Maintaining your outdoor space requires reliable and well-functioning tools. Knowing how various elements of your equipment work together can significantly enhance its longevity and performance. A clear understanding of how different mechanisms fit and operate ensures that you’re always prepared for any necessary adjustments or repairs.

In this guide, we will dive into the key mechanical aspects that contribute to the smooth operation of your gardening tools. From the smallest details to the core structural elements, every component plays a crucial role in ensuring precision and ease of use during your landscaping tasks.

Understanding the configuration of these mechanisms can help you make informed decisions, whether it’s about routine maintenance or replacing a specific piece. Let’s explore how you can keep your equipment in optimal condition with the right insights.

Honda Strimmer Parts Overview

This section provides a comprehensive look at the various components involved in the operation of a garden cutting tool. Understanding these elements is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring the machine operates smoothly, making it essential to familiarize oneself with their functions and interrelations.

Key Components

Among the primary elements are the cutting mechanism, which is responsible for the actual trimming action, and the motor assembly that powers the device. Additionally, the handle and support structures enhance user control and comfort during operation. Regular inspection of these components can prevent potential issues and extend the lifespan of the equipment.

Maintenance Tips

To keep the equipment in optimal condition, it is advisable to clean the cutting mechanism after use and check for any signs of wear. Lubricating moving parts and ensuring secure connections can significantly improve performance. Familiarity with these components and their upkeep is essential for any user seeking efficient operation.

Key Components and Their Functions

This section explores the essential elements of a cutting tool and their respective roles in ensuring optimal performance. Understanding these components can significantly enhance the user experience and maintenance of the equipment.

- Engine: The heart of the device, providing the necessary power for operation. It converts fuel into mechanical energy, enabling the tool to perform efficiently.

- Cutting Head: This is where the action happens, utilizing blades or string to effectively trim vegetation. The design of the cutting head can impact the efficiency of the cutting process.

- Shaft: Connecting the engine to the cutting head, the shaft transmits power and motion. Its length and rigidity are crucial for maneuverability and comfort during use.

- Handle: Designed for user interaction, the handle ensures control and stability. Ergonomic designs can significantly reduce fatigue during extended use.

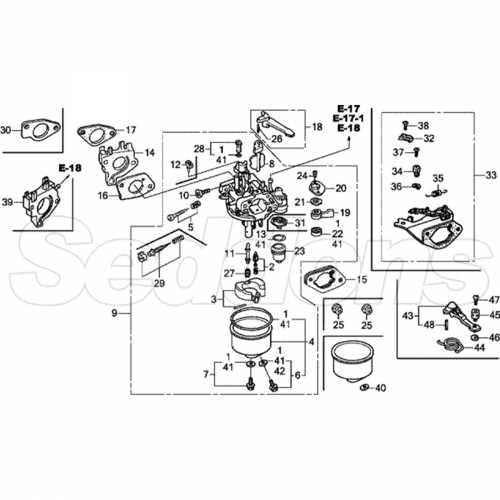

- Fuel System: Comprising the tank and lines, this system delivers fuel to the engine. Proper maintenance of this system is essential for reliable operation.

By familiarizing oneself with these crucial elements, users can ensure their equipment operates efficiently, prolonging its lifespan and enhancing overall productivity.

How to Identify Common Replacement Parts

Recognizing essential components for maintenance is crucial for ensuring optimal performance of your equipment. Familiarity with various elements can significantly enhance your ability to troubleshoot and replace worn-out items effectively. This section provides insights into the most frequently needed components and how to identify them.

1. Understand the Equipment’s Structure: Begin by familiarizing yourself with the general layout and functioning of your tool. Knowing how different elements interact will help you pinpoint which components may require replacement over time.

2. Consult the User Manual: A detailed guide often contains valuable information about each element’s specifications and replacement frequency. Regularly reviewing this document can prevent unnecessary wear and tear by informing you of potential issues.

