The functionality of garden maintenance devices relies on a variety of essential components, each playing a pivotal role in ensuring efficient performance. A clear representation of these elements can significantly enhance the user’s understanding and maintenance practices, leading to improved longevity and reliability of the equipment.

By examining the layout of these critical components, users can identify specific elements that may require attention or replacement. This knowledge empowers owners to perform routine checks and repairs, promoting a seamless experience when using their garden maintenance devices.

Furthermore, familiarizing oneself with the intricate workings of these tools fosters a deeper appreciation for their design and engineering. This insight not only aids in troubleshooting but also encourages more effective usage, ultimately contributing to a well-maintained outdoor space.

Understanding Husqvarna Trimmer Components

Familiarizing oneself with the various elements of a grass cutting device can greatly enhance its functionality and maintenance. Each component plays a vital role in the overall performance, contributing to efficiency and ease of use. Recognizing these elements allows users to troubleshoot issues effectively and perform necessary repairs or replacements.

Power Source: The energy source is essential for driving the cutting mechanism. Whether powered by electricity or fuel, this component determines the device’s operational capability.

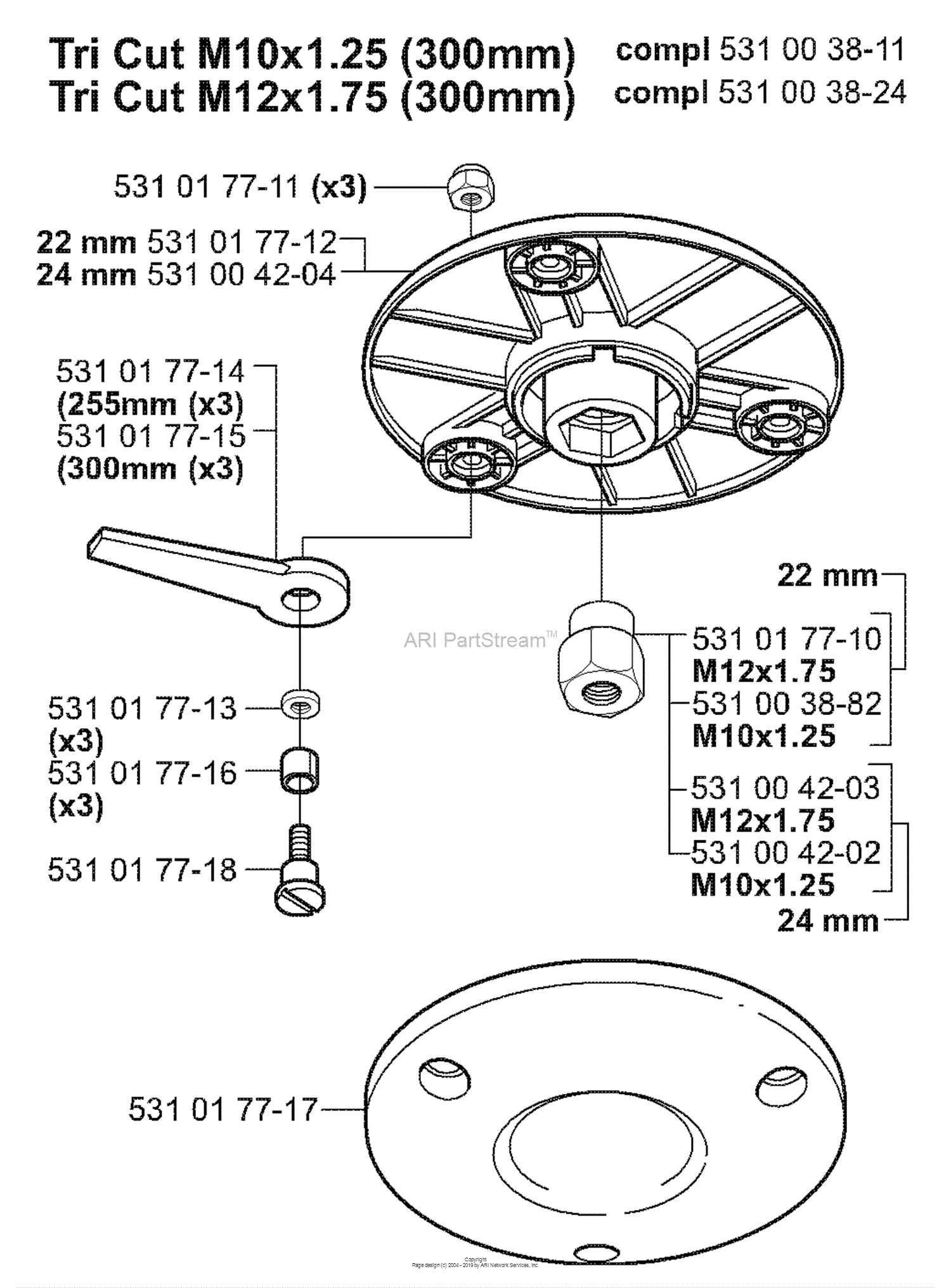

Cutting Head: This section contains the blades or line responsible for trimming vegetation. Understanding its design and function is crucial for achieving the desired results.

