In the realm of heavy machinery, the intricate systems that facilitate movement and control play a crucial role in performance and efficiency. This section aims to explore the various components that contribute to the seamless operation of these robust machines.

By dissecting the mechanics involved, we can gain valuable insights into how each element interacts to enhance functionality. From the foundational elements to the more specialized sections, understanding these components is essential for anyone involved in maintenance or repair.

In this exploration, we will delve into the ultimate configuration of these systems, providing a comprehensive overview that can serve as a useful reference. Whether you are a professional or an enthusiast, this knowledge will empower you to appreciate the complexity of heavy-duty vehicle mechanics.

Understanding Truck Transmission Components

Grasping the intricacies of gear systems is essential for appreciating how vehicles operate efficiently. Each element plays a vital role, contributing to the overall functionality and performance. By familiarizing oneself with these components, one can better understand the mechanics behind vehicle movement and power delivery.

Key Elements of Gear Systems

Several crucial elements ensure smooth operation, including the main gear, clutch mechanism, and shifting devices. Each of these components works in unison to facilitate the transfer of power from the engine to the wheels, ensuring optimal performance under various conditions.

Importance of Maintenance

Regular upkeep of these systems is paramount for longevity and reliability. Neglecting any part can lead to decreased efficiency and potential failure, highlighting the ultimate importance of preventive care in maintaining a vehicle’s performance.

Essential Parts of Truck Transmissions

The inner workings of heavy vehicles rely on a complex assembly of components that facilitate the efficient transfer of power from the engine to the wheels. Understanding these fundamental elements is crucial for maintenance and repair, ensuring optimal performance and longevity.

Main Components

- Clutch: Engages and disengages the engine from the drive system, allowing for smooth gear changes.

- Gear Sets: A collection of gears that manage the speed and torque delivered to the wheels.

- Shafts: Rods that transmit power between the engine and the wheel assembly.

- Bearings: Support rotating elements, minimizing friction and wear during operation.

Supporting Elements

- Fluid Pump: Circulates lubricant, ensuring all moving components operate efficiently.

- Seals: Prevent fluid leaks, maintaining pressure within the system.

- Control Linkages: Facilitate the driver’s input, connecting the gear shift to the internal mechanisms.

- Electronic Sensors: Monitor performance and provide feedback for optimal functioning.

Functions of Transmission Gear Sets

Gear sets play a crucial role in the overall performance of vehicles by managing power distribution and enhancing driving efficiency. Their design allows for varying speeds and torque, facilitating smooth acceleration and deceleration under different conditions.

Power Distribution

One primary function of gear assemblies is to optimize the transfer of energy from the engine to the wheels. By adjusting gear ratios, these systems ensure that the engine operates within its ideal performance range, improving fuel efficiency and responsiveness.

Speed Regulation

Another essential function is to regulate vehicle speed. Different gear configurations enable the driver to select appropriate ratios for various driving scenarios, whether it’s climbing a steep incline or cruising on a highway, thereby enhancing control and stability.

Importance of Synchronizers in Trucks

Synchronizers play a crucial role in enhancing the efficiency and smoothness of gear changes in heavy-duty vehicles. Their primary function is to ensure that gears mesh properly, allowing for seamless transitions during operation. This not only improves performance but also extends the longevity of the vehicle’s drivetrain components.

Functionality of Synchronizers

These components work by matching the speeds of the gears, which prevents grinding and promotes optimal engagement. By facilitating smoother shifts, synchronizers reduce the strain on other mechanical parts, contributing to overall reliability and performance.

Benefits of Efficient Synchronizers

Utilizing high-quality synchronizers leads to several advantages, including enhanced driving comfort, reduced wear on the gear system, and improved fuel efficiency. Overall, they are vital for ensuring that operators can manage their vehicles effectively under various conditions.

| Benefit | Description |

|---|---|

| Smooth Gear Changes | Minimizes noise and vibration during shifting. |

| Increased Durability | Reduces wear on gears, extending lifespan. |

| Enhanced Control | Improves handling and response during driving. |

Exploring Clutch Systems in Detail

The clutch system plays a pivotal role in the operation of heavy vehicles, ensuring smooth engagement and disengagement of the power source. Understanding its intricacies allows for better maintenance and performance optimization. This section delves into the components and mechanics that facilitate this essential function, highlighting their significance in overall vehicle operation.

