In this section, we explore the essential elements that make up one of the most reliable mechanical assemblies in modern vehicles. Understanding how the internal mechanisms interact and function together is crucial for anyone looking to maintain or improve the performance of their vehicle. This overview provides a closer look at the various components, offering valuable insights into their roles and significance.

As we delve into the intricate layout of this system, you’ll discover how each individual element contributes to the overall operation. Highlighting key features and critical aspects, we aim to give you a deeper understanding of the structure and its functionality.

By the end of this guide, you’ll have a clear grasp of how these essential units are connected, working in harmony to ensure smooth and efficient performance. Whether you’re an enthusiast or a professional, this detailed look will enhance your knowledge and appreciation of the system’s engineering.

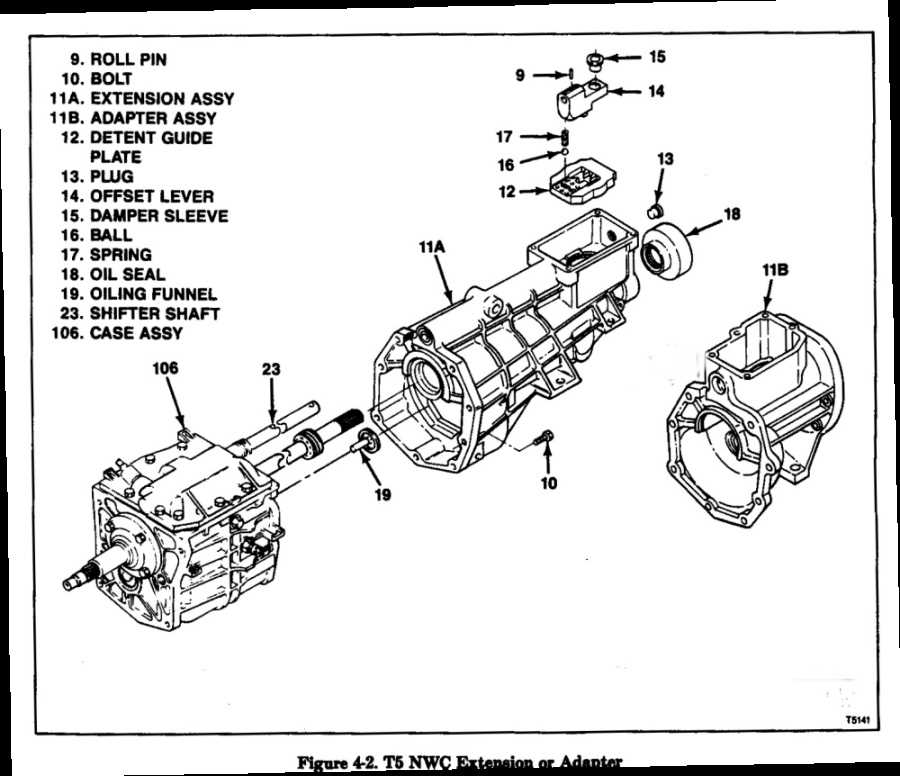

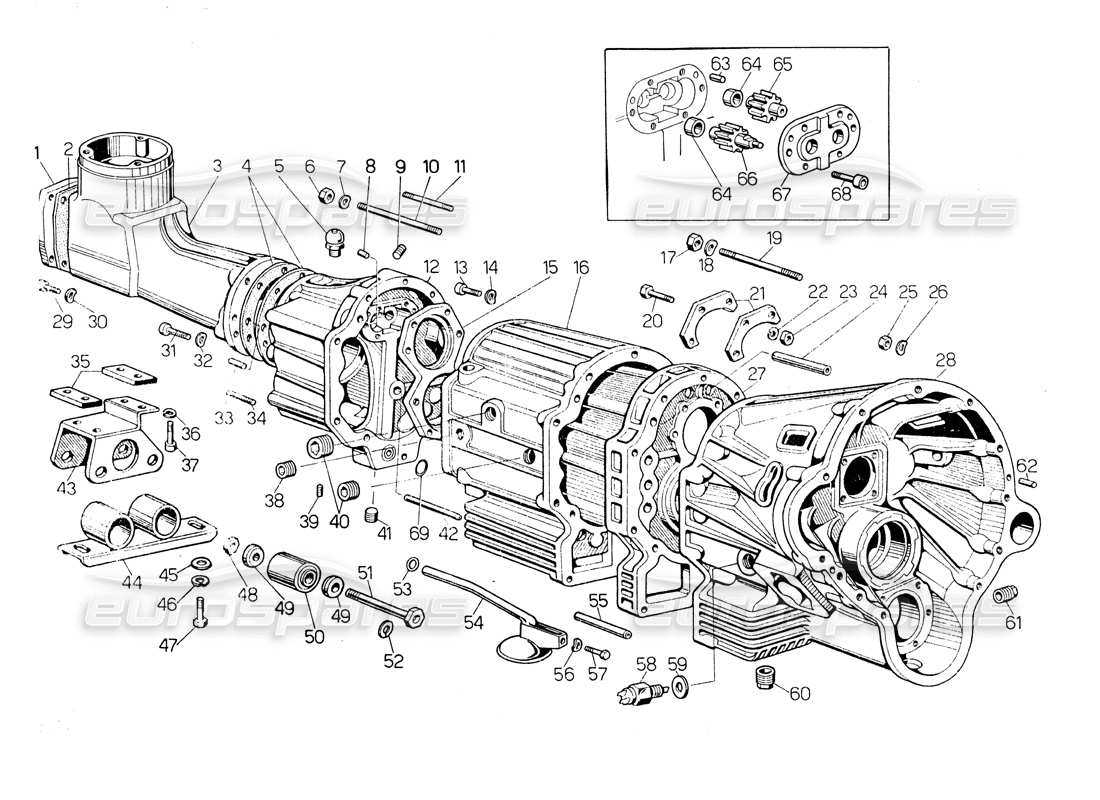

Overview of T5 Transmission Components

The T5 system consists of several key elements that work together to ensure smooth and efficient operation. These elements are designed to interact seamlessly, providing the necessary control and functionality for different driving conditions. Each section plays a specific role in maintaining balance and performance, allowing for optimal handling and durability over time.

Main Functional Elements

The primary components include a range of mechanical and fluid-based systems that regulate movement and force distribution. These systems are crafted for precise operation, ensuring the driver experiences responsive control under various demands. Their design is both robust and adaptable, suitable for a wide range of vehicle types.

Auxiliary Systems and Their Role

Supporting elements contribute to the overall structure by managing secondary tasks, such as lubrication and heat dissipation. These systems are critical for maintaining operational integrity and preventing wear over prolonged usage. By reducing friction and managing thermal levels, they help ensure consistent and reliable function.