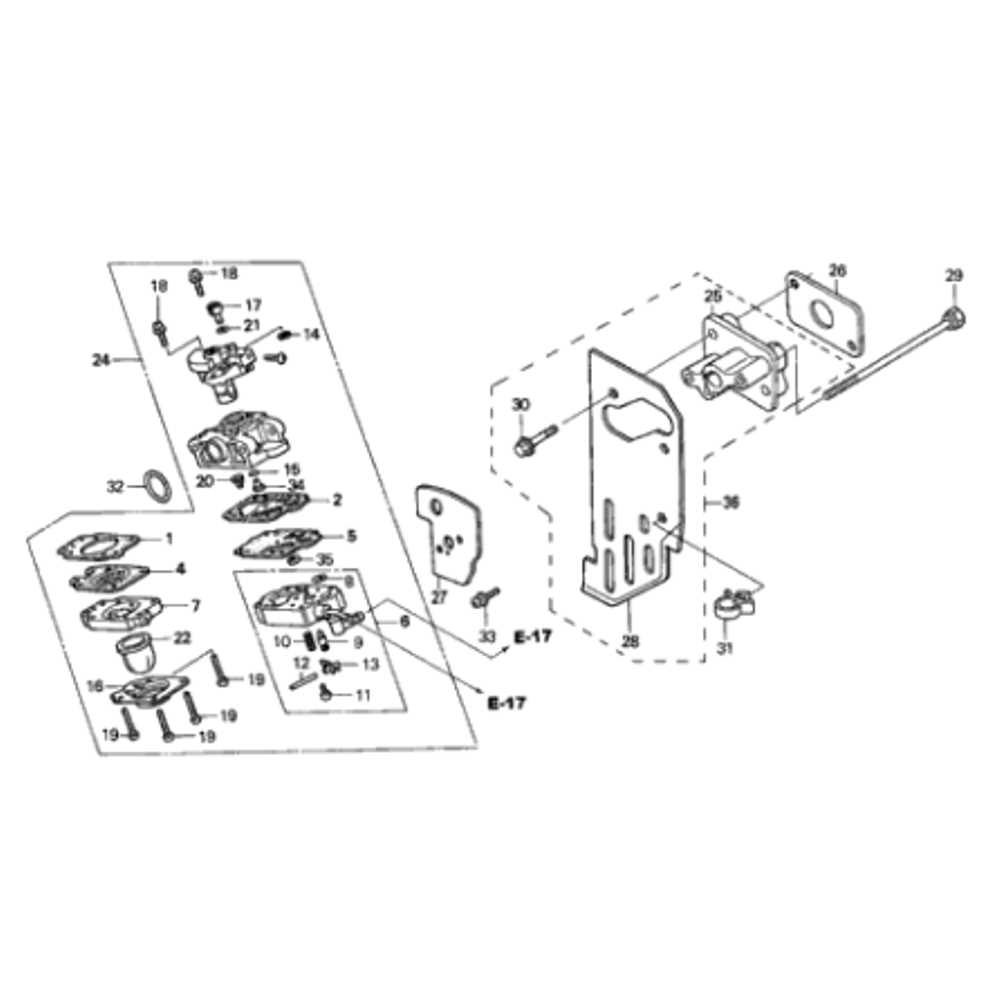

3. Examine Visual References: Utilize reference images or guides that illustrate the various components. Visual aids can be particularly helpful in recognizing and distinguishing similar-looking elements that may have different functions.

4. Monitor Performance Indicators: Keep an eye on how your equipment operates. Changes in performance, such as unusual noises or decreased efficiency, can signal that a particular component needs attention or replacement.

5. Seek Professional Assistance: If unsure about identifying specific items, consulting with experts can provide clarity. They can offer guidance based on experience and help ensure the correct replacements are made.

