The proper functioning of garden maintenance tools significantly impacts their efficiency and longevity. Familiarity with the essential components of these machines can lead to better performance and ease of use. This section aims to provide an insightful look into the various elements that make up these valuable devices.

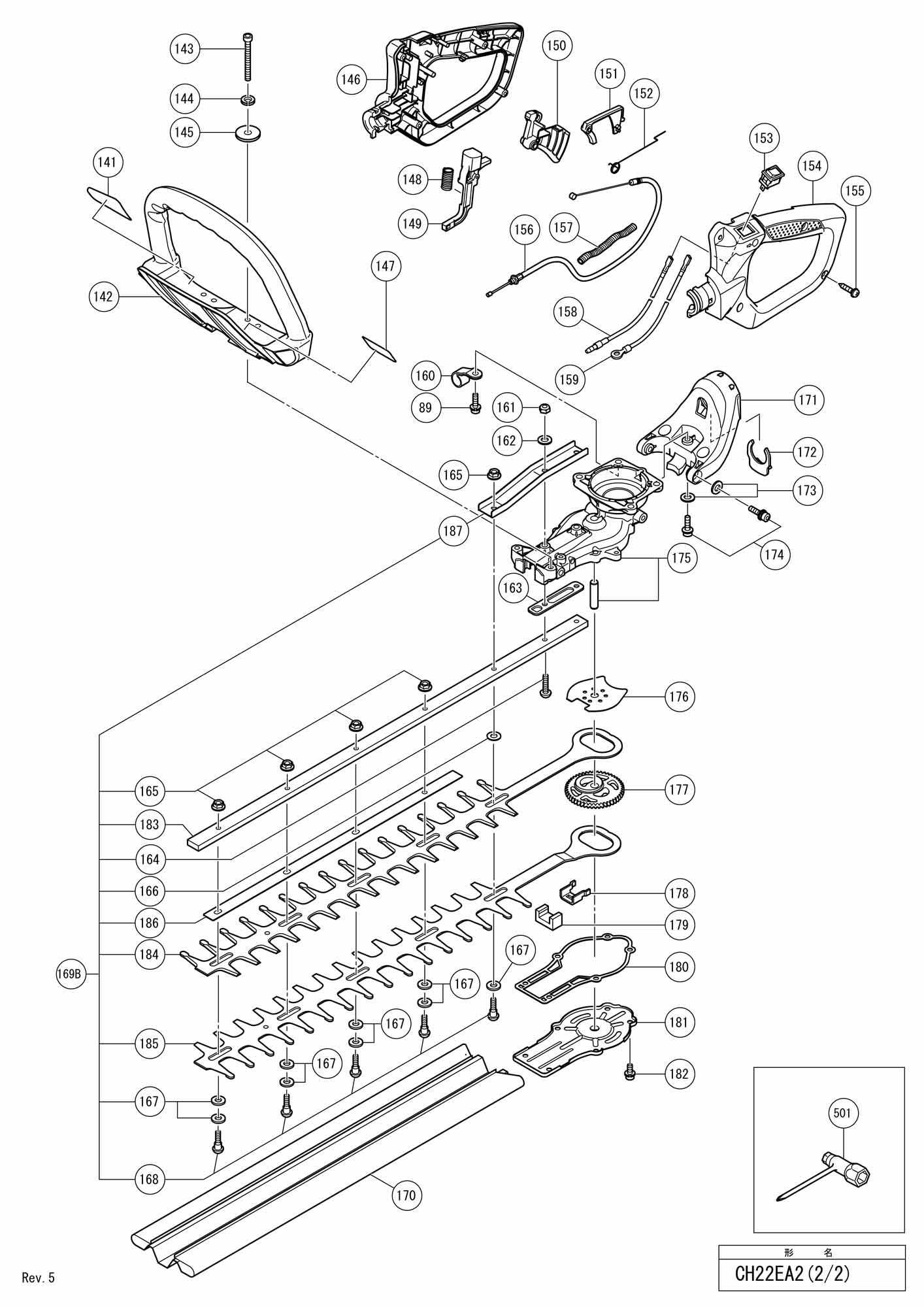

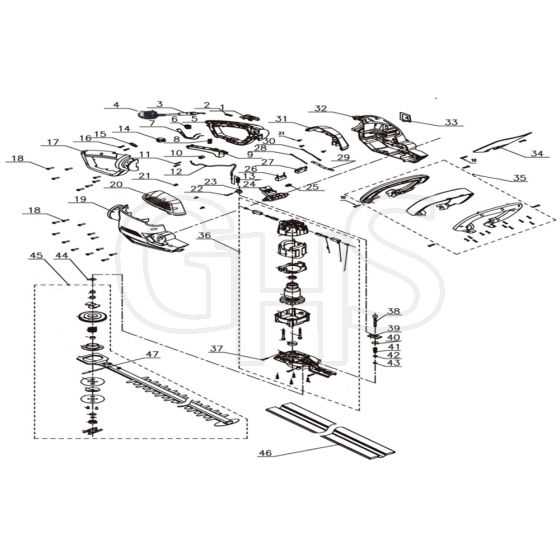

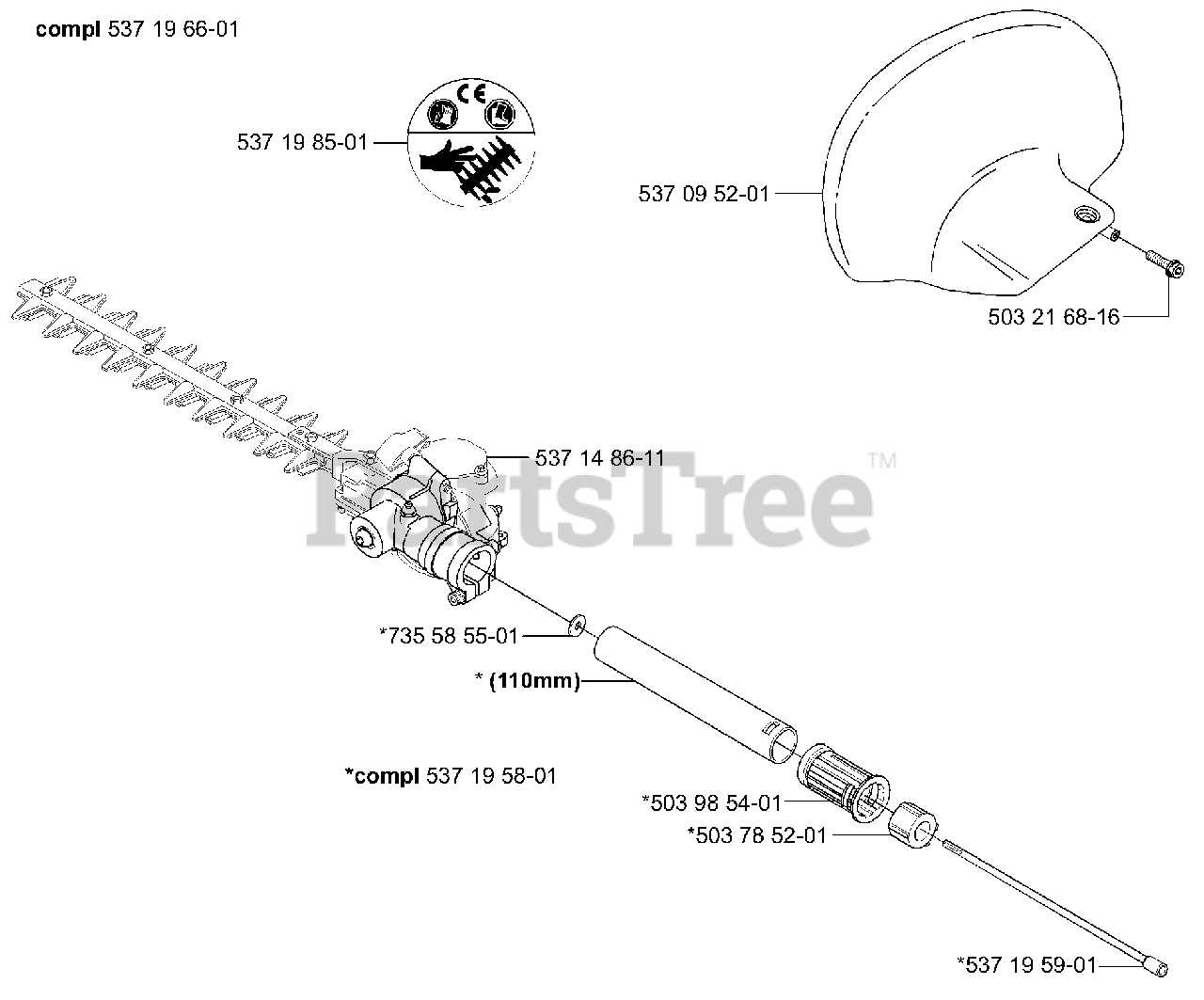

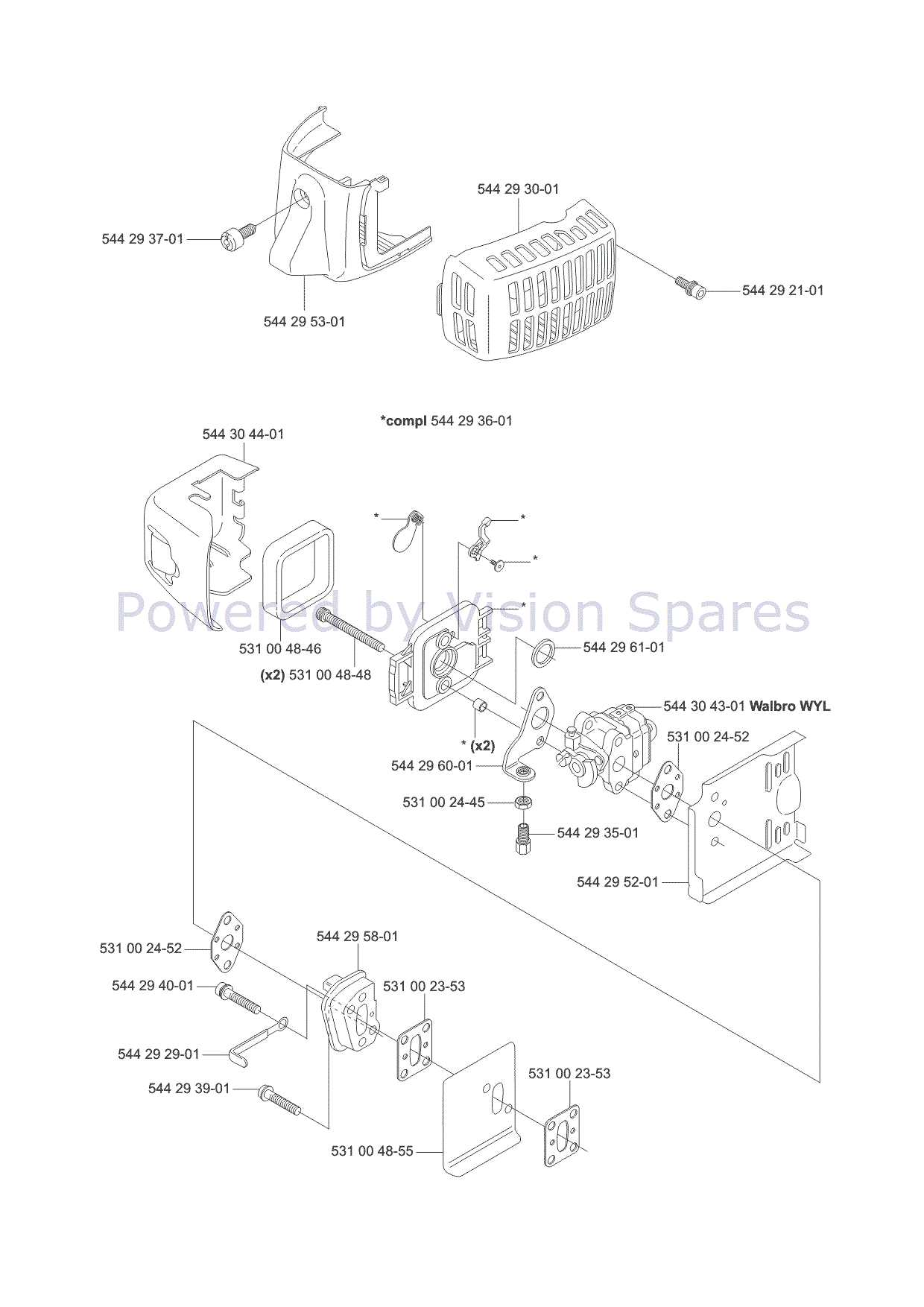

Having a clear visualization of the internal mechanisms allows users to troubleshoot issues effectively. Whether it’s a