At the heart of the clutch system lies the friction material, which enables the transfer of power between the engine and the drivetrain. The design and composition of this material are crucial, as they determine the system’s effectiveness and longevity. Additionally, the pressure plate and release mechanism work in unison to manage the engagement process, providing the driver with control and responsiveness.

Another vital aspect is the hydraulic or mechanical linkage that connects the pedal to the clutch assembly. This system ensures that the driver’s inputs translate accurately into action, allowing for precise gear shifts. Regular inspection and maintenance of these linkages can prevent performance issues and extend the lifespan of the entire system.

Furthermore, modern advancements have led to the development of various types of clutch systems, including single and multi-plate configurations. Each type has its own advantages and is suited for different applications, emphasizing the importance of choosing the right system based on vehicle requirements and operational conditions.

In conclusion, a thorough understanding of clutch systems not only aids in effective maintenance but also enhances driving experience and safety. Recognizing the interplay between components can lead to informed decisions regarding upgrades and repairs, ultimately ensuring optimal performance on the road.

How Torque Converters Operate

Torque converters are essential components that facilitate the transfer of power from an engine to a drivetrain. They enable smooth acceleration and efficient power delivery by utilizing hydraulic principles to multiply torque. This section explores the fundamental mechanics behind their operation.

At the heart of a torque converter are several key elements:

- Impeller: This component is connected to the engine and spins, creating a flow of fluid.

- Turbine: Positioned opposite the impeller, the turbine receives the fluid flow, converting its energy into rotational motion.

- Stator: Located between the impeller and turbine, the stator redirects the fluid returning from the turbine to enhance efficiency.

- Fluid: Hydraulic fluid is the medium that transfers energy and allows for the torque multiplication effect.

The operation of a torque converter can be summarized in the following steps:

- The engine spins the impeller, forcing hydraulic fluid to move.

- This movement generates a flow that drives the turbine, which in turn rotates the output shaft.

- The stator ensures that the returning fluid maintains optimal flow direction, further enhancing the system’s efficiency.

- As the speed increases, the converter can lock up to provide a direct drive, minimizing slip and maximizing power transfer.

By harnessing these components and processes, torque converters play a pivotal role in enhancing vehicle performance and providing a seamless driving experience.

Role of Transmission Fluid in Performance

The essence of efficient machinery operation relies heavily on the fluid that circulates within its systems. This vital substance serves multiple functions, ensuring smooth engagement and optimal performance under varying conditions. Understanding its significance can greatly enhance the longevity and functionality of the entire mechanism.

Functions of the Fluid

This essential liquid provides lubrication, cooling, and cleaning within the system. By reducing friction, it prevents wear and tear on moving components, while also dissipating heat generated during operation.

Impact on Performance

The quality and consistency of the fluid directly influence overall performance. Regular maintenance and timely replacement can lead to improved responsiveness and efficiency, ultimately enhancing the operational capabilities of the machinery.

| Function | Importance |

|---|---|

| Lubrication | Minimizes friction and wear |

| Cooling | Prevents overheating |

| Cleaning | Removes debris and contaminants |

Common Issues with Transmission Parts

Understanding the frequent challenges associated with essential mechanisms can significantly enhance performance and longevity. Many users encounter specific malfunctions that may lead to inefficiencies or failures.

Frequent Challenges

- Overheating: Excessive heat can cause components to degrade rapidly.

- Fluid Leaks: Loss of vital fluids can lead to insufficient lubrication.

- Worn Components: Regular wear and tear can compromise functionality.

Symptoms to Watch For

- Unusual noises during operation.

- Slipping or delayed engagement when shifting.

- Warning lights illuminated on the dashboard.

