In the world of mechanical engineering, grasping the configuration of individual elements is crucial for effective assembly and maintenance. The arrangement of these essential components can significantly influence performance, reliability, and longevity. This section aims to shed light on the intricate relationships and functions within a complex system.

By exploring various layouts, one can gain insights into how each piece interacts with others, leading to a harmonious operation. The visualization of these relationships not only aids in troubleshooting but also enhances overall comprehension of the machinery’s functionality. Understanding these configurations empowers technicians and enthusiasts alike to optimize performance and address potential issues.

Through detailed illustrations and descriptions, we will delve into the fundamental aspects that define how these mechanisms work together. Emphasizing clarity and precision, this guide will serve as a valuable resource for those seeking to deepen their knowledge and expertise in the field.

This section will explore the essential elements involved in the functionality of a specific mechanical assembly used in motorcycles. A comprehensive overview of these components will provide valuable insights into their roles and how they work together to ensure optimal performance. Understanding these elements is crucial for enthusiasts and professionals alike, as it enhances knowledge about maintenance and potential upgrades.

| Heading Number | Heading Title |

|---|---|

| 1 | Overview of the Mechanism |

| 2 | Key Elements and Their Functions |

| 3 | How Components Interact |

| 4 | Common Issues and Solutions |

| 5 | Maintenance Practices for Longevity |

| 6 | Understanding Gear Ratios |

| 7 | Upgrades for Improved Performance |

| 8 | Visual Representation of Components |

| 9 | Expert Tips for Installation |

| 10 | Comparative Analysis of Alternatives |

| 11 | Future Trends in Mechanical Designs |

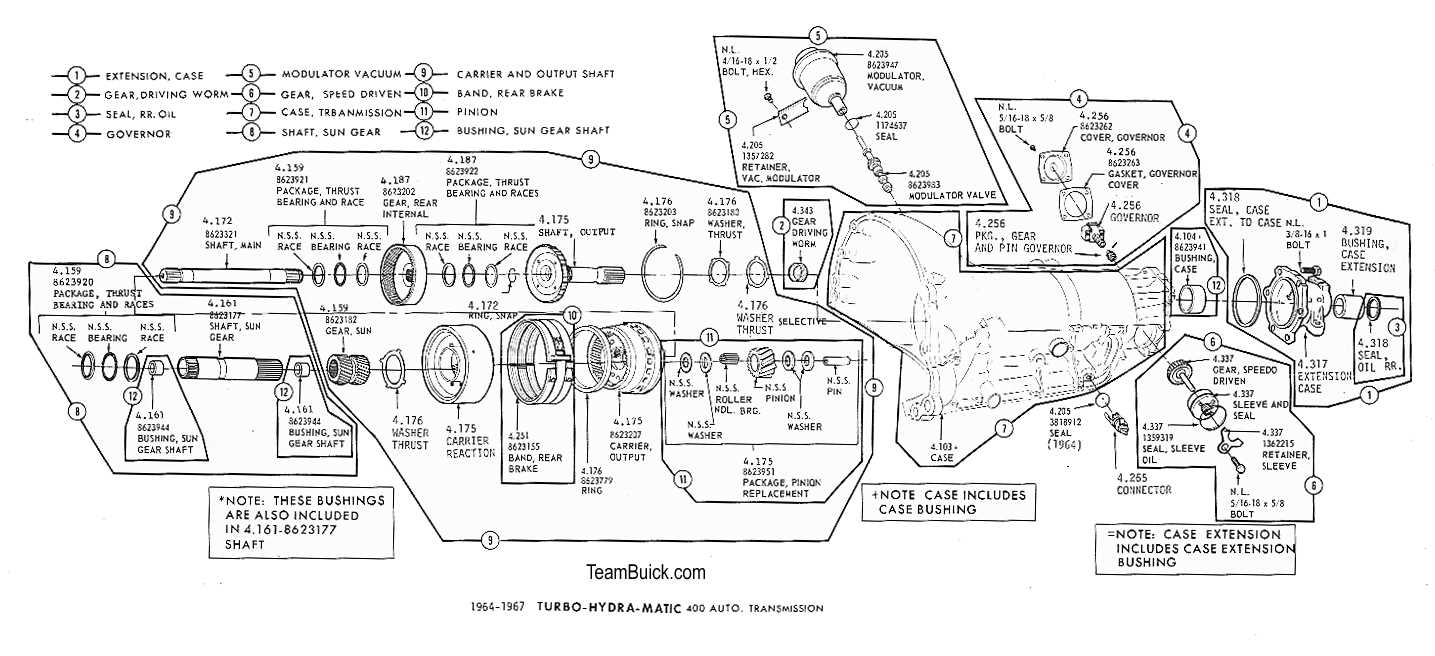

Overview of Transmission Systems

The mechanism responsible for transferring power within a vehicle is essential for its operation and performance. Understanding how this system functions can provide insights into its importance and the role it plays in ensuring smooth movement.

