When it comes to maintaining outdoor machinery, a thorough comprehension of its components is essential. Each segment plays a crucial role in ensuring optimal performance and longevity. Familiarizing oneself with these elements can significantly enhance the efficiency of your device, preventing unnecessary breakdowns and prolonging its life.

In this section, we will explore the various elements that make up your gardening tool. By understanding how each part functions and interrelates, you can more effectively troubleshoot issues and perform maintenance tasks. This knowledge not only empowers you to care for your equipment better but also helps you make informed decisions when it comes to replacements or upgrades.

By delving into the intricate details of the assembly, you’ll gain insights into its design and operation. This understanding lays the groundwork for more advanced repairs and modifications, allowing you to maximize the effectiveness of your gardening endeavors. Let’s uncover the intricacies that lie within this essential machinery.

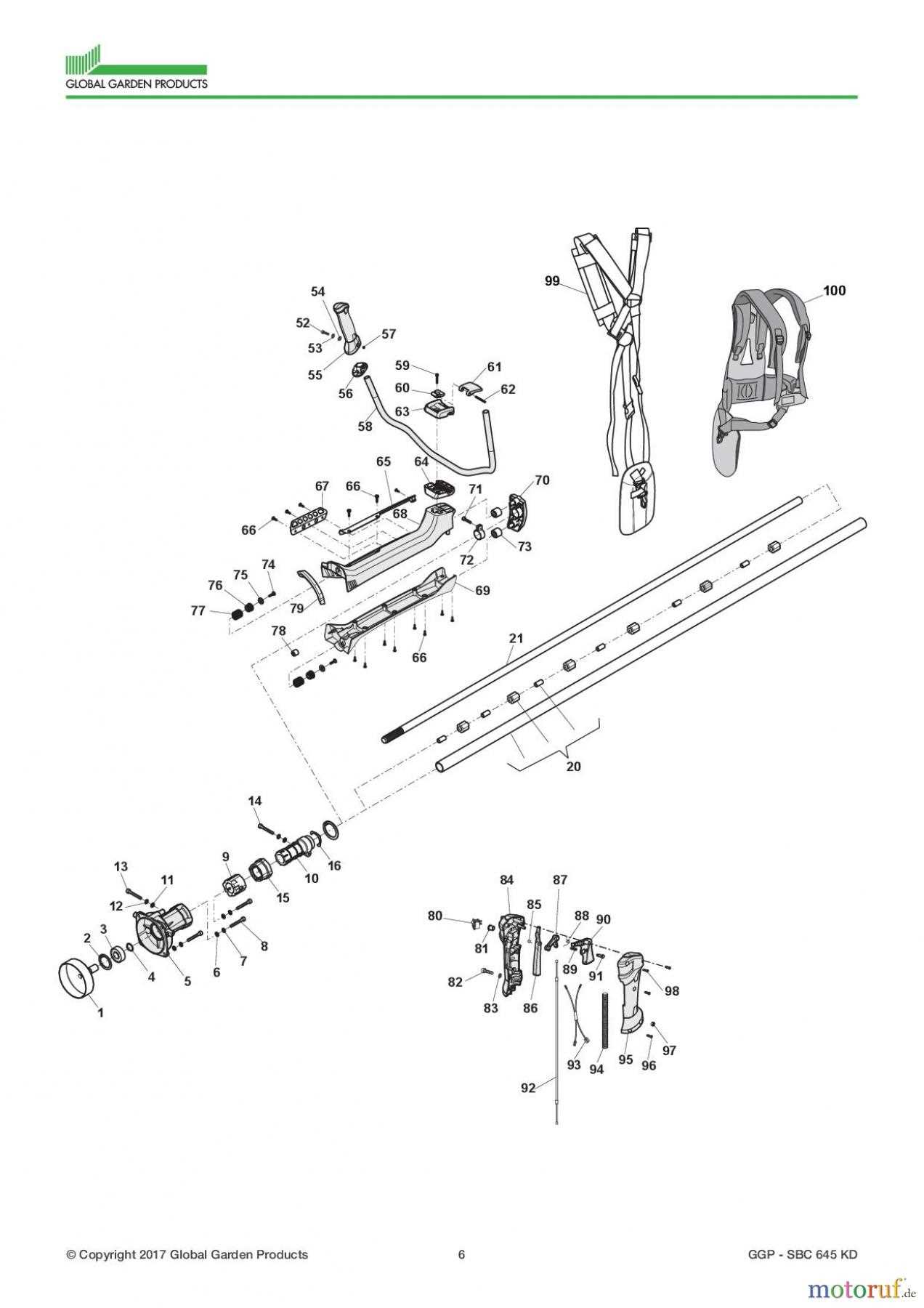

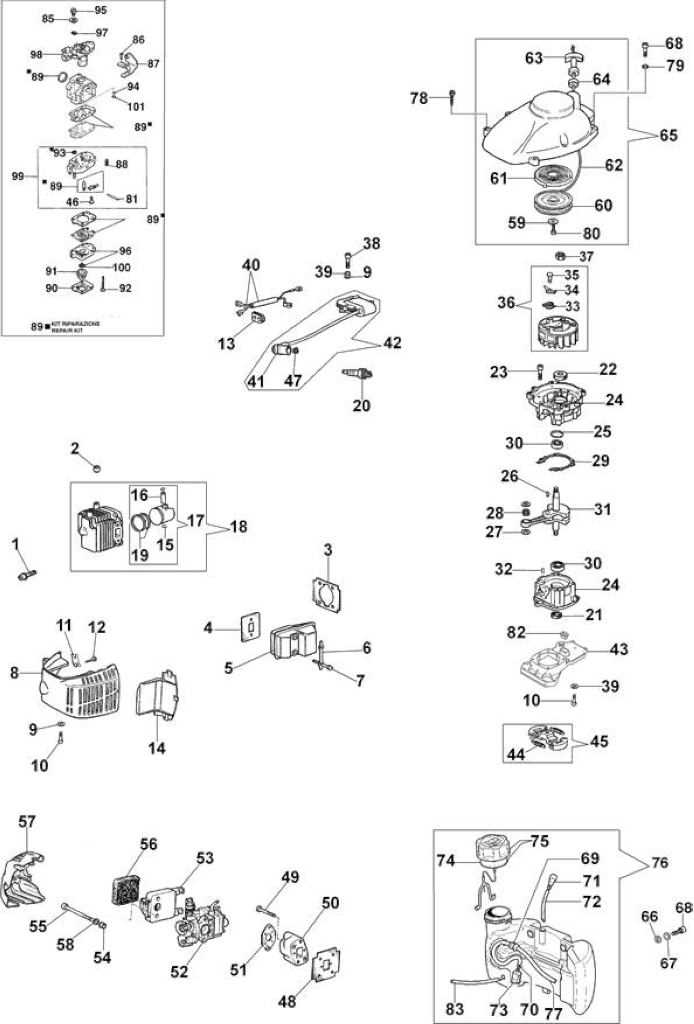

This section aims to provide a comprehensive overview of the various elements that make up a specific cutting tool, emphasizing their functions and importance in maintaining optimal performance. Understanding these components is crucial for effective operation and troubleshooting.

Key Elements of the Tool

- Engine: The heart of the device, responsible for generating power.

- Cutting Head: This component is essential for executing the trimming task efficiently.

- Shaft: Serves as the connection between the engine and the cutting head, facilitating power transfer.

- Handle: Provides user control and comfort during operation.

- Fuel System: Ensures the engine receives the necessary energy to function properly.

Maintaining Optimal Performance

Regular inspection and maintenance of these components can significantly enhance the longevity and efficiency of the device. Users are encouraged to familiarize themselves with the individual parts to address any potential issues promptly.

Overview of Trimmer Parts

This section provides an insightful look into the various components that make up a cutting tool designed for maintaining landscapes. Understanding these elements is essential for effective operation and maintenance.

Every model comprises several critical components, each serving a distinct purpose:

- Power Source: This is the engine or motor that provides the necessary energy to operate the equipment.

- Cutting Head: The part responsible for the actual cutting action, which can utilize different types of blades or lines.

- Handle: Offers the user control and maneuverability, allowing for precise cutting in various positions.

- Shaft: Connects the power source to the cutting head, transmitting energy efficiently.

- Safety Features: Include guards or shields that protect the user from debris during operation.

Familiarity with these components enhances the ability to troubleshoot and ensure optimal performance.