Handle: A well-designed grip is vital for comfort and control during operation. It also impacts the overall maneuverability of the device.

Safety Features: Safety mechanisms are integrated to protect the user from potential hazards. Knowing how these features work ensures a safer experience.

By gaining insight into these elements, users can optimize their experience and extend the lifespan of their grass cutting device.

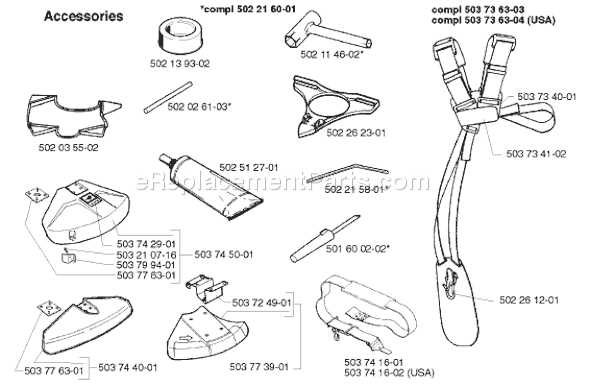

Parts Identification and Functions

Understanding the various components of a cutting tool is essential for effective operation and maintenance. Each element plays a specific role, contributing to the overall performance and efficiency of the equipment.

Key components include:

- Motor: The power source that drives the tool.

- Shaft: Connects the motor to the cutting mechanism, transmitting power.

- Cutting Head: Houses the blade or line, designed to execute the cutting action.

- Handle: Provides grip and control for the user during operation.

- Guard: Ensures safety by protecting the user from debris and accidental contact with the cutting element.