matter of routine maintenance or addressing specific malfunctions, understanding each segment’s role can enhance overall functionality. This information is crucial for both novices and experienced users, ensuring that all aspects of the equipment are well cared for.

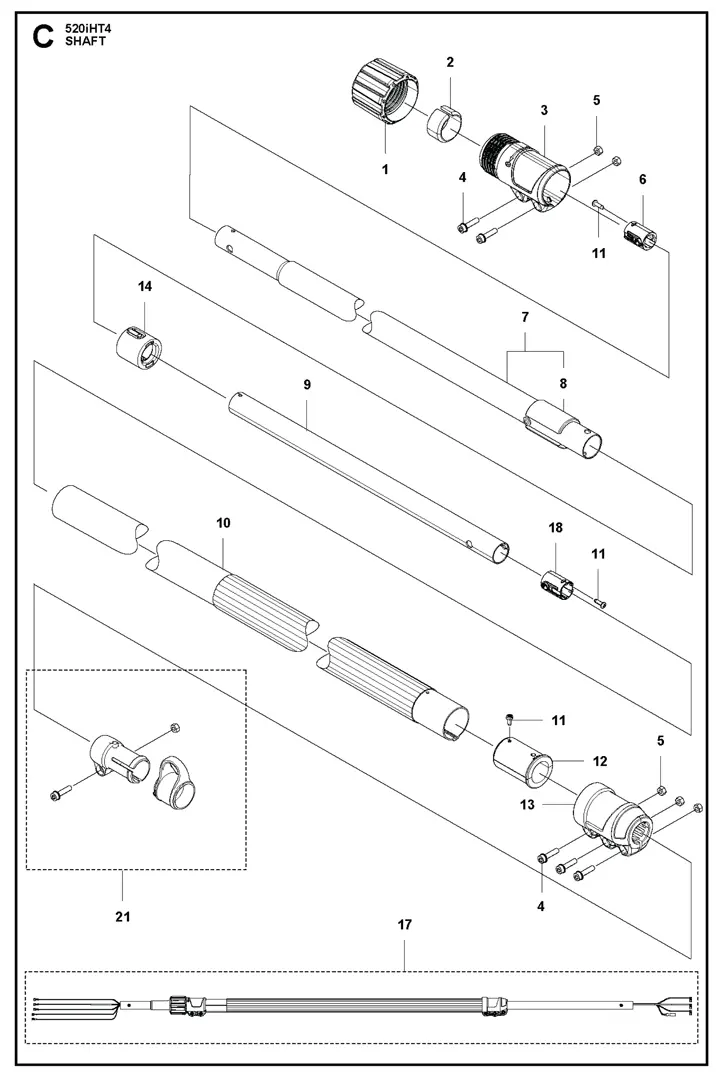

Through this exploration, we will delve into the specific sections of these tools, breaking down their individual functions and importance. With an organized representation of the components, you’ll gain a comprehensive view that empowers you to make informed decisions regarding maintenance and repairs.

