The effective maintenance of green spaces relies heavily on the efficiency and functionality of various essential equipment. A comprehensive understanding of the intricate elements that contribute to the performance of such tools is vital for both hobbyists and professionals. Identifying each component and its role can significantly enhance the user experience and extend the lifespan of the equipment.

In this section, we will explore the individual segments that make up a widely-used gardening implement. From the motor mechanisms to the cutting systems, every piece plays a crucial role in achieving optimal results. A detailed overview will facilitate better decision-making during repairs and upgrades, ensuring that users can tackle their gardening tasks with confidence.

Furthermore, grasping how these elements interconnect fosters a deeper appreciation for the technology involved. Whether one is seeking to troubleshoot an issue or simply wishing to enhance their understanding of the device, recognizing the layout and function of each segment is essential. This knowledge not only empowers users but also contributes to more effective gardening practices.

Understanding California Trimmer Components

In the world of gardening tools, understanding the individual elements that make up a cutting device is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality, and knowing how they interact can enhance your experience and extend the life of your equipment.

Key Elements and Their Functions

- Motor: The heart of the machine, providing the necessary power to operate the blades.

- Blades: Sharp edges designed for precision cutting, available in various styles depending on the desired finish.

- Frame: The structural foundation that holds all components together, ensuring stability during operation.

- Handle: Ergonomically designed for comfortable use, allowing for better control and maneuverability.

Maintenance Tips for Longevity

- Regularly clean all components to prevent buildup of debris.

- Inspect the blades for wear and sharpen as needed to maintain cutting efficiency.

- Check electrical connections and ensure the motor is functioning properly.

- Store the equipment in a dry place to prevent rust and corrosion.

