The intricate system that facilitates the transfer of power in vehicles is a marvel of engineering. Within this assembly, various elements work in harmony to ensure smooth operation and efficiency. Each component plays a crucial role, contributing to the overall functionality and reliability of the machinery.

In the following sections, we will delve into the specific elements that make up this complex mechanism. By examining their arrangement and interaction, one can gain a clearer picture of how these systems function. Knowledge of these components not only enhances comprehension but also aids in effective maintenance and repair.

Whether you are a seasoned technician or a curious enthusiast, understanding the layout and relationship of these crucial pieces will provide valuable insights. Let’s explore the essential features that drive performance and innovation in modern vehicles.

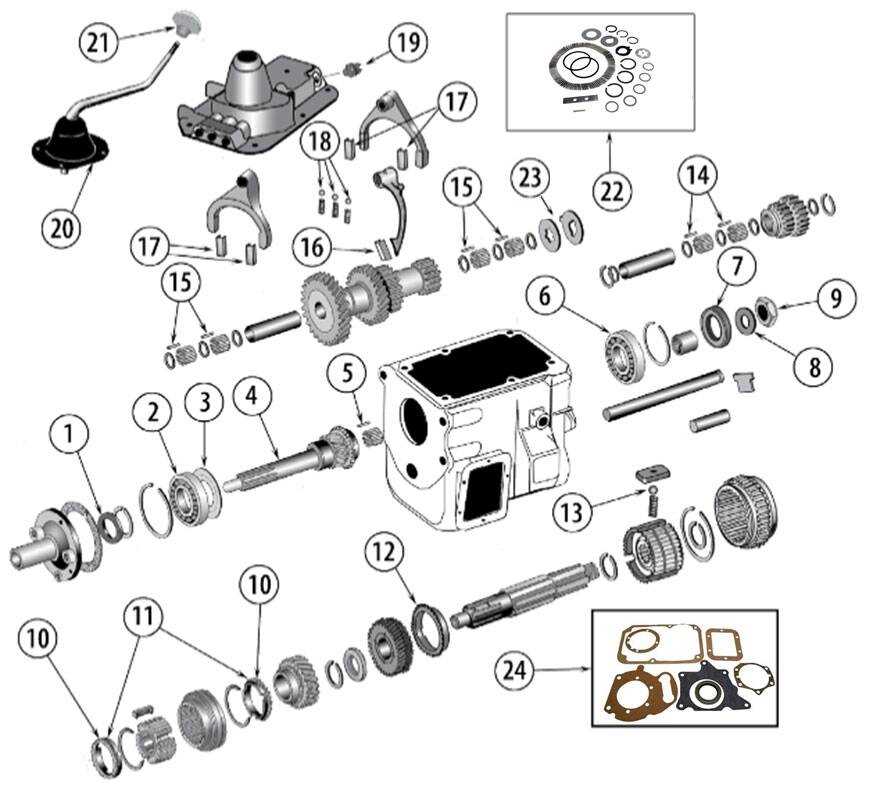

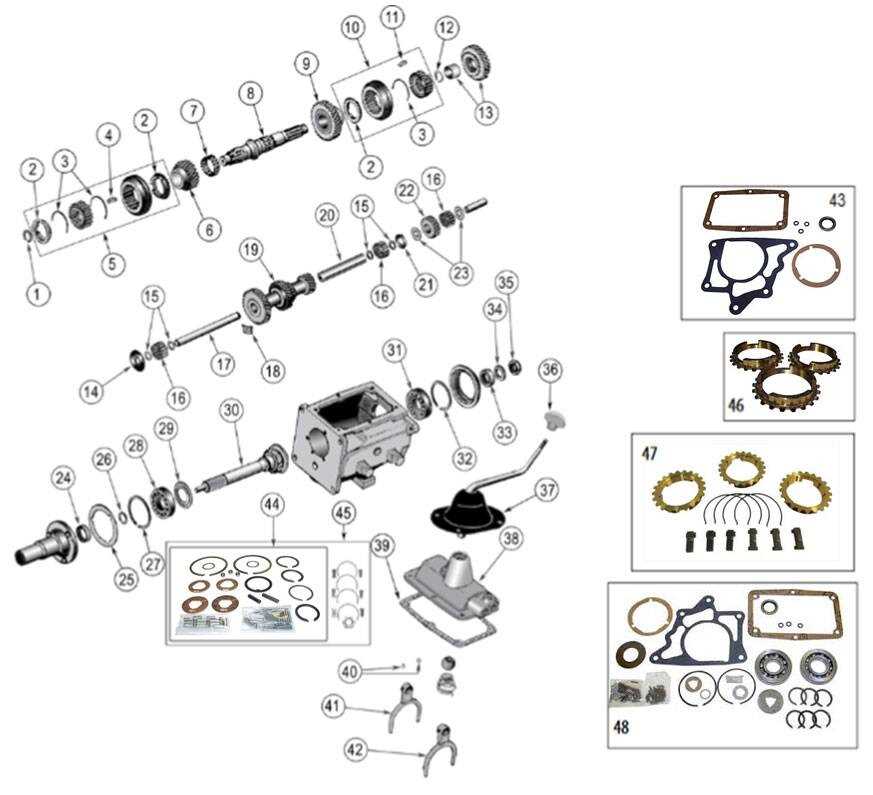

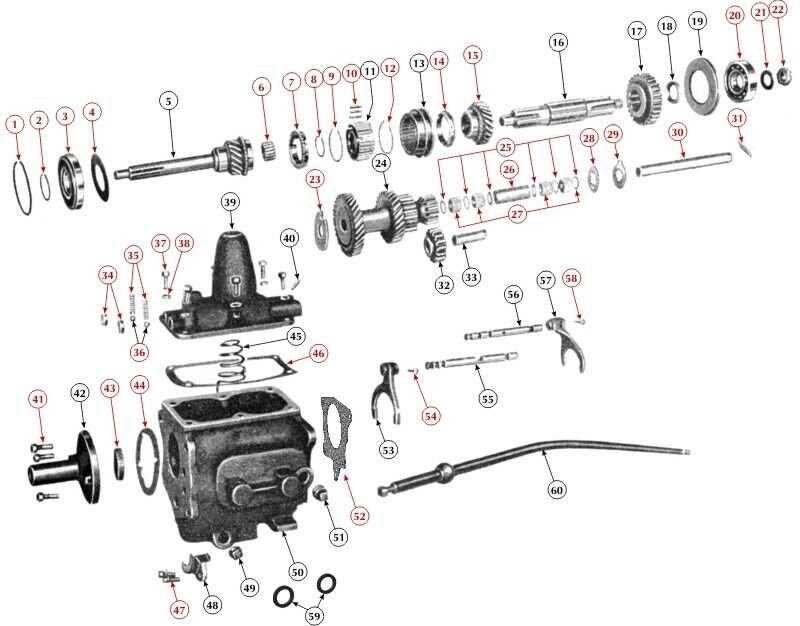

T18 Transmission Parts Overview

The inner workings of a mechanical system that transfers power are crucial for optimal performance. Understanding the various components involved is essential for maintenance and repair. Each element plays a specific role, contributing to the overall efficiency and functionality of the assembly.

Among the key components, the casing serves as the outer shell, housing all internal elements. Inside, a series of gears are responsible for altering speed and torque, allowing for smooth transitions during operation. Couplings and linkages connect these gears, ensuring seamless interaction between moving parts.

Another vital aspect is the control mechanism, which enables precise adjustments to shifting patterns. Lubrication systems are equally important, as they minimize friction and wear, extending the lifespan of the entire assembly. Understanding these components not only aids in troubleshooting but also enhances the ability to optimize performance.

In summary, a thorough comprehension of the various elements involved in this mechanical assembly is fundamental for anyone looking to enhance their knowledge or perform repairs. Recognizing how each component interacts within the system can lead to improved efficiency and reliability.

Key Components of T18 Transmission

This section explores the essential elements that contribute to the efficient functioning of a specific gear system. Understanding these crucial components can enhance maintenance and performance, ensuring longevity and reliability.

- Main Case: The sturdy outer shell that houses all internal components, providing structural integrity.

- Input Shaft: The rotating shaft that transfers power from the engine to the gearbox.

- Output Shaft: This element delivers power to the drive train, ensuring smooth vehicle movement.

- Gear Set: A series of gears that allow for varying ratios, facilitating different speed and torque outputs.

- Synchronizers: Mechanisms that enable smooth engagement of gears, reducing grinding and wear.

