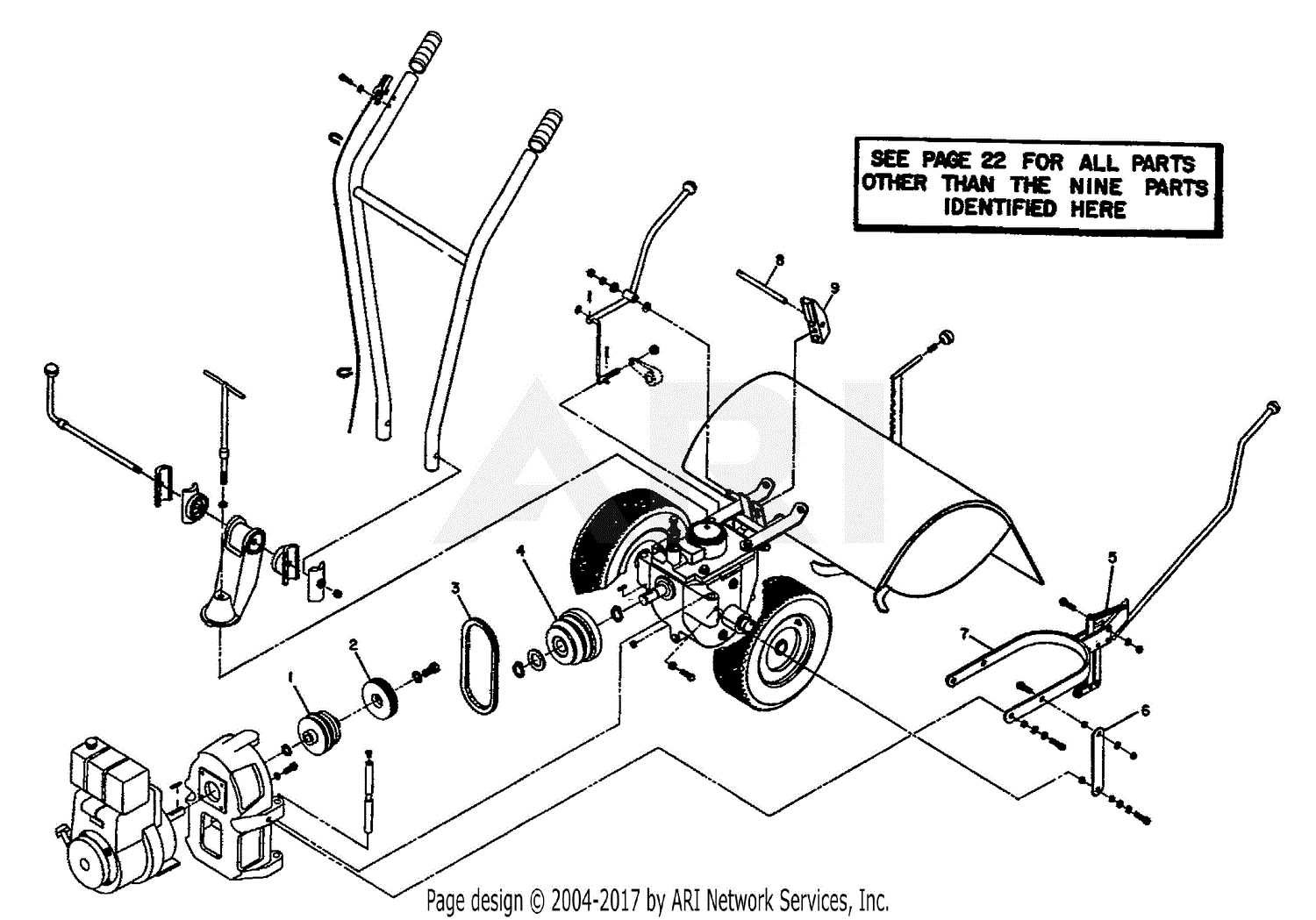

Understanding how soil-cultivating machinery functions is essential for those looking to maintain their garden equipment. These robust devices, known for their ability to break up the earth and prepare it for planting, consist of numerous interconnected elements that work in unison. Grasping the structure and arrangement of these elements can simplify both maintenance and repairs, ensuring a longer lifespan for the equipment.