Key components of this mechanism include:

- Gear Assemblies: These are crucial for altering the speed and torque generated by the engine.

- Clutches: They enable the engagement and disengagement of the power flow, allowing for smooth transitions.

- Linkages: These facilitate the connection between various elements, ensuring coordinated movement.

Moreover, different types of mechanisms exist, each designed to cater to specific needs:

- Manual: Offers the driver complete control over gear selection, enhancing the driving experience.

- Automatic: Adjusts gear ratios automatically, allowing for effortless operation.

- Continuously Variable: Provides a seamless range of gear ratios, optimizing performance and efficiency.

Overall, this system is a critical element in automotive engineering, impacting performance, efficiency, and the overall driving experience.

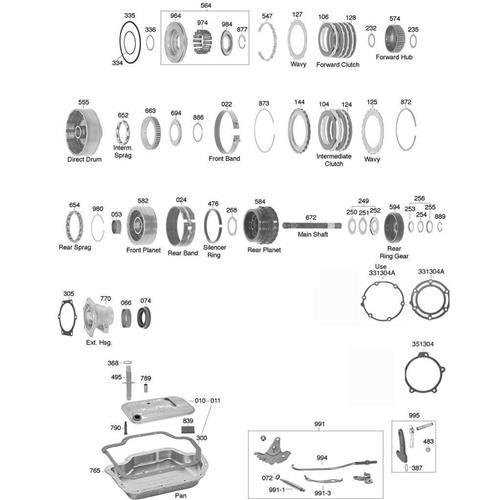

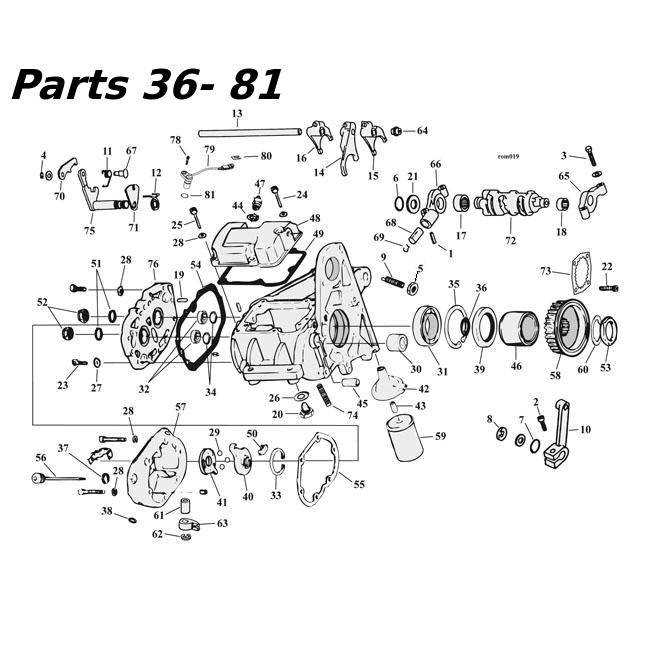

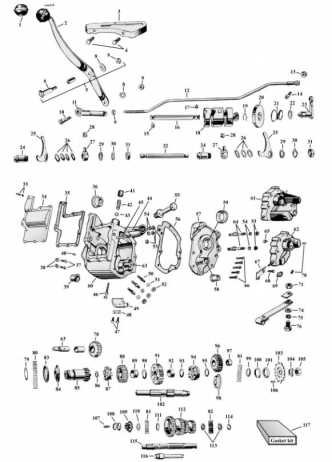

Key Parts of Revtech Transmission

The components of a particular mechanical assembly play a vital role in its overall functionality and performance. Understanding these elements allows enthusiasts and mechanics alike to appreciate the intricacies of the system, ensuring smooth operation and maintenance. In this section, we will explore some essential elements that contribute to the effective functioning of this assembly.

Essential Components Overview

Each unit consists of several critical components that work together seamlessly. Below is a brief description of these key elements, highlighting their functions:

| Component | Function |

|---|---|

| Gear Set | Transforms rotational force to drive the system. |

| Clutch Assembly | Engages and disengages power flow to the drive mechanism. |

| Shafts | Transmits rotational motion between components. |

| Seals | Prevents leakage of fluids and contaminants. |

| Bearings | Supports rotating elements, reducing friction. |

Understanding Component Interaction

Comprehending how these elements interact is crucial for effective troubleshooting and upgrades. Each part must function harmoniously to ensure the assembly operates at its best, offering durability and efficiency. Regular inspections and proper maintenance of these components can significantly enhance the lifespan and performance of the entire system.

