Maintaining a well-functioning garden cultivator requires knowledge of its key elements. Each mechanism plays a vital role in ensuring smooth operation and efficiency in preparing soil for planting. By familiarizing yourself with how the various parts work together, you can keep the equipment in top shape and ensure its longevity.

In this guide, we’ll explore the essential components of these machines, from the engine to the blades, highlighting their functions and how they contribute to the overall performance. This understanding will not only help with repairs but also assist in regular maintenance, allowing you to maximize the productivity of your garden tool.

Whether you’re dealing with repairs or regular upkeep, knowing the function of each element is crucial. A well-maintained tool can save time and energy in the long run, helping you achieve the best results in your gardening projects. Understanding these core elements will enable you to troubleshoot more effectively and make informed decisions when replacement or adjustments are necessary.

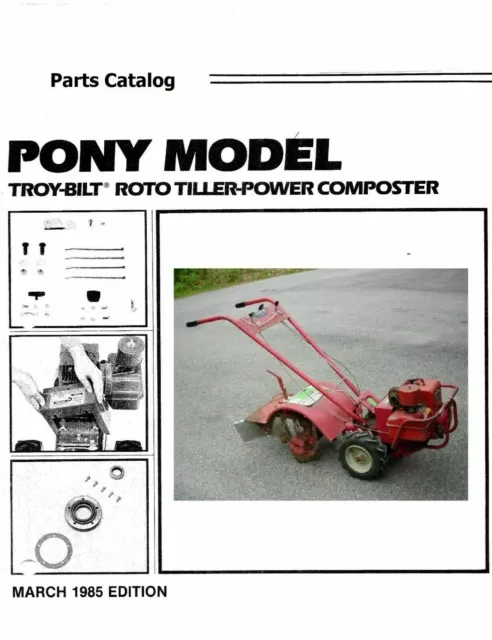

Key Components Overview

The equipment consists of multiple crucial elements designed to work together seamlessly for effective soil preparation. Each of these components plays a unique role, ensuring optimal performance during operation. Understanding how these pieces interact will help in maintaining and repairing the machine efficiently.

Engine and Power Source: The heart of the machine, responsible for generating the necessary power to drive the entire system. Proper care and regular maintenance of this section are essential for long-term use.