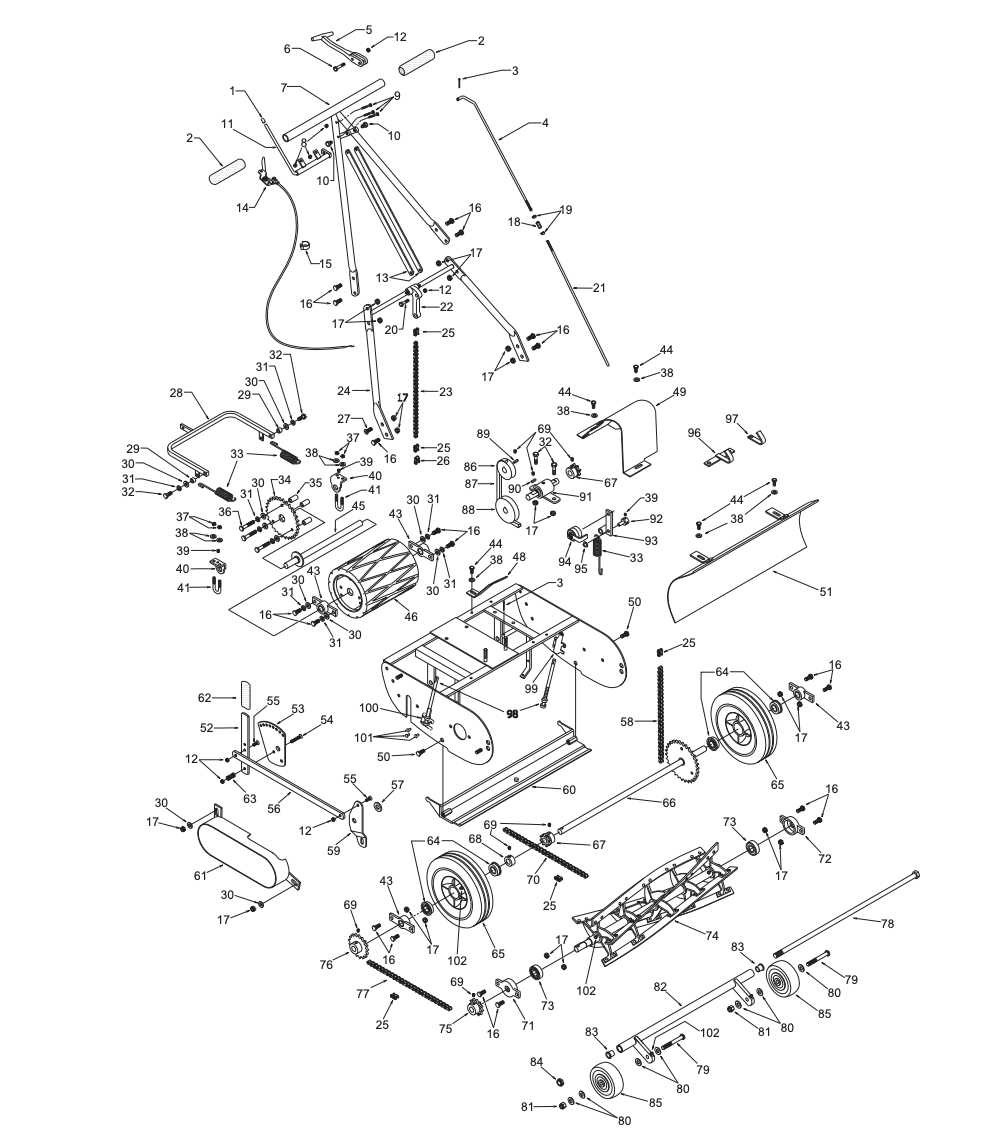

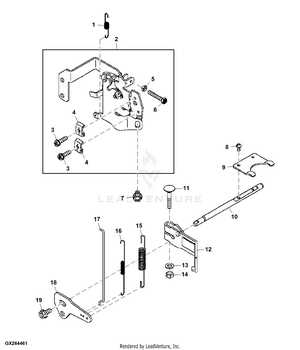

Importance of Parts Diagrams

Understanding the layout of components is crucial for effective maintenance and repair of any machinery. These visual representations serve as essential tools for users, enabling them to identify, locate, and understand the relationships between various elements. With a clear overview, operators can enhance their troubleshooting skills and streamline repair processes.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex structures, making it easier to follow instructions. |

| Efficient Repairs | Identifying faulty components becomes quicker, reducing downtime. |

| Improved Understanding | Users gain insights into how each element functions within the whole system. |

| Informed Upgrades | Knowledge of existing components aids in making informed choices for enhancements. |

Key Features of California Trimmers

When it comes to maintaining a pristine landscape, certain tools stand out due to their innovative design and functionality. These devices are engineered to enhance efficiency while ensuring precision in every cut. Users can rely on them for exceptional performance in a variety of settings, from residential gardens to professional landscaping projects.

Durability and Performance

Robust construction is a hallmark of these machines, allowing them to withstand rigorous use in various conditions. With high-quality materials, they offer longevity that ensures they remain a staple in any gardening toolkit. Additionally, their powerful engines deliver consistent results, making yard work a breeze.

User-Friendly Features

Ergonomically designed handles and intuitive controls enhance comfort and ease of use. Lightweight models are available, minimizing fatigue during extended periods of operation. These characteristics, combined with efficient cutting mechanisms, allow for a seamless experience, whether one is a novice gardener or an experienced professional.

Common Parts and Their Functions

This section explores the essential components of a lawn maintenance device, highlighting their roles and significance in ensuring optimal performance.

- Motor: The powerhouse that drives the entire machine, converting electrical energy into mechanical motion.

- Cutting Head: The attachment responsible for the actual cutting, utilizing blades or string to trim grass and weeds effectively.

- Handle: Provides control and maneuverability, allowing users to guide the device easily during operation.

- Guard: A protective cover that shields the user from debris and enhances safety during use.

- Throttle Trigger: Regulates speed and power, giving users the ability to adjust the intensity of the cutting action.

Understanding these components can enhance maintenance practices and improve overall efficiency.