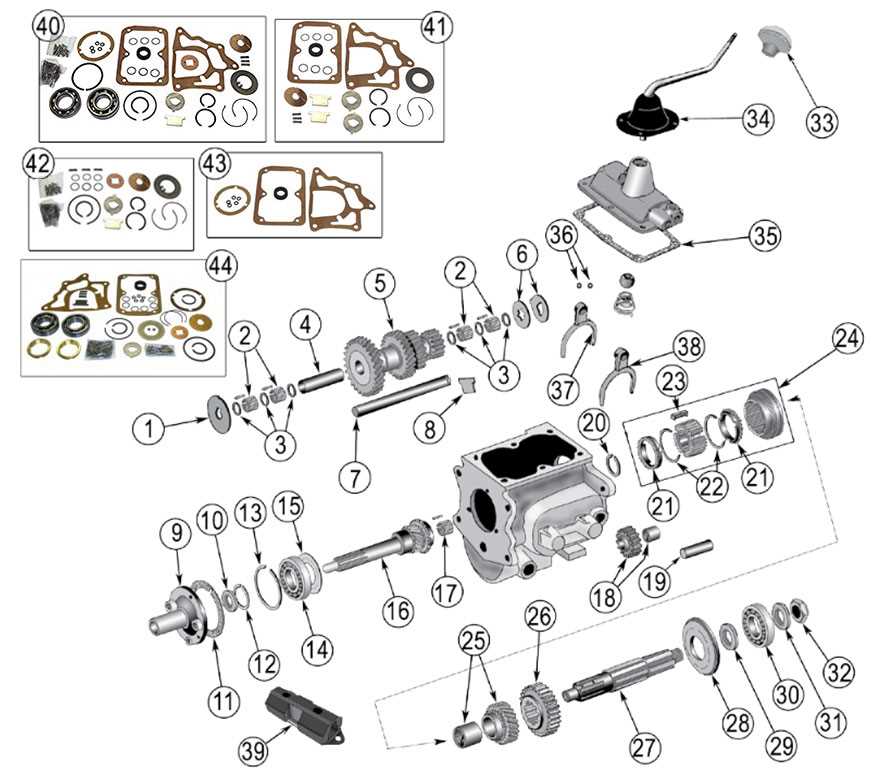

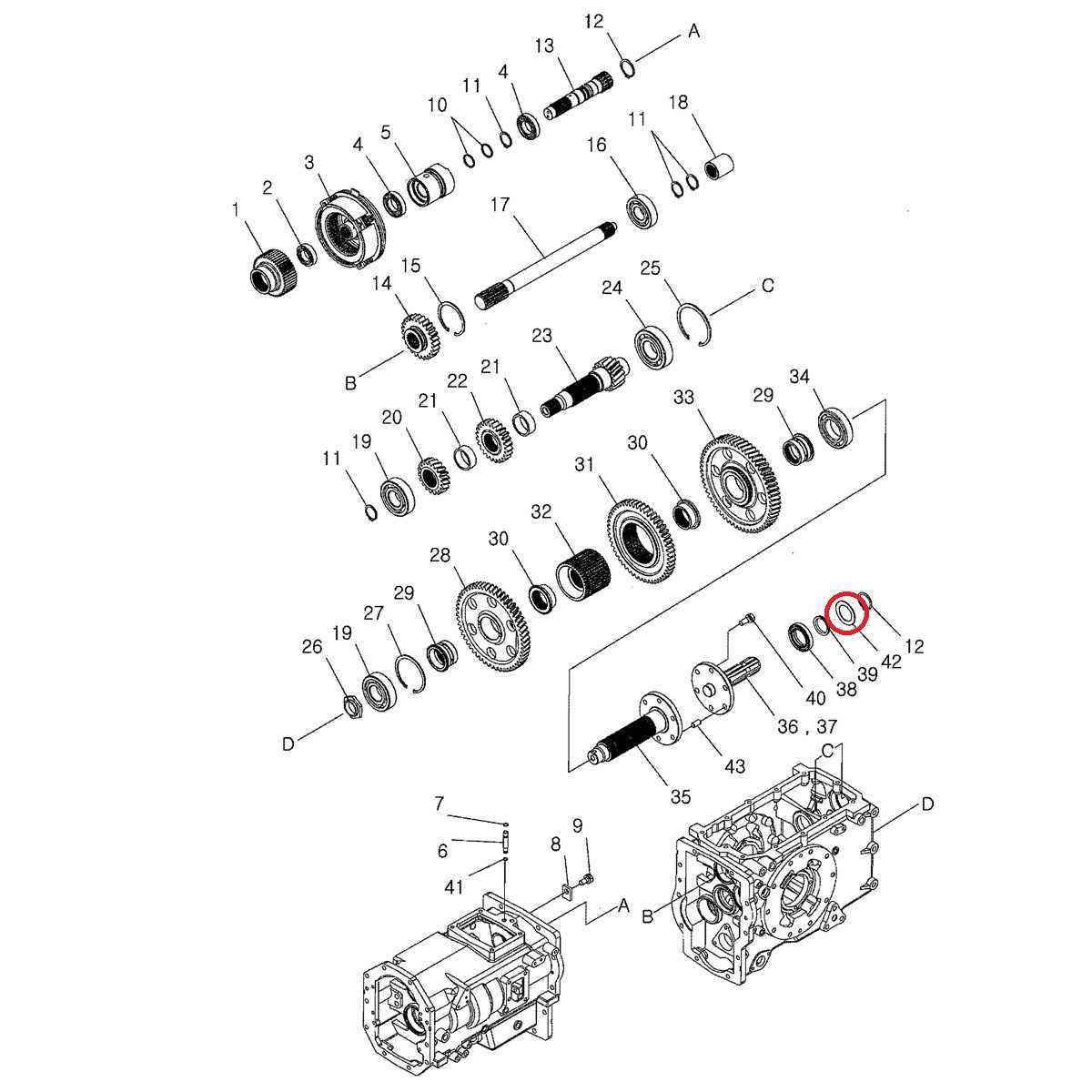

Main Gear Assembly Breakdown

The central mechanism responsible for the smooth transfer of motion relies on a well-coordinated series of components. Each element in the assembly plays a crucial role in ensuring seamless operation and balanced distribution of forces. Understanding how these pieces interact is essential for proper maintenance and troubleshooting.

