In any well-maintained outdoor space, the functionality of garden machinery plays a vital role. Familiarity with the various elements that make up these machines can greatly enhance their performance and longevity. By comprehending how each component contributes to the overall operation, users can ensure that their equipment runs smoothly and efficiently.

Moreover, a clear visualization of these components helps in identifying any issues that may arise during use. When problems occur, knowing the arrangement and purpose of each part enables more effective troubleshooting and repairs. This knowledge not only saves time but also reduces maintenance costs in the long run.

Understanding the layout of the machinery is essential for anyone looking to optimize their gardening experience. Whether you are a novice or an experienced gardener, having a grasp of how the machine functions can lead to better results and a more enjoyable outdoor activity.

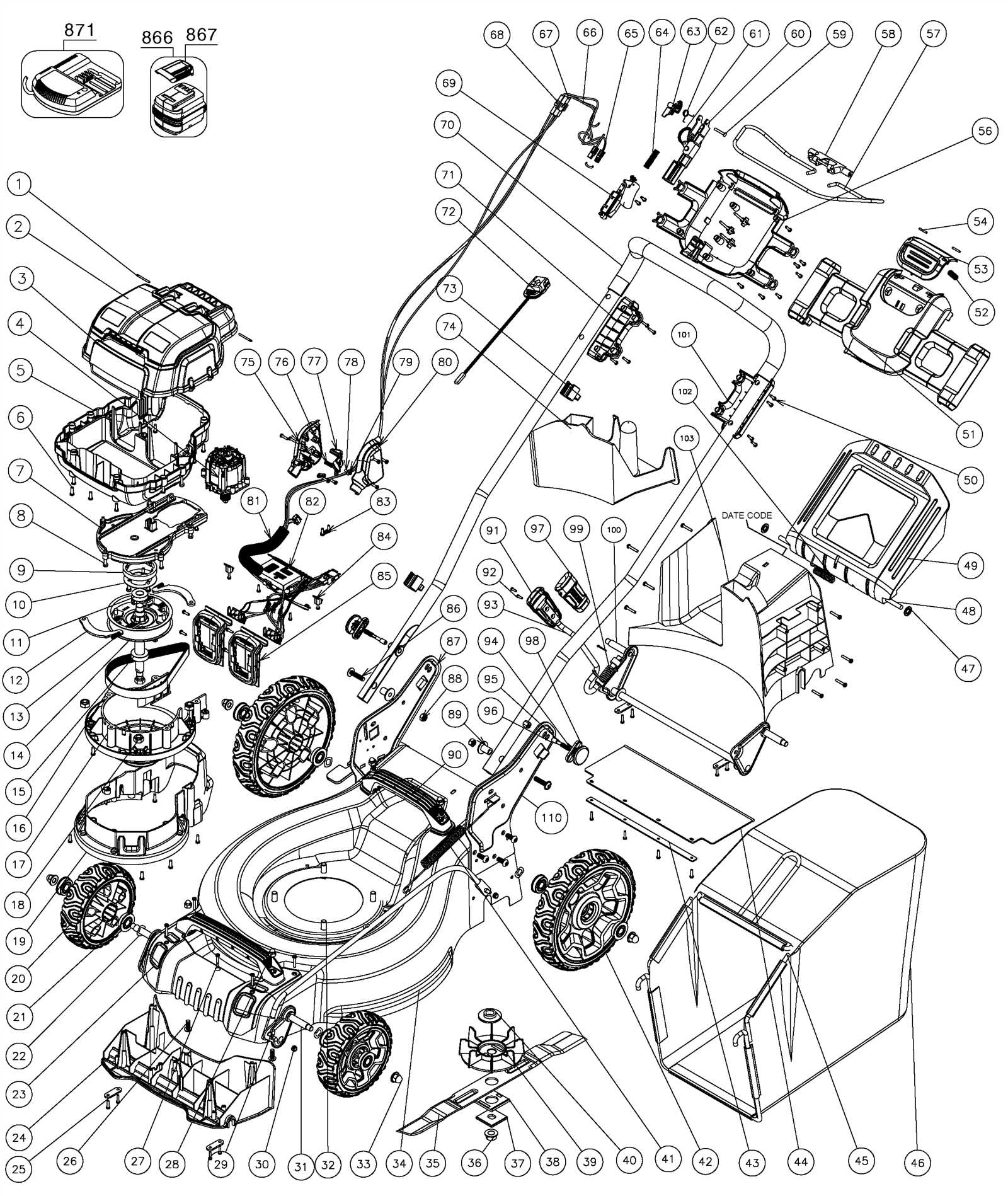

Understanding the fundamental components of grass-cutting machines is crucial for their maintenance and efficient operation. Each element plays a significant role in the overall functionality, contributing to the effectiveness and longevity of the equipment. Familiarity with these essential components can enhance the user experience and ensure optimal performance.