Each component plays a crucial role in the operation of the machinery, from the rotating blades that dig into the ground to the drive systems that provide the necessary power. Knowing the arrangement of these parts helps users address potential issues and fine-tune performance for different soil types. This knowledge can prevent disruptions during use and minimize wear over time.

When servicing these devices, having a visual representation of their internal and external components proves invaluable. Such illustrations allow enthusiasts and professionals alike to identify specific elements and understand their precise locations and connections. This makes the task of replacing or adjusting any element far more efficient, leading to smoother operation and improved results in the field.

Understanding the Components of the Horse Tiller

The machinery used for soil cultivation is made up of various essential elements that work together to ensure efficient performance. Each piece is designed to play a specific role in preparing the land, making it easier for planting and overall soil management. Recognizing these elements helps in maintaining the equipment and ensures long-term durability.

Engine Unit: The power source of the equipment, driving all other mechanisms. It converts fuel into energy, enabling movement and rotation of key parts. Regular maintenance of this section is crucial for the device’s longevity.

Transmission System: This mechanism transfers the generated energy to the rotating elements. It ensures smooth operation and allows users to adjust the speed and depth of cultivation. Proper lubrication is necessary to avoid wear and tear.

Rotating Blades: These are the primary tools for breaking up the soil. Made from sturdy materials, they dig into the ground, turning and loosening it for better aeration. The sharpness and integrity of these components are vital for optimal

Engine Structure and Its Functionality

The core of any robust soil cultivation machine is its power unit, designed to provide efficient energy conversion and reliable operation. The mechanism ensures smooth interactions between its various components, allowing seamless motion and performance during heavy-duty tasks. Understanding the layout of these elements helps in maintaining and troubleshooting the system.

Main Components Overview

The engine is built around a series of key elements that work together to generate and manage mechanical energy. This includes the combustion chamber, piston, crankshaft, and cooling systems. The combustion process generates the initial power, which is then converted into rotational force, driving the machine’s operation. A well-maintained cooling system ensures that heat generated during use is effectively managed, preventing overheating.

Role of the Drive System

The drive system is essential for channeling energy from the power source to the operational tools. It includes a transmission mechanism, which adjusts the speed and torque for various tasks. The efficient transfer of power ensures that the machine can handle different soil types and conditions, providing consistent output even under challenging environments.

Transmission System Overview

The power transfer mechanism plays a crucial role in ensuring efficient motion and smooth operation. This setup is designed to distribute energy from the source, allowing for effective control over speed and torque. Understanding its key elements is essential for maintaining peak performance and addressing potential issues that may arise over time.

Key Components

This system consists of several integral parts that work together to facilitate smooth energy flow. Each component is designed to perform specific functions, from adjusting speed to managing directional changes, ensuring that the overall operation remains consistent and reliable. Below is a breakdown of these essential elements:

| Component | Description | |

|---|---|---|

| Drive Shaft | Transfers power from the motor to the mechanism, providing rotational energy required for operation. |

| Function | Description |

|---|---|

| Speed Control | Regulates the pace at which the machine operates, allowing for adjustments based on the task at hand. |

| Direction Adjustment | Enables the operator to change the trajectory of the equipment, facilitating maneuverability in tight spaces. |

| Operational Efficiency | Enhances the effectiveness of the equipment by providing responsive feedback to the user’s inputs. |

Fuel Tank Capacity and Compatibility

The capacity of the fuel reservoir is a crucial factor that affects the efficiency and operational time of any outdoor equipment. Understanding the specifications and compatibility with various fuel types ensures optimal performance and longevity of the machinery.

