When working with outdoor machines, it’s essential to have a clear understanding of how each element fits together. Whether you’re performing maintenance or repairs, a detailed breakdown of various mechanisms can provide crucial insights. This overview will guide you through the critical aspects of mechanical structures, helping you identify key components and how they interact within the system.

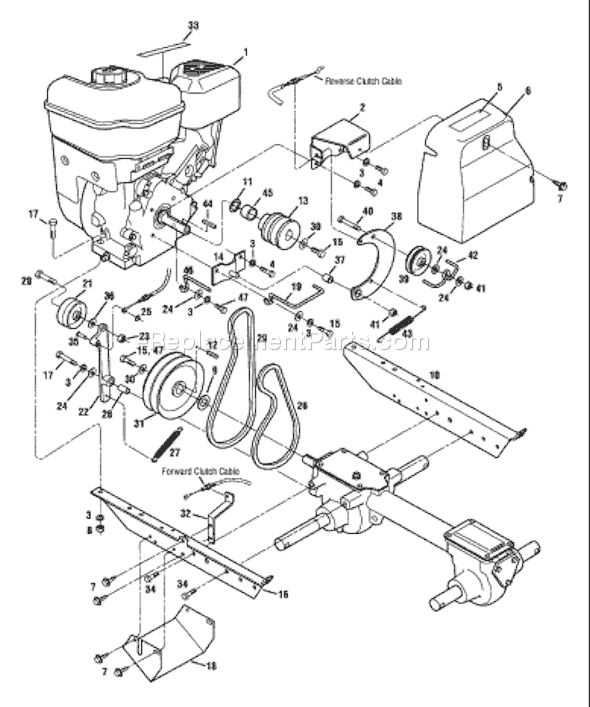

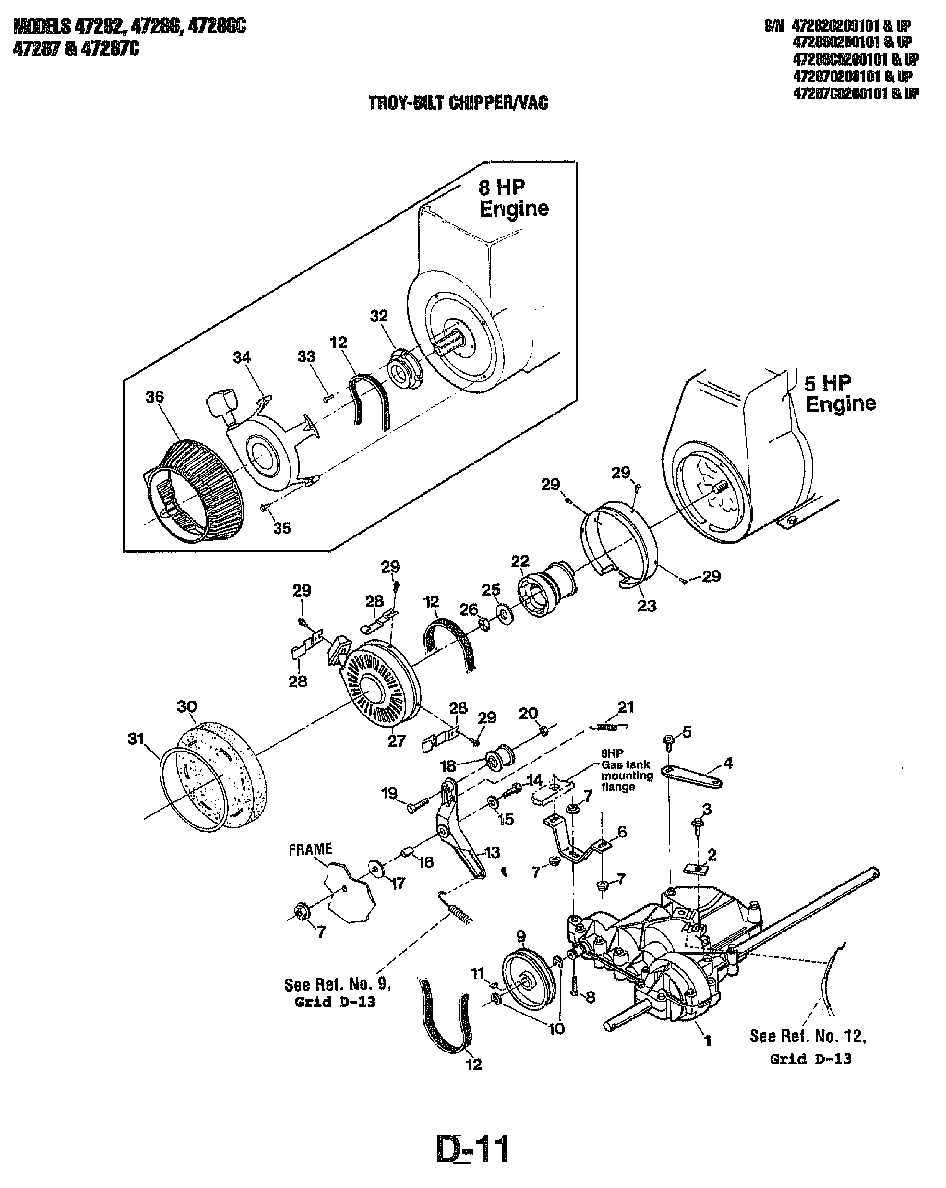

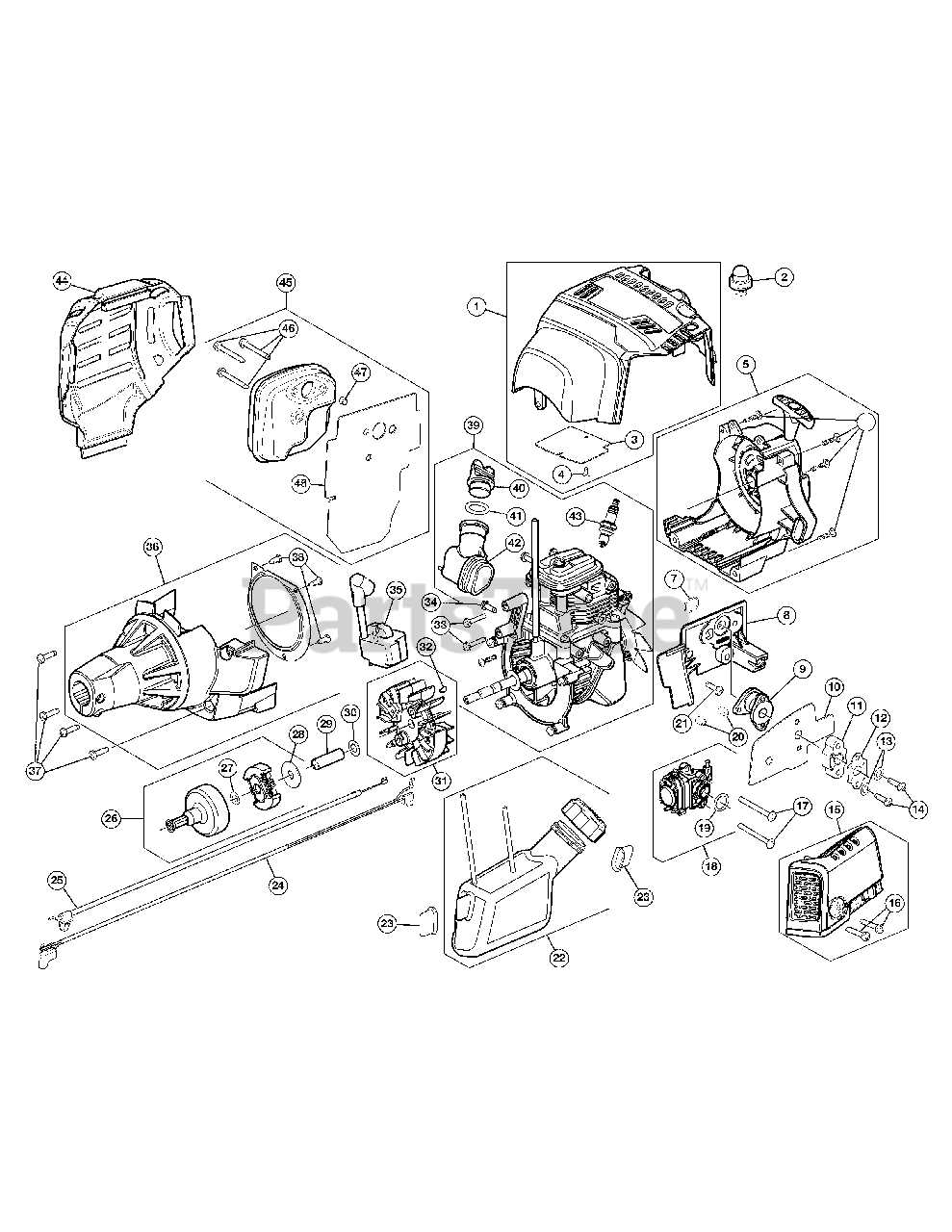

By examining a visual representation of the system, you can ensure that all individual elements are correctly aligned and functioning as intended. Such visual aids make it easier to comprehend complex machinery and enhance your ability to troubleshoot any issues that may arise during operation.