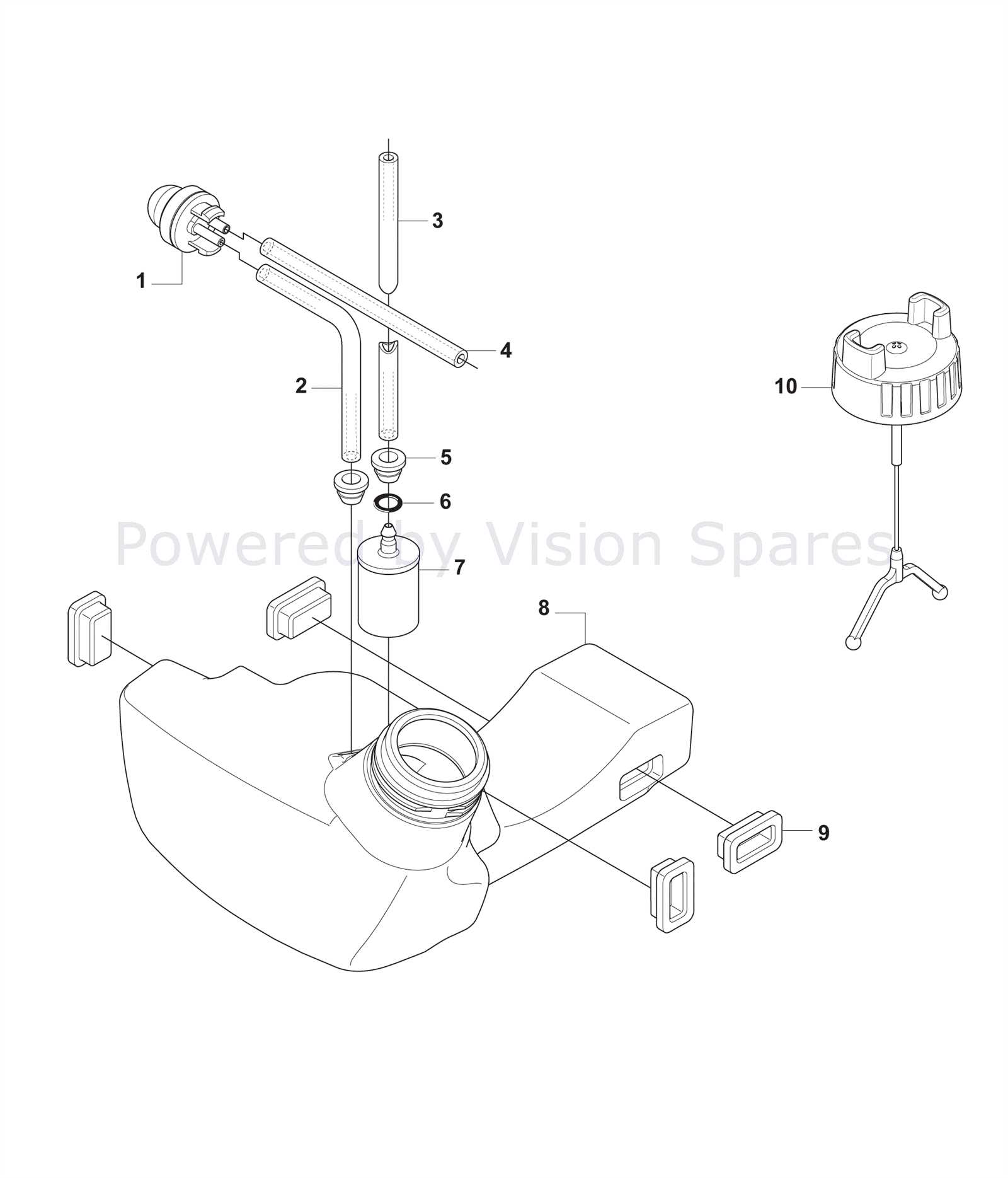

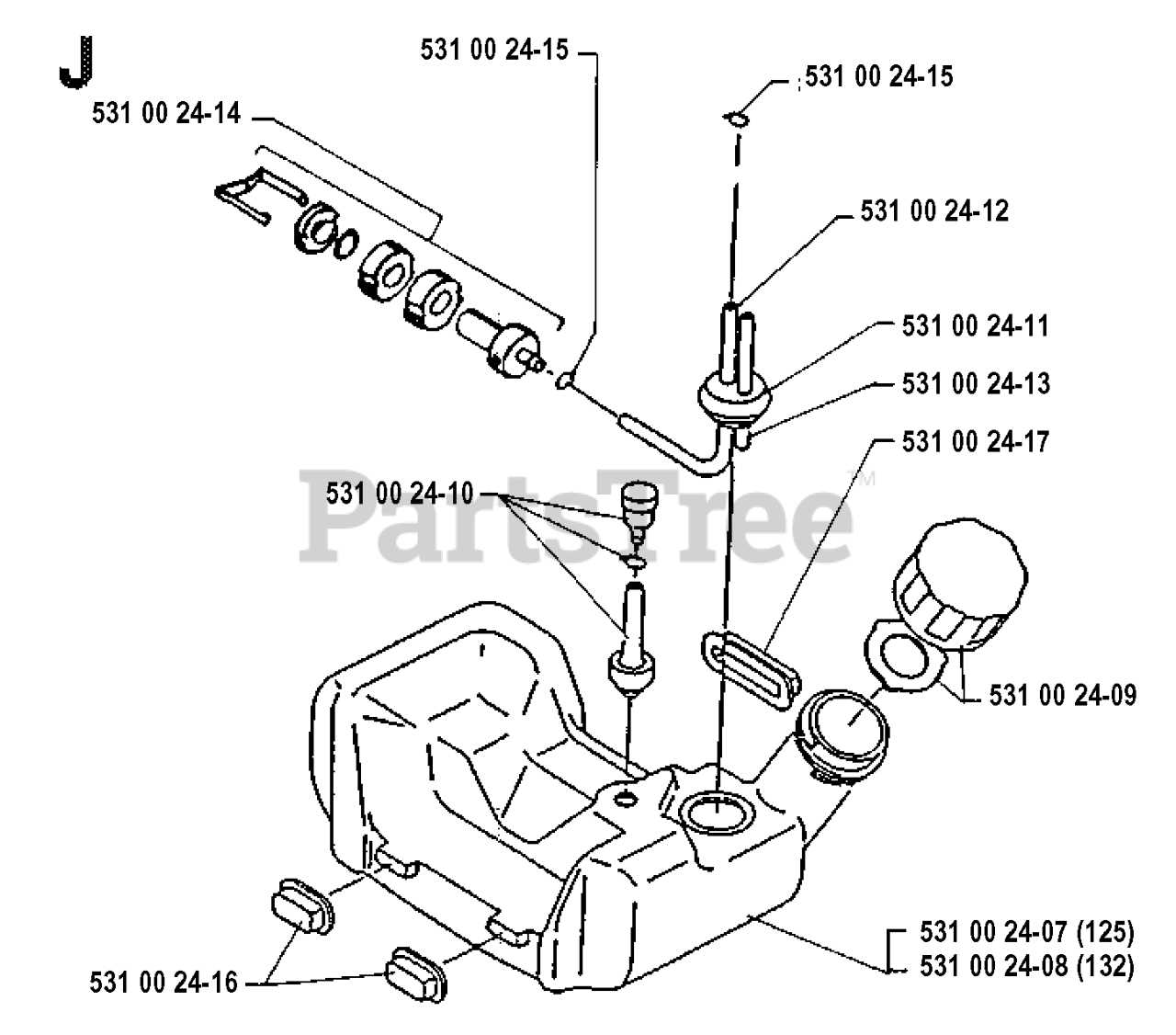

- Fuel Tank: Stores the necessary fuel for operation, crucial for functionality.

Each of these components has a specific function, contributing to the efficiency and safety of the tool. Regular inspection and understanding of these parts can aid in identifying issues and ensuring optimal performance.

Common Issues with Trimmer Parts

When using gardening tools, certain challenges may arise that can hinder their performance. Understanding these common difficulties can help users maintain their equipment effectively and ensure optimal functioning.

Frequent Performance Problems

One of the most prevalent issues involves the tool’s inability to start or function properly. This can result from various factors, including fuel quality, spark plug condition, or air filter blockage. Regular maintenance is essential to avoid these complications and prolong the lifespan of the equipment.

Wear and Tear of Components

Over time, components can become worn out due to continuous use. This wear can lead to reduced efficiency and may require replacement parts to restore optimal performance. Regular inspection of these elements is vital, as it allows for early detection of potential issues and helps maintain the effectiveness of the machinery.

Maintenance Tips for Longevity

Ensuring the durability and effectiveness of your gardening tool requires regular upkeep and attention. By following a few straightforward practices, you can significantly enhance the lifespan of your equipment while maintaining optimal performance. Consistent maintenance not only prevents wear and tear but also promotes efficiency in usage.

Regular Cleaning

After each use, it’s essential to clean your tool thoroughly. Remove any debris, dirt, or grass clippings that may have accumulated. This prevents buildup that can lead to malfunctions. Utilize a brush or a cloth to wipe down surfaces, ensuring that all components are free from contaminants.

Inspecting Components

Frequent inspections of various elements are crucial. Look for signs of damage, wear, or loosening connections. Pay special attention to the cutting edge and any moving parts. Replacing worn components promptly can prevent further damage and enhance overall functionality.

How to Replace Worn Components

Maintaining your equipment involves regularly replacing components that show signs of wear. This process ensures optimal performance and prolongs the lifespan of your device. Here are the steps to effectively replace these components.

