When tackling outdoor maintenance tasks, having a clear understanding of the assembly and components of your cleaning equipment is essential. This knowledge enables users to efficiently troubleshoot, repair, and maintain their machines, ensuring optimal performance during usage.

In this section, we will explore the intricate layouts of various elements found within these machines. By examining their structure, we can identify the function of each piece and appreciate how they work together to achieve the ultimate goal of cleanliness.

Additionally, understanding these configurations can empower users to make informed decisions regarding replacements or upgrades. Whether you’re a seasoned professional or a weekend warrior, diving into the specifics of your cleaning apparatus can greatly enhance your experience.

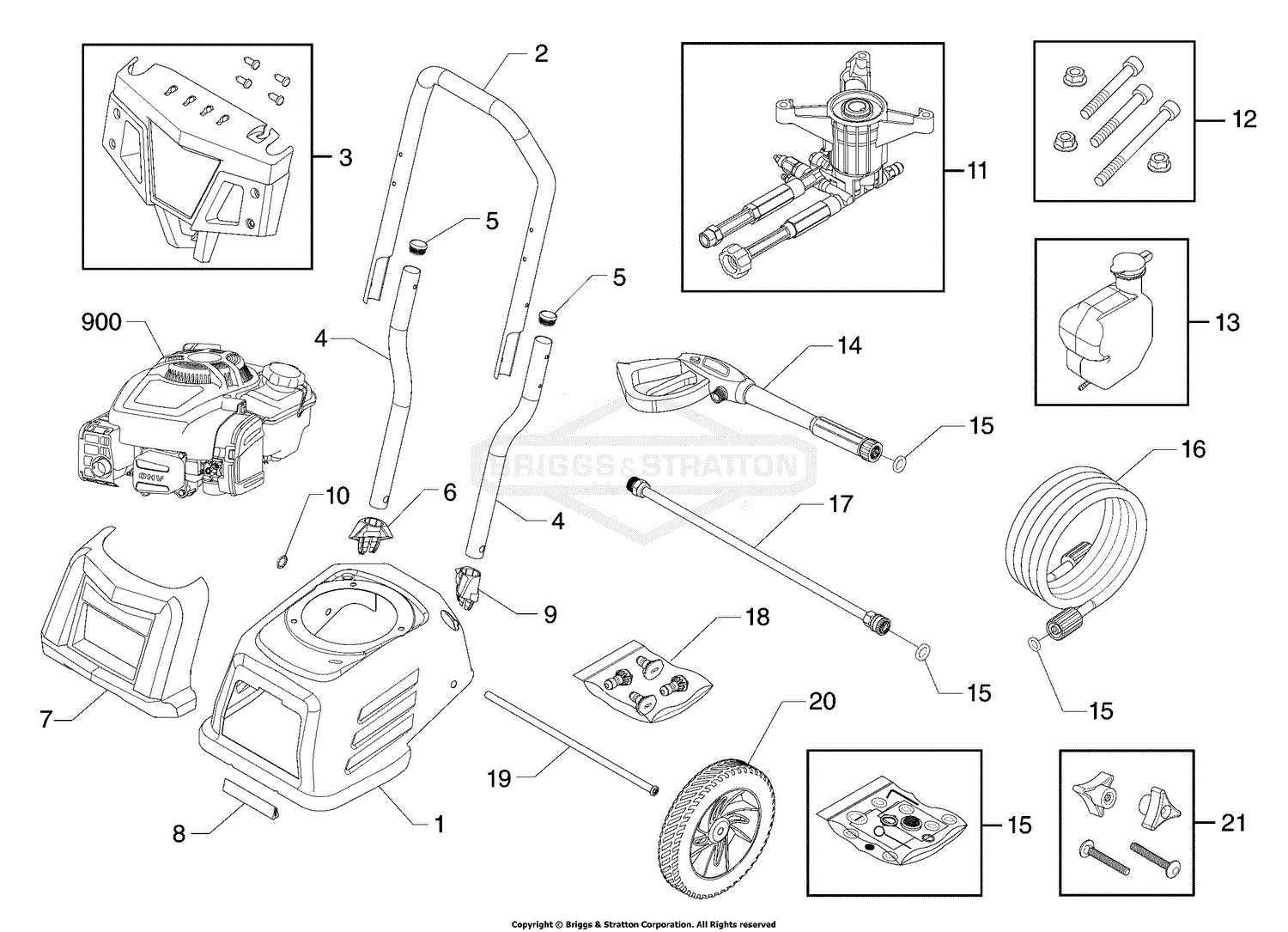

Troy Bilt Power Washer Overview

This section provides an in-depth look at a renowned cleaning device designed for efficient outdoor maintenance. Understanding its features, components, and functionality can enhance user experience and ensure optimal performance.