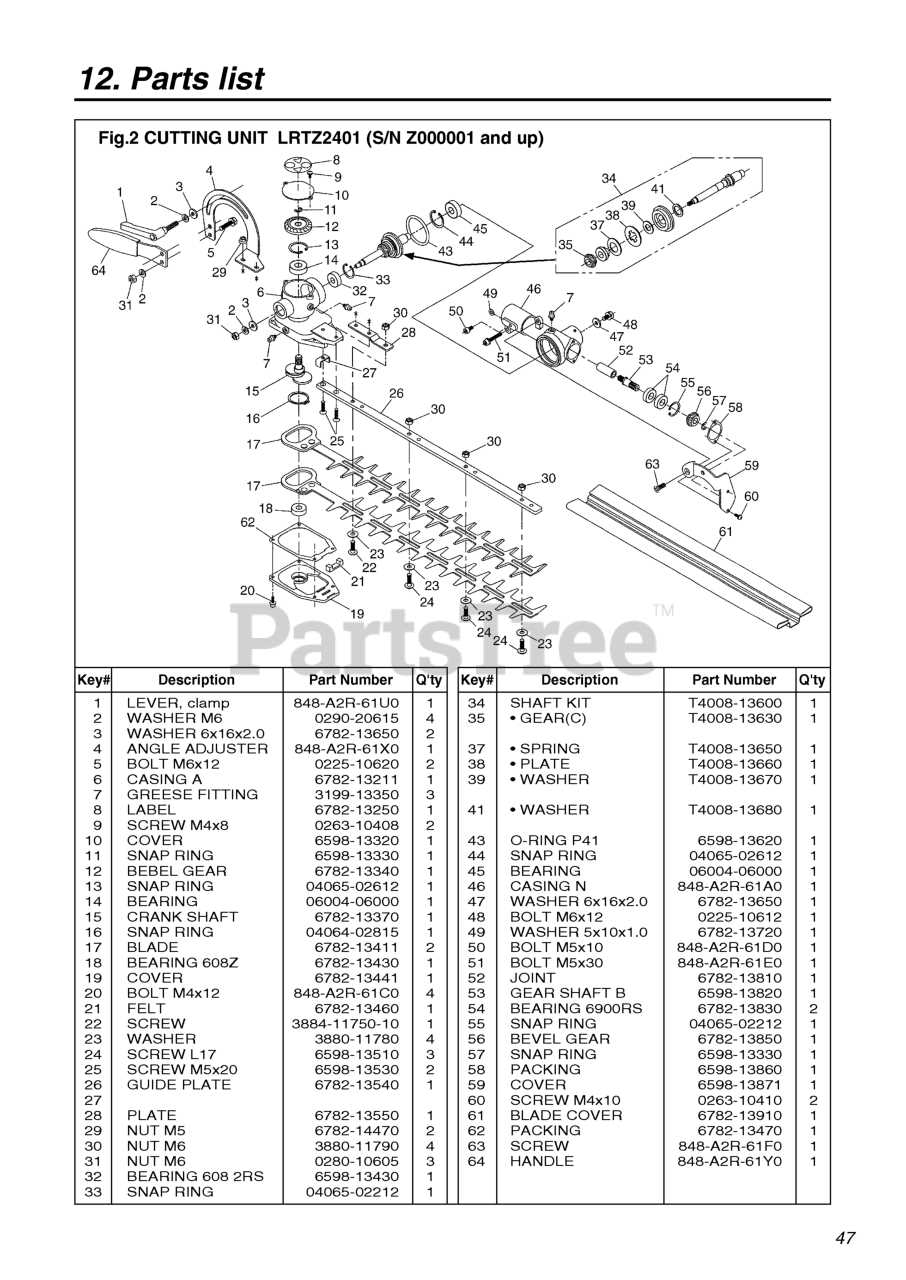

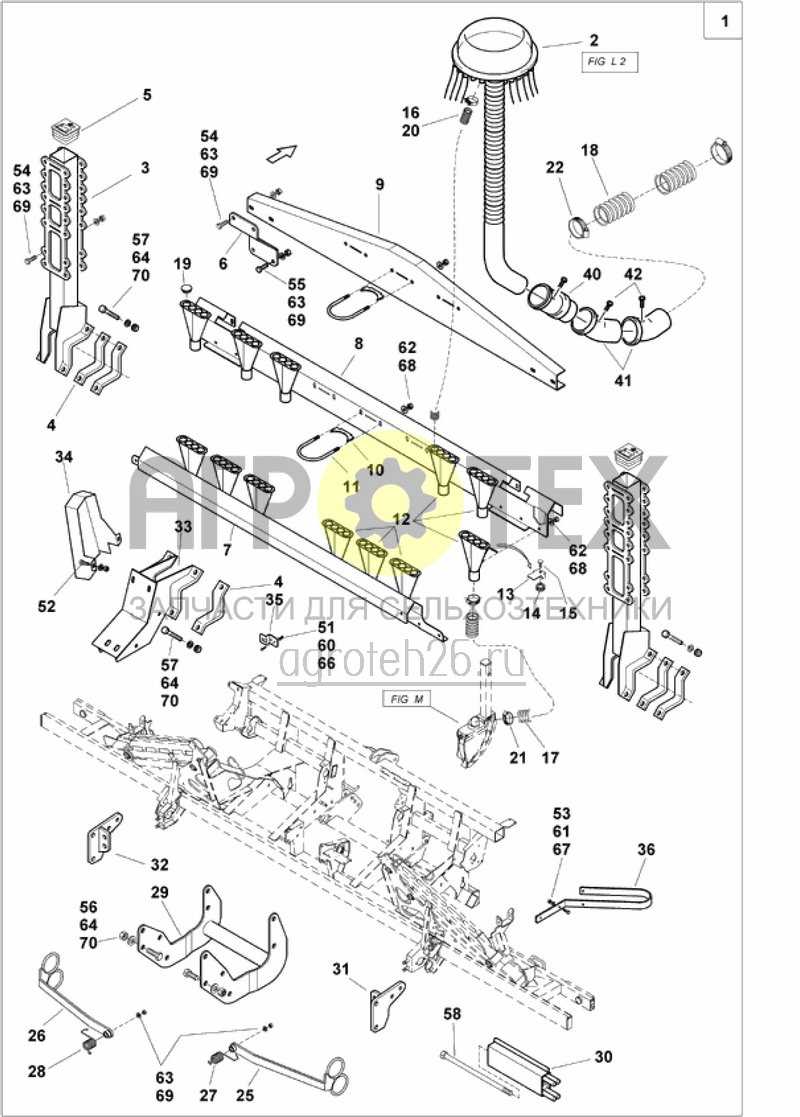

Importance of a Parts Diagram

Understanding the assembly and functioning of any mechanical device is crucial for maintenance and repair. A visual representation of components provides essential insights into how parts interact, making it easier to identify issues and perform replacements or adjustments effectively. This knowledge not only aids in troubleshooting but also enhances the efficiency of repairs, ensuring that equipment operates smoothly and reliably.

Enhanced Troubleshooting

When faced with a malfunction, having a clear overview of the components involved simplifies the diagnostic process. By referencing a visual guide, users can quickly pinpoint the source of the problem, reducing downtime and frustration. This clarity fosters a proactive approach to maintenance, enabling timely interventions before minor issues escalate.

Facilitating Replacement

Replacing worn or damaged components can be daunting without proper guidance. A visual representation assists users in identifying the correct parts needed for their specific models. This ensures compatibility and minimizes the risk of errors during the repair process, ultimately saving time and resources.

| Benefits | Description |

|---|---|

| Improved Diagnostics | Quick identification of issues and faulty components. |

| Efficient Repairs | Streamlined process for locating and replacing parts. |

| Resource Management | Prevention of unnecessary purchases and waste. |

Key Components of Redmax Trimmers

Understanding the essential elements of these gardening tools is crucial for both maintenance and optimal performance. Each component plays a significant role in ensuring the equipment operates smoothly, delivering efficient results for lawn care and landscaping tasks.