Typically, the fuel tank of these devices is designed to hold a specific volume, which allows for extended use without frequent refills. It is essential to match this capacity with the intended application to achieve the best results.

| Model | Fuel Tank Capacity (Gallons) | Recommended Fuel Type |

|---|---|---|

| Model A | 1.5 | Regular Unleaded |

| Model B | 2.0 | Premium Unleaded |

| Model C | 1.75 | Ethnol-Free Gasoline |

Ensuring the proper fuel type is used in accordance with the recommended specifications is vital for maintaining the engine’s efficiency and preventing damage. Compatibility with fuel additives should also be considered to avoid any adverse effects on performance.

Safety Mechanisms to Consider

When operating garden cultivation equipment, ensuring user safety is paramount. Various mechanisms are designed to minimize the risk of accidents and injuries. Understanding these features can enhance the overall experience and promote responsible use of the machinery.

Emergency Stop Features

Most modern devices include emergency stop buttons or levers that allow users to quickly halt operations in case of unforeseen circumstances. This feature can prevent potential hazards, providing peace of mind while working in the field.

Protective Shields and Guards

Another essential component is the incorporation of protective shields and guards. These elements help to safeguard the user from debris and moving parts, reducing the likelihood of injury during operation. Regular maintenance and inspection of these safety features are crucial to ensure they function correctly.

Replacing Worn-Out Seals and Gaskets

Maintaining the efficiency of your equipment often requires attention to the integrity of its components. Over time, certain elements may degrade, leading to potential leaks or performance issues. Regular inspection and timely replacement of these critical components are essential for optimal functionality.

When it comes to ensuring a tight seal, gaskets and seals play a crucial role. They prevent fluid loss and protect against contaminants, thereby prolonging the life of the machinery. If you notice any signs of wear, such as leaks or unusual noises, it’s imperative to address these issues promptly.

The replacement process typically involves disassembling the affected areas. Carefully remove the old components, ensuring that the surfaces are clean and free from debris. This step is vital for achieving a proper fit for the new items. Once prepared, install the new seals and gaskets according to the manufacturer’s specifications, applying the necessary torque to secure them without over-tightening.

By proactively replacing these elements, you enhance the reliability and efficiency of your machinery, preventing further complications and ensuring smooth operation.

Troubleshooting the Ignition System

When dealing with ignition challenges in your equipment, understanding the underlying components and their functions is essential for effective diagnostics. This process involves identifying potential issues that may prevent the engine from starting or running smoothly.

Start by checking the battery: Ensure it is fully charged and connections are clean and tight. A weak or dead battery can lead to starting problems. If the battery is functioning properly, proceed to inspect the ignition switch and wiring for any signs of damage or corrosion.

Next, examine the spark plug: Remove it and inspect for wear or deposits. A faulty spark plug can hinder ignition. If necessary, replace it with a new one, ensuring proper gap settings. Additionally, verify the ignition coil’s condition; a malfunctioning coil may not deliver sufficient voltage.

Lastly, assess the safety switches: These mechanisms are designed to prevent starting under unsafe conditions. Ensure all are engaged correctly and functioning as intended. If any switch is faulty, it may disrupt the ignition process.

By methodically following these steps, you can effectively troubleshoot ignition system issues, leading to a more reliable operation of your equipment.

Finding the Right Replacement Blades

When maintaining your gardening equipment, ensuring you have the appropriate cutting tools is essential for optimal performance. Selecting the right replacements can significantly affect efficiency and productivity. This section will guide you through the key considerations for choosing suitable blades for your equipment.

Understanding Compatibility

Before purchasing new cutting tools, it’s crucial to check compatibility with your machine. Each model has specific requirements, and using incompatible replacements can lead to inefficiency or damage. Referencing the manufacturer’s guidelines can help you make informed decisions.

Material Considerations

The material of the cutting implements is another critical factor. Different materials offer varying degrees of durability and sharpness. Choosing blades made from high-quality steel or other robust materials can enhance longevity and performance.

| Blade Material | Durability | Sharpening Frequency |

|---|---|---|

| High-Carbon Steel | High | Every Season |

| Stainless Steel | Medium | Every Other Season |

| Alloy Steel | Very High | Every Two Seasons |

Choosing the right blades not only ensures effective operation but also extends the lifespan of your equipment. Take the time to research and select wisely for the best results in your gardening endeavors.