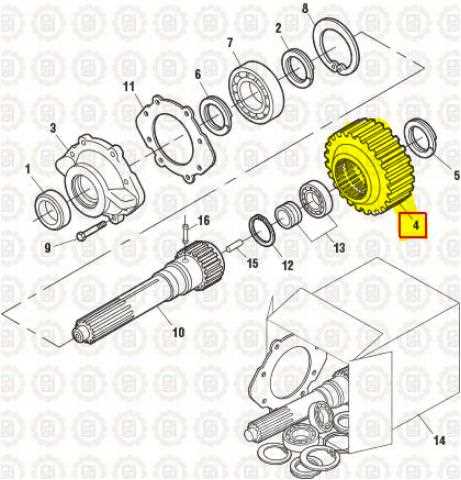

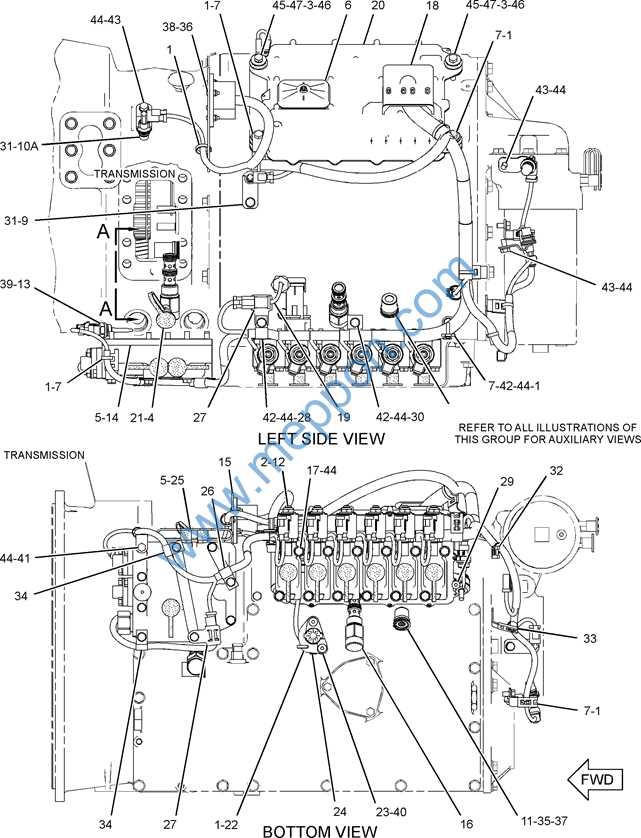

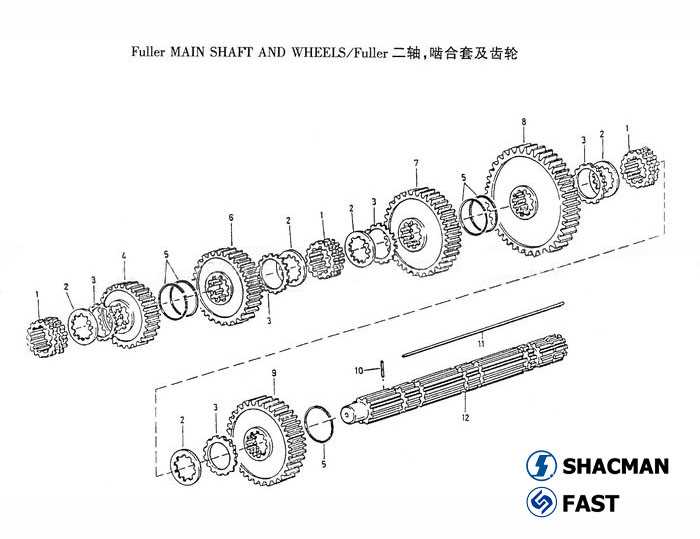

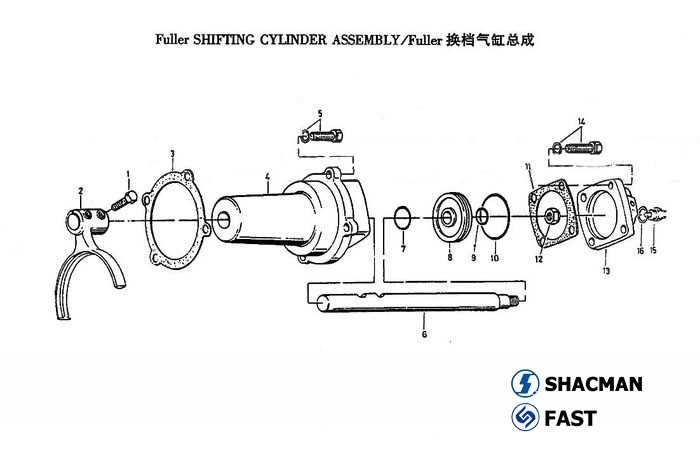

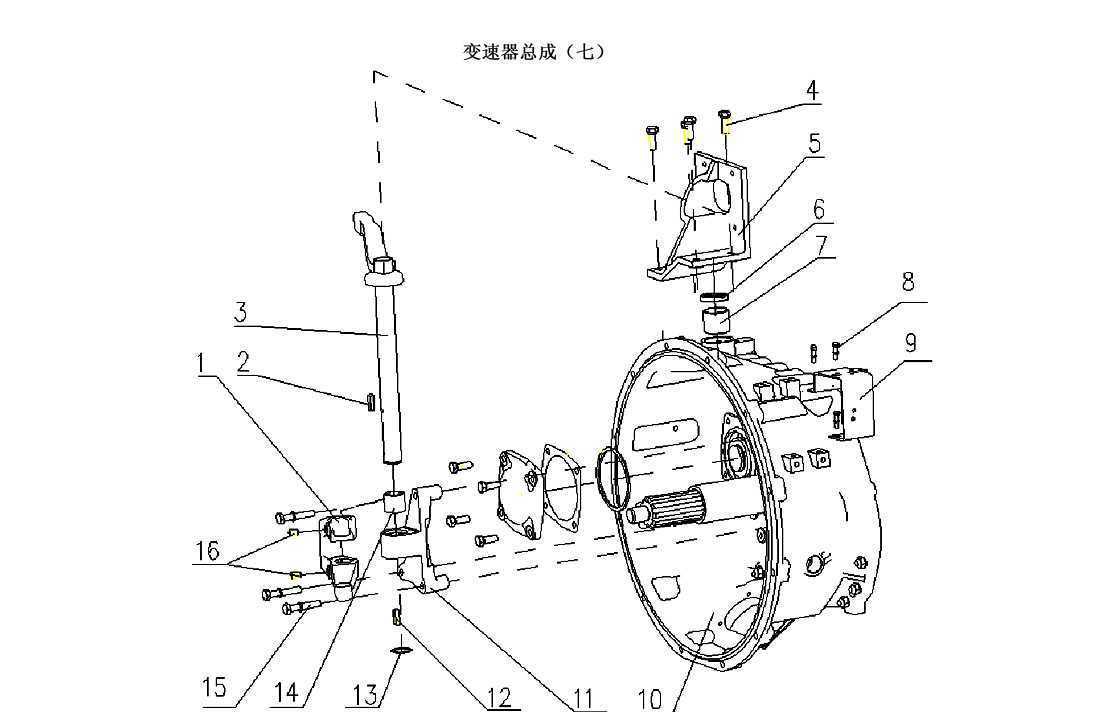

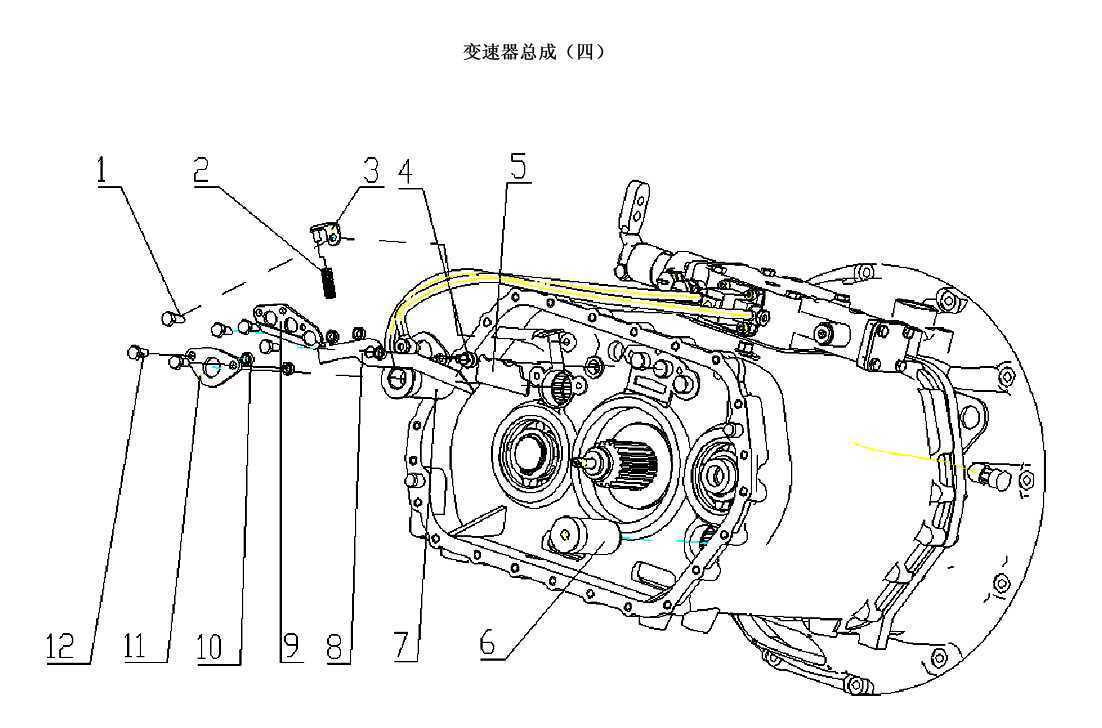

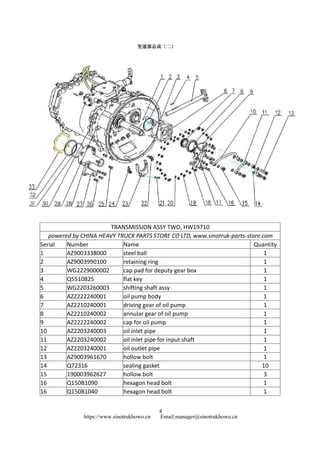