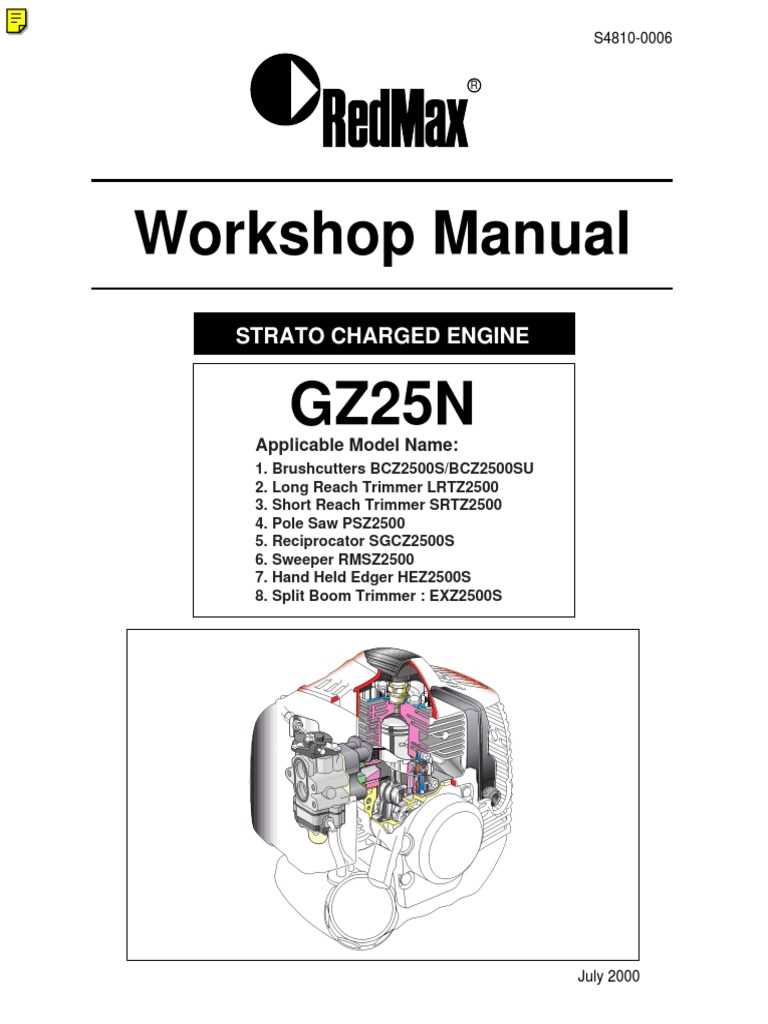

Engine and Power System

The heart of any outdoor power equipment is its engine, which provides the necessary energy to drive the cutting mechanism. This system is designed for reliability and efficiency, ensuring that the tool can handle various tasks without overheating or losing power. Additionally, the fuel delivery system, including the tank and carburetor, is crucial for optimal performance.

Cutting Mechanism

At the forefront of the operation is the cutting apparatus, which is engineered to tackle grass and weeds effectively. This includes the blades or line, which must be appropriately matched to the specific tasks. The ease of replacing these elements is essential for maintaining productivity, making regular checks on this component vital.

Common Issues with Trimmer Parts

Garden maintenance tools can encounter various challenges that affect their efficiency and performance. Identifying these common problems can help in ensuring that the equipment operates smoothly and effectively.

One frequent issue is wear and tear on components due to prolonged use. Over time, this can lead to reduced functionality, making it essential to inspect and replace worn-out items to maintain optimal performance.

Another common problem is the accumulation of debris in critical areas. Grass, dirt, and other materials can obstruct movement and hinder operation, necessitating regular cleaning to prevent these blockages.

Additionally, misalignment of elements can result in inefficient operation. When parts are not properly aligned, it may lead to increased vibration and stress on the tool, potentially causing further damage. Regular checks and adjustments can help mitigate these issues.

Lastly, improper assembly during maintenance or repairs can create significant complications. Ensuring that each component is correctly fitted is crucial for the effective functioning of the equipment. Regular maintenance checks can help identify and rectify these assembly-related problems.