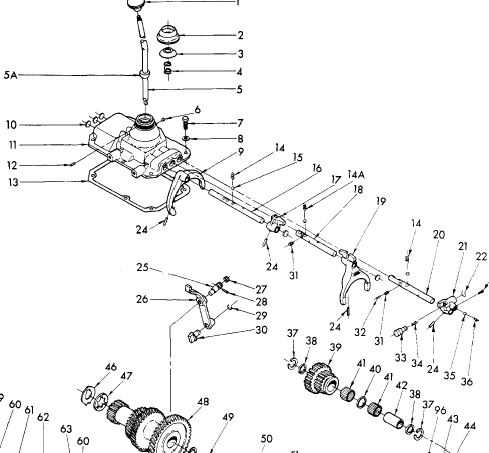

- Shift Forks: Components that move the gears into position during shifting, providing precise control.

- Bearings: These reduce friction between moving parts, enhancing efficiency and reducing heat.

Understanding each of these components allows for better diagnostics and effective repairs, leading to improved performance.

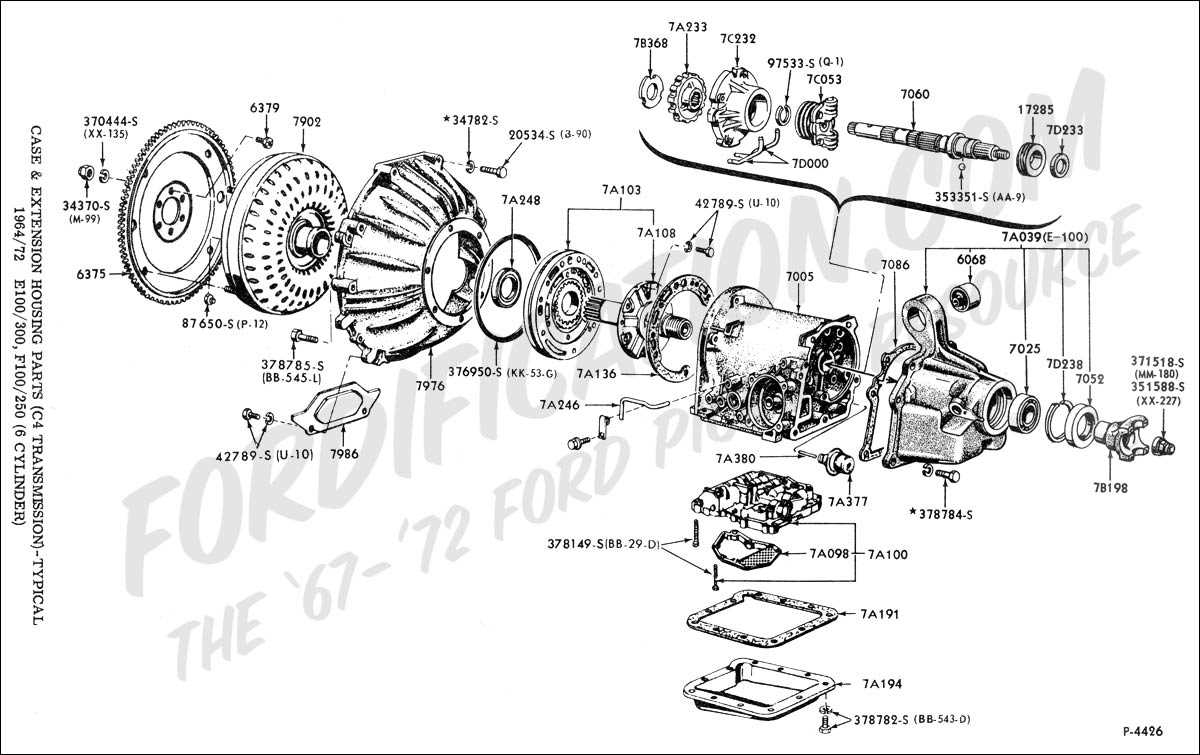

Understanding the Parts Diagram

Gaining insight into mechanical assemblies is crucial for effective maintenance and repair. Visual representations serve as invaluable tools, allowing enthusiasts and professionals alike to identify components and understand their interrelations within a system. This section will explore the essential elements that comprise such illustrations and how to interpret them efficiently.

Key Components

Recognizing the various elements depicted in a schematic can significantly enhance comprehension. Each symbol and line serves a purpose, guiding users through the complexities of the machinery.

