Exploring the intricacies of your cleaning device can enhance both its efficiency and lifespan. A thorough grasp of its components allows for optimal maintenance and informed repairs, ensuring you get the best performance.

Visual aids play a crucial role in this understanding, as they provide clear representations of each element within the system. By examining these illustrations, users can easily identify and address potential issues.

Whether you are a seasoned technician or a novice user, knowing the structure and function of these components is ultimately beneficial. Delve into the specifics to unlock the full potential of your equipment and maintain its reliability.

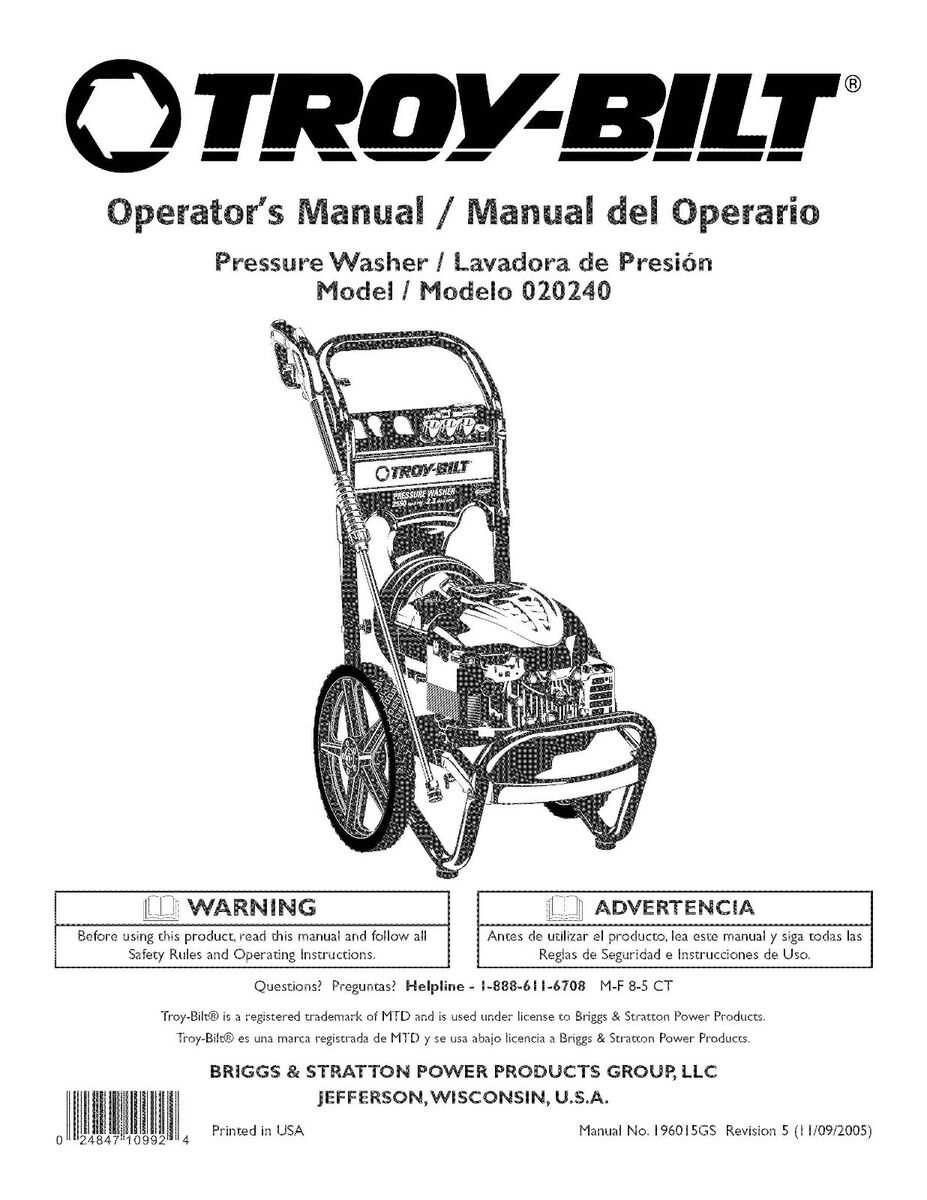

Understanding Troy Bilt Pressure Washers

When it comes to maintaining the cleanliness of outdoor spaces, having the right equipment is essential. This equipment not only enhances efficiency but also ensures that tasks are completed with minimal effort. Familiarity with how these machines function and their key components can significantly improve user experience and extend the lifespan of the device.

Components play a crucial role in the overall performance of these machines. Each section, from the motor to the nozzle, contributes to the effectiveness of the cleaning process. Understanding these elements allows users to troubleshoot common issues and make informed decisions regarding maintenance and repairs.

Regular upkeep is vital for optimal performance. Knowing the specific functions of each component can help users identify wear and tear, ensuring that the machine operates smoothly. This knowledge not only saves time but also minimizes costs associated with professional repairs.

Key Components of Pressure Washers

Understanding the essential elements of cleaning machines can significantly enhance their performance and longevity. Each part plays a crucial role in delivering efficient results, ensuring that tasks are completed effectively.