Having a well-organized layout of mechanical elements at your disposal is invaluable when it comes to improving the efficiency of both routine upkeep and more intricate fixes. This section will offer you an easy-to-follow reference to ensure that every piece is in its proper place, ultimately extending the life

Overview of Troy Bilt Equipment Components

Understanding the various elements that make up outdoor machinery is essential for maintaining its performance and longevity. These machines are composed of a range of components, each playing a crucial role in ensuring efficient operation. By exploring the individual elements and their roles, users can better appreciate how these systems work together to tackle demanding tasks.

Key Structural Components

The core structure of outdoor equipment includes essential mechanical elements designed to support various functions. These include durable frames that provide stability and support, drive systems responsible for movement, and cutting or tilling mechanisms that interact with the environment. The combination of these components allows for efficient execution of tasks like cultivating soil or trimming grass.

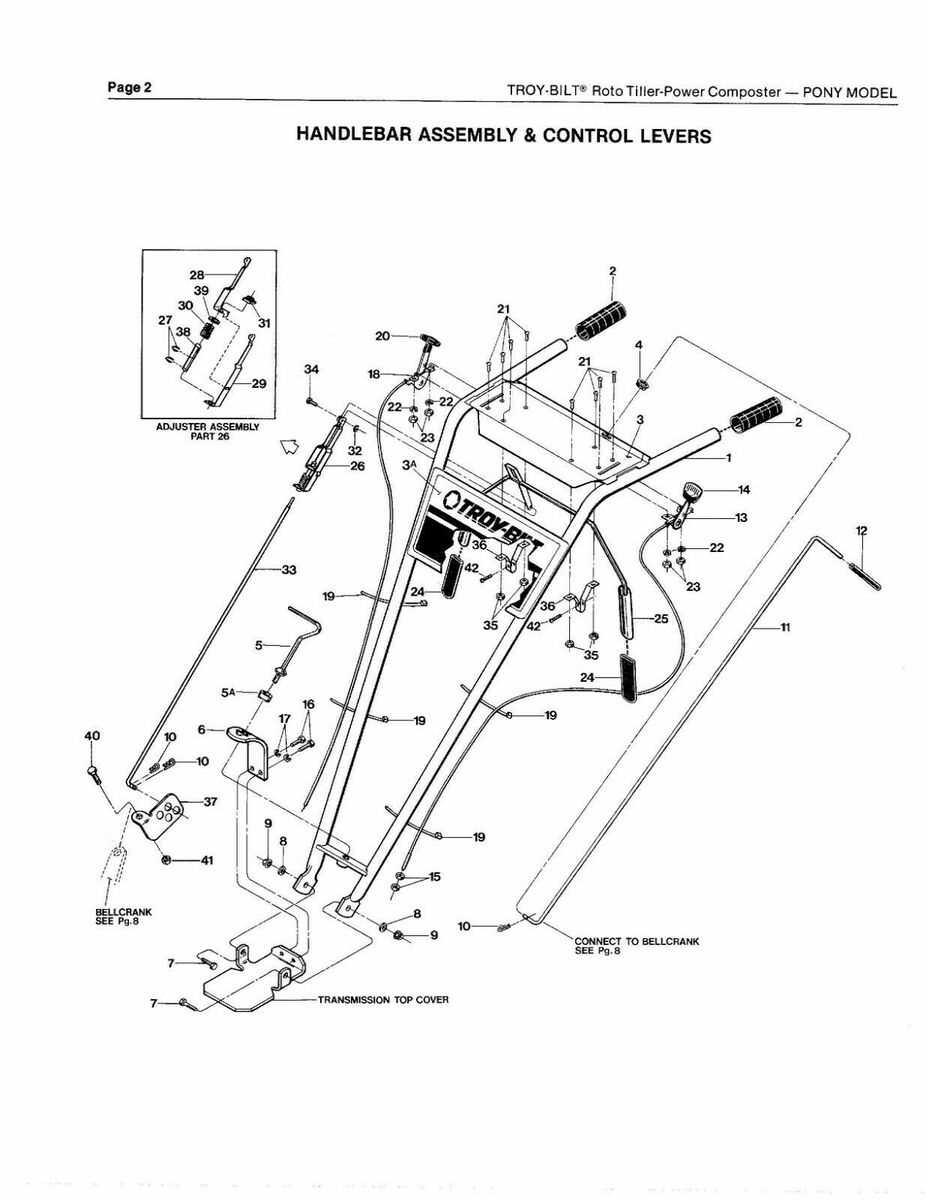

Mechanical and Control Systems

Equally important are the internal mechanisms and control systems that regulate the machine’s function. This includes power transmission assemblies, steering controls, and safety features. These elements ensure smooth operation and provide the user with control over the equipment. Regular

Identifying Key Parts in Your Machine

Understanding the various elements that make up your equipment is essential for effective maintenance and repairs. Recognizing the essential components will help ensure smoother operation and longer service life. By familiarizing yourself with the primary mechanisms, you can identify potential issues early and address them before they lead to major problems.

Main Components Overview

The core structure of your equipment includes several critical elements that contribute to its functionality. These include the propulsion system, cutting mechanism, and the control panel. Each of these has its own specific role in ensuring optimal performance. Regular checks on these areas can prevent unnecessary breakdowns and improve efficiency.

Understanding the Drive and Control Systems

The driving force behind the machine is an intricate system responsible for movement and control. Paying attention to this section ensures that the equipment runs

Understanding the Function of Each Component

To ensure the optimal performance of any machine, it’s important to grasp how each element works in harmony. Each unit has a specific role that contributes to the overall functionality of the system, whether it’s ensuring power distribution, motion control, or structural support. Knowing these roles allows for more efficient troubleshooting, maintenance, and replacement processes.

Engine and Transmission System

The power unit is responsible for generating the necessary energy to drive the machine, while the transmission system distributes that energy to the necessary areas. Proper coordination between these elements ensures smooth operation and allows for various speeds and movements.

Cutting and Drive Mechanisms

The cutting assembly, equipped with precision blades, is designed to perform the primary task efficiently, while the drive system propels the machine forward. Adjustments in the height or angle of these components allow for different outcomes, depending