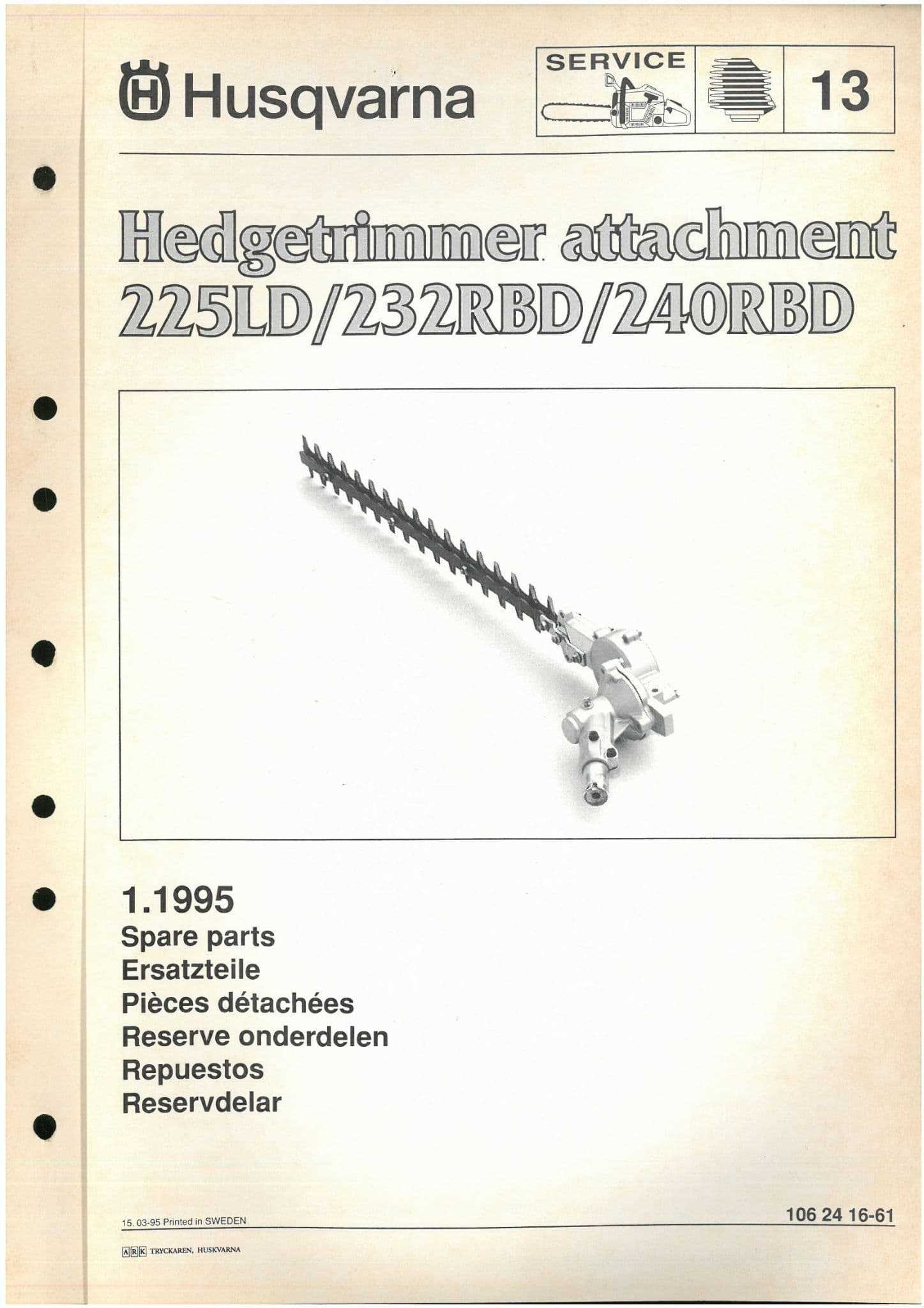

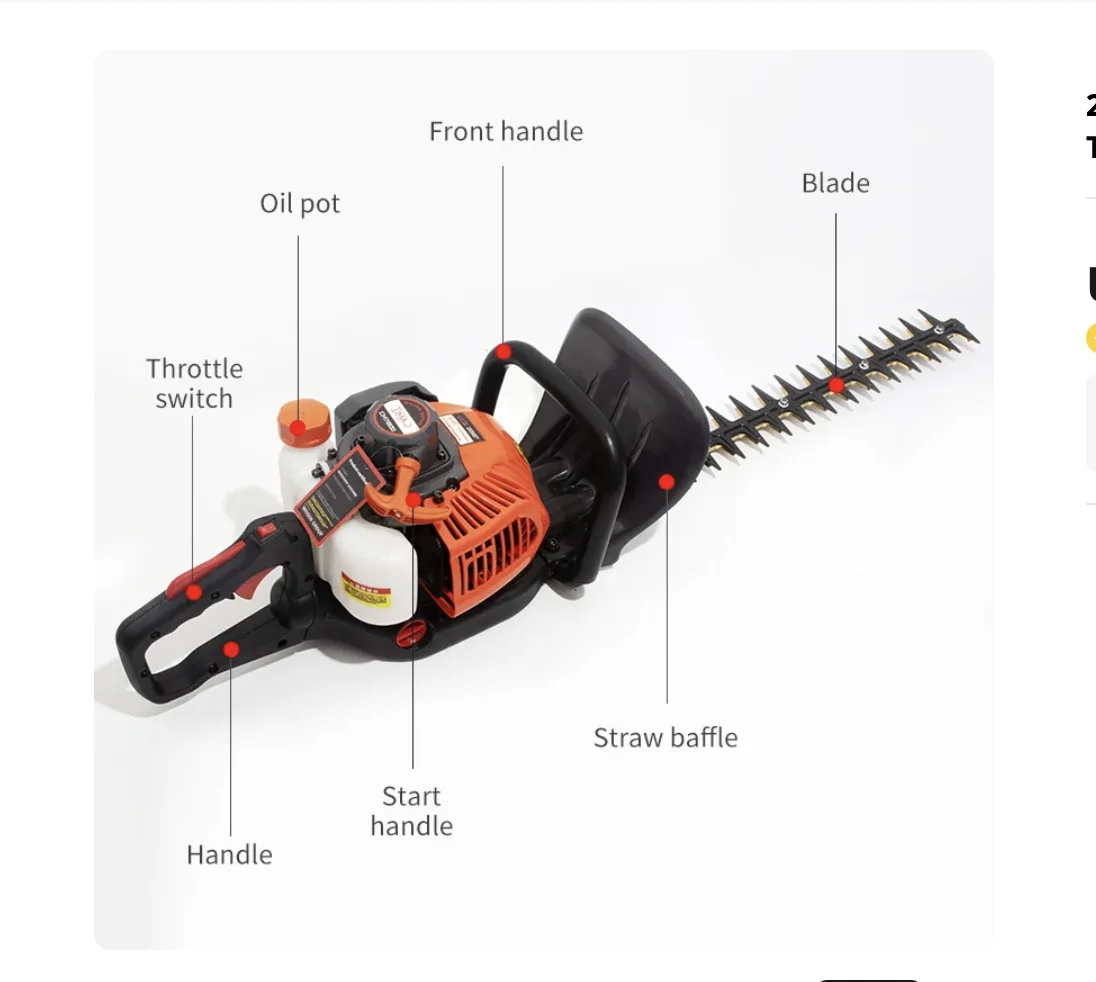

Understanding Your Hedge Trimmer’s Components

Familiarizing oneself with the various elements of a cutting tool can significantly enhance its functionality and longevity. Each component plays a crucial role in ensuring efficient operation and achieving the desired results. By understanding the individual parts, users can better maintain their equipment and troubleshoot any issues that may arise.