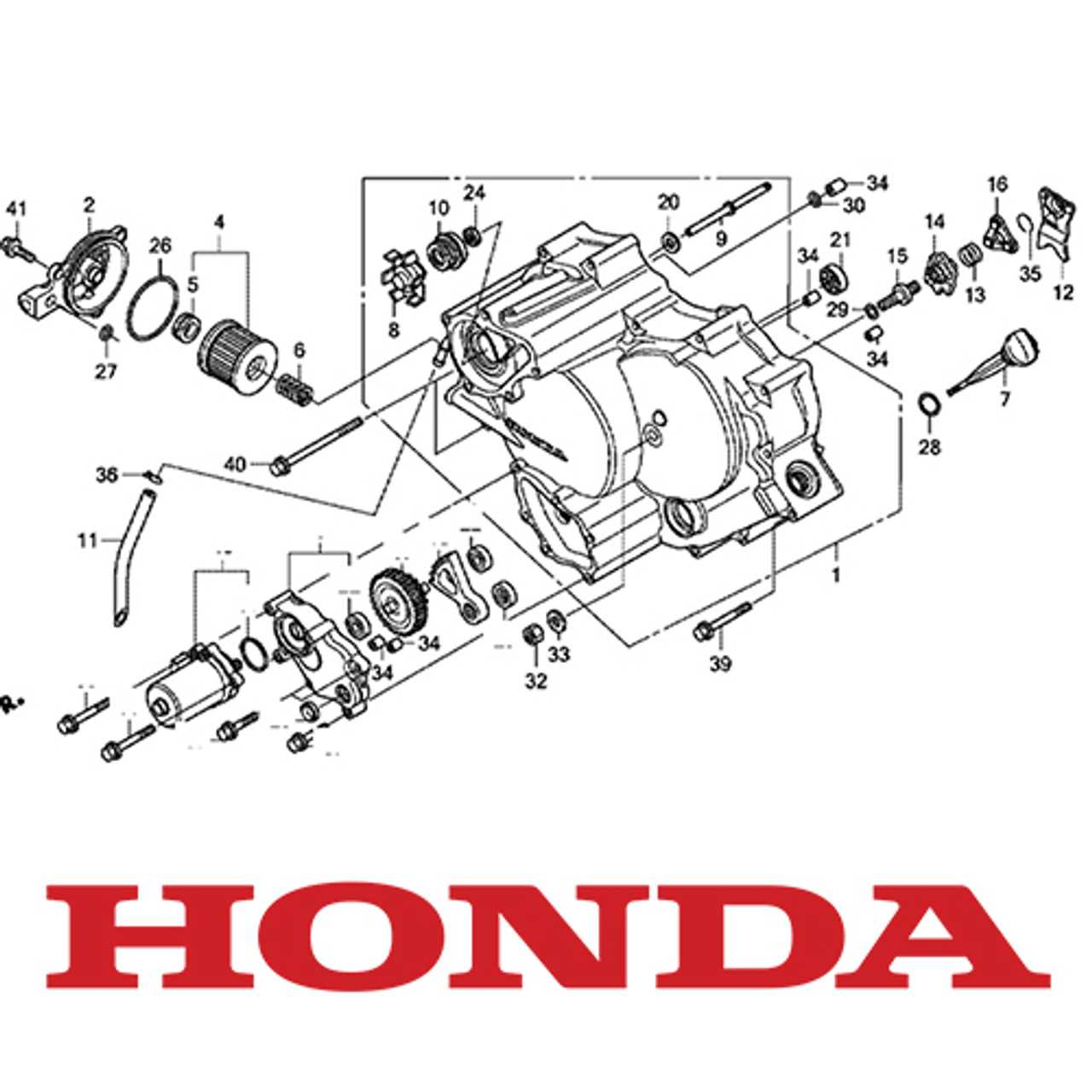

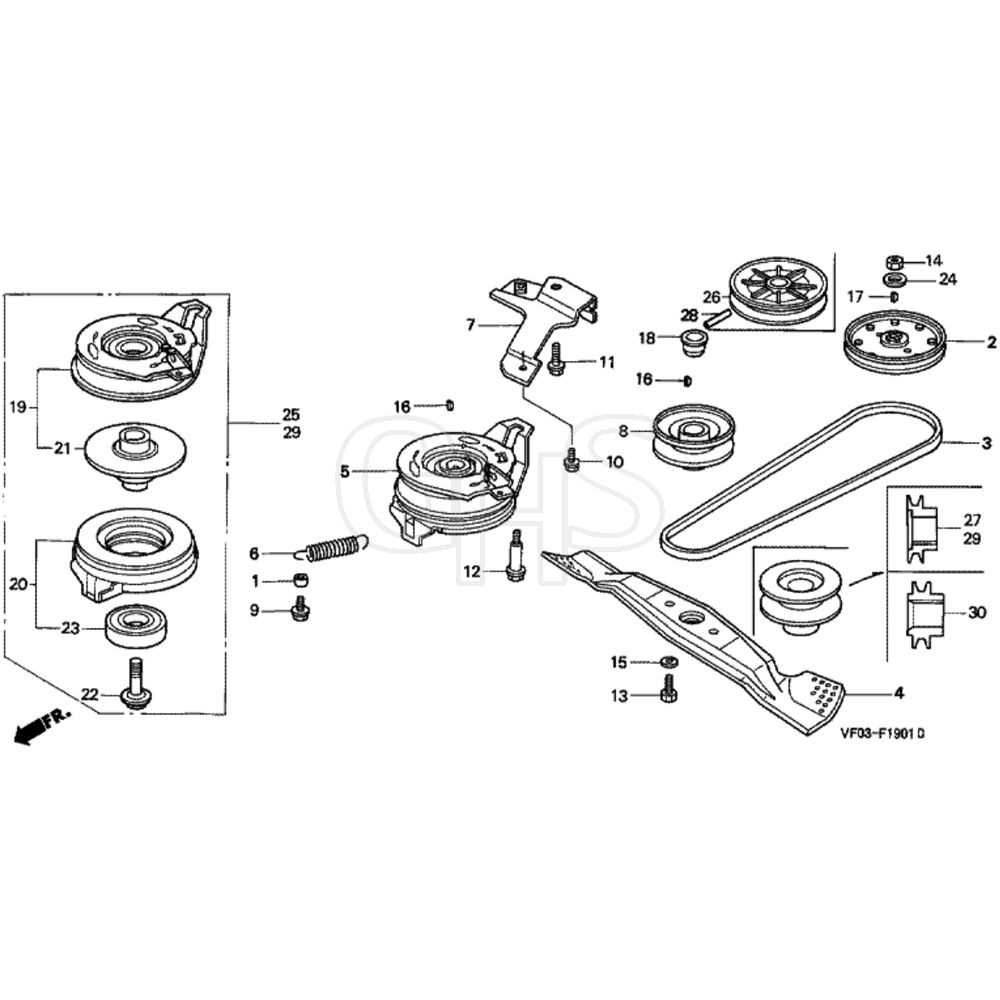

Exploded View of Honda Strimmer

The detailed representation of a garden tool’s assembly provides valuable insights into its construction and functionality. This visual breakdown helps users understand the interrelation of components, enabling effective maintenance and repairs. By examining the configuration, one can identify each section’s role within the overall system.

Understanding the layout of this equipment is crucial for anyone aiming to enhance their gardening experience. The illustration highlights various elements, showcasing how they fit together seamlessly. It serves as a guide for troubleshooting common issues and ensuring optimal performance.

With a comprehensive overview, users can easily locate specific features and their functions. This clarity not only aids in repairs but also fosters a deeper appreciation for the engineering behind the tool.

Maintenance Tips for Optimal Performance

To ensure your gardening tool operates efficiently, regular upkeep is essential. Consistent maintenance not only prolongs the life of the equipment but also enhances its functionality. This section provides valuable guidance on how to keep your device in top shape for the best results.

Regular inspection and cleaning of key components are vital. It is advisable to check for any signs of wear or damage and clean the equipment after each use to prevent dirt and debris accumulation. Keeping the blades sharp will improve cutting efficiency and reduce strain on the motor.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for wear | Every use | Look for cracks or breaks in components. |

| Clean after use | After each session | Remove dirt and grass clippings. |

| Sharpen blades | Every 5 uses | Use a file or sharpening tool for optimal sharpness. |

| Check fuel level | Before each use | Ensure there is enough fuel for operation. |

| Replace air filter | Every season | A clean filter ensures proper airflow. |