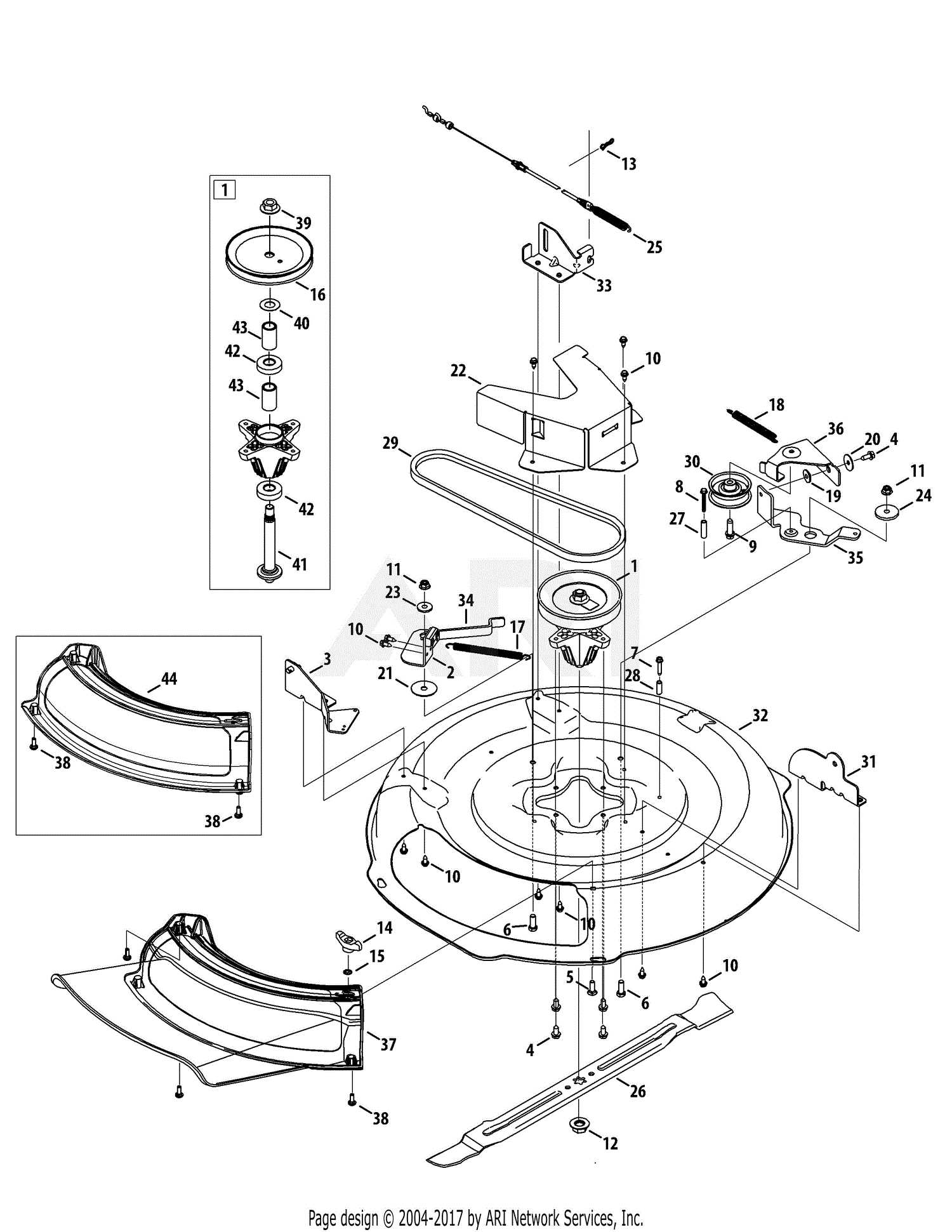

How to Use a Parts Diagram Effectively

Understanding how to navigate a visual representation of machine components is essential for maintaining and repairing equipment. This guide provides clear steps on how to interpret these visuals and apply the information to resolve issues or order necessary elements.