Motor or Engine: This is the powerhouse, providing the necessary energy to operate the unit. The type of motor, whether electric or gas, affects the machine’s efficiency and power output.

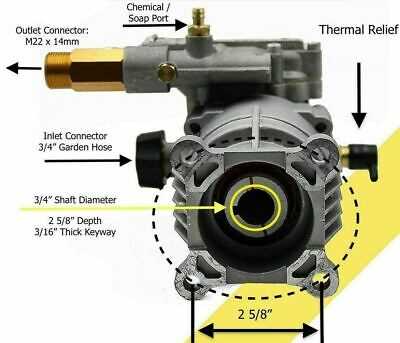

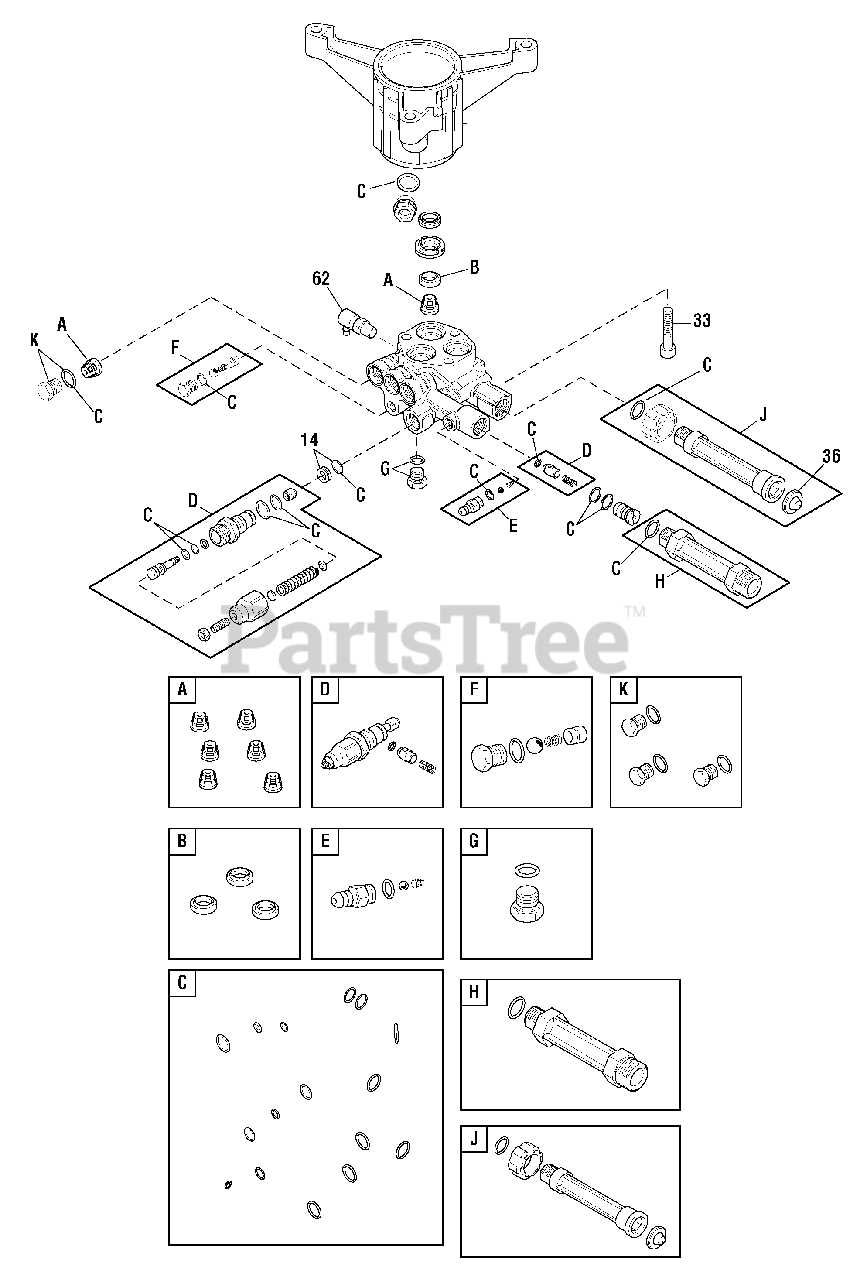

Pump: The pump is responsible for generating the high-pressure flow of liquid. Its quality directly influences the machine’s ability to clean surfaces thoroughly.

Spray Gun: This component allows users to direct the flow of liquid with precision. Various nozzles can alter the spray pattern and intensity, making it adaptable for different tasks.

Hose: The hose delivers the pressurized liquid from the pump to the spray gun. Its length and durability are vital for ease of use and overall effectiveness.

