In the realm of aquatic power systems, a comprehensive grasp of engine elements is essential for optimal performance and maintenance. This section explores the intricate relationships and functionalities of various components that drive watercraft efficiency. By dissecting each part, we aim to enhance your familiarity with the mechanics that keep vessels running smoothly.

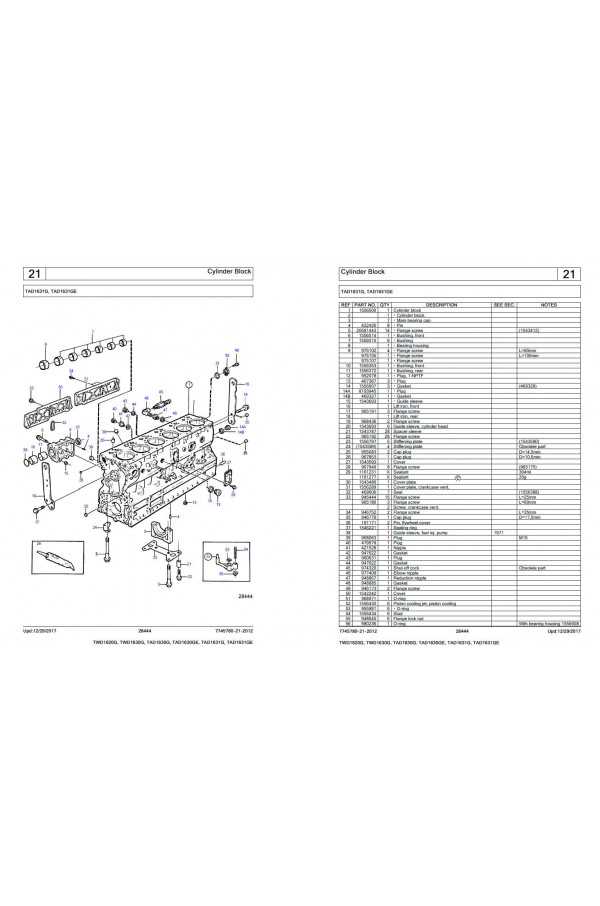

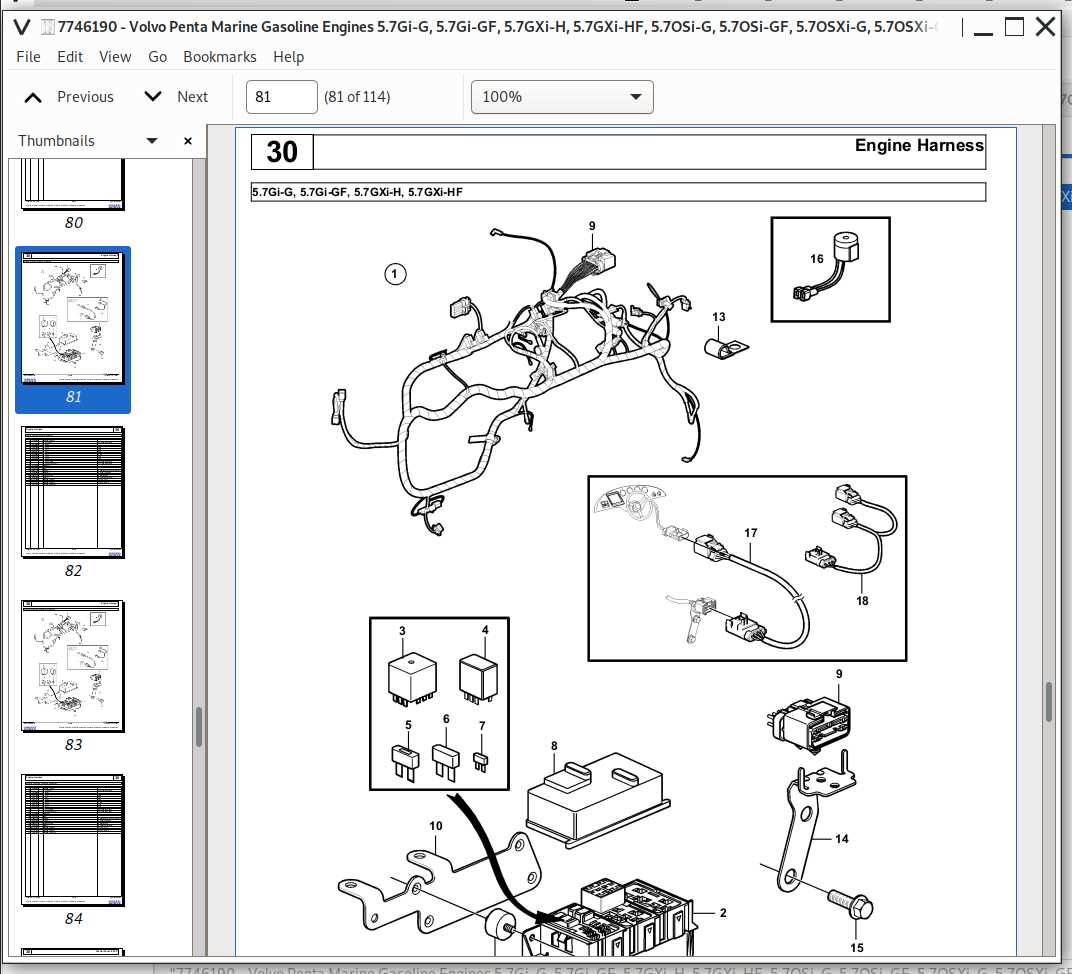

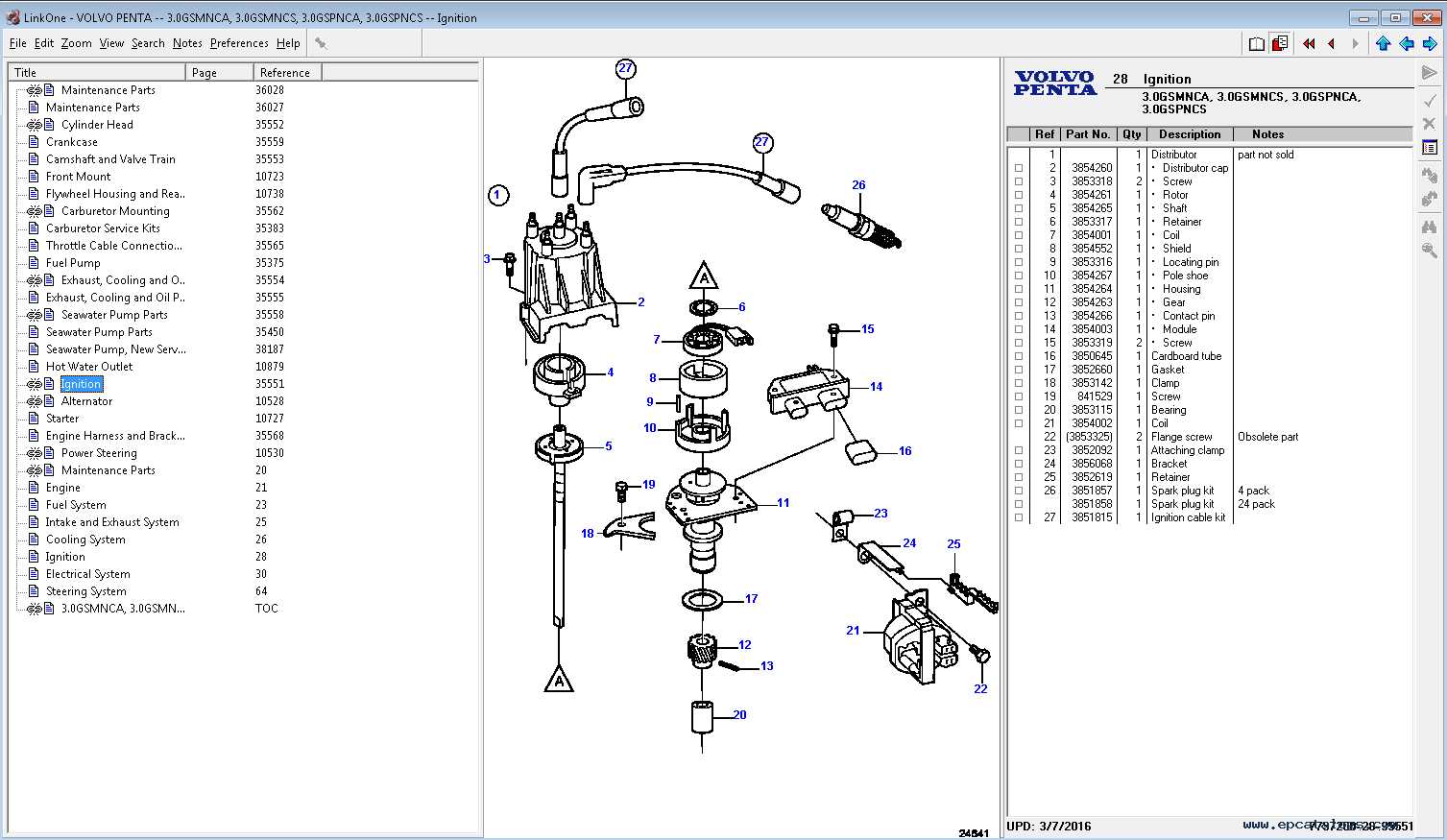