Following these maintenance tips will lead to improved performance and longevity of your equipment, allowing you to achieve your gardening goals with ease.

Steps to Replace Damaged Parts

Replacing worn or broken components is essential for maintaining optimal functionality and performance. Following a structured approach ensures that the replacement process is efficient and effective, minimizing the risk of further issues.

- Identify the Damaged Components:

Begin by carefully inspecting the equipment to determine which parts require replacement. Look for signs of wear, cracks, or any other form of damage.

- Gather Necessary Tools:

Collect all the tools and replacement items you will need. Commonly required tools include:

- Screwdrivers

- Wrenches

- Replacement components

- Safety gloves

- Disconnect the Equipment:

Ensure that the machine is turned off and unplugged or the battery is removed to prevent any accidental starts while working.

- Remove the Damaged Components:

Use the appropriate tools to carefully detach the damaged parts. Follow the manufacturer’s guidelines if available.

- Install New Components:

Place the new parts in their designated positions. Ensure that they fit securely and are aligned correctly.

- Reconnect and Test:

Once everything is securely in place, reconnect the equipment and perform a test run to verify that the new components are functioning properly.

Regular maintenance and timely replacement of essential components can extend the life of the equipment and improve its overall performance.

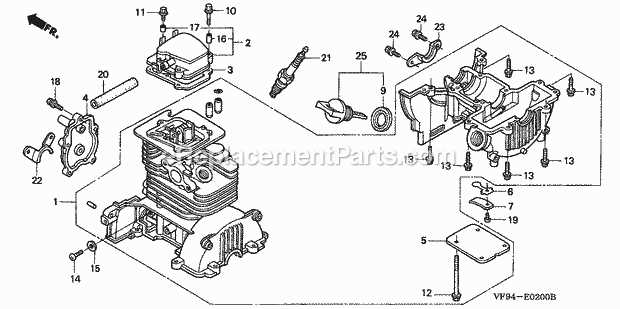

Understanding the Engine Layout

The arrangement of the motor in cutting tools plays a crucial role in their overall performance and efficiency. By examining the various components and their functions, users can gain a better grasp of how the machinery operates. This knowledge not only aids in maintenance but also enhances the effectiveness of usage.