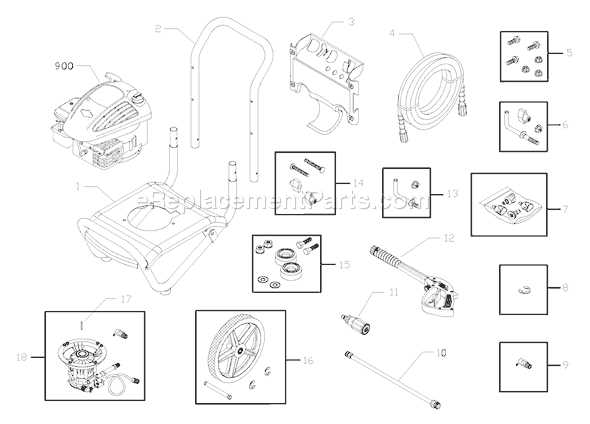

Accessories: Additional tools, such as surface cleaners and extension wands, can enhance functionality, allowing for a broader range of cleaning applications.

How Diagrams Aid Repair Efforts

Visual representations play a crucial role in simplifying the maintenance and restoration of equipment. They provide clarity and help users grasp complex structures quickly.

- Enhances understanding of component relationships.

- Streamlines the identification of necessary tools.

- Facilitates step-by-step troubleshooting processes.

Using these illustrations can significantly improve the efficiency of repair tasks, reducing the likelihood of errors and saving time.

- Review the visual aid before starting.

- Follow each step carefully as depicted.

- Consult additional resources if confusion arises.

Ultimately, effective use of these guides can transform daunting repair challenges into manageable tasks.

Common Issues and Solutions

Maintaining equipment often reveals various challenges that can impede performance. Understanding these common problems and their corresponding fixes is essential for optimal functionality and longevity.

Low Performance

Experiencing reduced efficiency can stem from several factors. Check for clogged filters or hoses, as blockages can significantly hinder output. Cleaning these components can restore functionality, allowing for improved operation.

Leakage Problems

Leaks can occur due to worn-out seals or loose connections. Inspect all joints and gaskets for signs of wear. Tightening connections or replacing faulty seals will typically resolve these issues, ensuring a secure system.