- High-efficiency engine for reliable operation.

- Durable construction for longevity in various conditions.

- Interchangeable nozzles for versatile cleaning applications.

- User-friendly controls for easy handling and adjustment.

In addition, proper maintenance and familiarity with the individual components are essential for maximizing the device’s capabilities.

- Regular inspection of the engine and pump.

- Cleaning filters to prevent clogging.

- Storing the unit in a dry place to avoid damage.

By delving into these aspects, users can achieve the ultimate performance from their cleaning equipment.

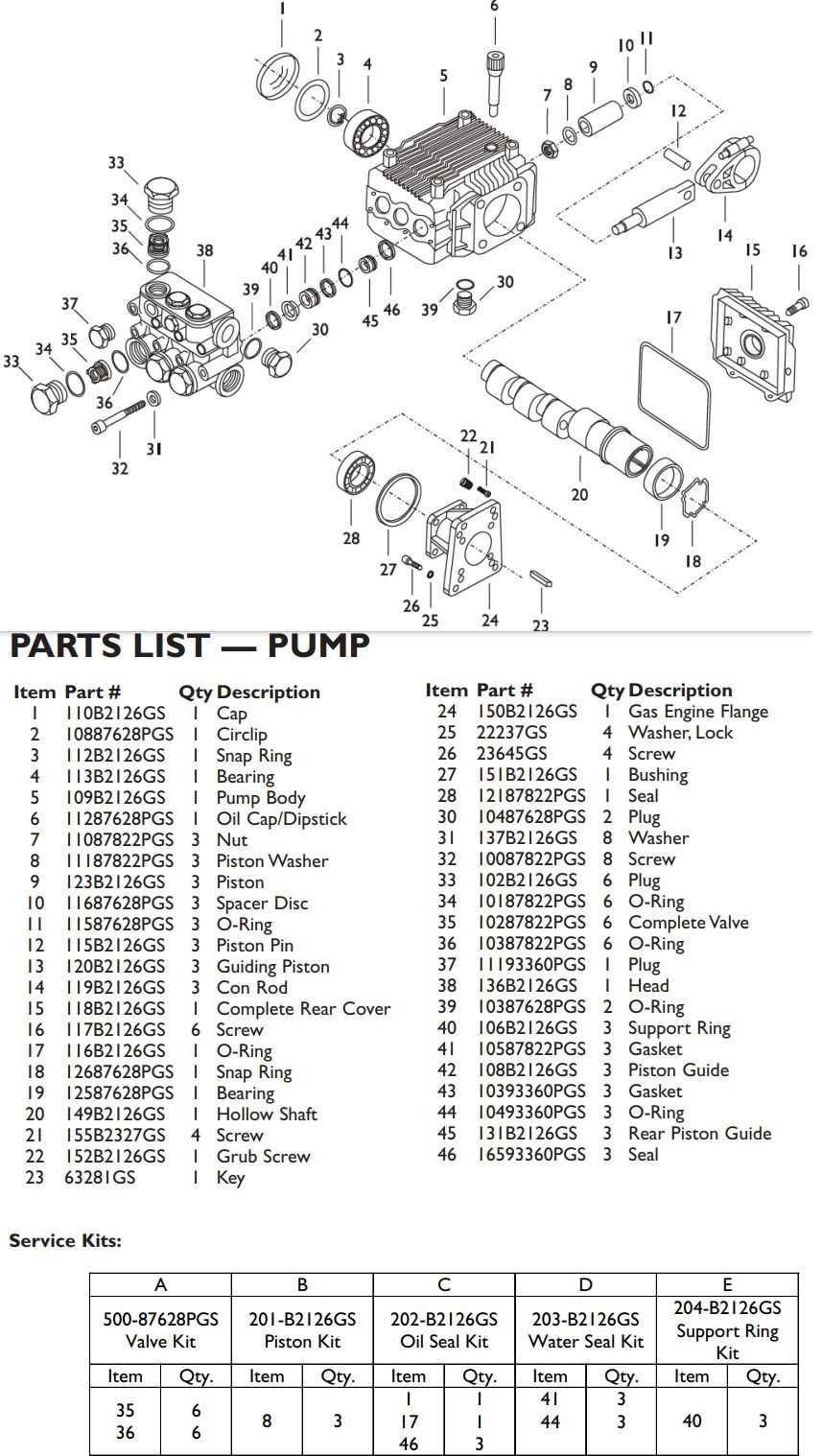

Understanding Power Washer Components

Every cleaning machine consists of several essential elements that work together to achieve optimal performance. Grasping the functionality and interrelationship of these components enhances maintenance and troubleshooting capabilities, leading to improved longevity and efficiency. Each part plays a crucial role, from generating pressure to directing water flow, ensuring effective cleaning results.

One of the primary components is the engine, which serves as the heart of the device, providing the necessary energy. Coupled with the pump, this element pressurizes the liquid, enabling it to be expelled forcefully through a nozzle. The nozzle itself is vital, as it determines the spray pattern and pressure level, allowing users to customize their cleaning experience.

Additional components, such as the hose and trigger gun, facilitate the user’s interaction with the machine. The hose carries the pressurized liquid from the pump to the nozzle, while the trigger gun controls the flow. Understanding these elements can help users select the right model for their needs and make informed decisions regarding repairs and upgrades.

Finally, regular maintenance of these components is essential for sustained performance. Knowledge of how to care for each part can prevent malfunctions and ensure that the cleaning tool remains effective over time, providing the ultimate cleaning experience.