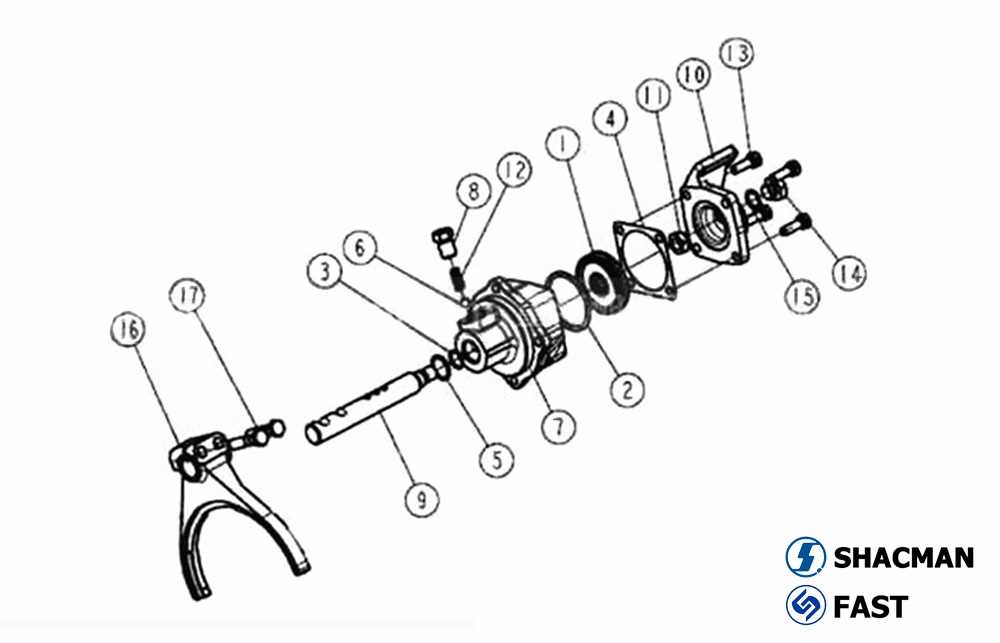

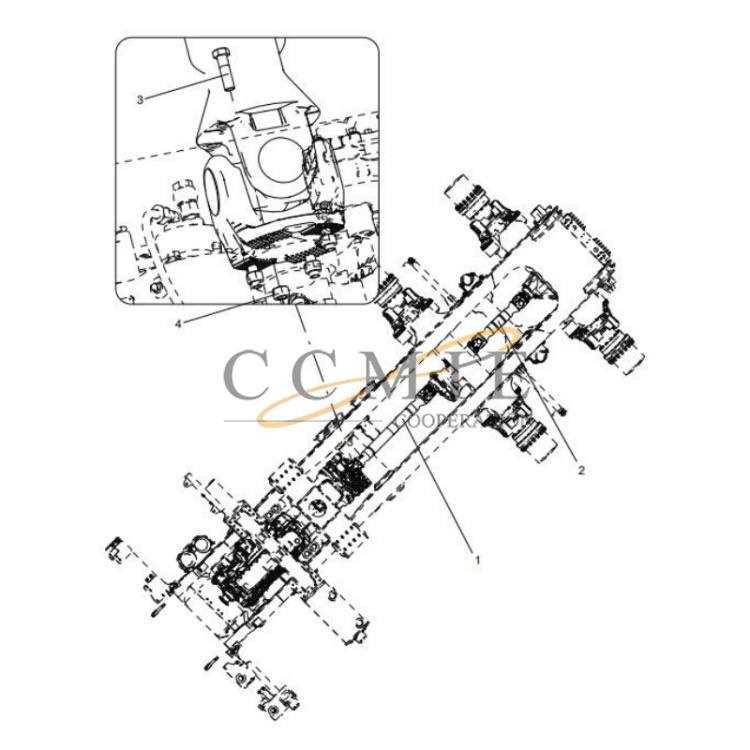

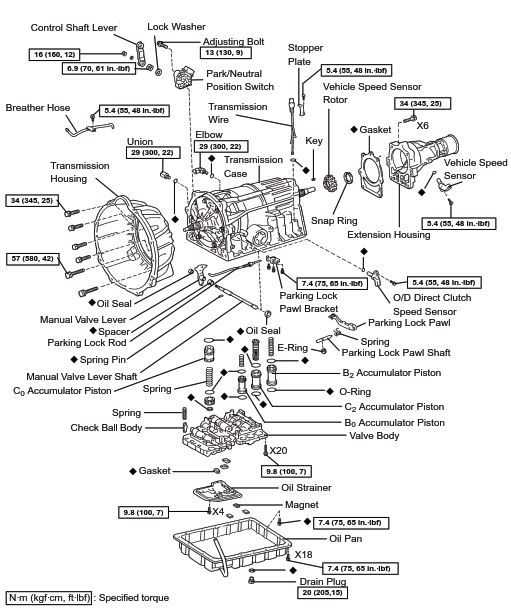

Visual Representation of Transmission Diagrams

Understanding complex machinery often requires a clear and concise visual format that illustrates the interconnections and functions of various components. This graphical approach enhances comprehension, allowing users to quickly grasp the intricate relationships that exist within mechanical systems. A well-crafted visual can serve as an ultimate tool for both learning and troubleshooting.

Importance of Clear Illustrations

Effective visuals not only simplify the learning process but also aid in identifying issues that may arise during operation. By providing an overview of how different elements interact, these representations become essential resources for technicians and enthusiasts alike. Clarity in these illustrations is paramount for successful maintenance and repairs.