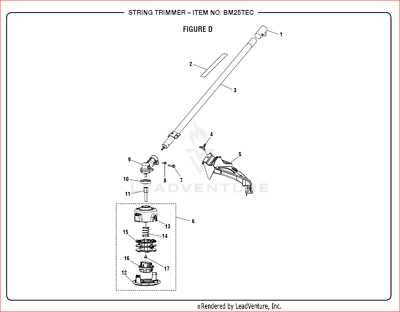

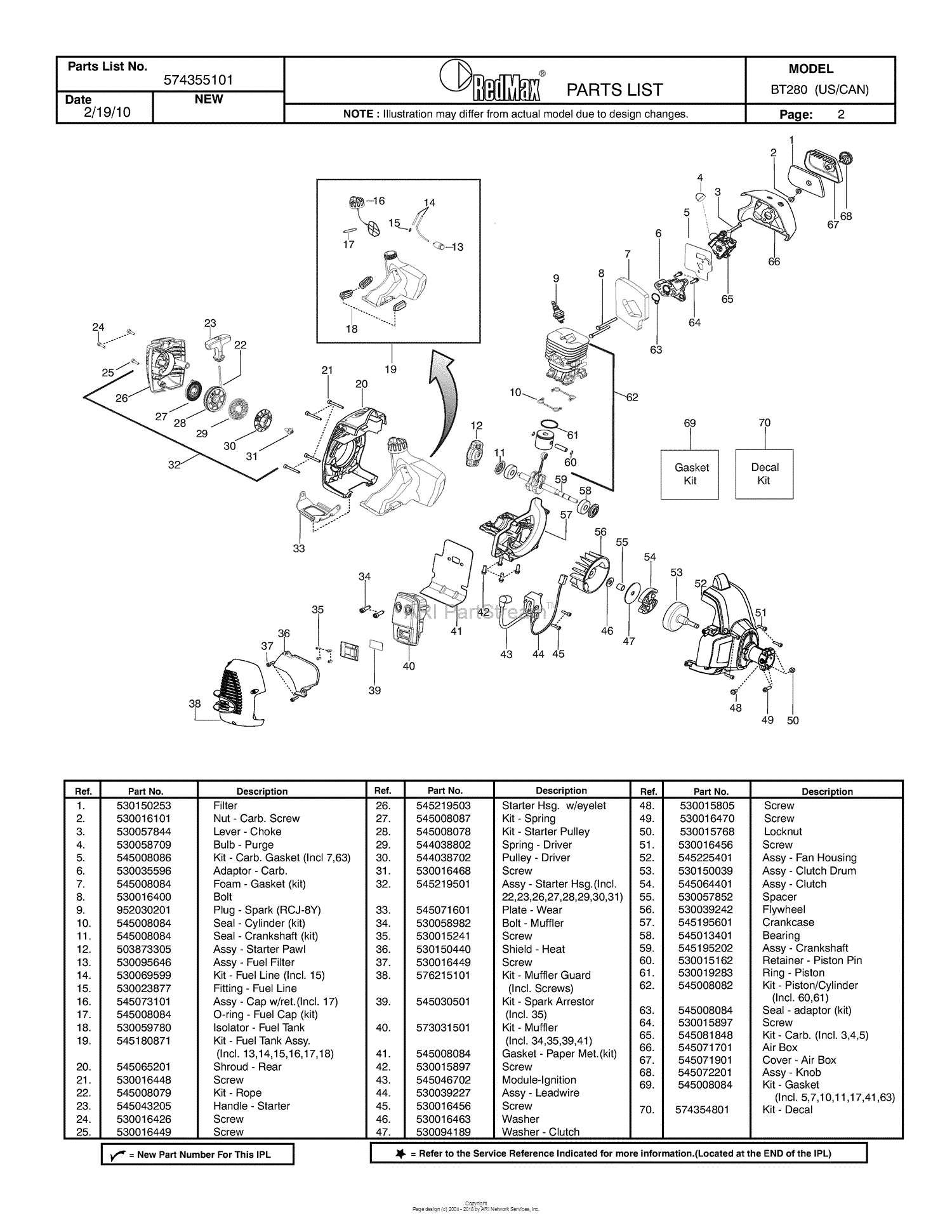

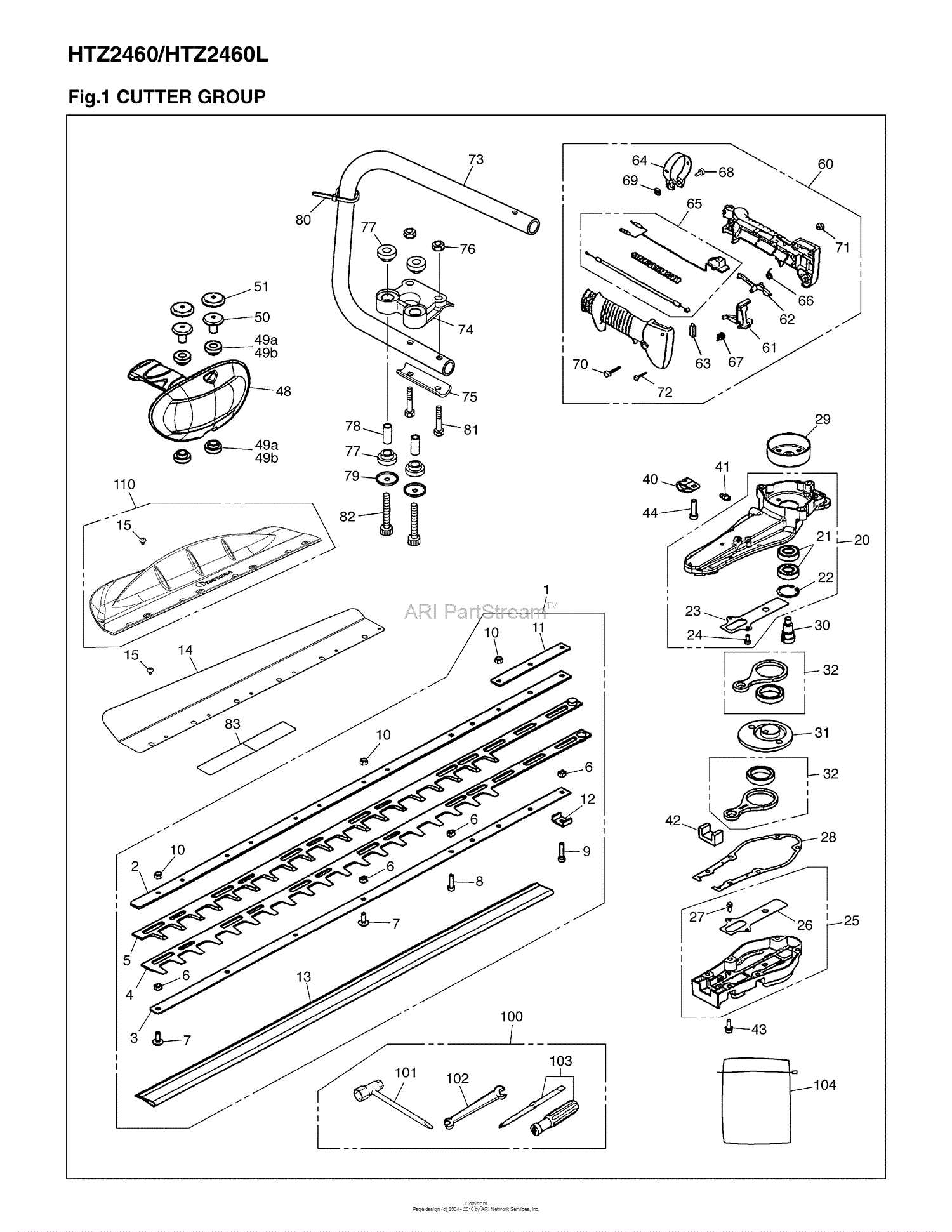

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repairs of equipment. These visuals provide a clear representation of components, their arrangement, and how they interact with one another. Grasping the layout can significantly enhance your ability to troubleshoot and replace elements when necessary.

To interpret an assembly illustration effectively, follow these steps:

- Familiarize Yourself with Symbols: Various symbols represent different components. Take time to learn what each symbol stands for to avoid confusion.

- Identify Key Sections: Most illustrations are divided into sections. Look for headings or labels that indicate specific areas or functionalities.

- Match Components to Real Parts: Use the visual guide to locate the actual items on your equipment. This will help in understanding where each piece fits within the whole system.

- Follow Assembly Order: Pay attention to any numbered sequences that indicate the order of assembly or disassembly. This ensures you correctly put together or take apart your equipment.

By mastering these techniques, you can navigate assembly visuals with confidence, leading to more efficient repairs and improved performance of your tools.

Identifying Each Component

Understanding the various elements of a cutting tool is essential for effective maintenance and operation. Each part plays a specific role in ensuring the overall functionality and performance of the equipment. By recognizing these individual components, users can make informed decisions regarding repairs, replacements, and upgrades.

Base Assembly: This foundational structure supports all other components, providing stability and durability during operation.

Power Unit: The heart of the device, responsible for generating the necessary energy to drive the cutting mechanism.

Cutting Head: This is where the actual cutting occurs, featuring various attachments or blades suited for different tasks.

Handle: Designed for user comfort and control, the handle enables efficient maneuvering of the tool while in use.

Fuel System: A critical component that supplies energy to the power unit, ensuring optimal performance and longevity.

Safety Guard: This protective feature shields the user from debris and potential injuries, promoting safer operation.