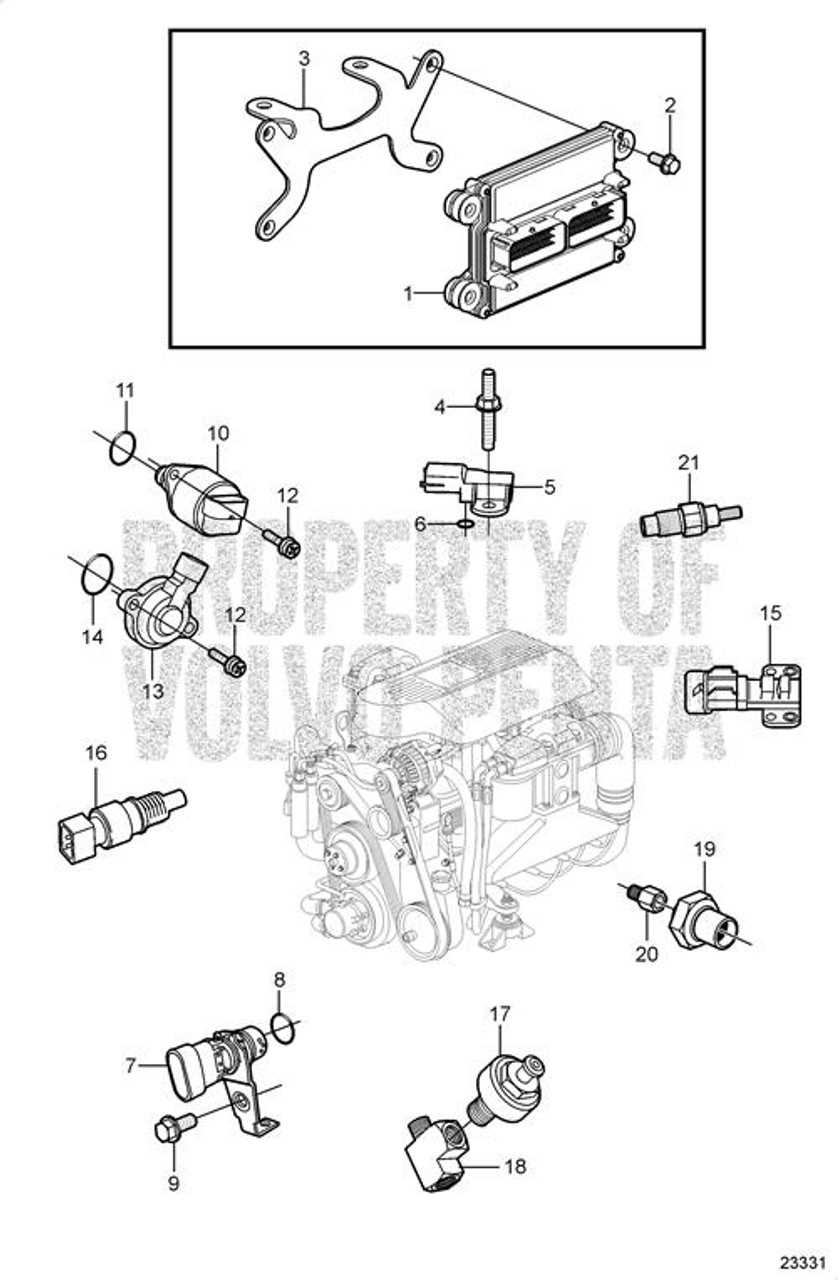

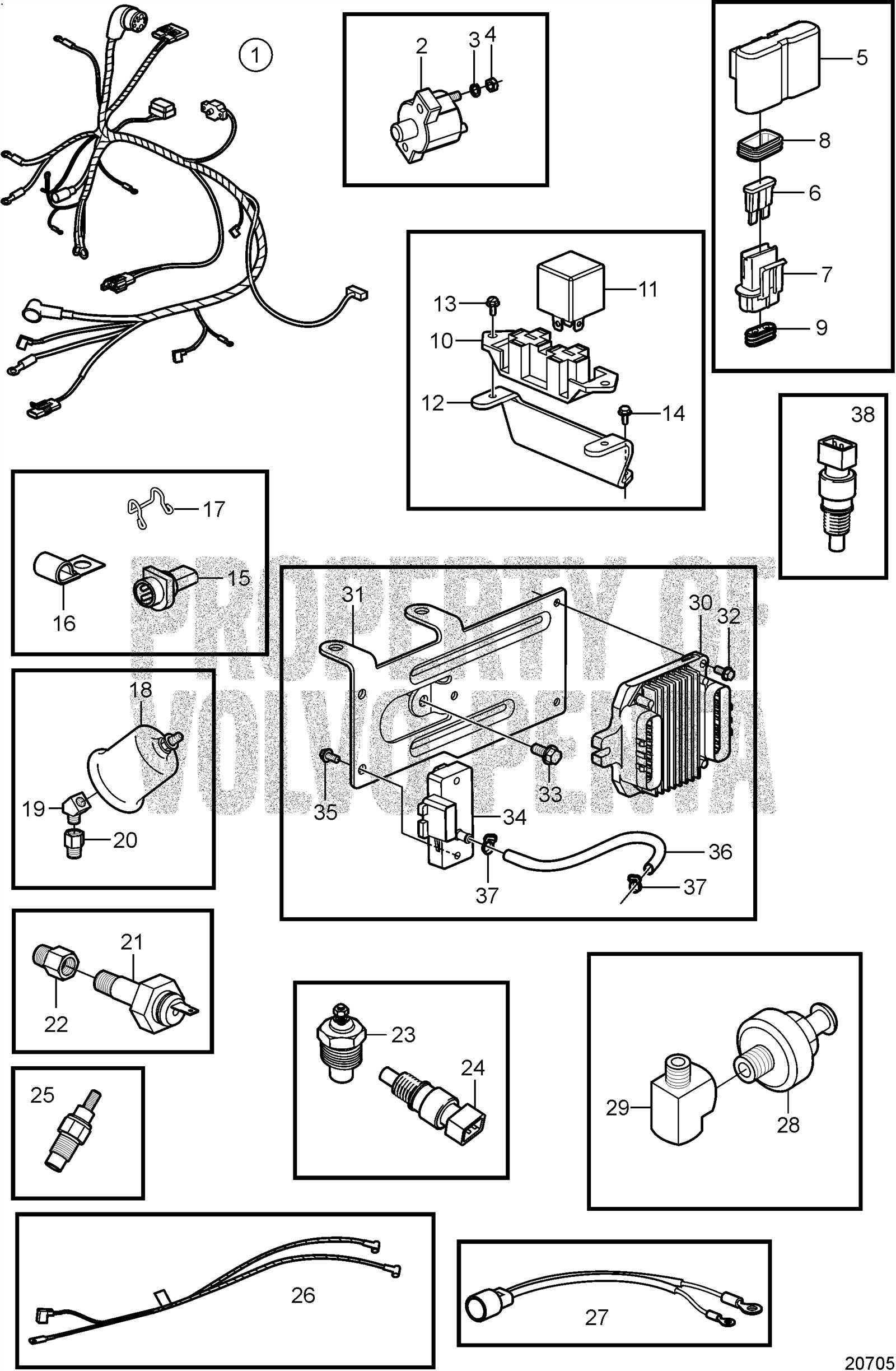

Detailed illustrations serve as invaluable tools, allowing enthusiasts and professionals alike to visualize the arrangement and connection of vital elements. By examining these representations, you can pinpoint specific sections and understand their roles within the broader system. This insight not only aids in repairs but also fosters a deeper appreciation for the engineering behind maritime technology.