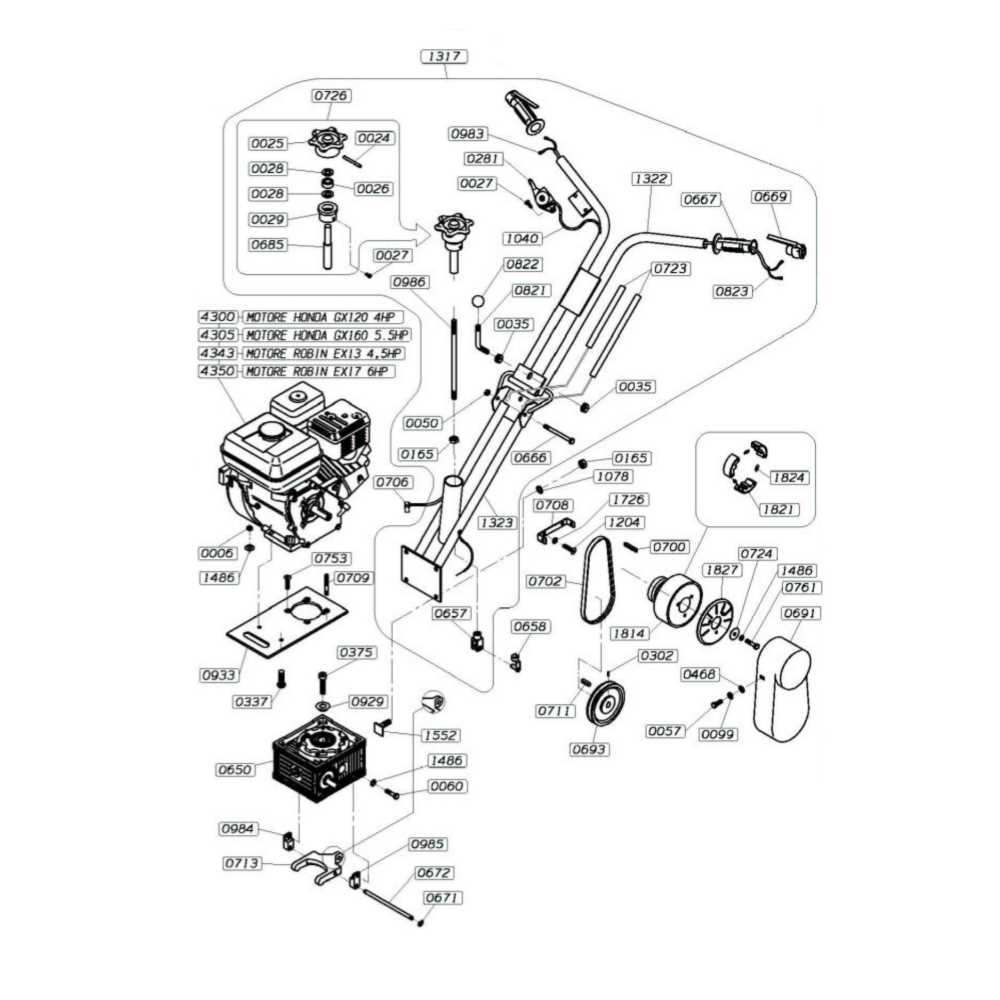

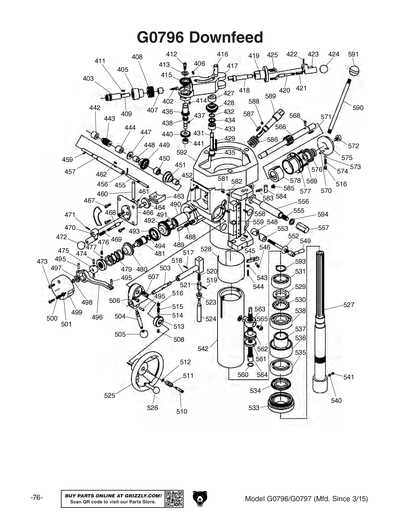

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining equipment. They provide clarity on the arrangement and functionality of various elements, facilitating effective repairs and replacements.

- Enhance comprehension of assembly and disassembly processes.

- Identify specific components needed for maintenance.

- Streamline troubleshooting by highlighting potential issues.

By utilizing these visual tools, users can ensure the longevity and optimal performance of their machinery. Moreover, they empower individuals to tackle repairs with confidence, reducing reliance on professional services.

Common Parts in Power Washers

Understanding the essential components of cleaning machines is crucial for effective maintenance and repair. These elements work together to ensure optimal functionality, enabling efficient operation and prolonging the lifespan of the equipment.

Key Components

- Engine: Provides the necessary power for operation.

- Pump: Pressurizes water for effective cleaning.

- Hose: Transports water from the pump to the nozzle.

- Nozzle: Directs water flow for various cleaning tasks.

- Trigger: Controls water flow from the nozzle.

Additional Features

- Filter: Prevents debris from entering the pump.

- Wheels: Facilitate mobility during use.

- Tank: Holds detergent for enhanced cleaning.

- Handle: Provides grip and maneuverability.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual representations provide a breakdown of components, helping users identify and locate specific elements within a device.

Here are some tips to enhance your comprehension:

- Familiarize Yourself with Symbols: Each illustration uses unique symbols for various components. Learn what these symbols represent.