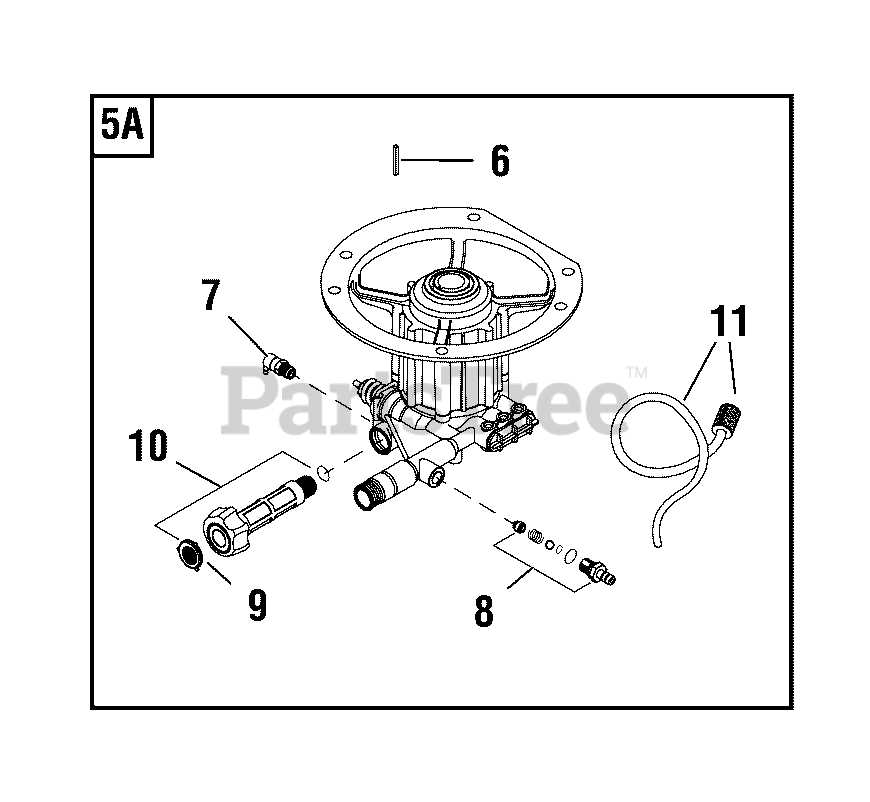

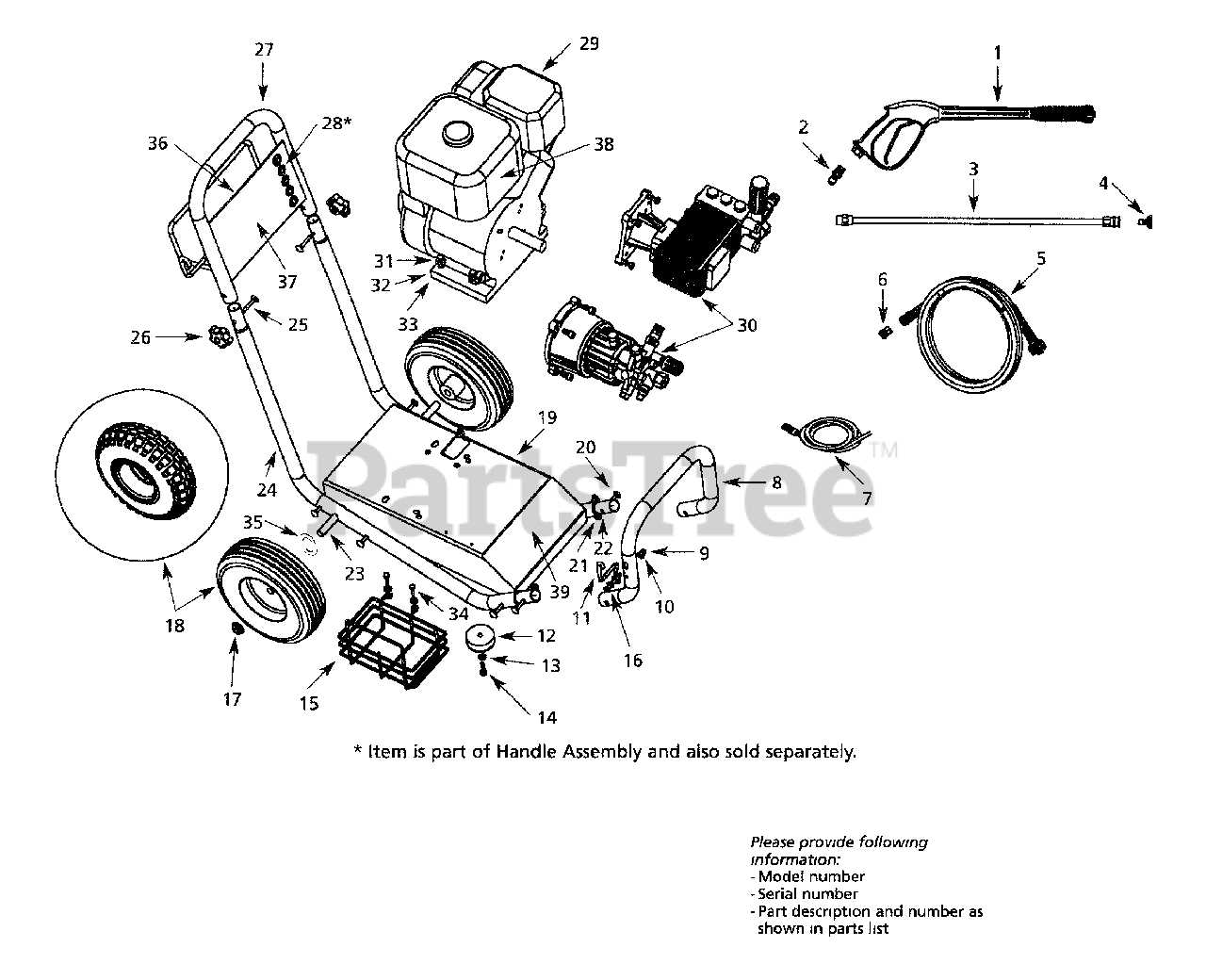

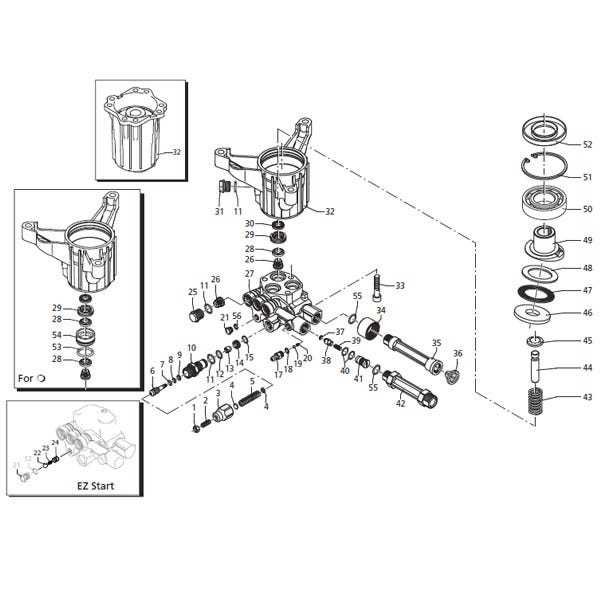

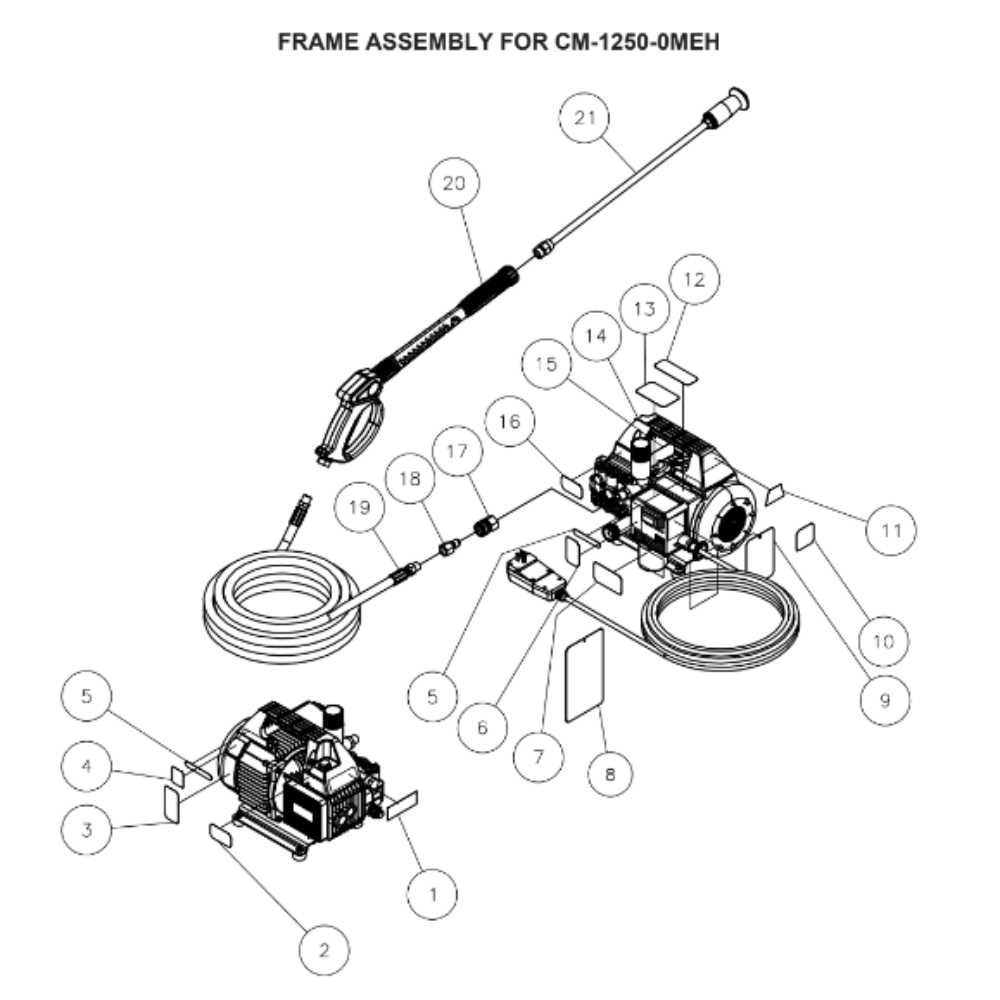

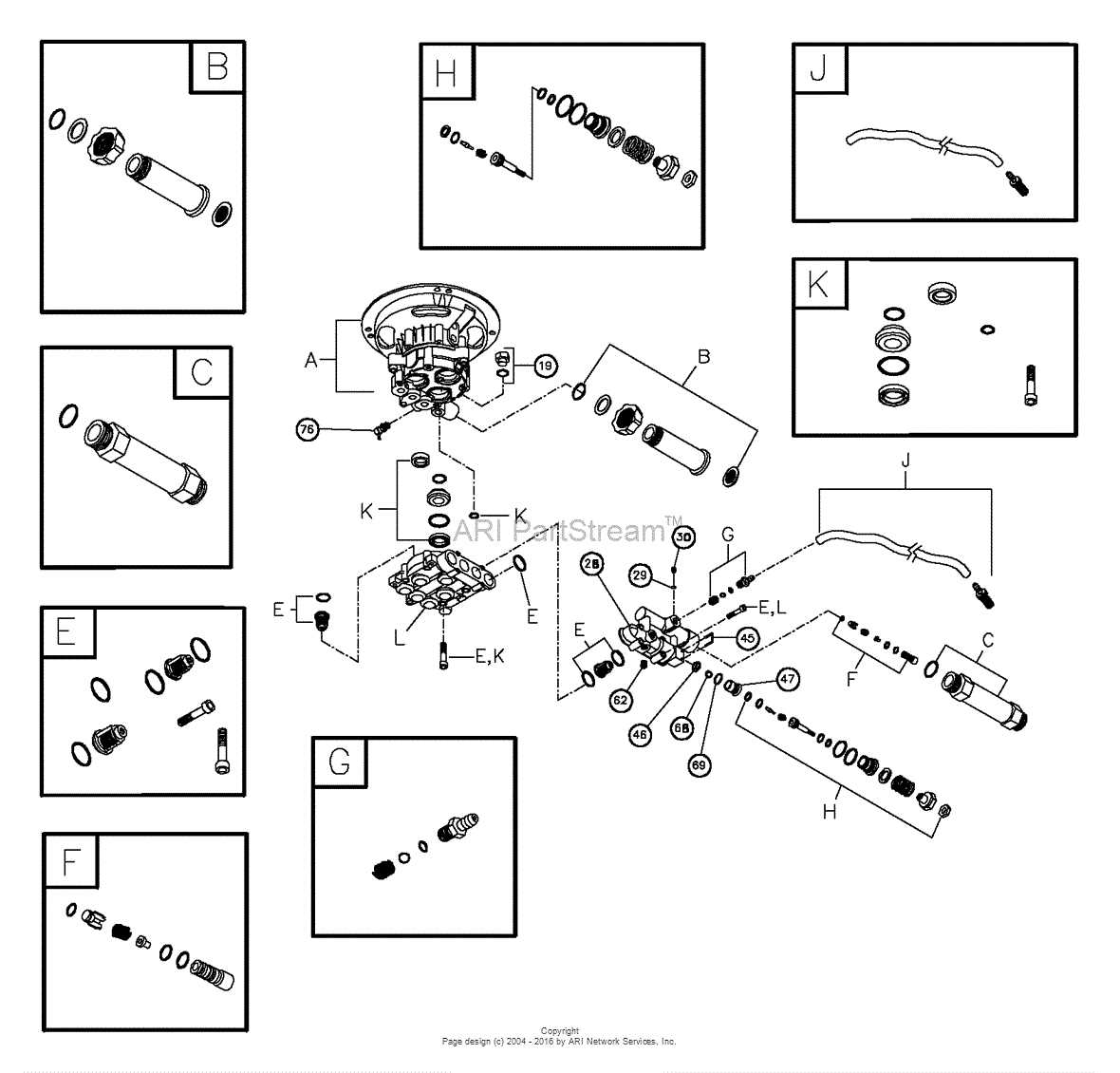

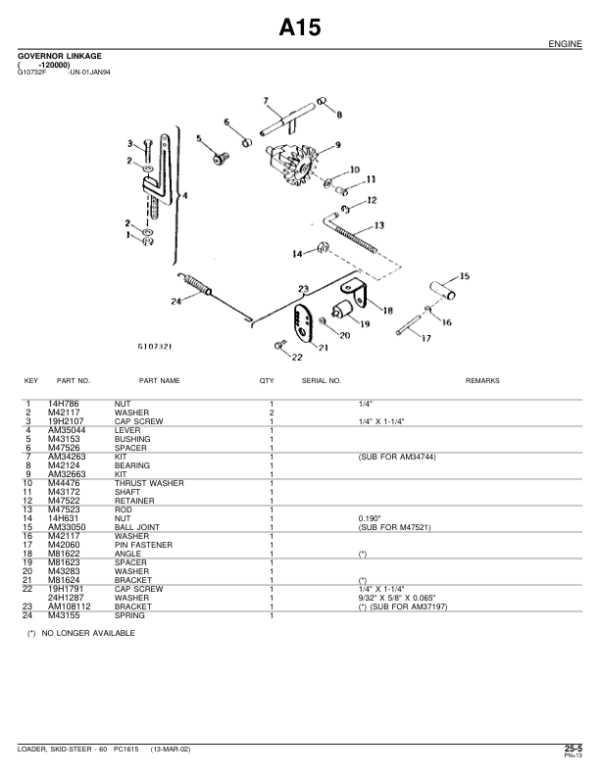

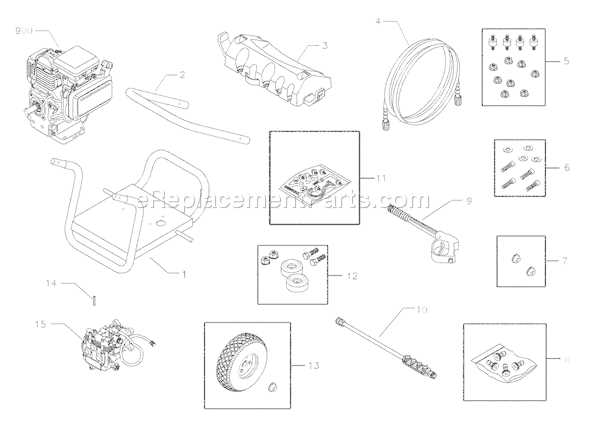

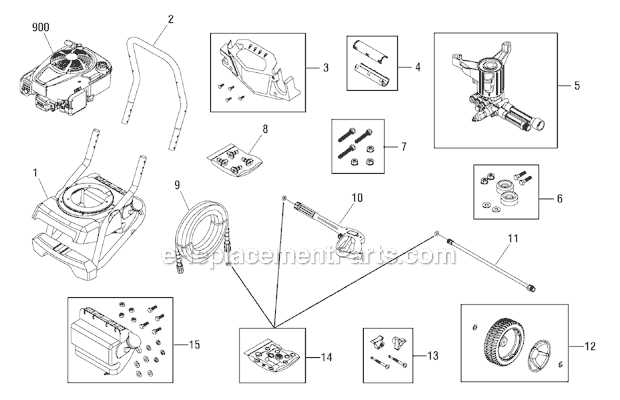

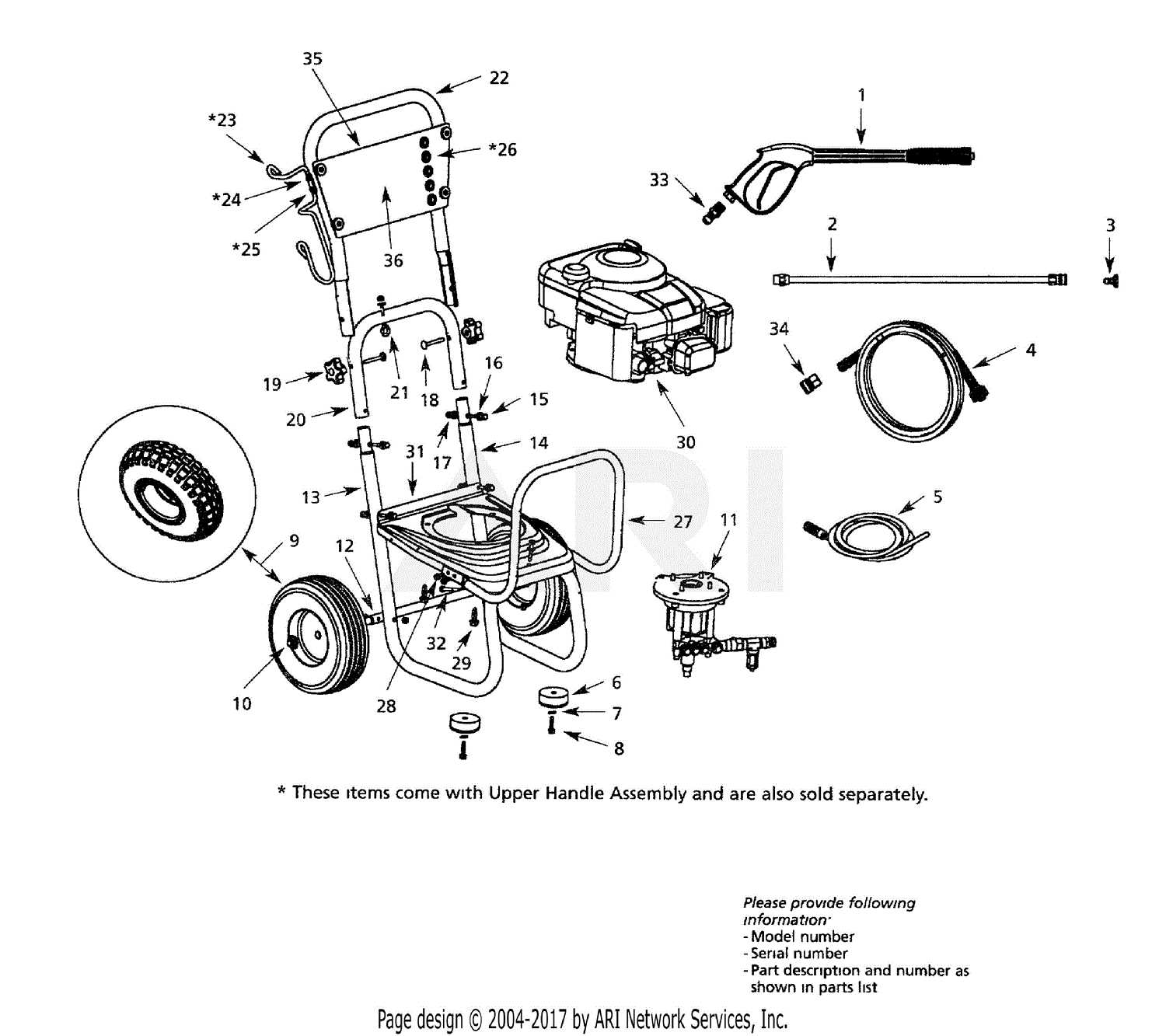

Identifying Parts in Diagrams

Understanding the various components within a schematic is crucial for effective maintenance and repairs. These illustrations serve as visual guides, enabling users to pinpoint individual elements and comprehend their functions within the overall system. By familiarizing oneself with these representations, one can streamline troubleshooting processes and ensure that the correct replacements are made when necessary.