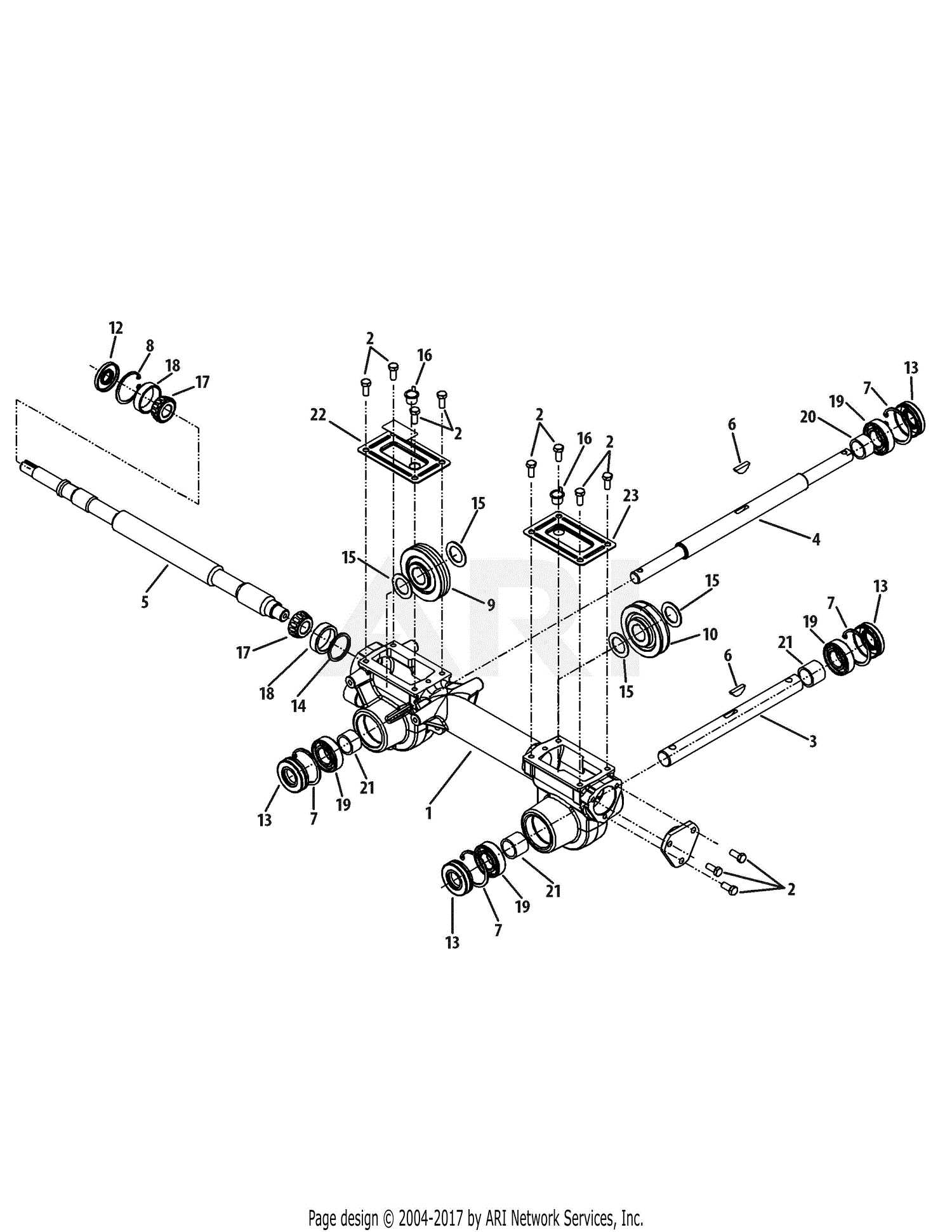

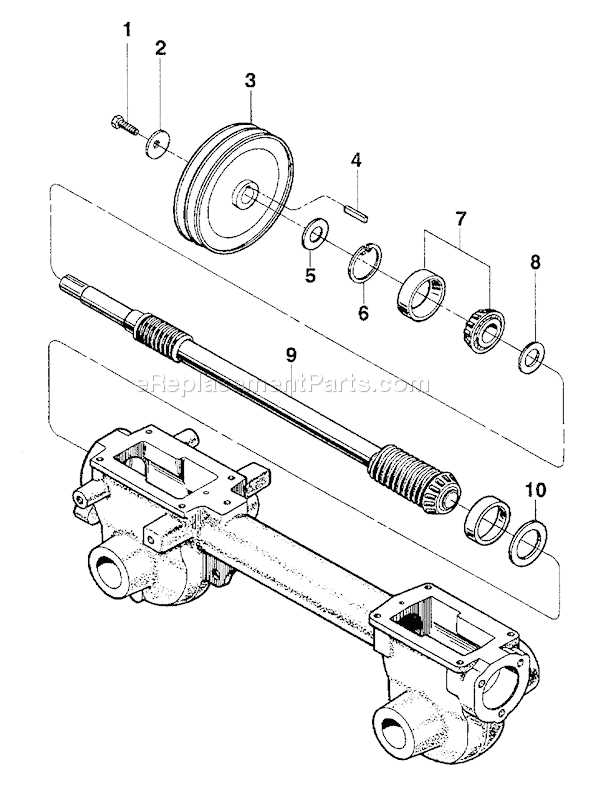

Transmission System: This part directs the power from the engine to the working components, allowing controlled movement and precise handling during operation. A well-maintained transmission ensures smooth operation in a variety of conditions.

Tines and Blades: These rotating elements are responsible for breaking up and turning the soil. Depending on the type and model, they vary in size and design to handle different soil types and tasks efficiently.