Whether you are a seasoned technician or a curious newcomer, this exploration promises to enrich your knowledge base. Emphasizing the importance of each component ensures that you are well-equipped to address any challenges that may arise, ultimately enhancing your boating experience.

Understanding Volvo Penta 5.0 GXi Components

The internal structure of marine engines is crucial for optimal performance and longevity. Each element plays a significant role, contributing to the overall efficiency and functionality of the system. A comprehensive grasp of these components enables better maintenance, troubleshooting, and enhancement of engine operations.

In examining the individual elements, it becomes evident that the interactions between them are vital. For instance, the power generation unit works in tandem with the cooling apparatus, ensuring that heat is managed effectively. Additionally, the fuel delivery system is essential for achieving the desired power output, highlighting the importance of precision in component design and integration.

Understanding these intricate relationships not only facilitates better operational knowledge but also aids in identifying potential issues before they escalate. Whether it’s a minor adjustment or a major overhaul, familiarity with these key parts empowers users to make informed decisions regarding repairs and upgrades.

By delving into the specifics of each unit, one can appreciate the craftsmanship involved in marine engineering. From the ignition mechanisms to the exhaust systems, every component is designed with purpose, ensuring reliability and performance on the water.

In summary, a detailed awareness of the various sections of a marine engine allows for improved maintenance strategies and enhances the overall boating experience. As technology evolves, staying informed about these essential elements remains paramount for enthusiasts and professionals alike.