Key Elements of Schematics

Each illustration typically includes labels and numbers that correspond to specific components. Recognizing these identifiers is essential for accurately determining which part needs attention. For instance, a label might indicate the location of a motor or a valve, while a number may refer to a particular bolt or connector. Taking the time to familiarize oneself with this coding system can significantly enhance the efficiency of any repair task.

Utilizing Resources for Accurate Identification

Accessing manufacturer resources, such as user manuals or online databases, can provide additional insights into the components depicted in the schematics. These resources often contain detailed descriptions and specifications, helping users better understand the function and compatibility of each element. Consulting these materials not only aids in identifying parts but also assists in selecting suitable alternatives when original components are unavailable. Investing time in this process ultimately leads to more effective maintenance practices.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and efficiency of your cleaning equipment. Proper care not only enhances performance but also prolongs the lifespan of various components. By adhering to a few straightforward practices, you can enjoy optimal functionality for years to come.

Here are some key maintenance strategies to consider:

- Clean the exterior: Regularly wipe down the outer surfaces to prevent grime buildup, which can lead to corrosion.

- Inspect hoses: Check for cracks or leaks in hoses before each use. Replacing damaged hoses promptly will prevent further issues.

- Change oil: Keep the engine well-lubricated by changing the oil according to the manufacturer’s recommendations. Fresh oil ensures smooth operation.

- Check filters: Replace or clean air and fuel filters regularly to maintain optimal airflow and efficiency.

- Winterize properly: If storing for winter, follow proper winterization procedures to avoid damage from freezing temperatures.

By implementing these practices, you can maximize the reliability and extend the life of your equipment, ensuring it remains ready for your cleaning tasks whenever needed.