- Identify the Worn Parts:

Examine your equipment for signs of damage or wear, such as:

- Fraying or broken components

- Decreased performance during operation

- Unusual noises or vibrations

- Gather Necessary Tools:

Before starting the replacement, ensure you have the following tools on hand:

- Screwdrivers (flathead and Phillips)

- Replacement components

- Wrench set

- Safety gloves

- Disassemble the Equipment:

Carefully disassemble the machine by following these steps:

- Turn off the power and unplug the device.

- Remove any outer covers or casings to access the internal components.

- Keep track of screws and parts to avoid losing them.

- Replace the Components:

Once you have access to the interior, proceed to replace the worn components:

- Carefully remove the damaged parts.

- Install the new components, ensuring they fit securely.

- Reassemble the Equipment:

After the replacement, reassemble the device by following these steps:

- Replace any covers or casings.

- Tighten all screws and ensure everything is secure.

- Test the Equipment:

Finally, plug in the device and perform a test run to ensure everything operates smoothly.

Trimmer Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures involved in putting together and taking apart a cutting device. Understanding these processes is essential for maintaining optimal performance and ensuring the longevity of the equipment. Proper assembly and disassembly techniques can prevent damage and facilitate easier repairs.

Assembly Steps:

- Begin by gathering all components necessary for assembly, including the body, cutting head, and handle.

- Securely attach the handle to the main body, ensuring all fasteners are tightened to prevent any looseness during operation.

- Install the cutting head, aligning it with the designated slots and ensuring it is firmly in place.

- Check that all connections are secure and conduct a visual inspection for any misalignments.

Disassembly Steps:

- Start by removing the cutting head, carefully loosening it from its position.

- Detach the handle from the main body, ensuring not to damage any connectors.

- Store all components in a safe location to prevent loss and damage during maintenance.

- Conduct a thorough inspection of all parts for wear and tear, preparing for any necessary replacements.

Final Note: Always refer to the user manual for specific instructions tailored to your equipment model. Following these guidelines ensures safe handling and effective performance during use.