- Identify Sections: Most visuals are divided into sections. Focus on one area at a time for better clarity.

- Refer to the Legend: Often, there’s a legend or key that explains the symbols and numbers used. Always check this first.

- Follow the Sequence: Many diagrams show the assembly order. Pay attention to the sequence for proper reassembly.

By mastering these techniques, you can effectively navigate and utilize technical visuals for any repair or assembly tasks. Delve into each component’s role to achieve ultimate efficiency in your projects.

Identifying Replacement Parts Needed

When maintaining equipment, it’s crucial to accurately determine which components require substitution. This ensures optimal performance and prolongs the lifespan of the machine. By understanding how to identify these essential elements, users can efficiently address any issues that arise.

Steps to Identify Components

- Examine the Equipment: Start by inspecting the machine for visible signs of wear or damage.

- Refer to the Manual: Consult the user guide for detailed information about specific elements and their functions.

- Take Notes: Document the identification numbers or descriptions of the components that seem compromised.

- Consult Online Resources: Utilize online forums or manufacturer websites for additional information and troubleshooting tips.

Common Indicators for Replacement

- Leaking fluids: Look for any fluid leaks that indicate a failing seal or gasket.

- Unusual noises: Listen for strange sounds that may signify worn bearings or other moving parts.

- Reduced efficiency: If the equipment isn’t performing as expected, it may be time to check for worn-out elements.

- Visible wear: Inspect surfaces for signs of wear, cracks, or corrosion that could impact functionality.