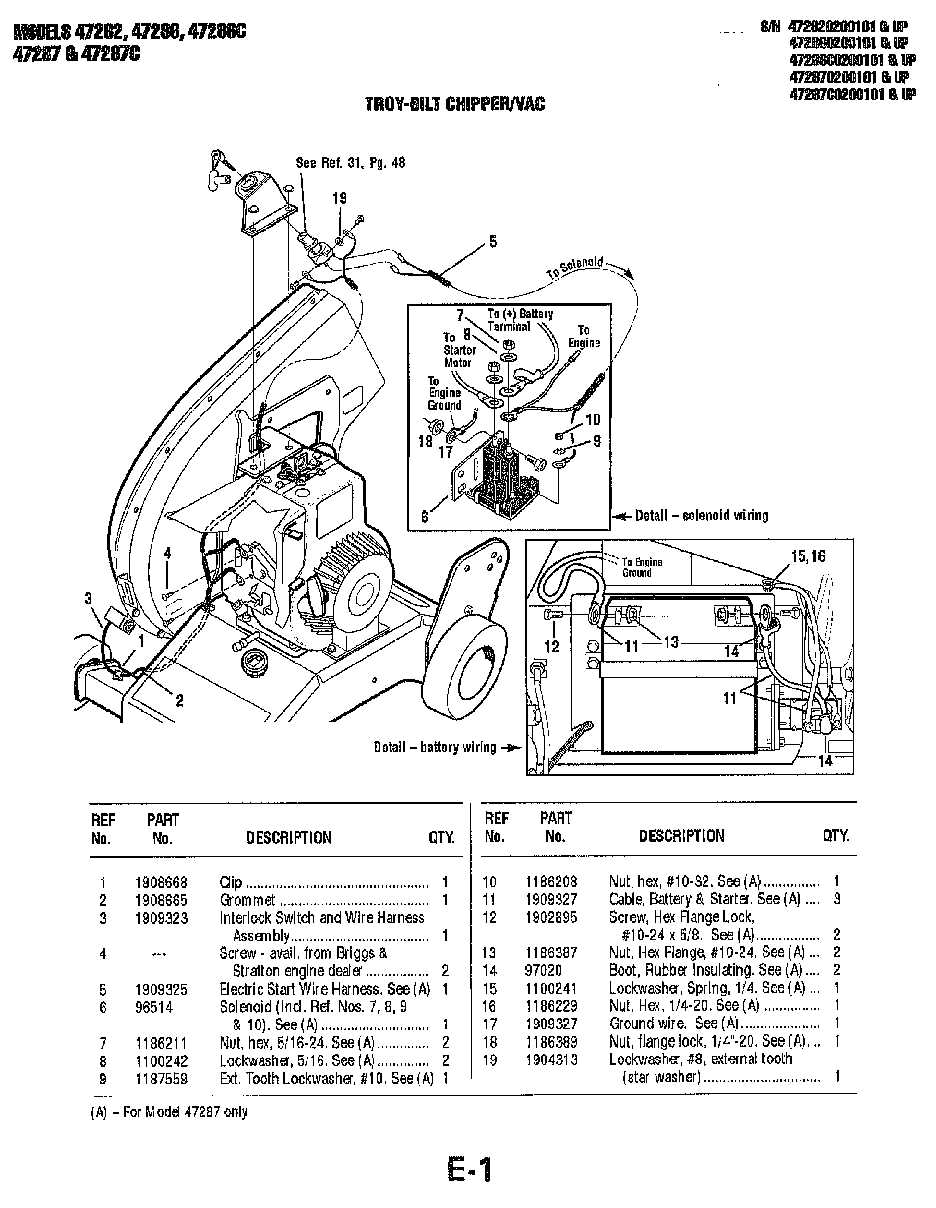

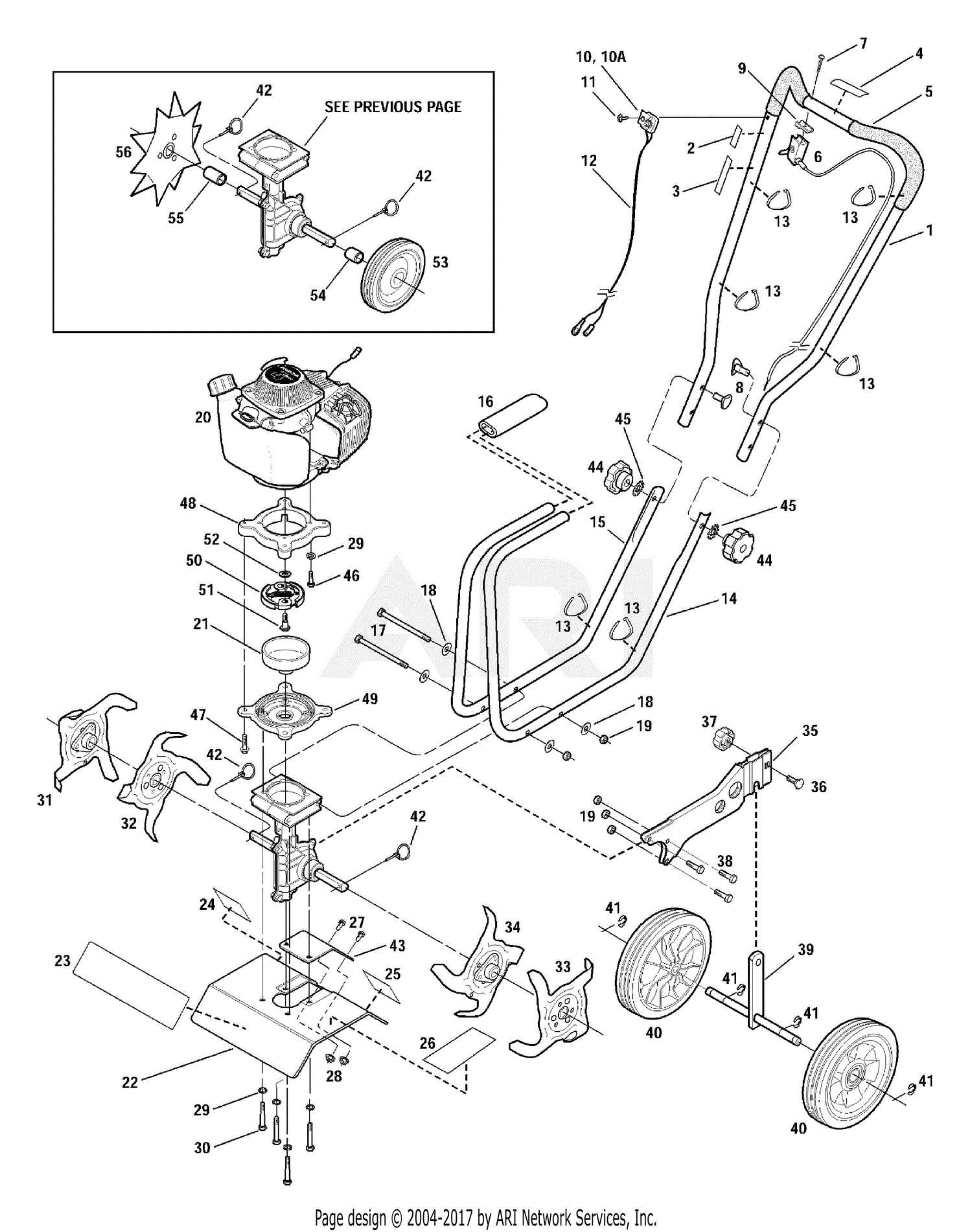

Identify Key Components

The first step is to familiarize yourself with the visual layout. Most illustrations categorize parts by system or function, helping users locate the necessary sections quickly. Take note of numbered references and labels, which correspond to specific components in the list below the image.