Key Components Overview

The primary components of these machines include the engine, blades, and the drive system. Each part serves a distinct purpose, working together to achieve a well-manicured yard. Here is a closer look at these vital elements:

| Component | Description |

|---|---|

| Engine | Powers the entire unit, providing the necessary force for operation. |

| Blades | Cut the grass to the desired length, varying in size and shape for different applications. |

| Drive System | Enables movement, allowing the operator to navigate the machine easily across the terrain. |

Importance of Regular Maintenance

Regular upkeep of these key components is vital to ensure the reliability and efficiency of the equipment. Neglecting any part can lead to diminished performance or even operational failure. Understanding and addressing maintenance needs is essential for every user aiming for a well-maintained outdoor space.

Common Issues and Solutions

Maintaining a garden care device can present various challenges that users may encounter over time. Understanding these common problems and their corresponding solutions can significantly enhance the user experience and prolong the lifespan of the equipment.

| Issue | Solution |

|---|---|

| Engine won’t start | Check the fuel level and ensure it is fresh. Inspect the spark plug for damage and replace if necessary. |

| Uneven cutting | Examine the blades for sharpness and alignment. Sharpen or replace blades as needed. |

| Device vibrates excessively | Inspect for loose parts and tighten any screws or bolts. Ensure the blade is properly installed. |

| Excessive fuel consumption | Ensure the air filter is clean and replace if it is dirty. Check for fuel leaks and rectify any issues. |

Maintenance Tips for Longevity

Proper care is essential for ensuring the durability and optimal performance of your gardening equipment. Regular upkeep not only enhances efficiency but also extends the lifespan of the device. Here are some essential practices to consider for maintaining your machine effectively.

Regular Cleaning

Keeping your equipment clean is crucial for preventing the buildup of debris and dirt, which can affect performance. Follow these steps:

- Remove grass clippings and dirt after each use.

- Use a brush or compressed air to clean hard-to-reach areas.

- Inspect and clean the wheels and chassis regularly.

Routine Checks and Adjustments

Performing periodic inspections can help identify potential issues early. Focus on these areas:

- Examine the blades for wear and replace them if dull.

- Check fluid levels and change oil according to the manufacturer’s schedule.

- Ensure all nuts and bolts are tightened to prevent loose components.