Where to Find Diagrams Online

Locating visual guides for your equipment can greatly assist in understanding its components and assembly. These resources can help simplify repairs and maintenance, ensuring you have everything you need at your fingertips. There are several reliable platforms where you can easily access these illustrations.

Manufacturer Websites

Many manufacturers offer detailed resources on their official sites. You can often find downloadable visuals that outline the various components of your machine. Check the support or resources section for comprehensive manuals and reference materials.

Online Retailers and Forums

Numerous online retailers provide access to visual guides along with the products they sell. Additionally, forums dedicated to equipment enthusiasts often feature shared resources, including diagrams contributed by other users. These platforms can be valuable for troubleshooting and learning from others’ experiences.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your cleaning equipment. By following a few straightforward practices, you can significantly extend its lifespan and maintain optimal performance over time.

Regular Inspections

Conducting routine checks is crucial. Examine the components for wear and tear, and ensure all connections are secure. Addressing minor issues promptly can prevent more serious problems down the line.

Cleaning and Storage

After each use, make it a habit to clean your equipment thoroughly. Remove any debris and residue that may accumulate. Store the unit in a dry, sheltered place to protect it from the elements, which can lead to corrosion and damage. By taking these simple steps, you can help preserve its functionality and extend its overall lifespan.

Common Issues and Solutions

When operating a cleaning device, users may encounter various challenges that hinder performance. Recognizing these common problems and implementing effective solutions can greatly enhance the efficiency and longevity of the equipment.

-

Device Won’t Start:

- Check the power source for any issues.

- Inspect the ignition system or starter components.

- Examine fuel levels and quality if applicable.

-

Low Pressure:

- Verify that the nozzle is not clogged.

- Ensure the hose is free from kinks or damage.

- Check for any leaks in the connections.

-

Unusual Noises:

- Listen for signs of wear in the motor or pump.

- Inspect for loose parts or connections.

- Examine the intake for foreign objects.

-

Overheating:

- Ensure adequate ventilation around the unit.

- Check the fluid levels and quality.

- Allow the device to cool down during extended use.

By addressing these issues promptly, users can maintain optimal operation and avoid more significant repairs in the future.

Ordering Genuine Troy Bilt Parts

Acquiring authentic components is crucial for maintaining the efficiency and longevity of your equipment. Ensuring you have the right elements can make a significant difference in performance.

Here are some key benefits of sourcing original elements:

- Enhanced compatibility with your device.

- Improved reliability and durability.

- Access to manufacturer support and warranties.

When seeking these authentic components, consider the following steps:

- Visit the official website or authorized retailers.

- Use the specific model number to locate the correct items.

- Check for customer reviews and ratings to ensure quality.

- Inquire about return policies in case of discrepancies.

Taking these steps will ensure you acquire the ultimate components necessary for optimal operation.

Assembly and Disassembly Guidance

This section provides essential instructions for the proper assembly and disassembly of equipment components. Understanding the correct procedures ensures optimal performance and longevity of the device.

Preparation Steps

- Gather necessary tools and safety equipment.

- Identify all components and their locations.

- Read through the manual to familiarize yourself with the setup.

Disassembly Process

- Ensure the device is powered off and disconnected from any power source.

- Begin by removing any external attachments or accessories.

- Carefully unscrew and detach components in the recommended order.

- Keep all fasteners and small parts organized for easy reassembly.

Follow these guidelines to facilitate a smooth assembly and disassembly experience, maximizing efficiency and safety throughout the process.

Upgrading Your Power Washer Components

Enhancing your cleaning equipment can significantly improve its efficiency and longevity. By selecting high-quality replacements or upgrades for various elements, you can achieve better performance and adapt the unit to suit specific tasks more effectively. This section will guide you through the benefits of component upgrades and suggest which areas to focus on for optimal results.

Benefits of Upgrading

Investing in superior components can lead to enhanced reliability and a smoother operational experience. Upgrades may provide increased pressure, improved durability, and better energy efficiency. Additionally, using advanced materials can help prevent wear and tear, prolonging the lifespan of your equipment.

Key Areas for Improvement

Focus on several crucial elements when considering enhancements. Pumps are essential for generating pressure, so opting for a high-performance model can yield significant improvements. Nozzles also play a critical role; selecting the right type can optimize water flow and cleaning power. Lastly, consider upgrading hoses for better flexibility and resistance to kinks, ensuring a more user-friendly experience.