Elements of a Comprehensive Visual

A thorough representation typically includes labels and annotations that highlight key features and functionalities. Color coding and structured layouts further enhance readability, making it easier for users to navigate through complex information. The ultimate goal is to create a resource that serves both educational and practical purposes.

Maintenance Tips for Truck Transmissions

Proper upkeep of your vehicle’s gear system is essential for optimal performance and longevity. Regular attention can prevent costly repairs and enhance overall functionality. Here are some effective strategies to maintain this crucial component.

1. Regular Fluid Checks: Ensure that the lubricant is at the correct level and in good condition. Contaminated or low fluid can lead to overheating and premature wear.

2. Schedule Routine Servicing: Adhering to a maintenance schedule recommended by the manufacturer helps identify issues early. Inspections can include checking seals, gaskets, and other critical elements.

3. Monitor for Unusual Sounds: Pay attention to any grinding, whining, or clunking noises during operation. These can be early signs of potential failure that should not be ignored.

4. Avoid Overloading: Respect the weight limits for your vehicle. Excessive loads can strain the gear system, leading to faster deterioration.

5. Use the Correct Lubricant: Always use the type of lubricant specified by the manufacturer. This ensures proper viscosity and protection under varying conditions.

6. Keep Components Clean: Dirt and debris can enter the system and cause damage. Regular cleaning and inspections help maintain performance and reliability.

7. Learn to Drive Smoothly: Gentle acceleration and deceleration can reduce stress on the system. Avoiding sudden shifts can enhance durability.

By implementing these practices, you can ensure the longevity and efficiency of your vehicle’s gear mechanism, contributing to a smoother and more reliable driving experience.

Choosing Quality Replacement Parts

Selecting high-quality components is essential for ensuring optimal performance and longevity in any mechanical system. By prioritizing durability and reliability, you can significantly reduce the risk of failures and costly repairs. Understanding the nuances of different materials and manufacturing processes can help you make informed decisions.

Research is crucial when evaluating options. Look for reputable manufacturers known for their commitment to quality. Additionally, consider user reviews and ratings, as they can provide insight into the experiences of others.

Compatibility is another key factor. Always verify that the components are designed to fit seamlessly with your specific configuration. Investing in parts that meet or exceed original specifications can lead to enhanced efficiency and performance.

Lastly, never underestimate the value of warranties and guarantees. A solid warranty can be a strong indicator of a manufacturer’s confidence in their products, offering you peace of mind with your investment.

Comparing Automatic and Manual Transmissions

When it comes to selecting a system for controlling vehicle speed and power, enthusiasts often find themselves weighing the benefits and drawbacks of two prevalent types: the self-shifting and the driver-operated varieties. Each option presents distinct characteristics that appeal to different preferences and driving styles.

Self-shifting systems offer convenience and ease of use, allowing drivers to focus more on the road than on gear changes. This type is particularly favored in urban environments where frequent stopping and starting is necessary. The technology involved often enhances fuel efficiency and provides a smoother ride, making it a popular choice for everyday use.

On the other hand, driver-operated systems provide a level of engagement and control that many enthusiasts cherish. These setups require more attention and skill, often resulting in a more connected driving experience. For those who enjoy the art of driving, manipulating gears manually can be both satisfying and rewarding, especially in performance-oriented situations.

In summary, the choice between these two options ultimately comes down to individual preferences, driving conditions, and the desired level of involvement behind the wheel. Understanding the nuances of each can help drivers make an informed decision that best suits their needs.

Future Trends in Truck Transmission Design

The evolution of power delivery systems is set to revolutionize the industry. Innovations driven by technology and sustainability are shaping the next generation of mechanical gear mechanisms, enhancing efficiency and performance.

Embracing Electrification

The shift towards electric solutions is becoming increasingly prominent. Integrating electric motors with traditional mechanical systems can optimize torque and improve energy management, ultimately leading to a more sustainable approach.

Advanced Materials and Durability

Utilizing lightweight, high-strength materials will be crucial for enhancing longevity and reducing weight. This advancement will not only improve overall performance but also contribute to lower fuel consumption and emissions.