Key Elements of the System

The main structure consists of interconnected gears, shafts, and bearings that work in harmony to regulate rotational movement. The primary gears are responsible for shifting energy across the mechanism, while the supporting elements ensure stability and alignment. Precision in the arrangement of these parts guarantees the overall efficiency of the system.

Interaction and Functionality

Each gear within the assembly is designed to handle specific loads, distributing torque evenly throughout the system. The arrangement of these components ensures optimal performance under various conditions, reducing wear and extending the life of the entire structure. Proper lubrication and alignment are critical to maintaining the integrity of the system over time.

Input and Output Shaft Details

The input and output shafts play a crucial role in managing the flow of power within mechanical systems. These components are responsible for receiving energy from one side and transmitting it efficiently to the other. Understanding the distinctions between these two elements is key to maintaining optimal performance and ensuring smooth operation.

Input Shaft Overview

The input shaft is the element that initially receives energy from the source. Its main task is to deliver this energy to other internal mechanisms, making it a vital part of the system’s efficiency. Typically, it is designed to withstand significant loads and rotations, ensuring that the flow of power remains steady and reliable.

Output Shaft Overview

On the opposite side, the output shaft takes the energy from the internal system and directs it towards the final destination. It must be precisely aligned with the receiving component to ensure the smooth transfer of energy. A well-maintained output shaft is essential for consistent performance and durability of the machinery.

| Component | Main Function | Key Characteristics |

|---|---|---|

| Input Shaft | Receives power from the source | High durability, manages high loads |

| Output Shaft | Transfers energy to the final mechanism | Precise alignment, smooth power delivery |

Function of Synchronizer Mechanism

The synchronizer mechanism ensures smooth gear changes by matching the rotational speeds of different components within the system. It allows for a seamless transition between various states of operation, reducing wear and enhancing the efficiency of shifting without causing harsh movements or vibrations.

How Synchronization Works

This mechanism operates by temporarily connecting elements at different speeds and synchronizing their motion. Once the speeds align, the gears can engage smoothly, providing a more comfortable and efficient driving experience. This process helps avoid potential damage to the system while improving overall performance.

Key Components Involved

The synchronizer consists of multiple elements, each contributing to the overall process of speed alignment and engagement. These include rings, hubs, and sleeves that work together to ensure proper synchronization during operation, creating a balanced and smooth transition during shifts.