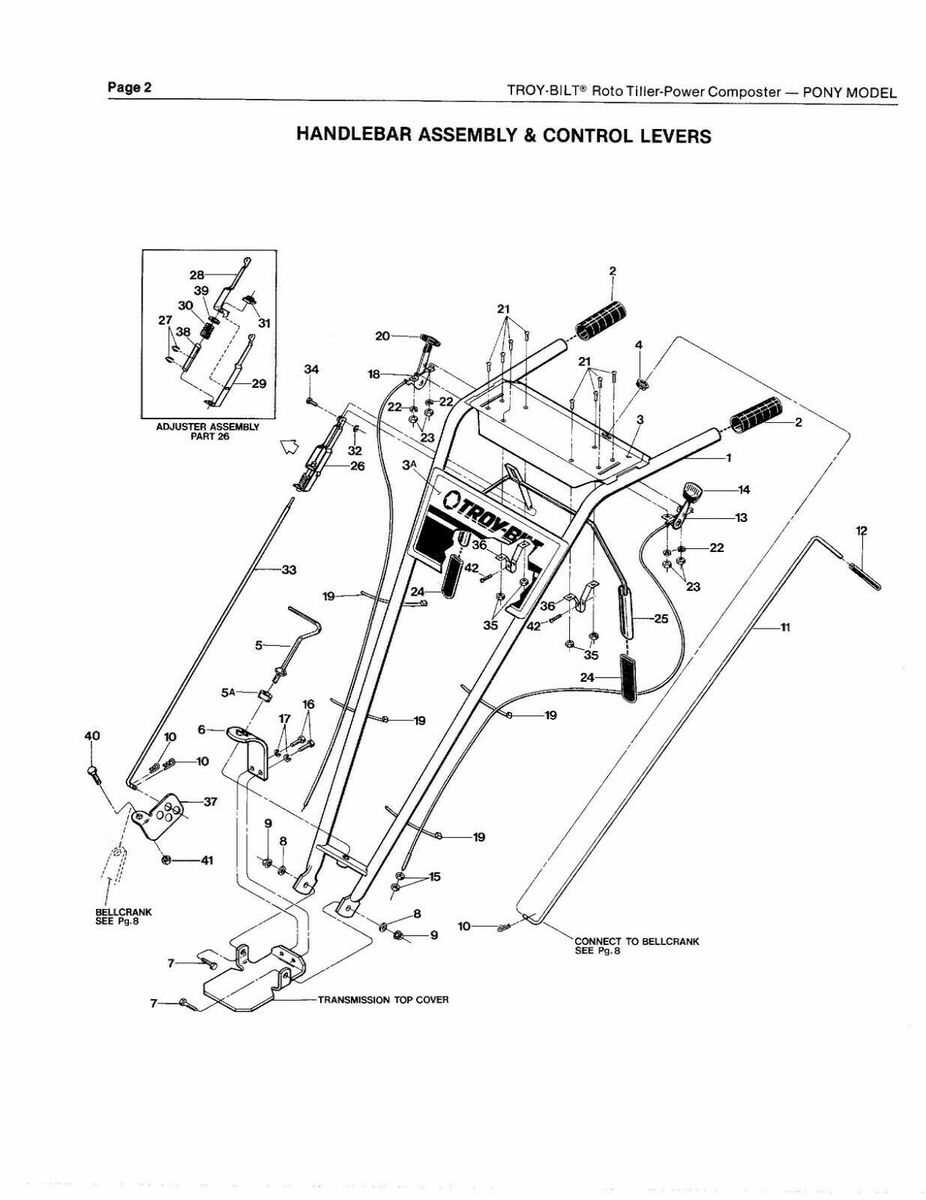

Handlebars and Control Mechanisms: The steering and control center, allowing the operator to guide the machine with precision. These elements are critical for user safety and ease of use, with ergonomic designs often included for comfort.

Understanding the Function of Key Components

In any machinery that is designed to work with soil, each individual element plays a vital role in ensuring smooth operation. These components work together to ensure that the machine performs its intended tasks efficiently. By gaining an understanding of how these key elements function, one can better maintain and troubleshoot the equipment.

Engine: The engine is the heart of the system, providing the necessary power to drive the entire mechanism. Without a properly functioning engine, the machine will not have the strength to complete its tasks.

Tines: These are responsible for digging into the soil. The sharp blades rotate, breaking up hard surfaces, making it easier for planting or other garden preparations.

Transmission: The transmission directs power from the engine to the tines. It controls the speed and torque, enabling precise adjustments based on the conditions of the ground.

Handlebars and controls: These elements provide the user with full command over the machine, allowing them to steer, adjust settings, and control the direction of the equipment.

How to Identify Worn-Out Parts

Over time, components in mechanical equipment may show signs of wear and tear. It is essential to regularly inspect key elements to ensure they function optimally. Failure to address aging or damaged elements can lead to decreased performance or even complete failure of the equipment.

Common Signs of Wear

Visual inspection is often the first step in identifying problematic areas. Look for cracks, rust, or any deformations that suggest weakening. Regular friction can cause surface damage, which is an early indication of potential issues.

Performance-Related Clues

If the equipment is not operating as smoothly as it once did, this could signal worn-out internal elements. A reduction in efficiency, strange noises, or excessive vibration may all be signs that certain components are reaching the end of their lifespan.