- Check for a legend or key that explains symbols or labels.

- Use the numbers or markers to cross-reference between the image and description list.

- Focus on the section of the equipment you are working on to avoid confusion.

Cross-Referencing for Accuracy

When using a diagram, it’s important to ensure the correct piece is identified. Often, several parts may look similar but differ in size or function. By cross

Commonly Replaced Items in Troy Bilt Equipment

Maintaining outdoor machinery often involves replacing certain components that wear out over time. Regular upkeep ensures optimal performance, and understanding which items are more likely to need replacement can help avoid unexpected issues. The most frequently replaced elements in such equipment are critical for smooth operation, and addressing these in time can prevent more significant damage.

Wear and Tear Components

Among the most commonly replaced components are those subject to frequent friction, pressure, and exposure to harsh environments. These include blades that lose sharpness, belts that stretch or break, and air filters that become clogged with debris. Ensuring these parts are in good condition is essential for both efficiency and longevity of the equipment.

Engine and Fuel System Components

Engine-related elements also tend to require periodic replacement. Spark plugs are often replaced due to wear, impacting ignition efficiency. Similarly, fuel filters and carburetors can become clogged or degraded over time, necessitating attention to ensure smooth fuel

Locating Hard-to-Find Components

Finding elusive elements for outdoor equipment can be a challenging task. Often, these crucial items are not readily available through standard retail channels, leaving users frustrated. However, there are effective strategies that can help streamline the search process and increase the chances of locating the necessary components.

1. Online Marketplaces: Websites like eBay and Amazon often have listings for rare items. Conducting thorough searches with specific model numbers or descriptions can yield fruitful results.

2. Specialty Retailers: Some retailers specialize in hard-to-find items. Establishing connections with these suppliers can provide access to rare components that mainstream stores might not carry.

3. Forums and Communities: Engaging with online forums dedicated to outdoor equipment can be invaluable. Members often share information about where to find specific elements or even offer items for sale or trade.

4. Salvage Yards: Local salvage yards or equipment recycling centers can be treasure troves for hard-to-find items. Visiting these places may lead to discovering components that are no longer manufactured.

5. Manufacturer Contact: Reaching out directly to the manufacturer can provide insight into availability or alternative options. Sometimes, manufacturers offer resources or can direct you to authorized dealers who carry the needed items.

By utilizing these strategies, individuals can enhance their chances of successfully locating those elusive components, ensuring their outdoor equipment remains functional and reliable.

Maintenance Tips Based on Your Diagram

Proper upkeep is essential to ensure the longevity and efficient operation of your equipment. By following a structured maintenance plan tailored to your visual reference, you can easily identify key areas that require attention. Regular inspections and care will not only enhance performance but also prevent potential issues from escalating.

Regular Inspection

- Check all moving components for signs of wear and tear.

- Examine the belts and cables for fraying or damage.

- Inspect fluid levels and look for leaks.

- Review fasteners to ensure everything is secure.

Seasonal Maintenance Tasks

- Clean or replace air filters to maintain airflow.

- Sharpen blades to ensure optimal cutting performance.

- Change oil and replace filters as recommended.

- Store equipment in a dry place to prevent rust and corrosion.

Decoding Part Numbers and Labels

Understanding the identification system used for components is essential for effective maintenance and repair. Each number and label offers insights into the specifications and compatibility of the item, ensuring users can easily find the right replacements or enhancements. This section explores the typical structure of these identifiers and how to interpret them accurately.

| Element | Description |

|---|---|

| Prefix | This often indicates the category or type of the item, providing a quick reference to its function. |

| Numeric Code | A series of digits that specify the unique identity of the item, usually reflecting size, shape, or capacity. |

| Suffix | Additional letters or numbers that may denote variations or specific features, such as color or model year. |

| Barcode/QR Code | A machine-readable code that allows for quick scanning, facilitating inventory management and tracking. |

By familiarizing oneself with this coding system, individuals can streamline their purchasing processes, ensuring they acquire the correct items for their needs. Proper understanding minimizes the risk of errors and enhances the overall experience when dealing with component replacements or upgrades.