Main Elements of the Cutting Tool

- Motor: The heart of the device, responsible for powering the entire mechanism.

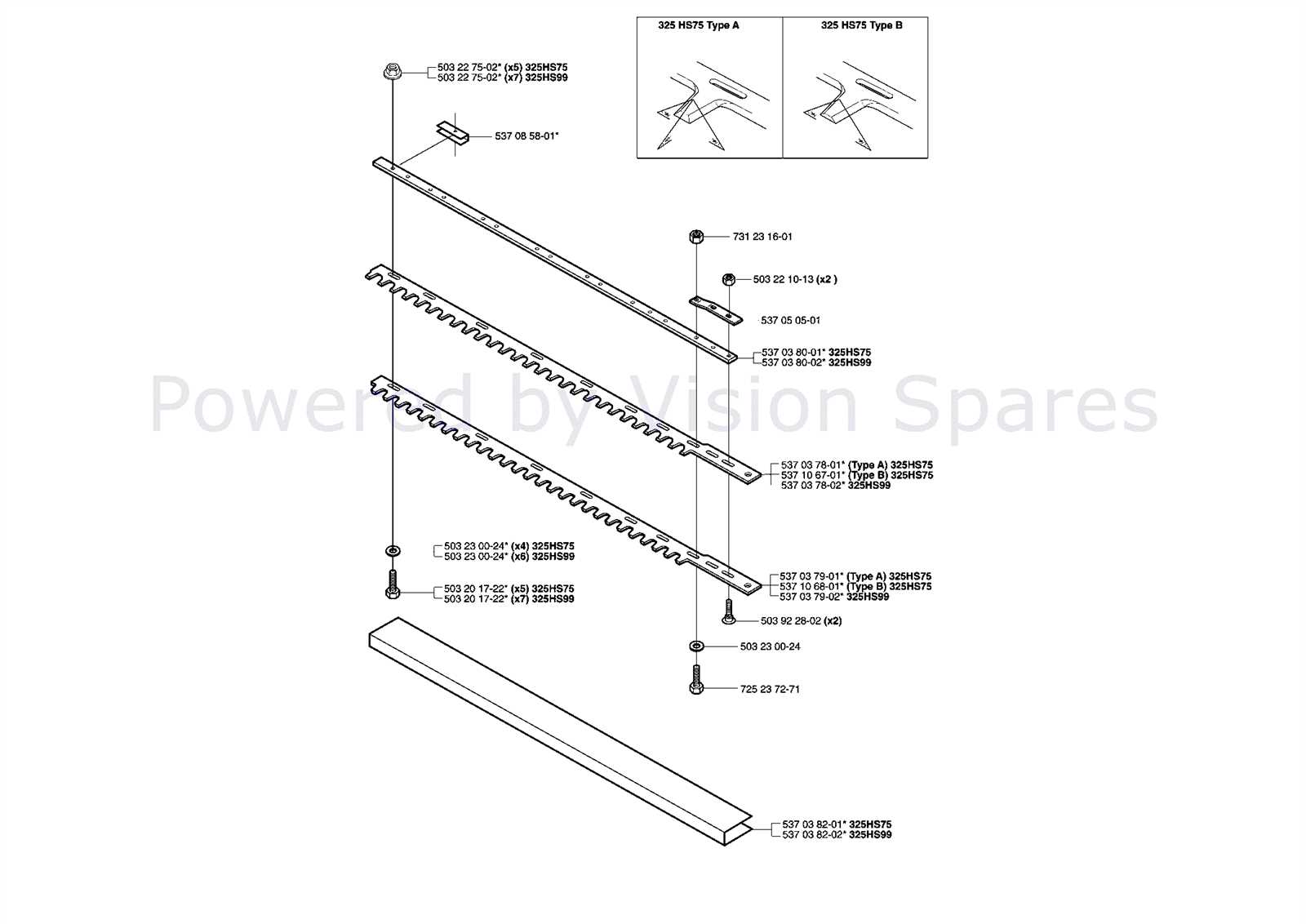

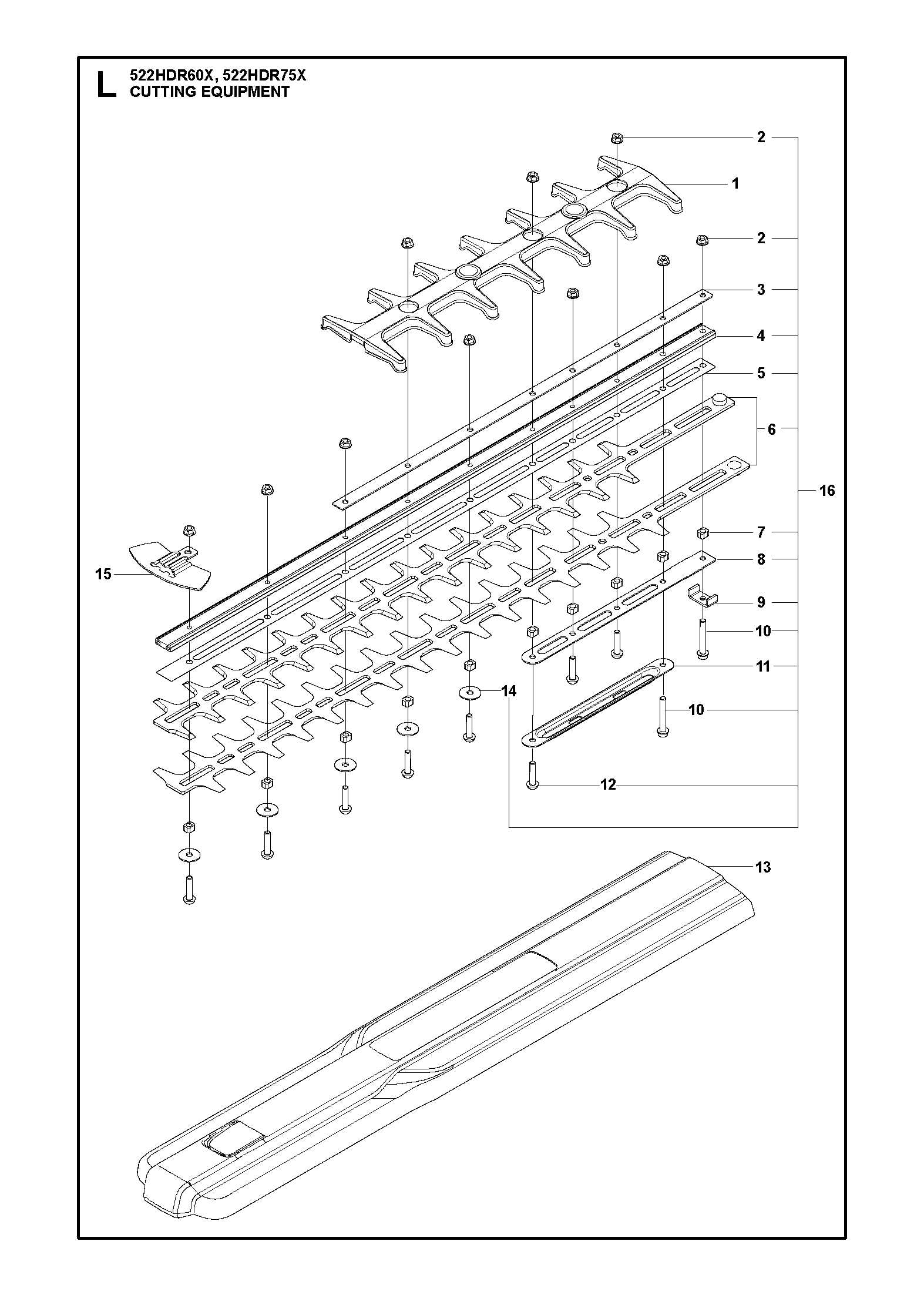

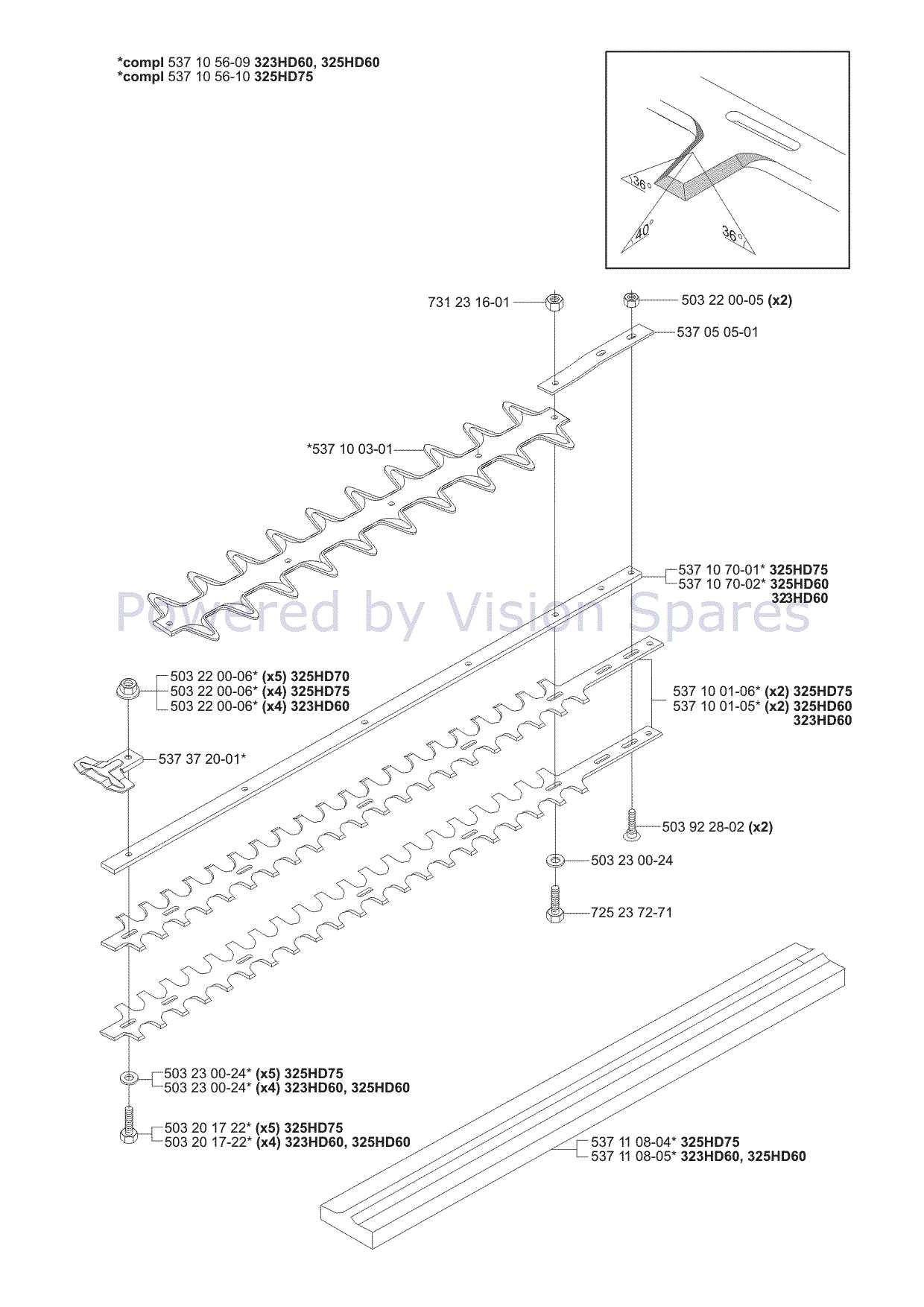

- Blades: Sharp edges that perform the cutting action, available in different shapes for varied tasks.

- Handle: The grip area that provides control and stability during use.

- Trigger: The mechanism that activates the motor and blades when pressed.

- Safety Switch: A feature designed to prevent accidental activation, enhancing user safety.

Maintenance Considerations

Regular upkeep of the components is essential for optimal performance. Key practices include:

- Cleaning the blades to prevent rust and sap buildup.

- Inspecting the motor for any signs of wear or damage.

- Ensuring that all fasteners are secure to avoid malfunction during operation.

- Lubricating moving parts to reduce friction and extend the lifespan of the tool.

By prioritizing the maintenance of these crucial elements, users can ensure a reliable and effective experience with their cutting equipment.