Essential Maintenance Tips for Longevity

Regular upkeep is vital to ensure that your equipment performs optimally and lasts for years. Proper care prevents wear and tear, reducing the likelihood of malfunctions. By focusing on essential tasks, you can extend the lifespan of your machine and maintain its efficiency.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Lubricate moving parts | Every 10 hours of use | Prevents rust and friction |

| Check and replace belts | Monthly | Ensures smooth operation |

| Clean air filters | After every use | Improves engine efficiency |

| Inspect blades for sharpness | Seasonally | Enhances cutting performance |

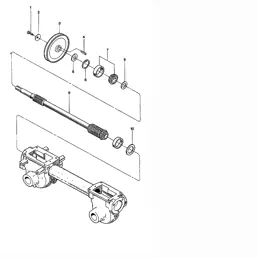

Replacing the Drive Belt: A Step-by-Step Guide

The drive belt plays a crucial role in the functionality of your gardening equipment. Over time, it can wear out, leading to reduced performance or complete failure of the machine’s ability to move properly. This guide will walk you through the process of changing the belt to restore efficient operation.

Step 1: Accessing the Belt

Before beginning the replacement, ensure the machine is powered off and unplugged for safety. Locate the belt housing by removing the cover that protects the belt system. This might require unscrewing a few bolts or fasteners to expose the mechanism inside.

Step 2: Removing the Old Belt

Once the housing is open, carefully loosen the tension on the belt by adjusting the tensioner or pulley system. Gently slide the old belt off the pulleys and remove it from the machine. Check the pulleys for any signs of damage or wear before proceeding with the new belt installation.

Important: Make sure the new belt is the correct size and type for your machine to ensure proper fit and function. Follow the manufacturer’s instructions for proper tension adjustment after installation.

Importance of Regular Gearbox Maintenance

Proper upkeep of the transmission system is essential for ensuring the longevity and optimal performance of any machinery. Regular maintenance helps to prevent wear and tear, which can lead to costly repairs and downtime. By taking proactive steps, operators can extend the life of their equipment and enhance its efficiency.

Neglecting maintenance can result in various issues, such as overheating, fluid leaks, and gear misalignment. These problems not only affect the machine’s functionality but can also pose safety risks. Therefore, it is crucial to establish a routine maintenance schedule that includes checking fluid levels, inspecting seals, and cleaning components.

Additionally, addressing minor issues promptly can prevent them from escalating into major failures. Regular checks and timely repairs create a reliable operation environment, ultimately saving time and resources. Emphasizing gearbox maintenance contributes to a smoother and more effective workflow.

Commonly Replaced Tines and Blades

In any garden cultivation machine, the tines and blades play a crucial role in soil preparation and aeration. Over time, these components can experience wear and tear due to regular use, necessitating their replacement to maintain optimal performance. Identifying which tines and blades are most frequently swapped out can help users ensure their equipment operates efficiently.

Some of the most commonly replaced components include the standard tines, designed for effective tilling, and heavy-duty blades, which provide additional durability in tougher soil conditions. Regular maintenance and timely replacements not only enhance the machine’s efficiency but also prolong its lifespan, making it essential for users to stay informed about these vital parts.

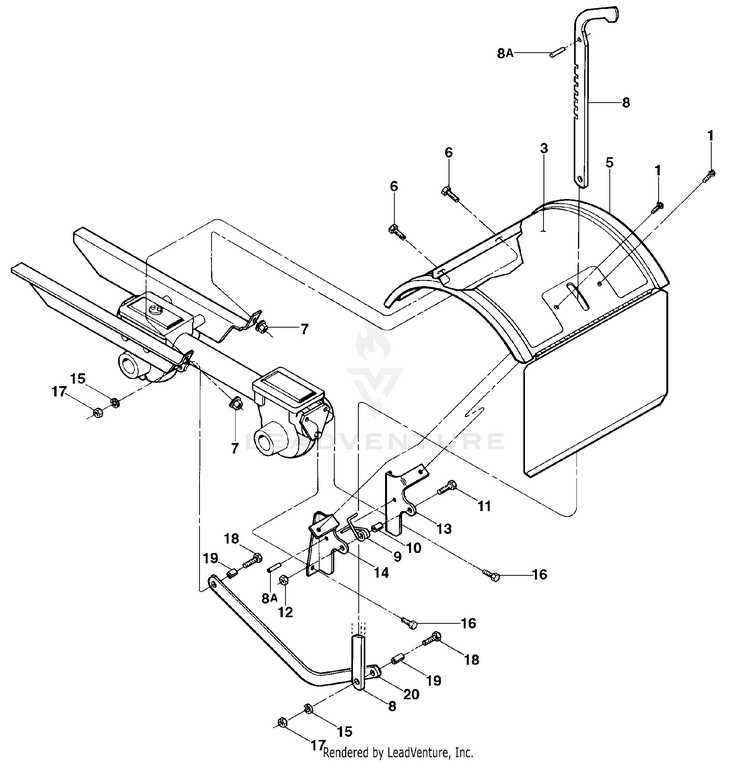

Troubleshooting Fuel System Issues

Fuel system malfunctions can hinder the performance of your gardening equipment, leading to operational difficulties. Identifying and resolving these issues promptly is essential for maintaining efficiency and functionality. Common problems include fuel delivery failures, contamination, and improper fuel mixture, all of which can affect the machine’s performance.