Interpreting Symbols

Symbols on these visuals often represent specific functionalities or connections. Familiarity with these representations is vital for accurate assembly and troubleshooting.

| Symbol | Description |

|---|---|

| Circle | Represents a component connection |

| Line | Indicates flow or movement |

| Arrow | Shows direction or operation |

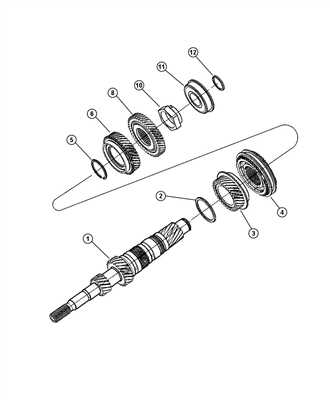

Functions of Each Transmission Part

Understanding the roles of various components within a gear system is essential for maintaining optimal performance and efficiency. Each element plays a distinct role in the overall mechanism, contributing to smooth operation and effective power transfer. Below is a detailed overview of these crucial elements and their specific functions.

| Component | Function |

|---|---|

| Input Shaft | Transmits power from the engine to the gearbox. |

| Gear Set | Changes the speed and torque of the output through varying gear ratios. |

| Output Shaft | Delivers the adjusted power to the drive system. |

| Synchronizers | Facilitate smooth engagement of gears during shifting. |

| Clutch | Enables disconnection between the engine and the gear system for gear changes. |

| Bearings | Support rotating elements, reducing friction and wear. |

| Oil Pump | Ensures lubrication throughout the system, minimizing heat and friction. |

Common Issues with T18 Components

Understanding the frequent problems associated with specific mechanical systems is crucial for effective maintenance and repair. Various components may exhibit wear and tear, leading to performance degradation. Identifying these common issues can help in preventing more significant failures and prolonging the lifespan of the entire system.

1. Gear Wear: One of the most prevalent issues involves the gradual erosion of gears. This can result from inadequate lubrication or excessive load, leading to a rough operation and potential breakdown.