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to maintain and repair equipment. Such illustrations provide a clear overview of each piece and its relationship to the whole assembly. Learning to interpret these images is essential for effective troubleshooting and replacement of components.

Key Elements to Identify

- Labels: Look for identifiers next to each item. These may include numbers or letters that correlate with a list of components.

- Lines and Arrows: Observe how lines and arrows connect different elements. They indicate the placement and orientation of each part.

- Groupings: Components may be grouped based on function or location. Recognizing these clusters can help in understanding assembly sequences.

Steps to Effectively Use a Visual Guide

- Familiarize yourself with the overall layout to grasp the context.

- Cross-reference labels with accompanying documentation to confirm part specifics.

- Take note of any color coding or symbols that may provide additional information.

- Practice by disassembling a unit, using the guide to identify each element as you go.

By mastering these techniques, you can navigate visual representations with confidence, ensuring proper maintenance and efficient repairs.

Identifying Wear and Tear

Understanding the signs of deterioration is essential for maintaining optimal performance. Regular inspections can help pinpoint issues that may lead to decreased efficiency or potential failures. By recognizing specific indicators of wear, users can ensure longevity and effectiveness in their equipment.

Common Signs of Deterioration

Look for visible damage such as cracks, fraying, or discoloration. These symptoms often suggest that components are nearing the end of their usable life. Additionally, unusual noises or vibrations during operation can be clear signals that something is amiss.

Preventive Measures

Regular maintenance routines can greatly reduce the risk of significant wear. Cleaning, lubrication, and timely replacements are crucial for enhancing the lifespan of each element. Adopting these practices not only preserves functionality but also saves costs in the long run.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular attention to maintenance not only enhances performance but also prevents unexpected failures. By following a few simple guidelines, you can ensure that your device remains in optimal condition for years to come.

Routine Inspections

Conducting frequent checks helps identify potential issues early. Look for signs of wear and tear, and ensure all components are functioning smoothly.

Cleaning and Lubrication

Keeping your equipment clean and well-lubricated is crucial. Remove debris and apply the appropriate lubricants to moving parts to minimize friction.

| Maintenance Task | Frequency |

|---|---|

| Inspect components | Weekly |

| Clean the device | Monthly |

| Lubricate moving parts | Every 3 months |

Where to Find Replacement Parts

Finding the right components for your equipment can be a challenge, but there are several reliable sources to help you locate what you need. Whether you prefer shopping online or visiting a local store, understanding your options can save you time and ensure you get quality items.

One of the most effective ways to find what you’re looking for is through authorized dealers. They often carry a comprehensive selection of items and can provide expert advice on compatibility. Additionally, many manufacturers have official websites that feature a catalog of available components.

Online marketplaces are another great option. Websites like Amazon or eBay frequently list various items, often with user reviews that can guide your purchase. Don’t forget to check local hardware shops, as they may have a surprising array of useful equipment.

| Source | Description |

|---|---|

| Authorized Dealers | Specialized retailers with extensive inventory and expert assistance. |

| Manufacturer Websites | Official sites offering a complete catalog and support information. |

| Online Marketplaces | Platforms like Amazon and eBay featuring customer reviews and competitive pricing. |

| Local Hardware Stores | Convenient locations that may carry a diverse selection of useful components. |