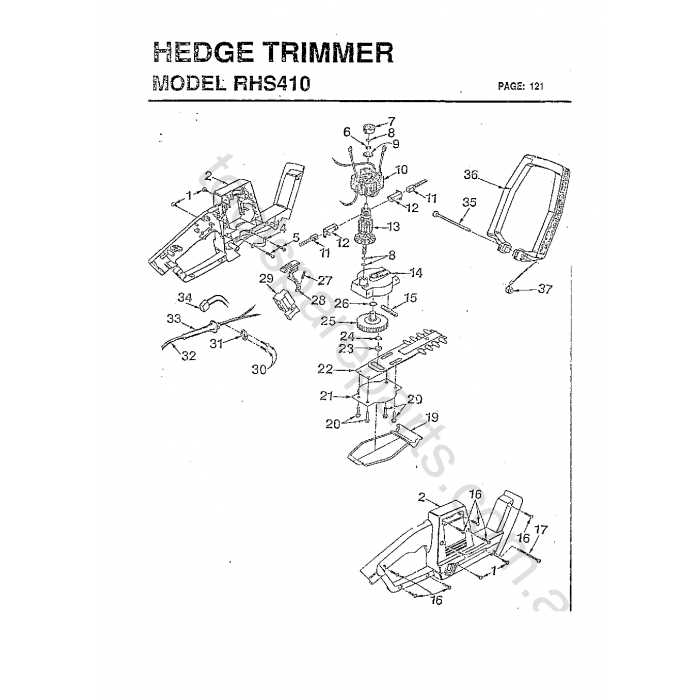

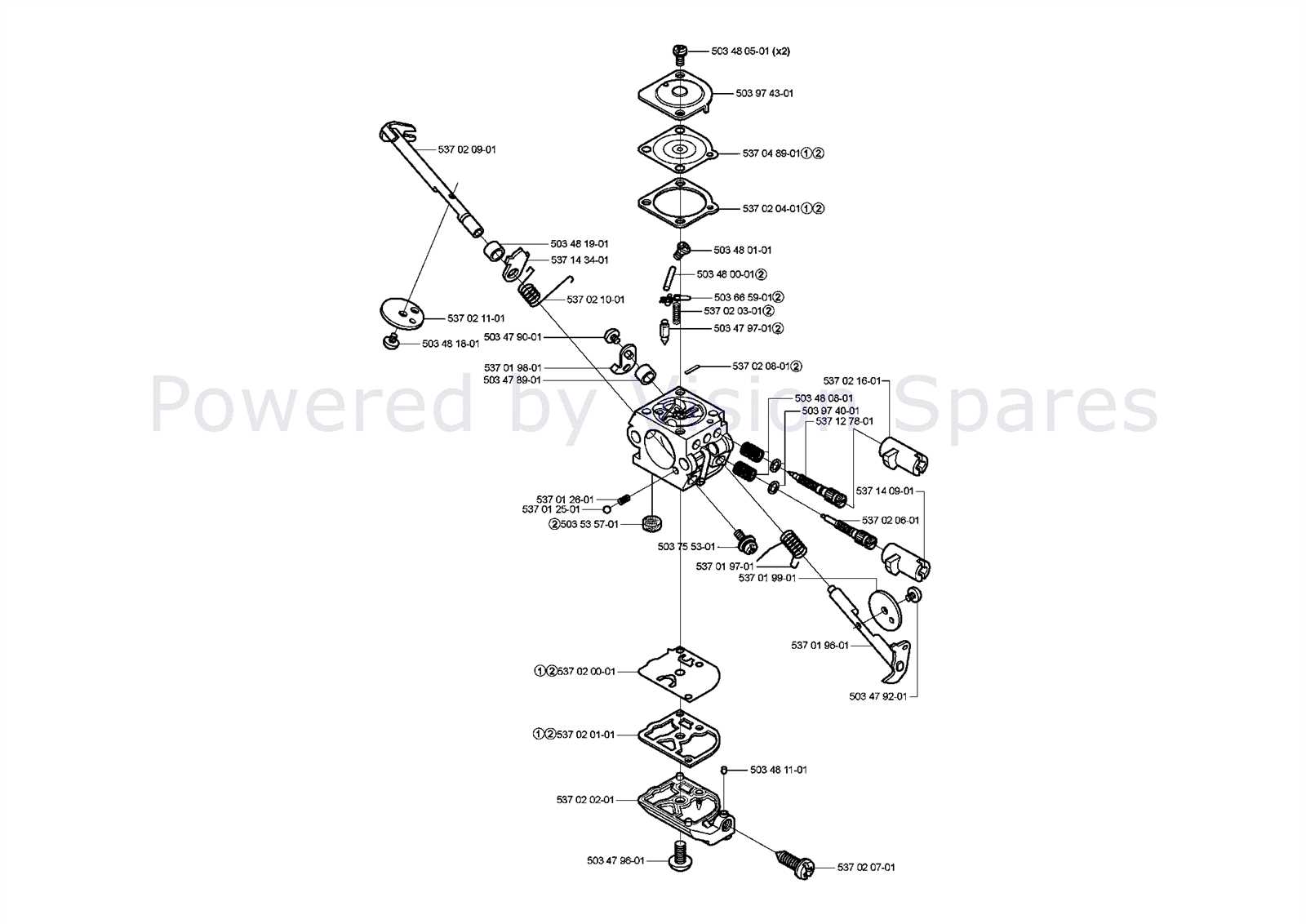

Essential Parts of Husqvarna Models

This section highlights the crucial components that contribute to the efficient functioning of various models. Understanding these elements is vital for maintenance and optimal performance, ensuring longevity and reliability during use.

Key Components

- Motor: The heart of the device, providing the necessary power for operation.

- Blades: Sharp, durable implements designed for effective cutting and shaping.

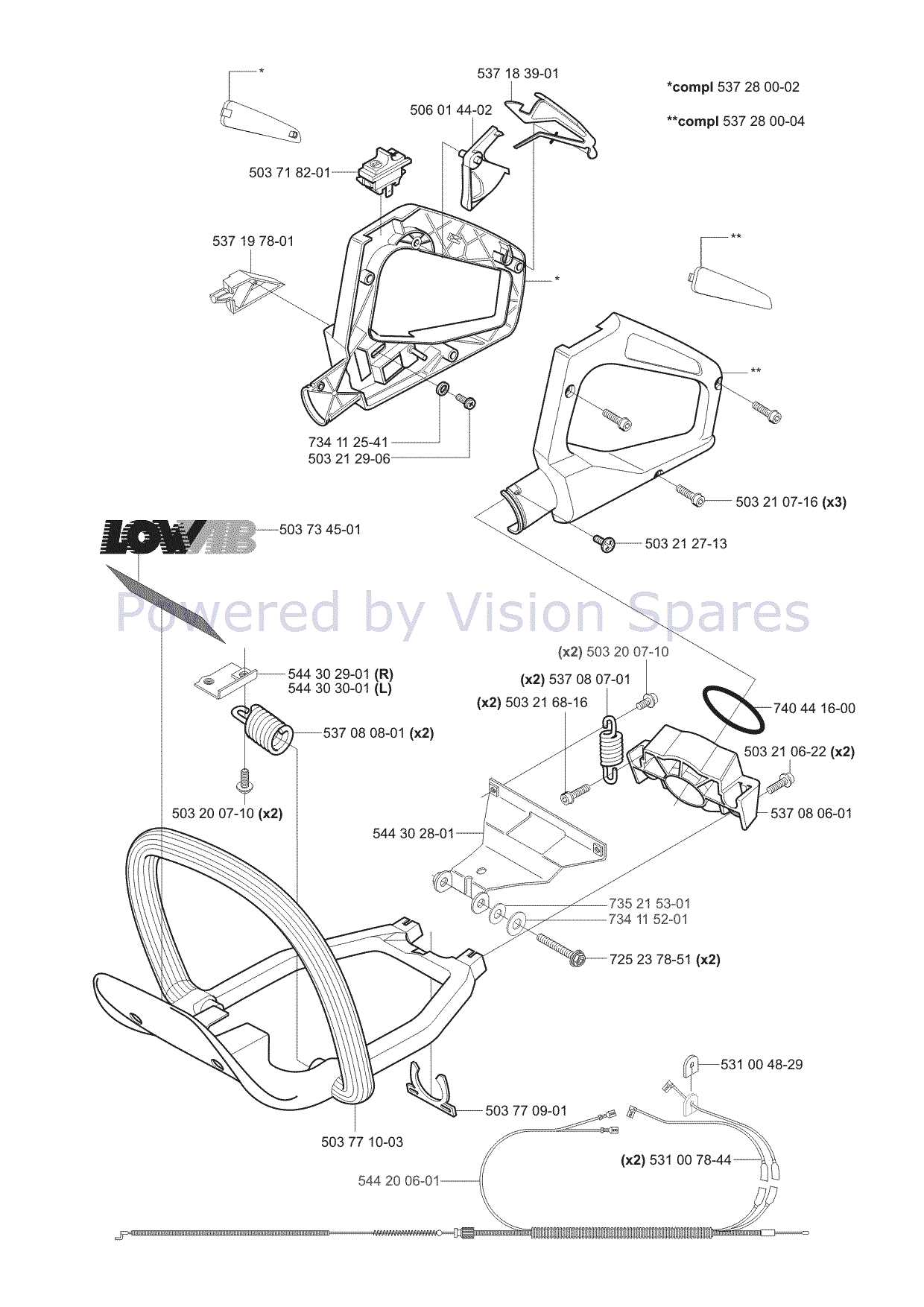

- Handle: Ergonomically designed for comfort and control during operation.

- Guard: A protective feature that ensures safety while working.