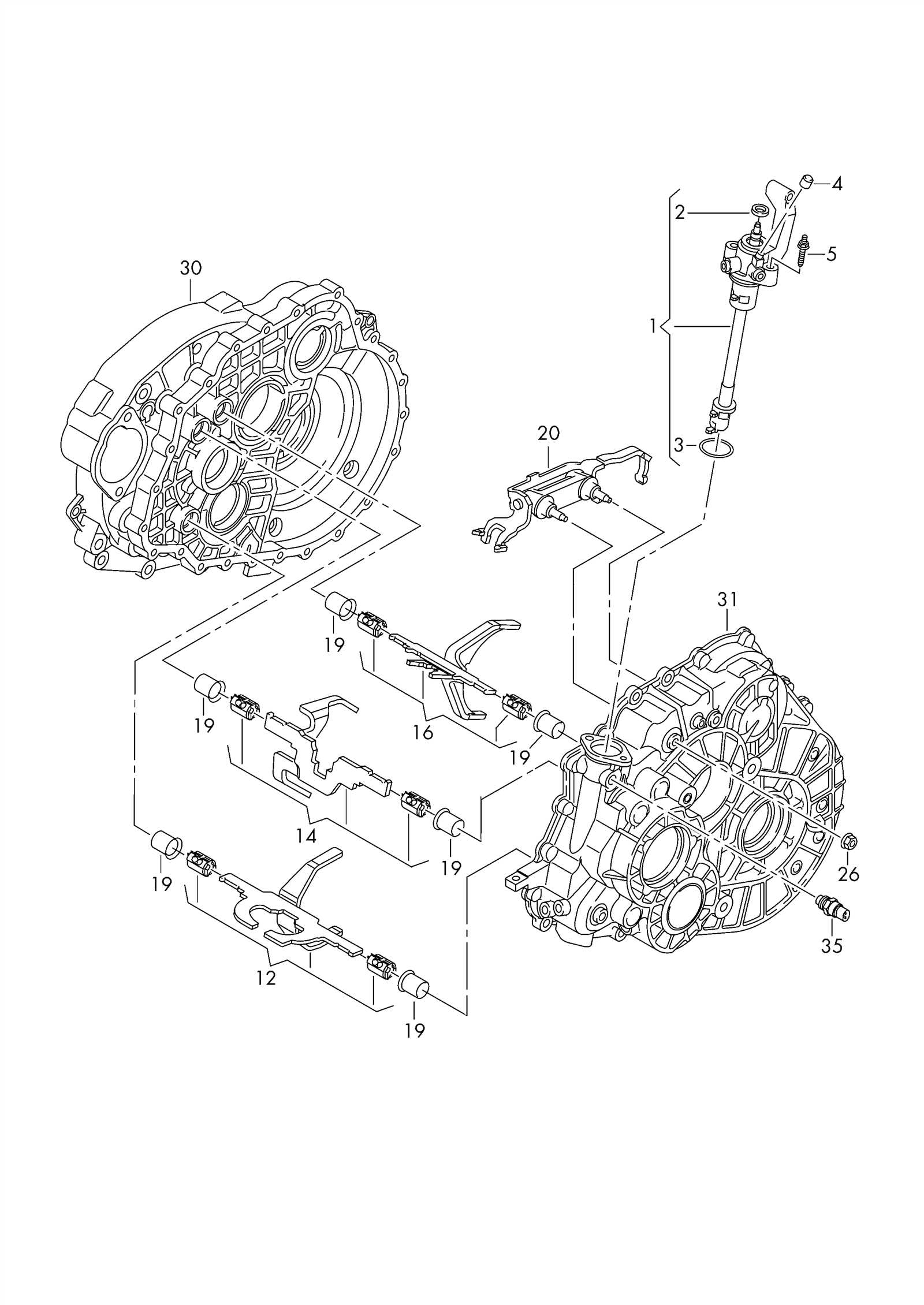

Exploring the Shift Fork Design

The shift fork plays a crucial role in the overall function of a gear-changing system. It ensures smooth movement between gears, guiding components to their correct positions during operation. This particular design feature is engineered to withstand both wear and pressure, maintaining a stable environment for the gear transition process. Its precise design is essential for reliability and efficiency, minimizing unnecessary friction and mechanical strain.

Materials and Durability

The construction of the shift fork is based on durable materials that resist friction and heat over time. Metals such as steel alloys are commonly used to provide the necessary strength for long-lasting performance. The durability of this component is crucial for reducing wear, as it must maintain its shape and alignment throughout the operation of the system.

Functionality and Precision

Designed for precise operation, the shift fork ensures seamless gear changes by accurately aligning components. This precision helps avoid misalignment, which could lead to mechanical failures or operational inefficiencies. The smooth engagement of gears largely depends on the shift fork’s ability to control movement with minimal resistance, which is key to the system’s overall functionality.

Cluster Gear Structure and Role

The cluster gear plays a critical role in the overall functioning of mechanical systems by enabling smooth movement and interaction between multiple components. Its design consists of interconnected wheels that ensure the seamless transition of power between different sections of the mechanism, enhancing efficiency and performance.

The structure is often compact, designed to maximize the space available while ensuring optimal operation. Each segment of the cluster serves a unique function, contributing to the overall efficiency of the system.

- Multiple gears are combined into a single unit, reducing space requirements.

- Each gear is precisely aligned to work in unison, ensuring efficient energy transfer.

- The durable materials used in construction prevent wear and ensure longevity.

The role of this assembly goes beyond mere connection; it ensures that different sections work harmoniously, providing a consistent flow of energy. Understanding its structure helps in comprehending how power is directed throughout the mechanism.