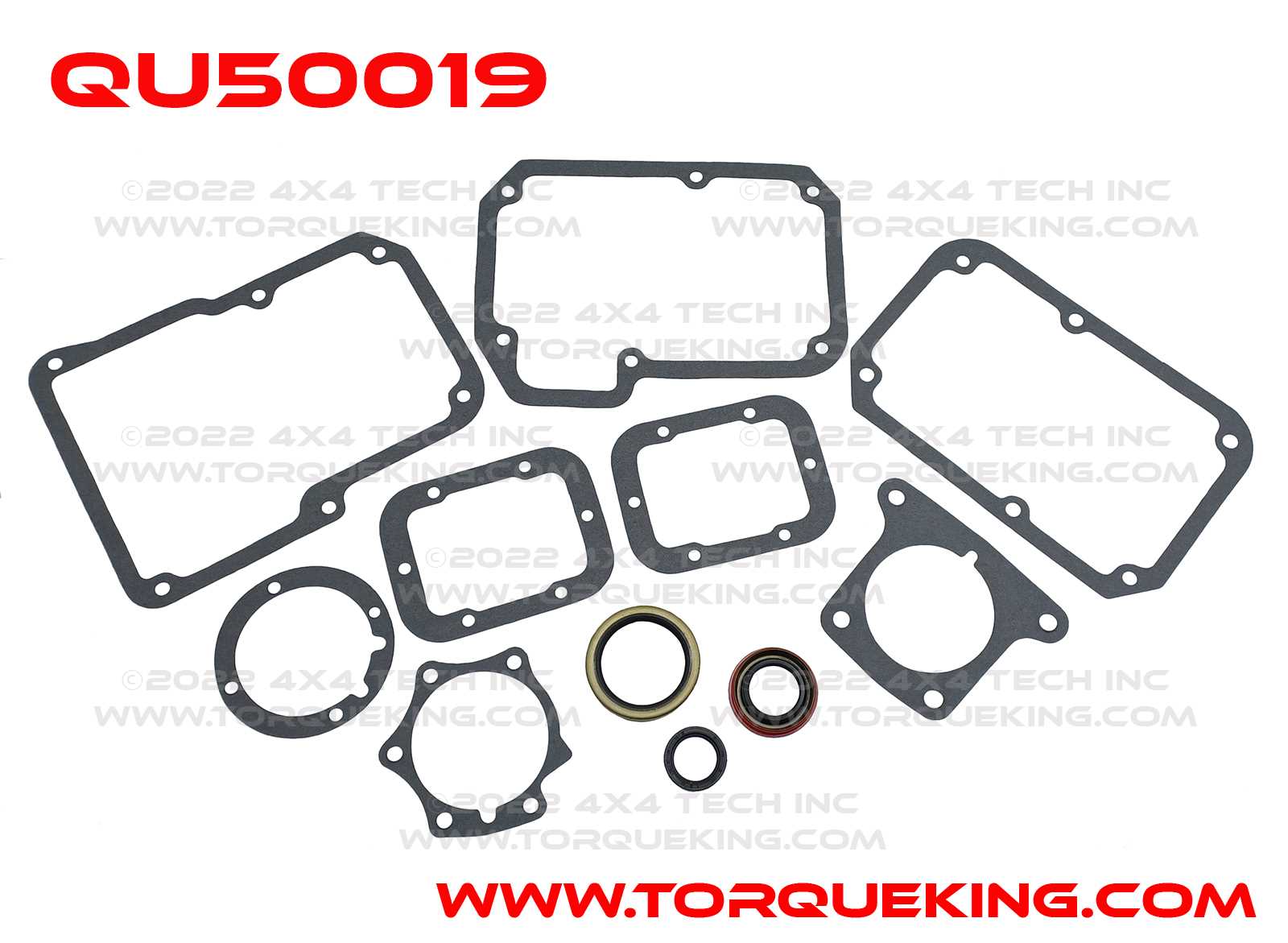

2. Seal Leaks: Seals play a vital role in maintaining fluid integrity. Over time, they may become brittle or damaged, causing leaks that can compromise the functionality of the entire assembly.

3. Bearing Failure: Bearings are essential for smooth movement. Lack of proper maintenance can lead to their deterioration, resulting in increased friction and noise, ultimately causing malfunction.

4. Shift Difficulties: Users often report issues with shifting gears, which may stem from misalignment or worn components. This can hinder the overall driving experience and should be addressed promptly.

5. Noise Issues: Unusual sounds during operation may indicate underlying problems. Identifying the source of these noises is essential for timely intervention and avoiding costly repairs.

Regular inspection and maintenance can mitigate these issues, ensuring reliable operation and enhancing the durability of the system.

Maintenance Tips for T18 Transmission

Proper upkeep of your vehicle’s gear system is essential for ensuring optimal performance and longevity. Regular attention can prevent wear and tear, ultimately saving you time and money on repairs. Here are some valuable suggestions to keep your setup running smoothly.

Regular Fluid Checks: Make it a habit to inspect the fluid levels periodically. Adequate lubrication is crucial for preventing overheating and reducing friction. If the fluid appears dirty or low, consider changing it to maintain efficiency.

Inspect for Leaks: Keep an eye out for any signs of leaks around the seals and connections. Addressing leaks promptly can help avoid further damage and preserve the integrity of the entire system.

Replace Worn Components: Pay attention to any unusual sounds or shifting issues. Worn components can lead to more significant problems if not addressed. Regularly replace any parts that show signs of wear to ensure optimal function.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for service intervals and fluid types. This ensures that you are using the appropriate materials and maintenance practices for your specific setup.

Professional Inspections: Consider having a qualified technician perform routine inspections. They can identify potential issues that may go unnoticed and provide expert advice on maintaining your system’s health.

By implementing these strategies, you can enhance the reliability and efficiency of your vehicle’s gear mechanism, ensuring it operates smoothly for years to come.

How to Identify Transmission Parts

Recognizing the various components of a gearbox can greatly enhance your understanding of its functionality and maintenance. Each element plays a crucial role in the overall performance, and distinguishing them is essential for troubleshooting and repairs. This guide will provide insights into effective methods for identifying these essential components.

Begin by familiarizing yourself with the basic structure. Most gearboxes contain elements such as gears, shafts, and clutches, each serving a specific purpose. Study diagrams or images to visualize their arrangement and interconnections. Knowing the general layout helps in understanding how each piece works together to transmit power.

Next, examine the components individually. Look for identifying markings, part numbers, or distinct shapes. Manufacturers often include specific identifiers that can assist in sourcing replacements or upgrades. Utilize resources such as service manuals or online databases that provide detailed descriptions and specifications.

Consider the materials used in construction. Different elements are crafted from various metals or composites, which can offer clues about their role and durability. Understanding these characteristics can help you assess wear and tear, guiding your maintenance decisions.