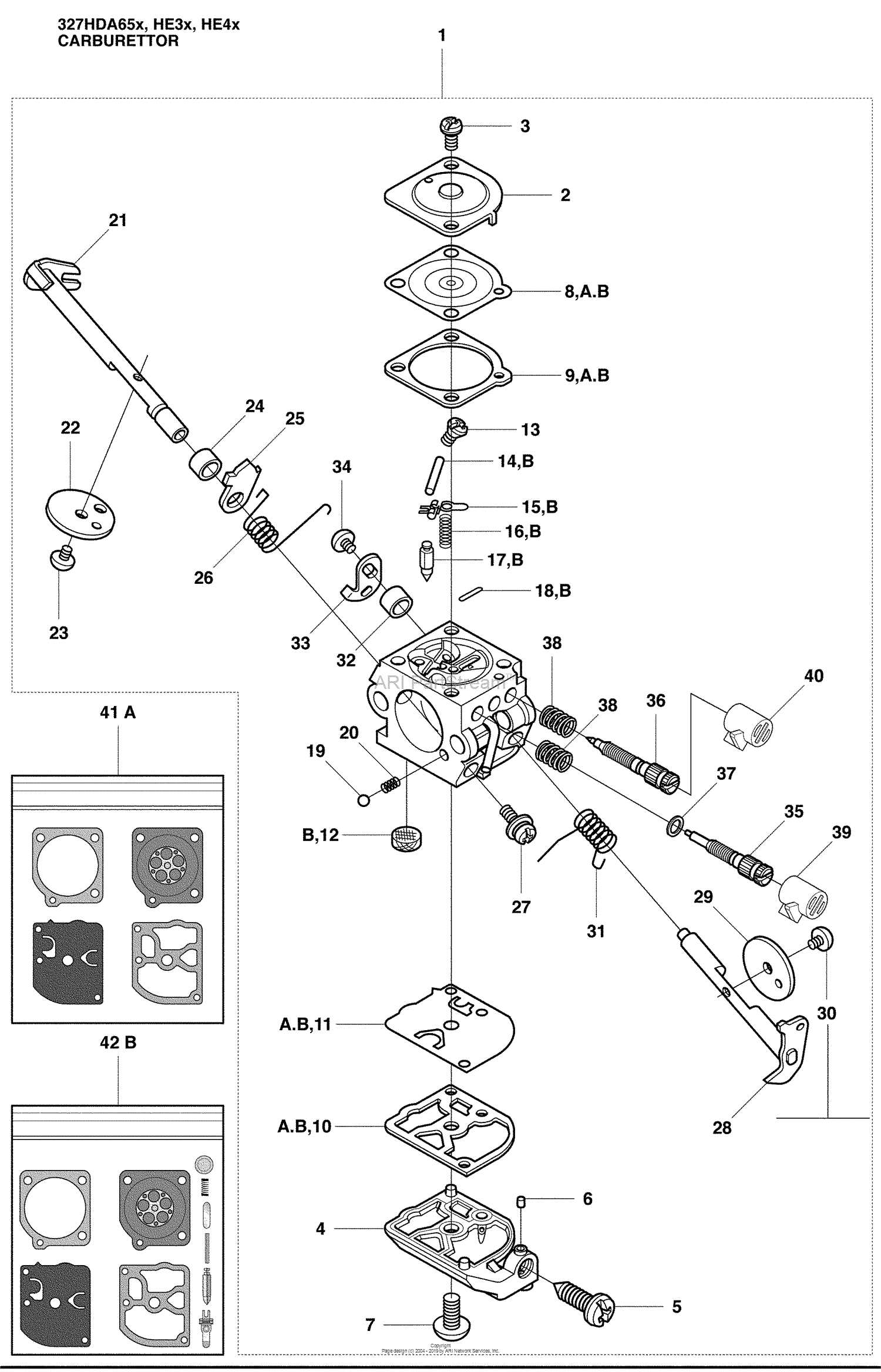

- Fuel System: Includes the tank and delivery mechanism, essential for powering the engine.

Additional Features

- Switch: Enables easy start and stop, enhancing user convenience.

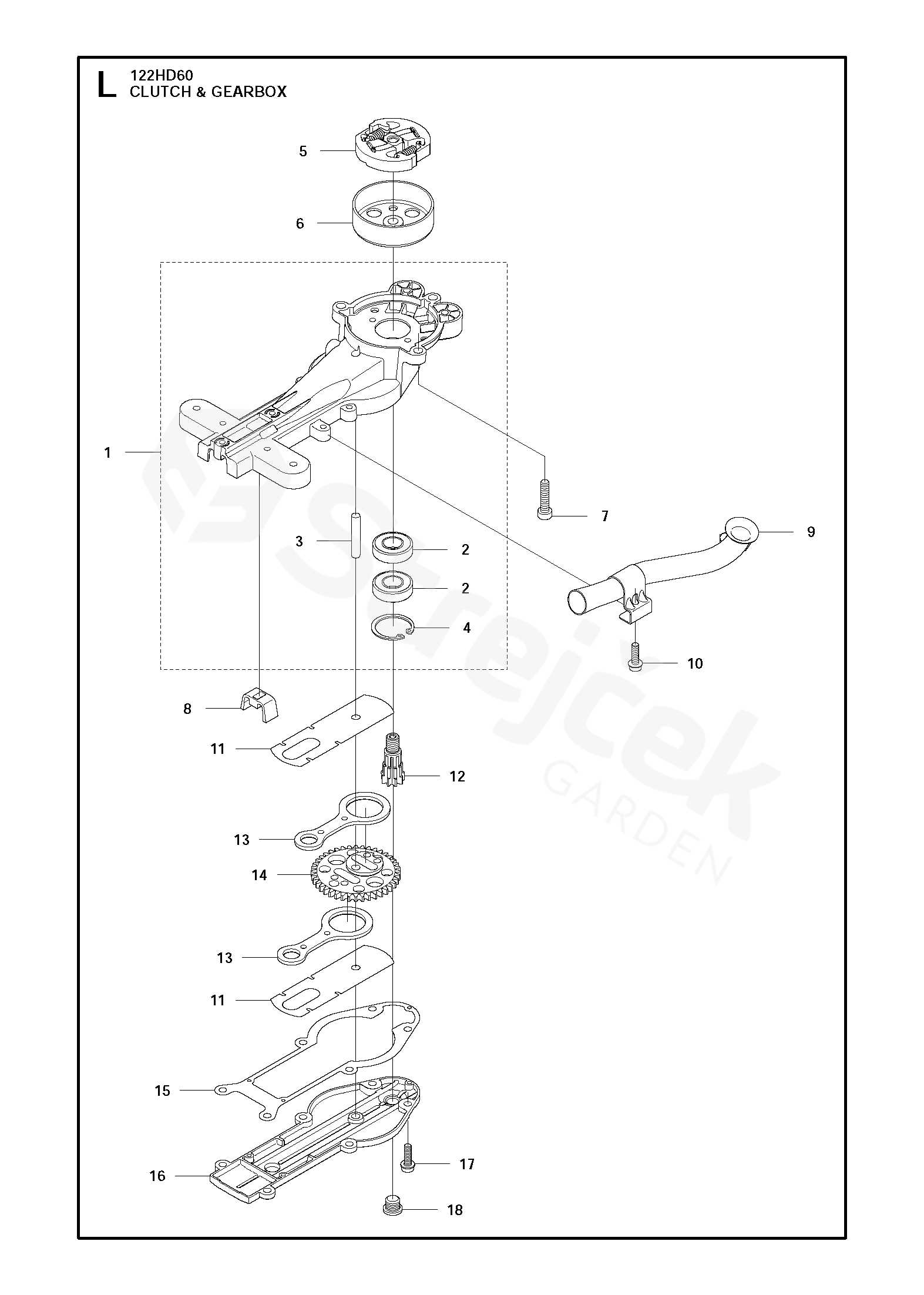

- Gearbox: Transmits power from the motor to the cutting blades, influencing performance.

- Vibration Dampers: Reduce fatigue during extended use by minimizing vibrations felt by the operator.

- Air Filter: Keeps contaminants out of the engine, ensuring efficient operation.

- Chassis: The structural frame that houses and supports all components, providing stability.

Identifying Key Trimmer Features

Understanding the essential components of a cutting device is crucial for effective operation and maintenance. Each feature plays a significant role in the overall functionality and efficiency, influencing the performance and user experience. Recognizing these attributes can help in making informed choices when selecting or servicing such equipment.

