achieving the ultimate balance between sustainability and functionality remains a pressing challenge.

Future Trends in Transmission Technology

The landscape of conveying power and information is undergoing significant transformations, driven by advancements in engineering and innovative practices. As industries strive for greater efficiency and sustainability, emerging methodologies are reshaping how systems operate, aiming to enhance performance while reducing environmental impact.

Integration of Smart Technologies

One of the most promising directions is the integration of intelligent systems. With the advent of the Internet of Things (IoT), devices are becoming increasingly interconnected, allowing for real-time monitoring and control. This connectivity not only optimizes performance but also enhances predictive maintenance, reducing downtime and operational costs.

Sustainability and Efficiency

Another crucial trend is the focus on eco-friendly solutions. The shift towards renewable energy sources and electric mobility is prompting the development of more efficient systems that minimize energy loss. Innovations in materials and design are also playing a vital role in reducing waste and improving overall effectiveness, reflecting a growing commitment to environmental stewardship in technology.

Importance of Maintenance and Diagnostics

Regular upkeep and thorough evaluations play a crucial role in ensuring optimal performance and longevity of mechanical systems. Proactive measures can prevent unexpected failures, saving time and resources in the long run.

Benefits of Routine Maintenance

- Enhances efficiency and functionality.

- Reduces the likelihood of costly repairs.

- Extends the lifespan of components.

Significance of Diagnostic Evaluations

- Identifies potential issues before they escalate.

- Provides insights into performance metrics.

- Facilitates informed decision-making for repairs or replacements.