Choosing the Right Replacement Parts

Selecting appropriate components for your outdoor equipment is essential for optimal performance and longevity. When it comes to replacements, ensuring compatibility and quality can significantly impact functionality. Understanding the various types of components available and their specific roles can help you make informed decisions.

Identifying Compatibility

Compatibility is crucial when sourcing new components. Always check specifications and model numbers to confirm that the chosen items align with your equipment. Mismatched components can lead to inefficiencies or even damage.

Quality and Durability

Investing in high-quality components can save you time and money in the long run. Look for reputable brands that offer durable materials and reliable performance. Read reviews and seek recommendations to find trustworthy options that will withstand regular use.

Tools Required for Repairs

When it comes to maintaining outdoor equipment, having the right tools is essential for efficient repairs. This section outlines the various instruments and supplies that can assist in ensuring your machinery operates smoothly and effectively.

Below are the key tools you may need:

- Screwdrivers: Both flathead and Phillips screwdrivers are vital for loosening or tightening screws.

- Wrenches: A set of adjustable wrenches will help in managing nuts and bolts of different sizes.

- Socket Set: A complete socket set allows for better torque application on fasteners.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending tasks.

- Replacement Blades: Keeping spare cutting edges on hand is crucial for optimal performance.

- Fuel Mix Container: For those models that require a specific fuel mixture, a dedicated container is necessary.

- Cleaning Brush: A brush will help in removing debris and buildup from various components.

- Safety Gear: Always wear protective gloves and eyewear to ensure safety during repairs.

Having these tools readily available can make the repair process smoother and more effective, ultimately extending the life of your equipment.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance or repairs on equipment. Adhering to specific guidelines can help prevent accidents and injuries while promoting an efficient workflow. The following recommendations are designed to enhance safety during the repair process.

- Wear Protective Gear: Always use appropriate safety equipment, including gloves, goggles, and sturdy footwear, to minimize the risk of injuries.

- Work in a Well-Lit Area: Ensure that your workspace is adequately illuminated to see clearly and avoid potential hazards.

- Disconnect Power Sources: Before beginning any repair work, unplug the equipment or disconnect the battery to prevent accidental activation.

- Follow Manufacturer Instructions: Adhere to the guidelines provided by the manufacturer for safe handling and disassembly of components.

- Keep Work Area Organized: Maintain a clutter-free workspace to reduce the risk of tripping and to easily locate tools and parts.

- Stay Focused: Avoid distractions and remain attentive during repairs to prevent mistakes that could lead to injury.

By following these safety precautions, individuals can ensure a safer environment while maintaining or repairing their equipment.

Where to Find Genuine Parts

When seeking authentic components for your gardening equipment, it’s crucial to identify reliable sources. Genuine replacements ensure optimal performance and longevity, allowing you to maintain your tools effectively. Here are some recommended avenues to explore for acquiring original items.

Authorized Retailers

One of the most trustworthy options is to visit authorized dealers or retailers. These establishments are officially recognized by manufacturers and offer a range of genuine items. You can expect knowledgeable staff who can assist you in finding the right components for your specific model.

Online Marketplaces

Numerous online platforms specialize in offering original equipment. These websites often provide detailed descriptions, compatibility information, and customer reviews, making it easier to make informed decisions. Always ensure that the marketplace is reputable and has a return policy to safeguard your purchase.

Troubleshooting Tips for Cutting Tool Components

Addressing issues with various components of your cutting device can significantly enhance its performance and longevity. Understanding common problems and their solutions can save time and effort, ensuring that your equipment operates efficiently.

Here are some essential troubleshooting tips:

- Check for Wear and Tear:

- Inspect blades and cutting lines for signs of damage or dullness.

- Replace worn components promptly to maintain optimal cutting performance.

- Ensure Proper Assembly:

- Verify that all components are securely attached and correctly aligned.

- Refer to the manufacturer’s instructions for proper assembly guidelines.

- Examine Fuel and Oil Levels:

- Ensure that fuel is fresh and properly mixed, as stale fuel can lead to performance issues.

- Check oil levels to prevent overheating and ensure smooth operation.

- Inspect Air Filters:

- Clean or replace air filters regularly to maintain airflow and prevent overheating.

- Blocked air filters can lead to reduced efficiency and increased emissions.

- Monitor Vibration Levels:

- Excessive vibration may indicate misalignment or imbalance in the cutting mechanism.

- Address vibration issues immediately to avoid further damage.

Implementing these troubleshooting strategies can help maintain the functionality and efficiency of your cutting equipment, allowing for a smoother operation and improved results.