Identifying Symptoms

Before addressing the fuel system, observe the machine’s behavior. If the engine struggles to start, runs unevenly, or experiences stalling, these may be indicators of underlying fuel system problems. Checking fuel levels and examining for leaks can provide initial insights into the issue. Additionally, consider whether the fuel is fresh and suitable for the equipment.

Common Solutions

To resolve fuel-related issues, start by ensuring that the fuel filter is clean and free of debris. If it appears clogged, replacing it can often restore proper fuel flow. Additionally, inspecting the fuel lines for any signs of wear or blockage is crucial. Regular maintenance and timely replacement of worn components can significantly reduce the likelihood of future complications.

How to Maintain the Engine for Optimal Performance

Proper care and regular maintenance of the engine are essential for ensuring peak efficiency and longevity. By adhering to a few straightforward practices, you can enhance the functionality of your equipment and prevent potential issues from arising.

Regular Oil Changes: Changing the oil at recommended intervals is crucial. Fresh oil lubricates the engine components, reducing friction and preventing wear. Always use the oil type specified by the manufacturer to maintain optimal performance.

Air Filter Maintenance: A clean air filter allows for proper airflow to the engine, which is vital for combustion. Inspect and replace the air filter regularly to avoid clogging, which can lead to decreased efficiency and performance.

Fuel Quality: Using high-quality fuel is essential for engine health. Ensure that the fuel is fresh and free from contaminants. Stale or low-quality fuel can cause starting issues and reduce overall performance.

Inspecting Spark Plugs: Regularly checking and replacing spark plugs can improve ignition and ensure smooth engine operation. Worn or fouled spark plugs can lead to misfires and poor performance, so they should be part of your maintenance routine.

Cooling System Checks: Ensure that the cooling system is functioning correctly. Overheating can cause significant engine damage. Regularly check the coolant levels and inspect for leaks to keep the engine operating within the ideal temperature range.

By following these maintenance tips, you can significantly extend the life of your engine and ensure that it operates at its best, providing reliable performance for all your tasks.

Protecting the Rototiller from Rust and Corrosion

Maintaining the longevity of your gardening equipment requires proactive measures to prevent damage from moisture and environmental factors. Rust and corrosion can significantly affect the performance and lifespan of machinery, making it crucial to adopt strategies that minimize exposure to harmful elements.

Regular Cleaning and Maintenance

Consistent upkeep is essential for keeping your equipment in optimal condition. After each use, thoroughly clean the metal surfaces to remove dirt, mud, and organic matter that can trap moisture. Utilize a brush or a damp cloth to wipe down components and ensure they are free from debris.

Applying Protective Coatings

Another effective method to shield your equipment is by applying protective coatings. Using rust-resistant sprays or oils can create a barrier against moisture. Focus on areas that are more susceptible to wear and tear, ensuring a long-lasting protective layer is established. Reapply these coatings periodically to maintain their effectiveness.

Where to Find Replacement Parts for Troy Bilt Rototillers

Maintaining your gardening equipment is crucial for optimal performance. When it comes to sourcing essential components for your tilling machine, there are several avenues to explore. Whether you’re in need of basic tools or specific mechanisms, knowing where to look can save time and effort.

Online Retailers: Numerous online marketplaces offer a wide range of components for various garden machines. Websites like Amazon or eBay frequently stock both original and aftermarket options. It’s advisable to read reviews and compare prices to ensure quality.

Manufacturer’s Website: The official website of the equipment manufacturer often provides access to an extensive catalog of items designed specifically for their products. This resource is ideal for finding authentic components that guarantee compatibility.

Local Hardware Stores: Many local stores carry a selection of components for popular gardening machines. Visiting these establishments allows you to consult with knowledgeable staff who can assist in identifying the right parts.

Specialty Shops: Some stores specialize in outdoor equipment and maintenance supplies. These shops may have a more comprehensive inventory of components, including those hard-to-find pieces that are essential for effective machine operation.

By utilizing these resources, you can ensure that your gardening machine remains in top shape, allowing you to maintain your outdoor space efficiently.