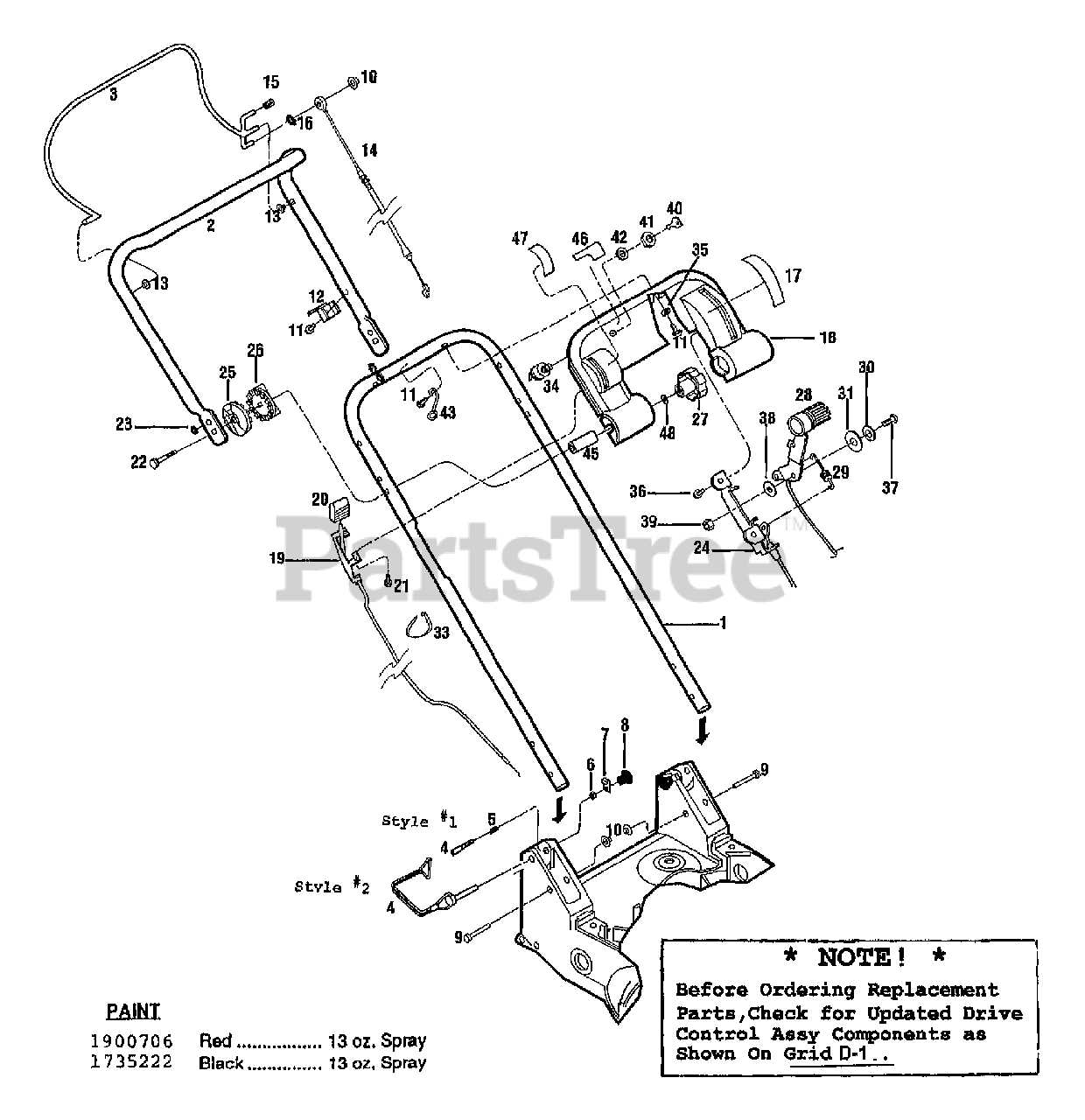

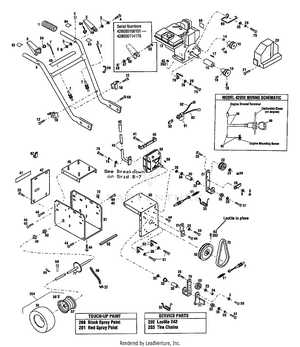

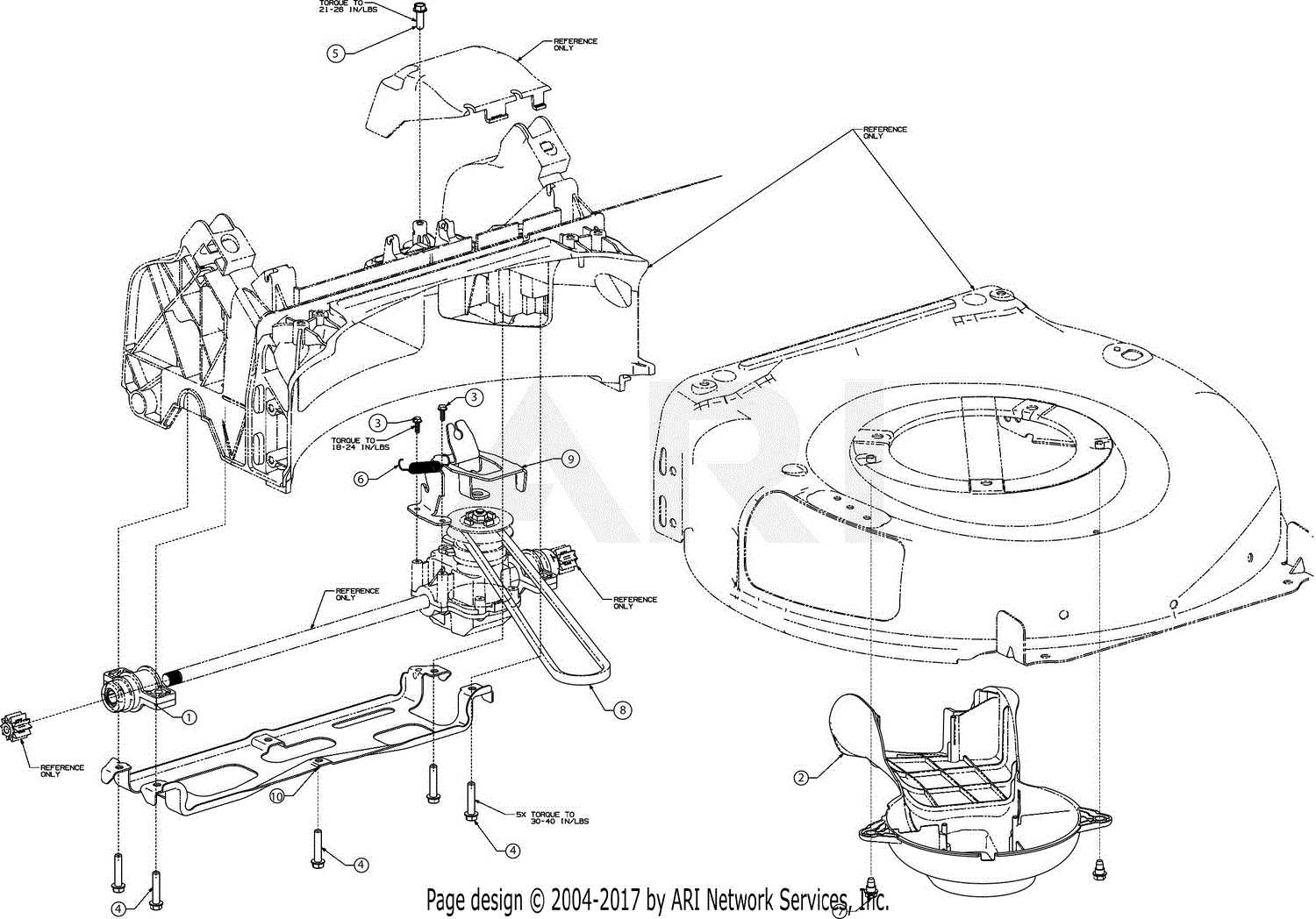

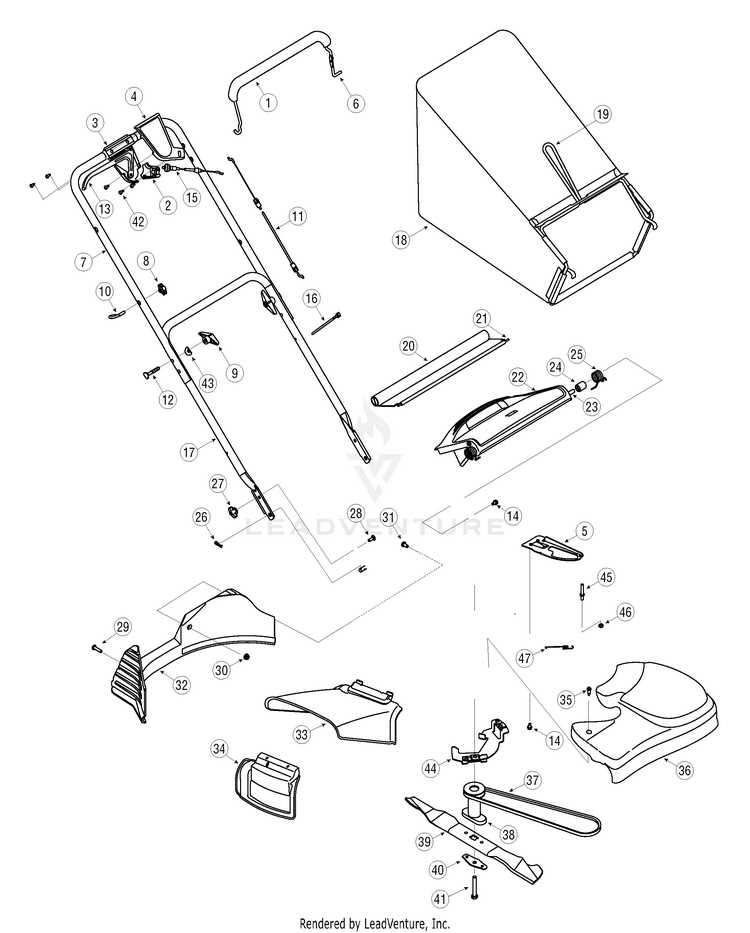

How to Identify Spare Parts

Recognizing the necessary components for your equipment can enhance its performance and longevity. Understanding how to determine the correct replacements is crucial for effective maintenance. This section offers guidance on the essential steps to identify these items accurately.

1. Refer to the Owner’s Manual: The first step in identifying components is consulting the owner’s guide. It typically includes a list of the essential elements and their specifications. This resource will assist in understanding the functionality of each element and its importance in the overall operation.

2. Examine the Existing Components: Carefully inspect the current elements in your equipment. Look for any numbers or labels that indicate the model or serial number. This information can be instrumental in finding exact replacements or compatible options.

3. Utilize Online Resources: Numerous websites offer detailed catalogs and schematics for various models. By entering your model number, you can access comprehensive information that facilitates the identification of replacements.

4. Consult with Professionals: If uncertainty persists, reaching out to experts or local service centers can provide valuable insights. They can guide you in identifying the correct components based on their experience and knowledge.

5. Join Community Forums: Engaging with online forums and user groups can also be beneficial. Many enthusiasts share their experiences and advice regarding component identification, which can aid in your search.