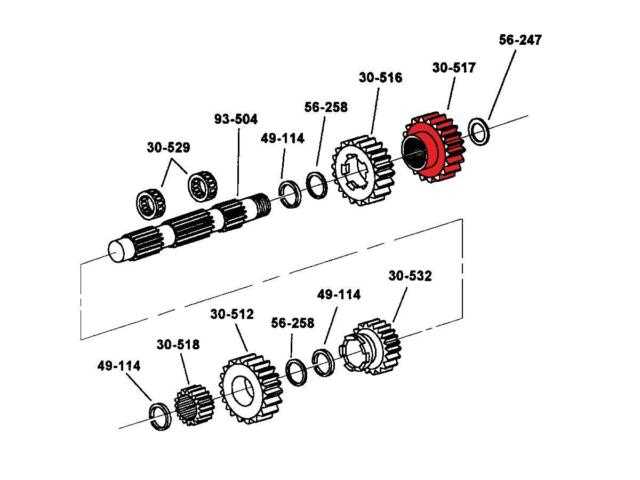

Functionality of Each Component

The effective operation of any mechanical system relies on the seamless interaction of its individual elements. Each component plays a crucial role in ensuring that the entire mechanism functions efficiently. Understanding the specific responsibilities of these elements is essential for optimal performance and longevity.

Core Elements and Their Roles

Gear Sets: These critical elements enable power transfer and torque multiplication. They work by engaging with one another to adjust rotational speed and force, providing the necessary adjustments for different operational conditions.

Control Mechanisms

Shift Linkages: Responsible for facilitating smooth transitions between different operational modes, these linkages ensure that the user can easily engage or disengage the system as required. Their precise design allows for immediate response, enhancing overall control.

Understanding the functionality of each component leads to better maintenance practices, ultimately extending the lifespan of the entire system.

Identifying Common Issues

Understanding frequent problems that can arise in complex mechanical systems is crucial for efficient maintenance and operation. By recognizing the signs of malfunction early, one can prevent more significant issues and ensure the longevity of the equipment.

Signs of Malfunction

- Unusual noises during operation, such as grinding or clunking sounds.

- Vibrations that are not typical for the equipment.

- Difficulty in shifting or changing gears smoothly.

- Fluid leaks around connection points or seals.

- Unexplained changes in performance or power delivery.

Routine Maintenance Tips

- Regularly inspect for signs of wear and tear.

- Check fluid levels and quality to ensure optimal function.

- Listen for unusual sounds during operation.

- Monitor performance to identify any inconsistencies.

- Address minor issues promptly to prevent escalation.

Importance of Proper Maintenance

Regular upkeep is crucial for ensuring optimal performance and longevity of any mechanical system. Neglecting this aspect can lead to premature wear and a range of operational issues. Maintaining components not only enhances their efficiency but also contributes to overall reliability.

Implementing a consistent maintenance routine offers several benefits:

- Enhanced Performance: Well-maintained systems operate more smoothly and efficiently, leading to improved functionality.

- Increased Lifespan: Routine checks and servicing can significantly extend the lifespan of crucial elements, reducing the need for costly replacements.

- Cost Savings: Addressing minor issues before they escalate into major problems can save substantial repair costs in the long run.

- Safety Assurance: Regular inspections help identify potential hazards, ensuring a safer environment for users.

To maintain efficiency, consider the following maintenance practices:

- Regular inspections to identify signs of wear or damage.

- Timely lubrication of moving components to minimize friction.

- Routine cleaning to prevent the buildup of dirt and grime.

- Adherence to manufacturer recommendations for service intervals.

In summary, prioritizing maintenance is essential for achieving reliable performance and maximizing the lifespan of mechanical systems. Investing time and resources into upkeep will yield significant benefits, making it a wise decision for any owner.

Choosing Quality Replacement Parts

Selecting high-grade components for your machinery is crucial for ensuring optimal performance and longevity. Quality alternatives not only enhance functionality but also minimize the risk of future complications. Prioritizing reliability in the selection process can lead to a smoother operation and a more satisfying user experience.

Understanding Material Quality

The durability and effectiveness of a component heavily depend on the materials used in its construction. Opting for components made from premium materials can significantly influence overall performance. Look for products that offer robust construction, corrosion resistance, and the ability to withstand varying conditions.

Evaluating Compatibility and Performance

Ensuring that the selected replacements are compatible with your equipment is essential. Mismatched components can lead to inefficiencies and potential damage. Researching performance ratings and user feedback can provide valuable insights into how well these alternatives function in real-world applications, helping you make informed decisions.