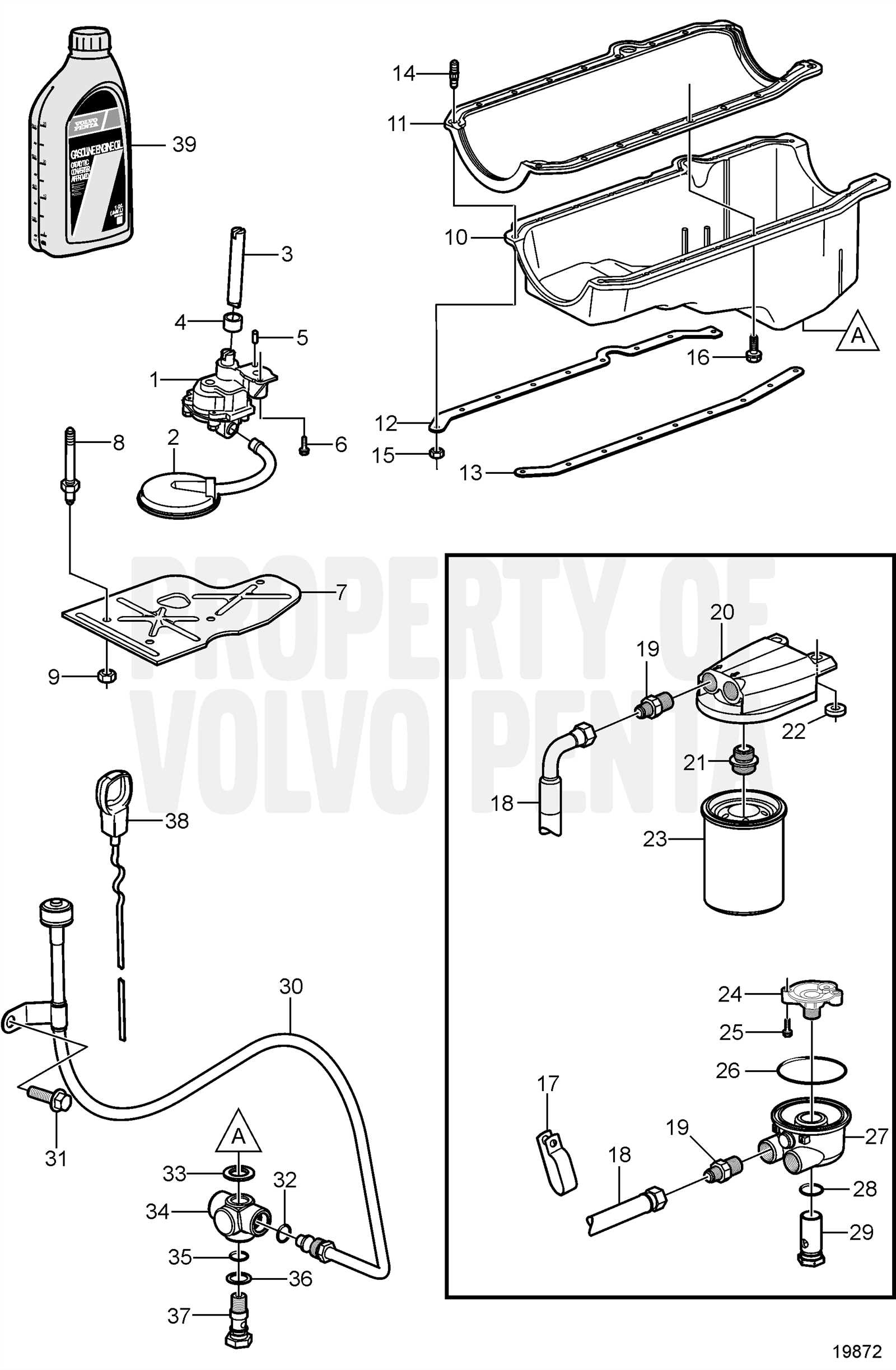

Essential Parts of the Engine Diagram

The functionality of an internal combustion engine relies heavily on various components working in harmony. Understanding the fundamental elements is crucial for anyone looking to maintain or repair these systems. Each part plays a specific role, contributing to the overall performance and efficiency of the engine.

Block: The core structure that houses critical internal components. Its design affects cooling and oil circulation.

Cylinder Head: Positioned atop the block, this component seals the cylinders and contains valves that control the intake of air and fuel, as well as the exhaust of combustion gases.

Pistons: These move within the cylinders, converting the energy from combustion into mechanical motion. Their design influences the engine’s power output and efficiency.

Crankshaft: This crucial element transforms the linear motion of the pistons into rotational motion, driving the vehicle’s wheels or other machinery.

Camshaft: Responsible for timing the opening and closing of valves, this component ensures the engine breathes properly, optimizing performance and fuel consumption.

Fuel Injectors: These deliver the precise amount of fuel into the combustion chamber, playing a vital role in the engine’s efficiency and power output.

Ignition System: This system generates the spark needed to ignite the fuel-air mixture, making it essential for starting and running the engine smoothly.

Familiarity with these key components allows for better troubleshooting and maintenance, ensuring the longevity and reliability of the engine.

Common Issues with 5.0 GXi Parts

Maintenance and performance can often be challenged by various issues related to engine components. Understanding these common problems is essential for ensuring longevity and optimal operation. From wear and tear to specific component failures, recognizing these issues can help in prompt diagnosis and repair.

1. Overheating: One prevalent concern is overheating, which can stem from a malfunctioning cooling system or blocked waterways. If not addressed, this can lead to severe damage.

2. Fuel Delivery Problems: Inconsistent fuel delivery can cause engine stalling or reduced performance. Issues with the fuel pump or filters often contribute to these disruptions.

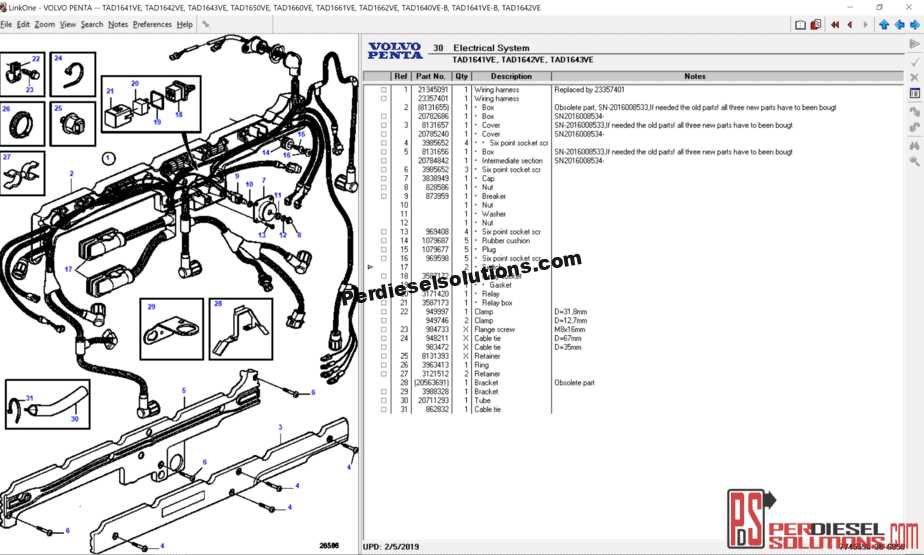

3. Electrical Failures: Electrical components, such as sensors and ignition systems, may experience failures due to corrosion or wear. This can lead to starting issues or erratic performance.