Finally, hands-on experience is invaluable. If possible, observe the assembly and disassembly process, noting how each piece interacts. This practical approach solidifies your knowledge and enables you to identify components with confidence in future projects.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right instruments is crucial for efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also ensures that repairs are performed to a high standard, minimizing the risk of future issues.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers form the backbone of any repair effort. These items allow for the manipulation and adjustment of various components, ensuring that everything is securely fastened and functioning properly. Investing in high-quality hand tools can greatly enhance the repair experience.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be necessary for more complex tasks. Items such as torque wrenches, seal pullers, and alignment tools play a significant role in ensuring precision. Having access to these specific instruments can greatly ease the repair process and contribute to the overall longevity of the system.

Replacing Worn-Out Components

Ensuring optimal performance requires addressing any deteriorating elements within the mechanical system. Regular maintenance is crucial for longevity and efficiency, preventing larger issues down the line.

Identifying Wear and Tear

Recognizing the signs of fatigue in your equipment can save time and resources. Common indicators include:

- Unusual noises during operation

- Inconsistent functionality

- Visible signs of damage or corrosion

Steps for Replacement

To effectively swap out outdated components, follow these steps:

- Gather necessary tools and replacement items.

- Carefully disassemble the affected area.

- Replace the worn components with new ones.

- Reassemble and test the system for proper function.

Importance of OEM vs. Aftermarket Parts

When it comes to vehicle maintenance and repair, the choice between original manufacturer components and those produced by third-party suppliers can significantly impact performance and longevity. Understanding the differences between these options is crucial for ensuring the reliability and efficiency of your machine.

Quality and Reliability

OEM components are designed specifically for a particular model, ensuring compatibility and high standards of quality. These items often undergo rigorous testing and are manufactured to meet strict specifications, leading to enhanced durability. In contrast, aftermarket alternatives may vary in quality. While some manufacturers offer products that meet or exceed OEM standards, others may compromise on materials or craftsmanship, potentially leading to premature failure.

Cost Considerations

While aftermarket options can often be more affordable, it’s essential to weigh this cost against potential risks. Saving money in the short term might result in higher expenses down the line if replacement or repairs are needed sooner than anticipated. Conversely, investing in genuine components may provide peace of mind and save costs over time by ensuring reliable operation and reducing the likelihood of future issues.

Upgrading T18 Transmission Performance

Enhancing the functionality and efficiency of your gearbox can significantly improve the overall driving experience. By focusing on specific components and modifications, you can achieve better responsiveness and durability. This section explores various strategies to boost performance, ensuring a smoother and more reliable operation.

| Upgrade Option | Description |

|---|---|

| Improved Gear Sets | Replacing stock gears with high-performance alternatives can reduce slippage and increase torque delivery. |

| High-Quality Bearings | Upgrading to precision-engineered bearings minimizes friction, enhancing efficiency and lifespan. |

| Enhanced Synchronizers | Using advanced synchronizers improves shifting speed and accuracy, leading to smoother transitions. |

| Modified Linkage | Adjusting the linkage can provide more direct and responsive control, enhancing driver engagement. |

| Fluid Upgrades | Utilizing synthetic lubricants can reduce heat and wear, promoting better operation under stress. |

By considering these enhancements, you can tailor your gearbox to meet specific performance goals, resulting in a more enjoyable and powerful driving experience.

Resources for Further Learning

Expanding your knowledge about mechanical systems is essential for anyone interested in automotive engineering. A variety of materials and platforms are available to deepen your understanding and enhance your skills. Below are some recommended resources that cater to different learning preferences and levels.

Online Courses and Tutorials

- Coursera – Offers a range of courses on automotive mechanics and engineering fundamentals.

- Udemy – Features tutorials specifically focused on vehicle systems and repair techniques.

- edX – Provides access to university-level courses related to mechanical engineering and automotive technology.

Books and Manuals

- The Automotive Engine by John B. Heywood – A comprehensive guide on engine fundamentals.

- How to Rebuild Your Small-Block Chevy by David Vizard – A detailed manual for enthusiasts.

- Automotive Technology: A Systems Approach by Jack Erjavec – Covers a wide range of vehicle systems and their interactions.

By utilizing these resources, you can gain valuable insights and practical knowledge to excel in the field of automotive engineering.