Where to Find Replacement Parts

Finding suitable components for your cleaning equipment can significantly enhance its performance and lifespan. Various sources offer a wide range of options, ensuring that you can maintain your machine efficiently. Below are some effective ways to locate the necessary replacements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official website often provides a comprehensive catalog of available components, along with detailed specifications and installation guides. |

| Local Hardware Stores | Many local retailers stock essential components and can provide assistance in identifying the correct items for your equipment. |

| Online Retailers | Websites like Amazon, eBay, and specialized online shops feature a vast inventory, making it easy to compare prices and availability. |

| Authorized Dealers | Authorized sellers can offer genuine components and expert advice on selecting the right parts for optimal performance. |

| Repair Shops | Local repair shops can provide not only the components but also professional installation services, ensuring your equipment operates efficiently. |

Comparing Different Models

When considering various models of outdoor cleaning equipment, it is essential to understand their unique features and specifications. Each model offers different capabilities, making it vital to evaluate which one best suits your needs. Factors such as power output, water flow rate, and design should be taken into account to ensure optimal performance for your specific tasks.

Performance and Specifications

Different designs can vary significantly in terms of performance. For instance, some units may provide higher pressure levels, making them suitable for tackling tough grime and stains, while others prioritize water efficiency and ease of use. Additionally, the specifications often include varying motor types, which can affect overall durability and maintenance requirements.

Features and Accessories

Another important aspect to compare is the availability of features and accessories. Certain models may come with advanced nozzles, adjustable pressure settings, or integrated storage options. These enhancements not only improve functionality but also contribute to user convenience. Evaluating the range of accessories can help users customize their equipment for specific tasks, ensuring a tailored cleaning experience.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment to optimal condition. Whether you are dealing with performance issues or specific malfunctions, following a systematic procedure can help you identify and resolve the problems effectively.

-

Gather Necessary Tools and Materials:

Before starting the repair, ensure you have the required tools and components. Common items include:

- Screwdriver set

- Wrench set

- Replacement seals or gaskets

- Cleaning supplies

- Owner’s manual for reference

-

Safety First:

Always prioritize safety by wearing appropriate gear such as gloves and goggles. Make sure the machine is turned off and disconnected from any power source.

-

Identify the Problem:

Examine the equipment to determine the source of the issue. Common problems may include:

- Inadequate power output

- Unusual noises during operation

- Fluid leaks

- Difficulty in starting

-

Disassemble Components:

Carefully remove the outer casing or housing to access internal components. Keep track of screws and small parts to avoid losing them.

-

Inspect and Replace Faulty Parts:

Once disassembled, inspect each part for wear or damage. Replace any defective components with new ones as necessary. Refer to your manual for correct part numbers and specifications.

-

Reassemble the Equipment:

After replacing the necessary parts, reassemble the unit in reverse order of disassembly. Ensure all connections are secure and properly aligned.

-

Testing:

Once reassembled, conduct a thorough test to ensure everything is functioning as expected. Monitor for any unusual signs during operation.

-

Final Touches:

After successful testing, clean the equipment and perform regular maintenance checks to prolong its lifespan. Store it in a dry and secure location.

Safety Precautions When Using Washers

When operating high-powered cleaning equipment, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions can significantly reduce the risks associated with these machines, ensuring a secure and effective cleaning process.

Always wear appropriate protective gear. This includes safety goggles to shield your eyes from debris and chemicals, gloves to protect your hands, and sturdy footwear to ensure stability while working. Additionally, wearing long sleeves and pants can provide further protection from splashes and high-pressure streams.

Before starting the device, inspect it thoroughly. Check for any signs of damage or wear, especially on hoses and connections. Ensure that all parts are securely attached and functioning correctly to avoid unexpected failures during operation.

It is crucial to maintain a safe distance from the cleaning surface and bystanders. The force of the water can be powerful enough to cause injury or damage if misdirected. Always aim the nozzle away from yourself and others, and be mindful of your surroundings.

Finally, read and follow the manufacturer’s instructions carefully. Familiarize yourself with the specific features and safety guidelines of the equipment to ensure proper usage and maintenance. Adhering to these practices will help you enjoy a safe and efficient cleaning experience.

Customer Reviews and Experiences

This section aims to highlight user feedback and insights regarding their experiences with a particular model of outdoor cleaning equipment. Reviews provide valuable perspectives on the effectiveness, reliability, and overall satisfaction users have found while utilizing these machines for various tasks.

Positive Feedback

- Many users praised the ease of use, mentioning that the setup process was straightforward and quick.

- Customers frequently noted the power and efficiency of the equipment, stating it handled tough grime and dirt with minimal effort.

- Several reviewers appreciated the durable construction, emphasizing that it remained operational even after extensive use.

Areas for Improvement

- Some users reported occasional difficulties in sourcing specific components for repairs or replacements.

- A few customers expressed a desire for more detailed user manuals to assist with maintenance and troubleshooting.

- There were mentions of noise levels being higher than expected during operation, which could be a consideration for residential use.

Overall, user experiences reflect a balance of satisfaction and suggestions for enhancements, offering potential buyers insights into what they might expect from their purchase.