Optimizing Performance with Correct Parts

Enhancing the efficiency and longevity of equipment relies heavily on utilizing the right components. Each element plays a crucial role in the overall functionality, and ensuring compatibility is essential for peak performance. Selecting suitable replacements can lead to significant improvements in operation, reducing the risk of breakdowns and extending the lifespan of the machinery.

To achieve optimal results, consider the following factors when choosing components:

- Quality: Always opt for high-quality replacements that meet or exceed original specifications.

- Compatibility: Ensure the new components are compatible with the existing system to avoid performance issues.

- Manufacturer Recommendations: Follow guidelines provided by the manufacturer for selecting components that enhance overall functionality.

Regular maintenance is also key to performance optimization. Keeping equipment in top condition can prevent costly repairs and downtime. Implementing a routine check-up can help identify worn or damaged elements that may require replacement.

Additionally, here are some steps to effectively manage your inventory of components:

- Maintain an organized inventory to quickly locate necessary items.

- Monitor usage trends to predict when replacements will be needed.

- Establish relationships with trusted suppliers for timely access to quality components.

By prioritizing the selection of the correct components and practicing routine maintenance, you can significantly enhance the performance and reliability of your equipment.

Ordering Replacement Parts for Troy Bilt

When it comes to maintaining your outdoor equipment, ensuring you have the correct components is essential for optimal performance. This guide provides insights into acquiring the necessary items efficiently, whether you’re tackling a repair or simply performing routine maintenance. Understanding the process will help you save time and avoid unnecessary hassle.

Identifying Required Components

Before placing an order, it’s crucial to determine which items need to be replaced. Referencing your user manual can be invaluable, as it typically includes essential information regarding the specifications and models compatible with your device. Additionally, you may find helpful resources online, such as community forums and manufacturer websites, that can assist in identifying the correct components.

Where to Order

Once you’ve pinpointed the necessary items, several avenues are available for purchase. Authorized dealers and manufacturers often provide a reliable source, ensuring you receive genuine components. Alternatively, reputable online retailers can offer convenience and competitive pricing. Always check for reviews and ratings to ensure you’re purchasing from a trustworthy source.

Tip: Keep your model number handy while searching; it will streamline the process and help you find the right items more quickly.

Ordering the correct components is a vital step in maintaining the functionality of your outdoor machinery. Following the right steps ensures that your equipment remains in top condition for years to come.

Interpreting Symbols in Parts Diagrams

Understanding the various indicators and representations in technical illustrations is crucial for effective maintenance and repair tasks. These visual aids serve as essential references, simplifying the identification of components and their respective functions. Familiarity with the commonly used icons enhances comprehension, enabling users to navigate through complex assemblies with ease.

Common Symbols and Their Meanings

Numerous illustrations utilize specific icons to convey important information. For instance, arrows typically indicate the direction of movement or flow, while circles may denote connection points or junctions. Additionally, color coding often highlights critical areas, differentiating between various types of components or materials. Recognizing these symbols helps users make informed decisions during repairs and replacements.

Tips for Effective Interpretation

To effectively interpret technical illustrations, it is beneficial to consult the accompanying legend or key, which explains the meaning of each symbol. Additionally, cross-referencing with product manuals or online resources can provide further context. Engaging with these resources not only enhances understanding but also builds confidence in tackling maintenance tasks independently.

Choosing the Right Parts for Your Model

When it comes to maintaining your equipment, selecting the appropriate components is essential for optimal performance and longevity. Each machine model has its unique specifications and requirements, making it crucial to ensure compatibility and quality when sourcing replacements. Understanding the features of your specific model will aid in making informed decisions, ultimately enhancing functionality and reducing the likelihood of issues arising from improper fitment.

Identifying Your Model

Start by accurately identifying your specific machine version. Look for the serial number or model identifier, usually located on the main body or near the engine. This information is vital, as it allows you to access relevant resources, such as manuals and catalogs, ensuring that you obtain components specifically designed for your equipment.

Quality vs. Cost

While it may be tempting to choose the least expensive options available, consider the long-term implications. Investing in high-quality components may involve a higher upfront cost but can lead to better durability and performance. Always evaluate the materials and manufacturing standards of the items you are considering, as this can greatly affect their lifespan and your overall satisfaction.