4. Oil Leaks: Leaks are a common issue that can result from worn gaskets or seals. Regular checks can prevent potential engine damage from low oil levels.

5. Exhaust Emissions: Elevated emissions may indicate problems with the exhaust system or engine tuning. Addressing these issues promptly is vital for compliance and performance.

By staying aware of these challenges, operators can take proactive measures to maintain their engines effectively.

Where to Find Replacement Components

Finding the right components for your marine engine can be a challenging task. Whether you are looking for maintenance parts or specific replacements, it is essential to know where to search to ensure you get quality items that meet your needs. There are several avenues available to source these components effectively.

Authorized Dealers

One of the most reliable sources for obtaining quality components is through authorized dealers. These establishments are certified to sell genuine products, ensuring compatibility and performance. Here’s what you can expect:

| Advantages | Considerations |

|---|---|

| Genuine quality assurance | Potentially higher prices |

| Expert advice available | Limited stock availability |

Online Retailers

Another option is to explore various online retailers. The internet offers a vast marketplace where you can find a wide range of components at competitive prices. Be sure to check reviews and ratings to ensure credibility:

| Pros | Cons |

|---|---|

| Convenient access from home | Quality may vary |

| Often lower prices | Shipping times may vary |

Maintenance Tips for Volvo Penta Engines

Regular upkeep is essential for ensuring the longevity and optimal performance of marine engines. By following a structured maintenance routine, you can prevent potential issues and enhance efficiency, ultimately contributing to a smoother boating experience.

Here are some key maintenance practices to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil and filter to maintain lubrication. |

| Cooling System Check | Annually | Inspect hoses and replace coolant as needed to prevent overheating. |

| Fuel System Inspection | Every season | Check fuel filters and lines for leaks or clogs. |

| Battery Maintenance | Monthly | Clean terminals and check charge levels to ensure reliability. |

| Propeller Examination | Before each use | Inspect for damage and debris to ensure efficient performance. |

Incorporating these practices into your maintenance schedule will help you delve deeper into the health of your engine and secure its ultimate performance on the water.

How to Read Parts Diagrams Effectively

Understanding schematic representations is essential for anyone looking to service or maintain machinery. These illustrations provide a visual guide to the components involved, making it easier to identify, locate, and order the necessary elements. By mastering the art of interpreting these visuals, you can streamline repairs and ensure your equipment runs smoothly.

Familiarize Yourself with the Symbols

Before diving into the illustration, take time to learn the common symbols and notations used. Each component typically has a specific representation, and recognizing these can save you time. Often, a key or legend accompanies the visual, detailing what each symbol signifies. By understanding these symbols, you’ll enhance your ability to decode the entire schematic effectively.

Follow the Flow of Information

As you examine the schematic, pay attention to how the information is organized. Many representations flow from one section to another, indicating relationships and dependencies between components. Start at the designated entry point and trace the paths, noting how different parts interact with each other. This approach helps in grasping the overall system and can guide you in troubleshooting or replacing specific elements.

Aftermarket Options for 5.0 GXi Parts

Exploring alternative components for marine engines can significantly enhance performance and reduce maintenance costs. The availability of aftermarket solutions offers boat owners a diverse range of choices, ensuring they can find suitable replacements that meet their needs without compromising quality.

Benefits of Aftermarket Components

- Cost-effectiveness: Often more affordable than original manufacturer items.

- Improved availability: Wider selection of suppliers increases accessibility.

- Enhanced performance: Some aftermarket options are designed to provide better efficiency.

Considerations When Choosing Alternatives

- Quality assurance: Always verify the reputation of the manufacturer.

- Compatibility: Ensure the components fit correctly with your specific engine model.

- Warranty options: Look for products that come with a guarantee for peace of mind.

Comparing Genuine vs. Generic Parts

When it comes to maintaining and repairing machinery, the choice between authentic components and their alternative counterparts can significantly impact performance and longevity. Genuine items are crafted by the original manufacturer and are often associated with higher quality assurance and compatibility. In contrast, generic alternatives are typically more budget-friendly but may vary in durability and reliability.