Examining the Countershaft Functionality

The countershaft plays a pivotal role in the overall operation of a vehicle’s drivetrain. This component serves as a vital link, facilitating the transfer of power from the engine to the wheels. Understanding its functionality is crucial for anyone interested in automotive mechanics, as it influences the performance and efficiency of the entire system.

At its core, the countershaft is designed to manage the rotational forces generated by the engine. It achieves this by allowing various gears to engage seamlessly, enabling the vehicle to shift through different speeds. The smooth operation of this element is essential for maintaining balance and stability while driving, particularly during acceleration or deceleration.

Moreover, the countershaft contributes to the distribution of torque, ensuring that power is effectively transmitted to the wheels. This distribution is vital for optimizing traction and enhancing the driving experience, especially in varying road conditions. A well-functioning countershaft not only improves responsiveness but also reduces wear on other critical components.

In conclusion, the countershaft’s functionality is integral to the performance of a vehicle. By facilitating power transfer and torque distribution, it ensures a smooth and efficient driving experience. Regular maintenance and inspection of this component can lead to improved longevity and overall vehicle reliability.

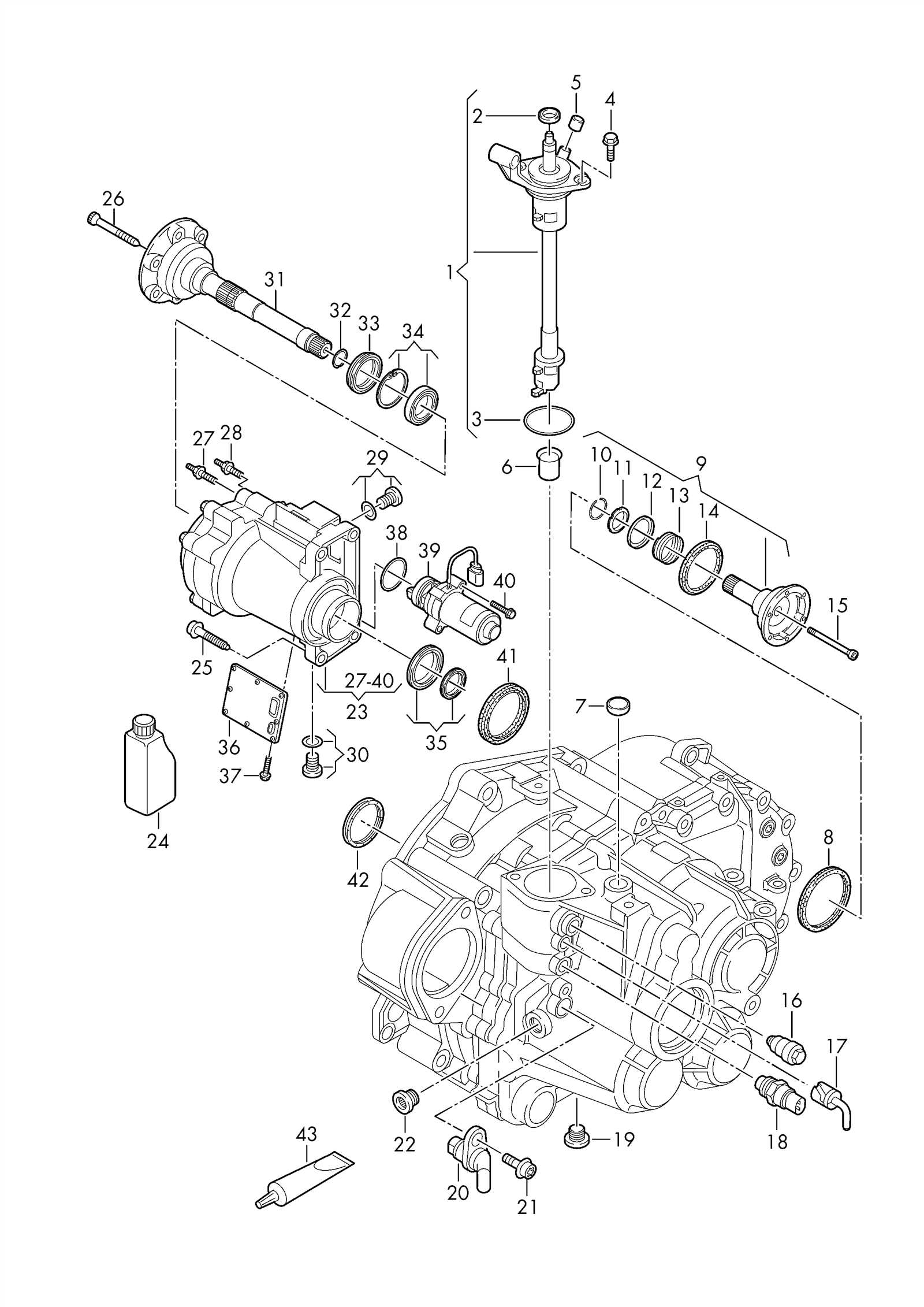

Bearing and Seal Placement Insights

Understanding the strategic arrangement of bearings and seals is essential for ensuring optimal functionality and durability in mechanical assemblies. Proper positioning plays a crucial role in minimizing friction, preventing leakage, and enhancing overall performance. This section delves into key considerations and techniques for effective installation and alignment.

Key Considerations for Installation