By familiarizing oneself with these components, users can enhance their understanding of the tool’s operation and ensure it remains in excellent working condition.

Maintenance Tips for Trimmer Parts

Regular upkeep of your gardening equipment is essential for ensuring optimal performance and longevity. Proper care not only enhances efficiency but also prevents unnecessary wear and tear, allowing your tools to function at their best. Here are some helpful suggestions to maintain your equipment effectively.

Cleaning and Inspection

After each use, it is crucial to clean the components to remove any debris, dirt, or grass clippings. Regularly inspect for signs of wear, such as cracks or fraying, and replace any damaged elements promptly to avoid further issues. Utilizing a soft brush or cloth can help maintain cleanliness without causing harm to delicate parts.

Lubrication and Storage

Ensure that moving elements are well-lubricated to minimize friction and prevent rust. A light oil or lubricant can significantly extend the lifespan of these parts. Additionally, store your equipment in a dry, sheltered area to protect it from the elements, which can lead to deterioration over time. Proper storage practices will help maintain the integrity of your tools, ensuring they are ready for use when needed.

Replacing Worn-Out Components

Over time, the various elements of a gardening tool may become less effective due to regular use. To maintain optimal performance, it’s essential to identify and replace any components that show signs of wear. By doing so, you can ensure that your equipment continues to operate efficiently and reliably.

Identifying Worn-Out Elements

Before replacing any parts, it’s important to recognize which components need attention. Common indicators of wear include:

- Decreased efficiency in cutting or trimming

- Unusual noises during operation

- Visible damage or fraying on cutting lines

- Difficulty in starting or maintaining operation

Steps for Replacement

Once you have identified the worn-out components, follow these steps for replacement:

- Gather the necessary tools and new components.

- Carefully remove the damaged parts, ensuring not to damage surrounding areas.

- Install the new components, making sure they fit securely.

- Test the tool to confirm that it operates correctly.

By replacing worn elements promptly, you can prolong the lifespan of your equipment and enhance its performance in your gardening tasks.

Where to Buy Replacement Parts

When it comes to maintaining outdoor equipment, sourcing quality components is essential for optimal performance. Numerous options exist for acquiring the necessary elements to keep your device running smoothly. Understanding where to find these items can help ensure you make informed choices while prolonging the lifespan of your equipment.

Online Retailers

One of the most convenient ways to obtain replacement items is through various online platforms. Here are some benefits of shopping online:

- Wide selection of products

- Competitive pricing

- Customer reviews for informed decisions

- Home delivery for added convenience

Popular websites such as Amazon, eBay, and specialized outdoor equipment retailers often have an extensive inventory of components.

Local Stores

For those who prefer a hands-on approach, visiting local hardware or outdoor supply shops can be advantageous. Consider the following:

- Immediate access to items

- Ability to consult with knowledgeable staff

- Opportunity to examine components before purchase

Check for dedicated sections within these stores that focus on outdoor machinery and tools, as they typically carry the most common replacements needed.

Benefits of Genuine Redmax Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. Genuine items are crafted to the highest standards, ensuring they fit seamlessly and function correctly within the machine. This commitment to quality means you can rely on their durability and efficiency over time.

One significant advantage of authentic components is the assurance of compatibility. When you choose original items, you avoid the risks associated with generic alternatives that may not work as intended. This compatibility leads to fewer breakdowns and enhances the overall effectiveness of your device.

Additionally, authentic components often come with warranties that provide peace of mind. Should any issues arise, you can have confidence in the manufacturer’s support. This level of assurance is invaluable, especially for those who rely on their tools for heavy-duty tasks.

Investing in original items also supports the brand’s integrity and innovation. By choosing genuine parts, you contribute to ongoing research and development, helping to enhance future products and maintain high standards within the industry.

Frequently Asked Questions

This section aims to address common inquiries regarding the various components and functionalities of outdoor equipment. Understanding the essential aspects of these machines can enhance their performance and longevity.

What should I consider when replacing components?

When it comes to replacing elements, it’s crucial to ensure compatibility with your equipment model. Check the specifications and opt for high-quality replacements to maintain optimal operation.

How can I troubleshoot common issues?

For effective troubleshooting, start by identifying any unusual noises or performance issues. Regular maintenance, including cleaning and checking connections, can prevent many common problems. If issues persist, consult the user manual for detailed guidance.