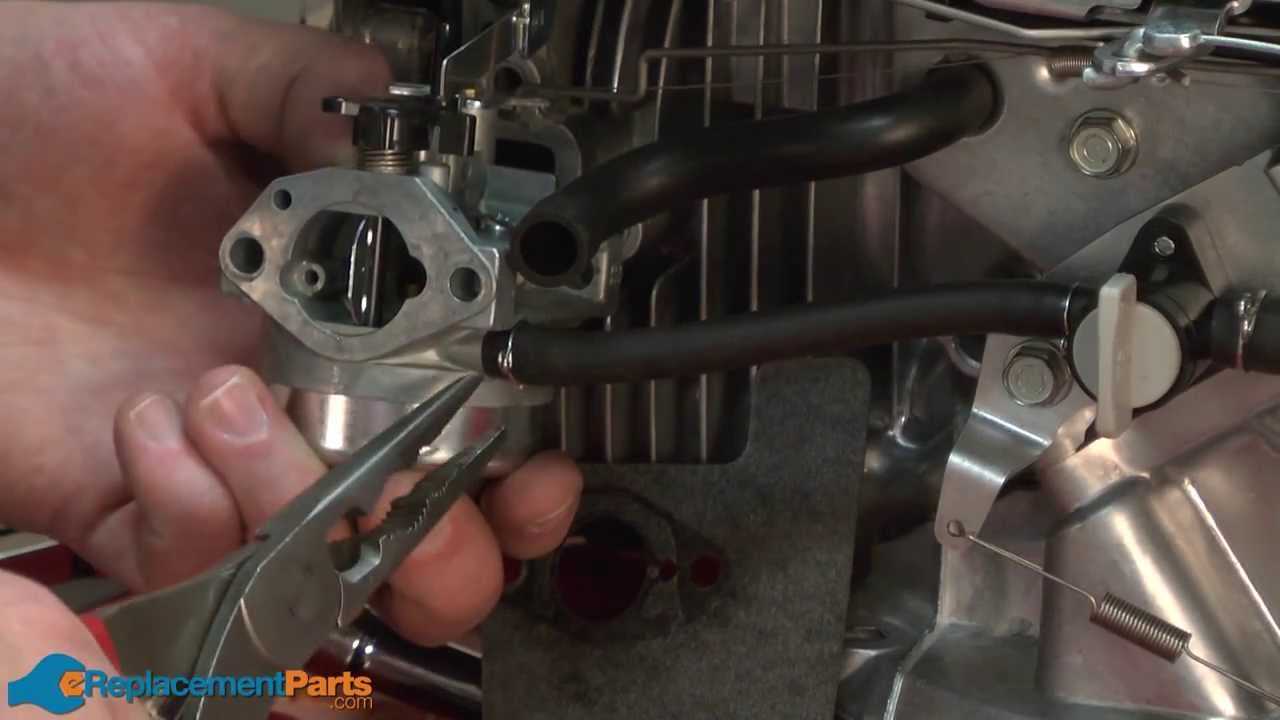

Tools Required for Repairs

When undertaking maintenance tasks, having the appropriate instruments is essential for ensuring effective and efficient repairs. Various implements are necessary to facilitate the disassembly and assembly of components, allowing for straightforward troubleshooting and adjustments.

Basic hand tools, such as wrenches and screwdrivers, form the foundation of any repair toolkit. These allow for the loosening and tightening of fasteners, which is critical during the replacement or adjustment of various components. Additionally, pliers can provide extra grip and leverage when dealing with stubborn parts.

Power tools, including drills and impact drivers, can significantly reduce the time required for tasks that involve repetitive actions. A multimeter may also be useful for diagnosing electrical issues, ensuring that the system operates smoothly. Finally, having a clean workspace with a sturdy workbench can enhance productivity and safety during the repair process.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring functionality to your equipment. The process outlined here will help you navigate through common issues, ensuring that each stage is manageable and understandable. By following these steps, you can effectively troubleshoot and resolve typical mechanical challenges.

Preparation and Safety Measures

Before starting any repair work, it’s crucial to take necessary precautions. Ensure that you have the right tools on hand and that your workspace is clear. Wearing protective gear is advisable to prevent any injuries during the repair process.

Identifying Common Issues

To effectively address the problem, begin by diagnosing the symptoms. Common issues may include difficulty in operation, unusual noises, or poor performance. Carefully observe the equipment and note any irregularities that could indicate underlying problems.

| Issue | Possible Cause | Suggested Action |

|---|---|---|

| Poor Performance | Clogged components | Clean or replace filters |

| Unusual Noises | Loose fittings | Tighten screws and bolts |

| Difficulty Starting | Faulty ignition system | Inspect and replace spark plug |

Following these guidelines will assist in restoring your equipment to optimal working condition. Remember to consult the user manual for specific details related to your model.

Where to Buy Replacement Parts

Finding suitable components for your outdoor equipment can significantly enhance its performance and longevity. Various sources provide these essential items, catering to different needs and budgets. Exploring reputable retailers ensures that you obtain quality replacements for optimal functionality.

Local hardware stores often stock a range of components, making it convenient to find what you need without extensive searching. Additionally, specialized garden centers might offer a selection of specific items that can be harder to locate elsewhere. Engaging with knowledgeable staff can help you identify the right pieces for your equipment.

Online marketplaces present a vast selection of options, allowing you to compare prices and reviews from various sellers. Websites dedicated to outdoor tools frequently have comprehensive catalogs, making it easier to find the exact replacements you require. Always verify the seller’s credibility and check for return policies to ensure a satisfactory purchase.

Manufacturer websites also provide direct access to authentic replacements. This option guarantees compatibility and quality, as these sources offer original components designed specifically for your model. Signing up for newsletters can alert you to sales or discounts, further aiding your search.

Comparing Different Lawn Mower Models

When selecting a suitable grass cutting machine, it’s essential to evaluate various designs and features to determine which best meets individual needs. Different models can offer distinct advantages in terms of functionality, efficiency, and ease of use. Understanding these variations can assist users in making informed choices.

Many machines are equipped with specific characteristics that cater to different mowing preferences and yard sizes. Below is a comparative overview of several popular models highlighting key aspects that may influence a buyer’s decision.

| Model Name | Engine Power (cc) | Cutting Width (inches) | Weight (lbs) | Drive Type |

|---|---|---|---|---|

| Model A | 160 | 21 | 45 | Rear-Wheel Drive |

| Model B | 190 | 22 | 50 | Front-Wheel Drive |

| Model C | 150 | 20 | 40 | All-Wheel Drive |

| Model D | 200 | 24 | 55 | Variable Speed |

Improving Mower Performance

Enhancing the efficiency of a cutting device requires a combination of maintenance, adjustments, and upgrades. By focusing on these key aspects, users can ensure optimal functionality and a smooth operation, leading to better results in yard care.