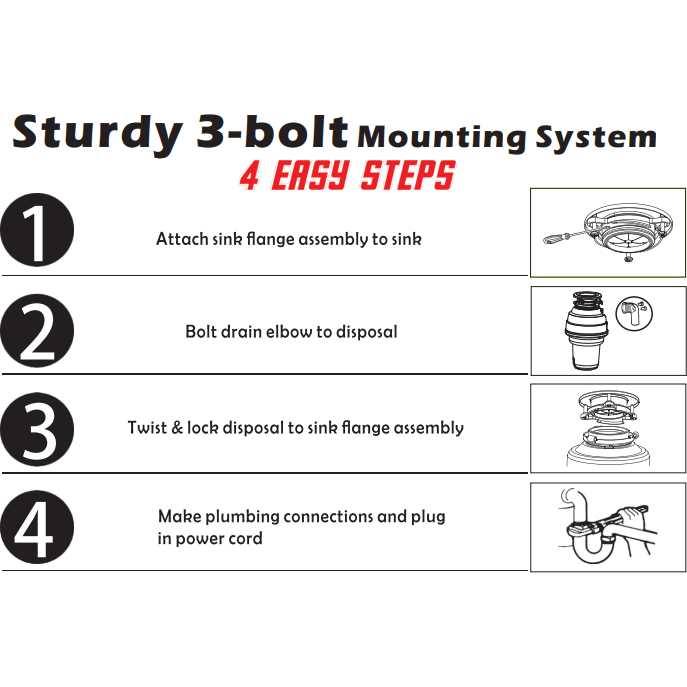

Assembly Instructions for New Owners

Assembling your new equipment can be an exciting yet challenging process. Following the right steps ensures that everything operates smoothly and efficiently. This section will guide you through the essential phases of assembly, making it straightforward for you to enjoy your new acquisition.

Preparation Steps

Before starting, gather all components and tools required for the assembly. Carefully review the instruction manual, as it contains crucial information about each piece. Make sure to work in a clean, organized area to prevent losing any parts.

Assembly Process

Begin by connecting the main components as outlined in the manual. Ensure that all fasteners are tightened securely but not overdone. Double-check your work as you progress to avoid any misalignments. Finally, perform a brief test to confirm that everything is functioning correctly. Following these steps will lead to optimal performance and longevity.

Upgrading Your Trimmer’s Performance

Enhancing the efficiency of your cutting device can significantly improve its overall functionality and extend its lifespan. By focusing on key components and making strategic adjustments, users can achieve optimal results in their gardening tasks. This section explores various methods to elevate performance levels and ensure a seamless experience.

Choosing Quality Components

Investing in high-quality replacements can lead to substantial improvements. Components such as blades and motors play a crucial role in the device’s effectiveness. When selecting replacements, prioritize durability and compatibility. Upgrading to premium materials can result in cleaner cuts and increased reliability during operation.

Regular Maintenance Practices

Consistent upkeep is essential for sustained performance. Regularly checking and cleaning the device can prevent build-up and wear. Routine inspections of key elements, including filters and cables, will help identify potential issues before they escalate. This proactive approach not only maintains efficiency but also prolongs the life of the equipment.

Frequently Asked Questions

This section aims to address common inquiries regarding the assembly and maintenance of lawn care equipment. Here, you’ll find valuable insights that can help enhance your understanding and efficiency in handling these tools.

General Inquiries

- What is the purpose of regular maintenance?

Regular upkeep ensures optimal performance and longevity of your equipment.

- How often should I inspect my equipment?

It is advisable to perform inspections before each use and carry out thorough checks at the beginning of each season.

Technical Support

- Where can I find replacement components?

Replacement components can typically be sourced from authorized dealers or online retailers specializing in lawn equipment.

- How do I know which component is compatible with my model?

Always refer to the user manual or consult with customer service for assistance in identifying compatible parts.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding of maintenance and repair techniques. Engaging with diverse sources provides valuable insights into the functionality and efficiency of various tools and equipment.

Online Tutorials: Numerous websites offer step-by-step guides that can help you master essential skills. Look for video tutorials that visually demonstrate processes.

Forums and Community Groups: Joining online communities allows you to connect with experts and enthusiasts who share tips and experiences. This collaborative environment fosters learning through shared knowledge.

Books and Manuals: Consider investing in comprehensive manuals or instructional books. These resources often contain detailed explanations and troubleshooting advice that can deepen your expertise.

Workshops and Classes: Local workshops or community college courses can provide hands-on experience. Participating in these activities often leads to practical skills and networking opportunities.

Utilizing these resources will empower you to delve into the intricacies of tool operation and maintenance, ultimately enhancing your proficiency.