Assembly Instructions for Revtech Parts

Proper assembly of essential components is crucial for ensuring optimal performance and longevity. This section outlines the necessary steps to effectively combine various elements, focusing on precision and adherence to guidelines for successful integration.

1. Preparation: Before starting the assembly, ensure all necessary components and tools are available. Organize the workspace to facilitate easy access and maintain a clutter-free environment. Carefully inspect each component for any defects or damage that may affect functionality.

2. Step-by-step Assembly: Begin with the largest components, as they will serve as the foundation for the assembly. Gradually introduce smaller elements, ensuring that each piece is aligned correctly. Use appropriate fasteners and torque specifications to secure each part firmly. Follow the recommended sequence to avoid misalignment or damage.

3. Final Inspection: Once all components are assembled, conduct a thorough inspection. Check for proper alignment, secure connections, and overall integrity. It is essential to test the assembled unit to ensure it operates smoothly and meets performance standards.

Following these guidelines will contribute to a successful assembly process, enhancing the reliability and functionality of your unit.

Tips for Troubleshooting Problems

When encountering issues with mechanical components, it’s essential to follow a systematic approach to identify and resolve the underlying causes. Effective troubleshooting can save time and resources while ensuring optimal functionality of the system.

Start with Observation: Carefully examine the unit for any visible signs of wear or damage. Listen for unusual sounds and pay attention to performance inconsistencies that might indicate specific areas needing attention.

Consult Documentation: Referring to the manufacturer’s manuals can provide invaluable insights into common issues and solutions. This can help pinpoint potential problems based on similar experiences shared by others.

Perform Routine Maintenance: Regular upkeep can prevent many issues from arising. Ensure that all components are properly lubricated and free from debris. Check seals and gaskets for integrity to avoid leaks.

Utilize Diagnostic Tools: Employ specialized instruments to test various functionalities. These tools can offer precise measurements and highlight areas requiring further investigation, facilitating a more effective troubleshooting process.

Engage with Experts: If the problem persists despite your efforts, don’t hesitate to seek advice from professionals. Their experience and knowledge can provide guidance that might not be readily apparent to the average user.

Enhancing Performance with Upgrades

Upgrading key components of your vehicle can significantly improve its overall functionality and responsiveness. By investing in high-quality enhancements, you can achieve smoother operation, greater efficiency, and an exhilarating driving experience. This section explores various upgrades that can elevate performance, ensuring that your machine operates at its best.

Key Areas for Improvement

Several critical areas can be targeted for upgrades, including the internal mechanisms and external accessories. Enhancing these components can lead to better power delivery and improved handling. It is essential to select the right upgrades tailored to your specific needs and performance goals.

Upgrade Options Overview

| Upgrade Type | Description | Benefits |

|---|---|---|

| High-Performance Gears | Reinforced gears designed for increased durability and efficiency. | Quicker acceleration and improved torque. |

| Custom Clutch Systems | Enhanced clutch assemblies for smoother engagement and disengagement. | Improved drivability and reduced wear. |

| Oil Coolers | Systems to maintain optimal operating temperatures. | Increased reliability and longevity of components. |

Implementing these upgrades can result in a remarkable transformation in your vehicle’s capabilities, providing not only enhanced performance but also a more enjoyable driving experience.

Compatibility with Other Transmission Types

Understanding the interplay between various mechanical systems is crucial for optimal performance. Different designs may share similarities that allow for interchanges, enhancing flexibility and functionality. This section explores the relationships between several systems and how components may integrate seamlessly.

Key Considerations

- Design Compatibility: Ensure that dimensions and configurations align for effective integration.

- Material Composition: Variations in material properties can affect durability and efficiency; matching materials is essential.

- Performance Standards: Each system may have specific performance metrics; understanding these is vital for successful compatibility.

Examples of Compatible Systems

- Type A: Often utilized in classic designs, allowing for easy retrofitting.

- Type B: Known for robust construction, providing an excellent fit with many contemporary models.

- Type C: Features advanced technology that can enhance the capabilities of traditional setups.

Identifying compatible systems can lead to improved efficiency and adaptability in various applications. Proper evaluation of design and performance will ensure successful integration, enhancing the overall functionality of mechanical assemblies.

Resources for Further Learning

Expanding your knowledge about mechanical components and their configurations can significantly enhance your understanding of their functionality and maintenance. Various educational resources are available to help enthusiasts and professionals alike deepen their comprehension and skills in this area.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Interactive lessons covering mechanical systems and their upkeep. | Coursera |

| Books | In-depth literature on automotive engineering principles and practices. | Amazon |

| Forums | Community discussions where members share insights and troubleshoot issues. | Reddit Mechanics |

| Video Tutorials | Visual guides demonstrating various assembly and maintenance techniques. | YouTube |