When placing bearings and seals, it is important to account for factors such as load distribution, environmental conditions, and thermal expansion. The correct alignment not only prolongs the lifespan of components but also enhances the efficiency of the entire system. Additionally, utilizing high-quality materials can significantly improve resilience against wear and tear.

Techniques for Effective Alignment

Employing precision tools during installation can aid in achieving accurate alignment. It is advisable to use gauges or indicators to measure clearances and ensure that components are seated properly. Regular inspection and maintenance can further enhance performance by identifying potential misalignments early on, allowing for timely adjustments.

Reverse Gear System Analysis

The reverse gear mechanism plays a crucial role in enabling vehicles to move backward. This functionality is essential for maneuvering in tight spaces and executing parking maneuvers. Understanding the various components and their interactions within this system can provide insights into its efficiency and performance.

Key elements of the reverse gear mechanism include:

- Gear Interaction: The relationship between the gear ratios affects how power is transferred and the overall responsiveness of the system.

- Engagement Mechanism: This component allows for smooth transitioning between forward and reverse motion, minimizing wear and tear.

- Safety Features: Various systems are in place to prevent unintended engagement, ensuring user safety while reversing.

In-depth analysis of these components reveals how they contribute to the system’s overall functionality:

- Efficiency: Assessing the mechanical advantages and potential friction losses can help optimize performance.

- Durability: Evaluating materials and design choices can lead to improvements in the longevity of the mechanism.

- Operational Ease: Understanding user interaction with the system can enhance user experience and vehicle handling.

Overall, a thorough examination of the reverse gear mechanism not only highlights its importance but also opens avenues for further innovations in vehicle design and functionality.