One of the primary advantages of authentic components is their precise engineering, which ensures seamless integration with existing systems. This often translates to reduced risk of malfunction and extended service life. On the other hand, generic options may appeal to those looking to cut costs, but potential drawbacks include variations in material quality and a lack of rigorous testing standards.

Another factor to consider is warranty coverage. Authentic items frequently come with comprehensive warranties, providing peace of mind for the user. Conversely, generic options might lack such guarantees, leaving the buyer vulnerable to unforeseen issues. Ultimately, the decision should be guided by factors such as budget, usage requirements, and the critical nature of the equipment involved.

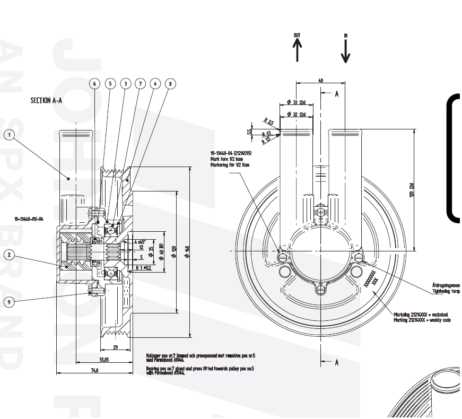

Assembly Process of 5.0 GXi Components

The assembly process of marine engine components involves a systematic approach to ensure optimal performance and longevity. Each element must be meticulously integrated, allowing for seamless functionality and reliability during operation. Understanding this intricate process is essential for maintenance and troubleshooting.

First, it is crucial to prepare the workspace and gather all necessary tools and components. This preparation phase includes cleaning surfaces, verifying that all parts are present, and ensuring that each piece meets quality standards. Attention to detail at this stage sets the foundation for successful assembly.

Next, components are typically assembled in a specific sequence. This sequence often starts with the base assembly, followed by the integration of critical systems such as the fuel delivery and ignition systems. Each step requires careful alignment and tightening of fasteners to maintain structural integrity and prevent future issues.

As the assembly progresses, testing at various stages is vital. This ensures that each system functions correctly before moving on to the next phase. Implementing this practice can significantly reduce the likelihood of complications later on.

Finally, the completed assembly undergoes a thorough inspection. This includes checking for proper fit and alignment, as well as verifying that all connections are secure. By adhering to these steps, the longevity and efficiency of the marine engine are greatly enhanced.

Impact of Quality on Engine Performance

The relationship between quality and engine functionality is crucial in determining overall performance. High-quality components and materials contribute significantly to the efficiency and reliability of any motor. When every element is crafted with precision and care, the entire system operates smoothly, minimizing the risk of failures and enhancing longevity.

Furthermore, the use of quality materials can reduce wear and tear, which in turn decreases maintenance costs and prolongs the lifespan of the engine. Investing in premium components ensures that users can enjoy optimal performance over time, making it a wise choice for both recreational and commercial applications.

Ultimately, the impact of quality on engine performance is evident across various metrics, underscoring the importance of selecting top-tier materials and components for any engine system.

Upgrades and Modifications for 5.0 GXi

Enhancing the performance and efficiency of marine engines can significantly elevate your boating experience. Various improvements can be implemented to achieve better power, fuel efficiency, and overall reliability. These adjustments not only optimize engine function but also extend its lifespan.

Performance Chips: Installing a performance chip can unlock additional horsepower and torque, providing a more exhilarating ride. This simple upgrade can drastically change how the vessel handles under load.

Exhaust Systems: Upgrading to a high-performance exhaust system improves airflow and reduces back pressure, leading to better engine efficiency and a sportier sound. This modification not only boosts performance but also enhances the aesthetic appeal of your craft.

Propeller Selection: Choosing the right propeller can optimize acceleration and top speed. Experimenting with different sizes and materials allows for tailored performance based on specific usage needs.

Cooling Systems: An upgraded cooling system can maintain optimal operating temperatures, especially during extended use. This modification ensures longevity and reliability, preventing overheating issues.

Ignition Systems: A modern ignition system enhances spark efficiency, leading to improved fuel combustion and better overall performance. This upgrade can make a noticeable difference in throttle response and fuel consumption.

By exploring these modifications, enthusiasts can ultimately achieve a more powerful and reliable engine setup, tailored to their unique needs on the water.