Main Components

Familiarizing oneself with the essential elements of the engine is vital. Each part contributes uniquely to the overall functionality, influencing both power output and operational smoothness. Below are the primary components typically found in such equipment:

| Component | Function |

|---|---|

| Crankshaft | Transforms linear motion into rotational energy. |

| Piston | Compresses the fuel-air mixture for ignition. |

| Cylinder | Houses the piston and contains combustion. |

| Fuel Tank | Stores the necessary fuel for operation. |

| Air Filter | Prevents dirt and debris from entering the engine. |

Importance of Proper Arrangement

The precise configuration of these elements significantly affects the efficiency and longevity of the machine. Proper alignment ensures optimal performance and reduces the likelihood of mechanical failure. Understanding this layout allows users to troubleshoot issues effectively and conduct routine maintenance, thereby extending the lifespan of the equipment.

Tools Needed for Honda Strimmer Repair

Repairing outdoor equipment requires a specific set of instruments to ensure efficiency and effectiveness. Whether it is a trimming device or other similar machinery, having the right tools can greatly simplify the maintenance process and extend the lifespan of the equipment.

Essential Instruments

Begin with a sturdy screwdriver set, which is crucial for removing and replacing screws. Additionally, a wrench will help in loosening and tightening nuts and bolts securely. Another key instrument is a pair of pliers, which can be used for gripping, bending, and cutting wires or components.

Safety Equipment

Safety should always be a priority when working on machinery. Equip yourself with safety goggles to protect your eyes from debris and gloves to prevent injuries while handling sharp parts. Lastly, a first aid kit is essential in case of any unforeseen accidents.

Troubleshooting Issues with Strimmer Parts

When using a cutting tool, encountering issues is common. Understanding the underlying problems can greatly enhance the efficiency and longevity of the equipment. This section focuses on identifying and resolving typical complications related to various components of these machines.

Common Problems and Their Solutions

- Power Issues: If the device fails to start or runs inconsistently, check the fuel level, battery condition, and ignition components.

- Excessive Vibration: This can be caused by unbalanced cutting elements or loose attachments. Ensure that all parts are securely fastened and properly aligned.

- Overheating: If the equipment becomes too hot during operation, inspect the air filters and cooling vents for blockages.

Maintenance Tips

- Regularly clean the air filter to ensure proper airflow.

- Inspect cutting edges for wear and replace them as needed.

- Check all connections and fastenings to prevent component dislocation during use.

Where to Source Genuine Honda Parts

Finding authentic components for your equipment is crucial for ensuring optimal performance and longevity. Utilizing reliable sources helps maintain the quality and reliability of your tools, allowing for seamless operation and reduced downtime.

Authorized Retailers

One of the best options for acquiring original components is through authorized dealers. These retailers specialize in providing high-quality items that meet the manufacturer’s specifications. You can expect a comprehensive selection and expert advice on installation and compatibility.

Online Marketplaces

Several online platforms cater to users seeking genuine components. These websites often feature detailed descriptions and customer reviews, helping you make informed choices. However, it’s essential to verify the seller’s credibility to avoid counterfeit items.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Quality assurance, expert advice | May have higher prices |

| Online Marketplaces | Convenience, variety | Risk of counterfeit products |

| Manufacturer Websites | Direct sourcing, reliable information | Limited to specific items |

Upgrading Your Strimmer for Better Efficiency

Improving the performance of your trimming device can significantly enhance its effectiveness and longevity. By focusing on key upgrades, you can optimize your tool’s functionality and ensure that it operates at peak performance. These enhancements not only boost efficiency but also make the trimming process smoother and more enjoyable.

One of the primary areas to consider is the cutting mechanism. Upgrading to a high-quality blade or line can make a noticeable difference in how well the device cuts through tough vegetation. A sharper, more durable cutting tool reduces the need for multiple passes, saving both time and effort.

Additionally, regular maintenance and the use of compatible accessories can lead to improved efficiency. Ensuring that all components are clean and well-lubricated minimizes wear and tear, allowing the device to function optimally. Investing in performance-enhancing attachments can also provide versatility for various tasks, making the equipment more adaptable to different gardening needs.