Blade Types and Their Benefits

The type of blade employed greatly affects the efficiency of the tool. Various designs cater to different applications, offering distinct advantages. Here are some common blade types:

| Blade Type | Description | Benefits |

|---|---|---|

| Dual-Sided | Features blades on both sides for bi-directional cutting. | Increases cutting speed and versatility. |

| Single-Sided | Contains blades on one side, typically designed for precision work. | Offers greater control and is ideal for shaping. |

| Laser-Cut | Utilizes advanced technology for precise cutting edges. | Enhances durability and reduces friction. |

Motor Specifications

The motor’s characteristics determine the power and efficiency of the device. Understanding the differences can help in selecting the right model for specific needs:

| Motor Type | Description | Advantages |

|---|---|---|

| Electric | Powered by electricity, usually quieter and lighter. | Low maintenance and environmentally friendly. |

| Gas-Powered | Uses a fuel mixture for operation, providing high mobility. | Offers greater power and longer operational times. |

Maintenance Tips for Longevity

Proper upkeep of outdoor equipment is essential for ensuring its efficiency and extending its lifespan. By adopting regular maintenance practices, users can minimize wear and tear, ultimately leading to improved performance and reduced repair costs.

First, regularly inspect the device for any signs of damage or wear. This includes checking the cutting components and ensuring they are sharp and free from obstructions. Dull blades can not only hinder performance but also increase the risk of injury.

Next, clean the unit thoroughly after each use. Removing debris, dirt, and sap can prevent buildup that may affect functionality. Pay special attention to air vents and filters, as clogged areas can lead to overheating and decreased efficiency.

Lubrication is also a crucial aspect of maintenance. Applying the appropriate lubricant to moving parts will reduce friction and help prevent premature wear. Ensure to follow the manufacturer’s guidelines for recommended lubricants and application frequency.

Lastly, store the equipment in a dry, sheltered location when not in use. Exposure to harsh weather conditions can accelerate deterioration, so keeping it in a controlled environment will protect it from rust and corrosion.

Common Issues and Solutions

In the realm of garden maintenance equipment, various challenges may arise, impacting performance and efficiency. Understanding these frequent problems and their remedies can significantly enhance the lifespan and functionality of the tools.

Frequent Performance Issues

One of the most common challenges is a lack of power or inadequate cutting capability. This issue can stem from a dull blade or an obstructed motor. Regularly inspecting the blade for sharpness and clearing any debris from the motor area can help restore optimal performance.

Starting Difficulties

Difficulty in starting the device often frustrates users. This may be due to fuel problems, such as stale fuel or incorrect fuel-to-oil ratios. Ensuring fresh fuel and adhering to the manufacturer’s recommendations can resolve these issues. Additionally, checking the ignition system for faults can prevent further starting complications.

How to Access Replacement Parts

Finding suitable components for your garden equipment can greatly enhance its performance and longevity. Whether you are repairing a malfunction or upgrading features, knowing how to locate the necessary items is essential for maintaining your tools effectively.

Here are some steps to guide you through the process:

- Identify the Model:

- Check the manufacturer’s label for the model number.

- Take note of the specific features and configurations of your equipment.

- Refer to the user manual for a list of compatible components.

- Look for a section that outlines troubleshooting and replacement information.

- Visit the official website of the manufacturer for direct links to authorized dealers.

- Utilize reputable online marketplaces to search for the required components.

- Find local hardware stores that specialize in gardening equipment.

- Inquire about the availability of specific items from their inventory.

- Research third-party suppliers that offer compatible components.

- Read reviews to ensure quality and reliability.

By following these steps, you can effectively source the necessary components to keep your garden equipment in optimal condition.

Tools Needed for Repairs

Effective maintenance and repair of garden equipment require specific tools to ensure efficient and safe operation. Having the right instruments on hand can significantly simplify the process, minimize downtime, and enhance the overall quality of the work. Below is a list of essential tools that are commonly utilized for repairs.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening and tightening various screws found in equipment.

- Wrenches: Adjustable and socket wrenches are important for securing nuts and bolts.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires.

- Replacement Blades: Keep a variety of replacement blades to ensure optimal cutting performance.

- Lubricants: Appropriate lubricants help maintain moving parts and prevent wear and tear.

- Cleaning Supplies: Brushes and cloths are needed to remove debris and keep equipment clean.

- Protective Gear: Safety glasses and gloves should be worn to protect against potential hazards during repairs.

Equipping yourself with these tools will not only facilitate smoother repairs but also contribute to the longevity of your equipment.

Exploring Safety Mechanisms

Ensuring user protection is a fundamental aspect of any outdoor equipment. Various systems are incorporated to minimize risks during operation, aiming to provide a secure experience while maximizing efficiency. These safety features are designed to prevent accidents and protect users from potential hazards associated with power tools.

Key Safety Features

Among the essential safety attributes, blade guards play a crucial role by shielding users from accidental contact with cutting elements. Additionally, the presence of an automatic shut-off mechanism can effectively halt operation in emergencies, significantly reducing the chance of injury. These features work in tandem to create a safer working environment.

Operational Guidelines

Adhering to proper handling techniques is equally important for maintaining safety. Operators are advised to familiarize themselves with the equipment’s safety protocols and to wear appropriate protective gear. Regular maintenance checks are also vital, as they ensure that all safety mechanisms function correctly and efficiently, thereby enhancing the overall security of the tool.

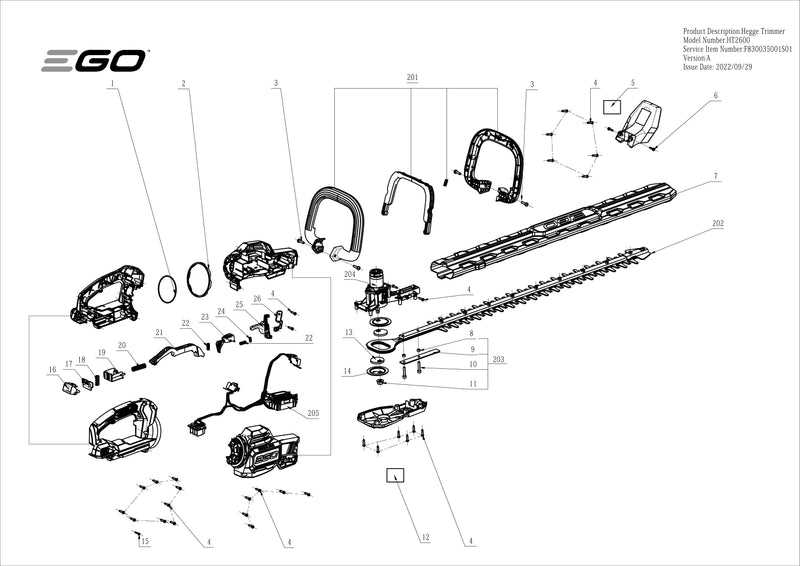

Comparing Different Model Diagrams

When exploring various versions of cutting equipment, understanding the distinct components and their arrangement is essential for optimal performance. Each model may feature unique elements that cater to different tasks, making it crucial to analyze how these variations impact usability and functionality.

This section presents a comparative overview of several models, highlighting key differences in their configurations. By examining these elements, users can make informed decisions about which equipment best meets their needs.

| Model | Component A | Component B | Component C |

|---|---|---|---|

| Model 1 | Type X | Type Y | Type Z |

| Model 2 | Type A | Type B | Type C |

| Model 3 | Type M | Type N | Type O |

Evaluating these configurations allows for a clearer understanding of each model’s strengths and weaknesses. Such insights facilitate a more effective choice based on individual requirements and preferences.

Upgrading Your Trimmer Effectively

Enhancing the efficiency and performance of your cutting tool can significantly improve your gardening experience. By focusing on key components and making strategic modifications, you can achieve better results and prolong the life of your equipment.

Consider the following approaches to elevate the functionality of your machine:

- Invest in Quality Blades: Upgrading to high-quality blades can improve cutting efficiency and reduce wear.

- Utilize Advanced Fuel Options: Experiment with premium fuels to enhance engine performance and longevity.

- Implement Ergonomic Features: Adding accessories that improve grip and reduce vibrations can make operation more comfortable.

- Regular Maintenance: Establish a routine for cleaning and servicing your equipment to ensure optimal performance.

These enhancements can transform your tool into a more effective asset in your landscaping tasks, enabling smoother operation and achieving precise cuts with ease.