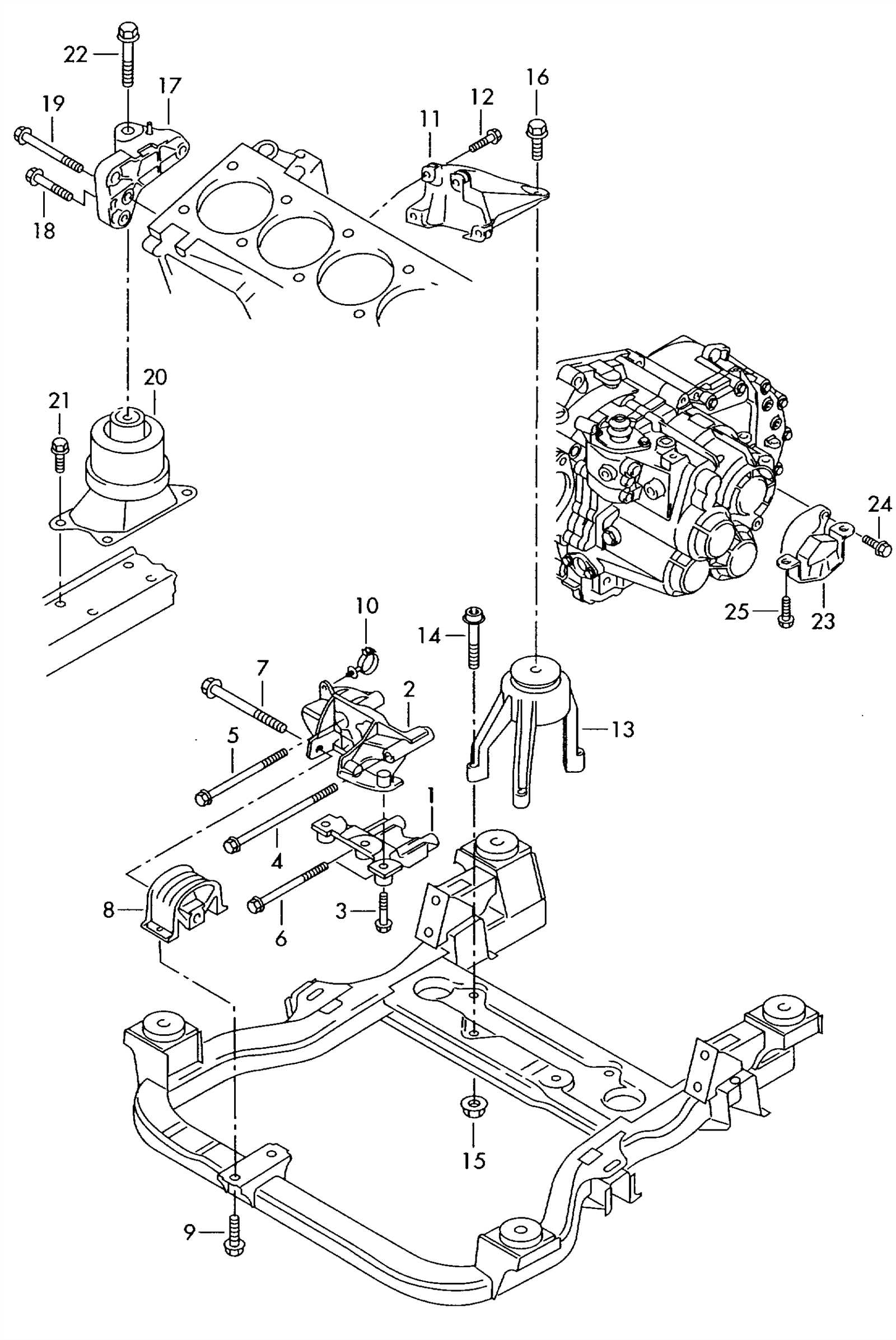

Understanding the Housing Layout

The layout of the housing is crucial for the overall functionality and efficiency of the system. It serves as the protective shell that encloses various mechanisms, ensuring they operate smoothly and in harmony. An intricate arrangement of components within this enclosure allows for optimal performance and durability.

Key Features of the Housing Design

The housing is designed with precision to accommodate different elements seamlessly. Strategic placement of various units not only enhances operational effectiveness but also facilitates easy maintenance. Each section is crafted to support specific functions, contributing to the overall integrity of the assembly.

Materials and Construction

Typically, high-quality materials are utilized to construct the housing, ensuring it withstands various stresses during operation. Robustness is a primary focus, as the exterior must protect the internal components from environmental factors while maintaining structural stability. This thoughtful design approach guarantees longevity and reliability.

Common Issues with Transmission Parts

In the realm of automotive mechanics, various challenges may arise that affect the functionality and efficiency of vehicle systems. Understanding these frequent complications is essential for maintaining optimal performance and longevity. This section highlights some of the prevalent concerns encountered in these systems, along with potential solutions to mitigate them.

1. Wear and Tear

Over time, components can experience significant wear due to constant friction and stress. This deterioration can lead to decreased efficiency and, ultimately, system failure. Regular inspections and timely replacements are crucial in preventing severe damage.

2. Fluid Leaks

Fluid leaks are a common issue that can arise from worn seals or gaskets. Such leaks can result in insufficient lubrication, leading to overheating and component damage. Monitoring fluid levels and addressing leaks promptly is vital for maintaining system integrity.

| Issue | Symptoms | Solutions |

|---|---|---|

| Wear and Tear | Slipping gears, unusual noises | Regular inspections, replace worn components |

| Fluid Leaks | Fluid spots on the ground, low fluid levels | Seal replacement, immediate fluid refills |