Regular Maintenance Practices

Consistent upkeep is essential for maintaining the effectiveness of any machinery. This includes cleaning the blades, checking for wear and tear, and ensuring that all components are functioning correctly. Lubrication of moving parts reduces friction and prolongs the lifespan of the equipment.

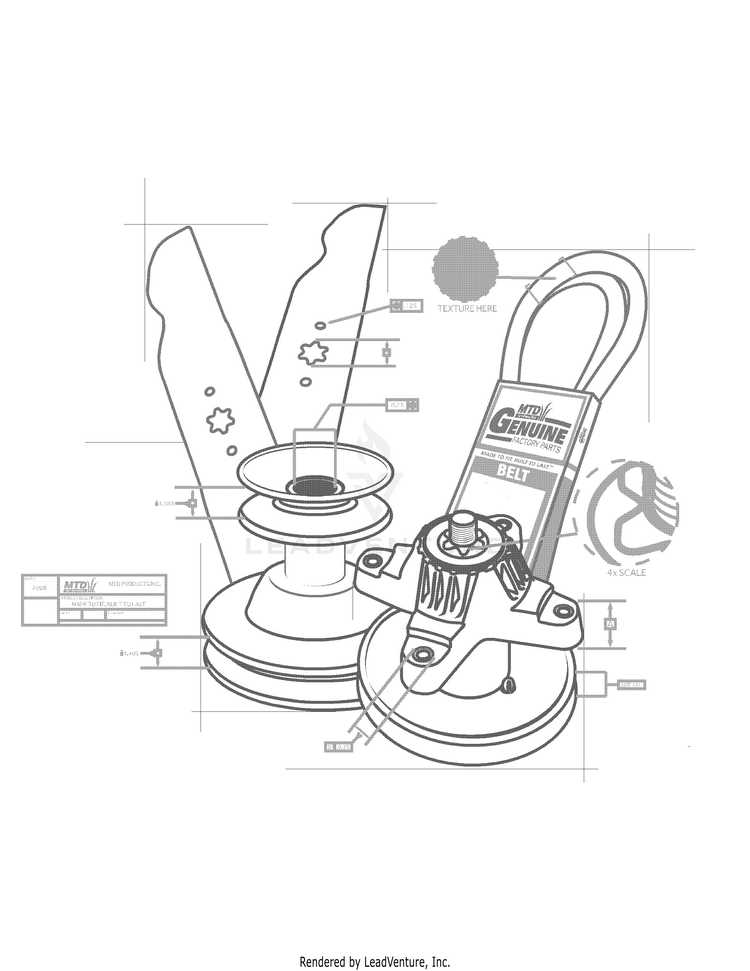

Upgrading Components

Investing in higher-quality components can significantly improve overall performance. Consider replacing dull or damaged blades with sharper alternatives that provide a cleaner cut. Additionally, upgrading the power source or fuel system can result in enhanced power and efficiency, making the device more effective for larger tasks.

Safety Precautions During Maintenance

Proper precautions are essential when performing upkeep on machinery to ensure both personal safety and equipment longevity. Recognizing potential hazards and implementing safety measures can prevent accidents and enhance the maintenance process. Below are critical guidelines to follow.

General Safety Guidelines

Before commencing any maintenance work, it is crucial to disconnect the power source to avoid accidental activation. Always wear appropriate protective gear, such as gloves and safety glasses, to shield against debris and sharp objects. Additionally, ensure the work area is clean and well-lit to minimize risks.

Handling Tools and Equipment

Using tools safely is paramount during maintenance activities. Inspect all tools for defects prior to use and employ them according to the manufacturer’s instructions. Store tools properly after use to prevent tripping hazards and ensure they remain in good condition.

| Precaution | Description |

|---|---|

| Disconnect Power | Always turn off the machine and unplug it before maintenance. |

| Wear Protective Gear | Use gloves and goggles to protect against injuries. |

| Keep Work Area Clear | Maintain a tidy workspace to reduce hazards. |

| Inspect Tools | Check tools for damage to ensure safe operation. |