In the realm of marine engineering, comprehending the intricacies of propulsion systems is essential for optimal performance and maintenance. This segment explores the essential elements that contribute to the efficient operation of watercraft, emphasizing the interconnectedness of various components.

With a detailed breakdown of the various mechanisms involved, one can appreciate how each segment plays a crucial role in enhancing maneuverability and speed. This knowledge is not only beneficial for enthusiasts but also vital for professionals aiming to ensure reliability in marine operations.

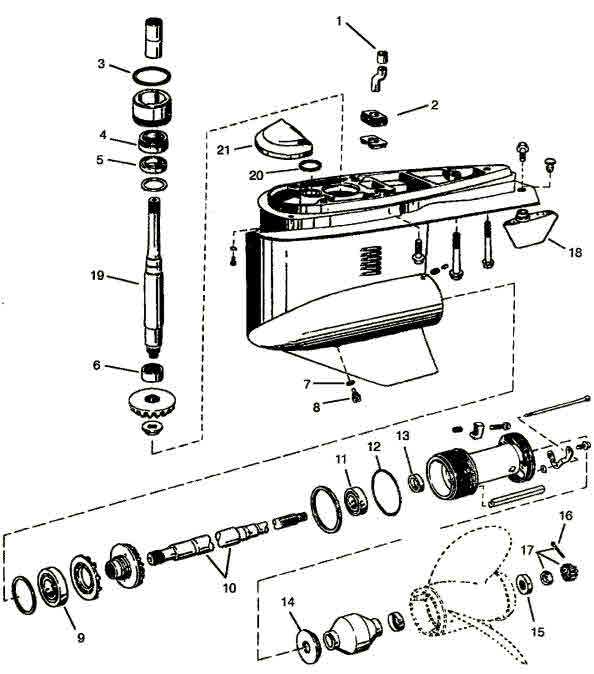

Through a comprehensive visual representation, readers will gain insights into the assembly and functionality of these critical components. By delving into the specifics, one can identify the ultimate elements that enhance durability and efficiency in maritime environments.

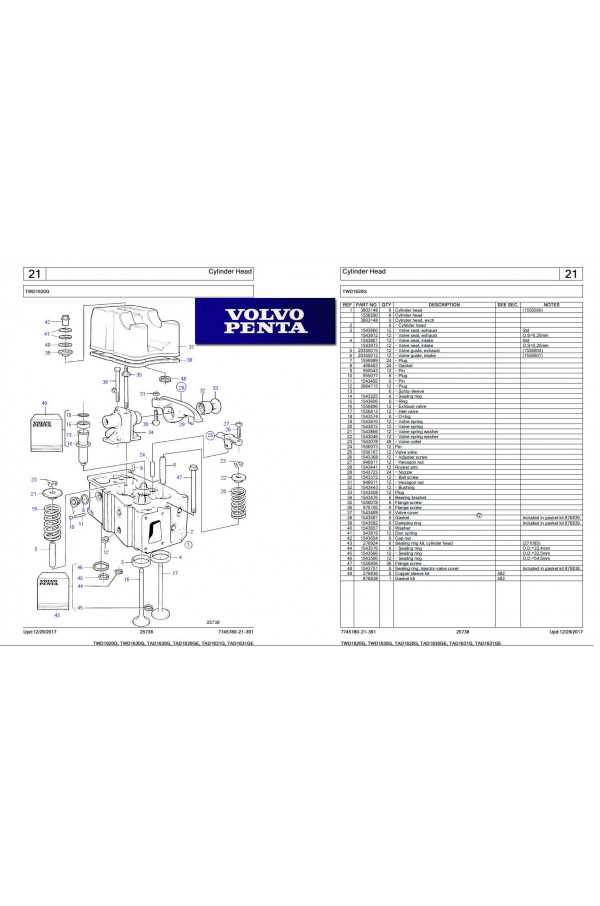

Overview of Volvo Penta DPS-B System

This section provides a comprehensive look at an advanced propulsion system designed for marine applications. It focuses on enhancing maneuverability and control, ensuring an optimized experience for both leisure and professional vessels. The innovative technology incorporated in this system allows for seamless integration with various marine engines, making it a popular choice among boaters.

Key Features

The system boasts several notable characteristics that contribute to its effectiveness in marine environments. These include enhanced steering responsiveness, reduced drag, and improved fuel efficiency. Additionally, the design incorporates sophisticated materials that withstand harsh marine conditions, ensuring longevity and reliability.

Operational Mechanism

The functionality of this propulsion system revolves around a unique interplay of mechanical and electronic components. It employs sensors and actuators to provide real-time feedback and adjustments, optimizing performance under various operating conditions. This dynamic approach allows users to maintain control over their vessels, even in challenging scenarios.

| Component | Function |

|---|---|

| Thruster | Provides lateral movement and stability |

| Control Unit | Processes input and manages system responses |

| Propeller | Generates thrust for forward and reverse motion |

| Steering Mechanism | Allows for precise directional control |

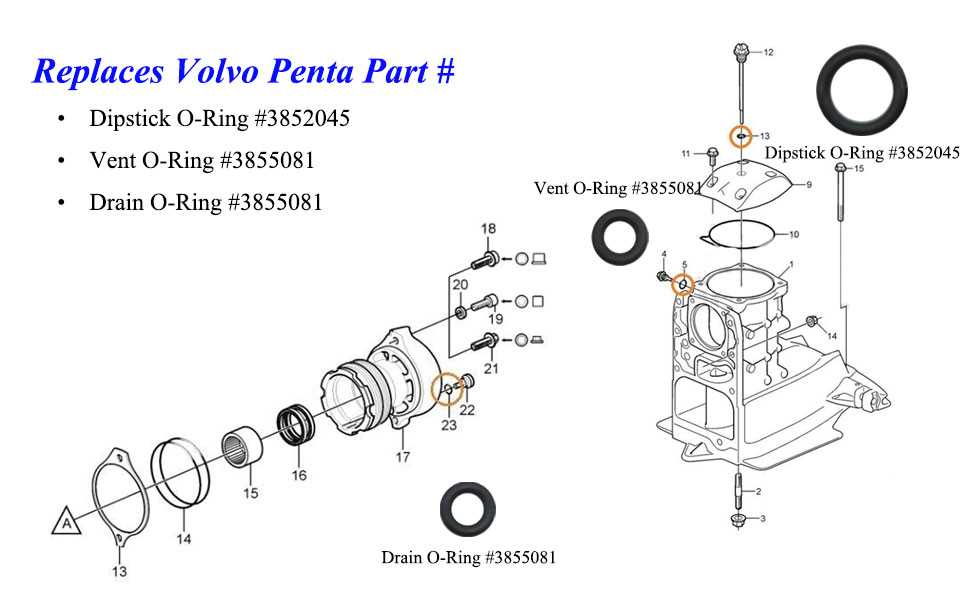

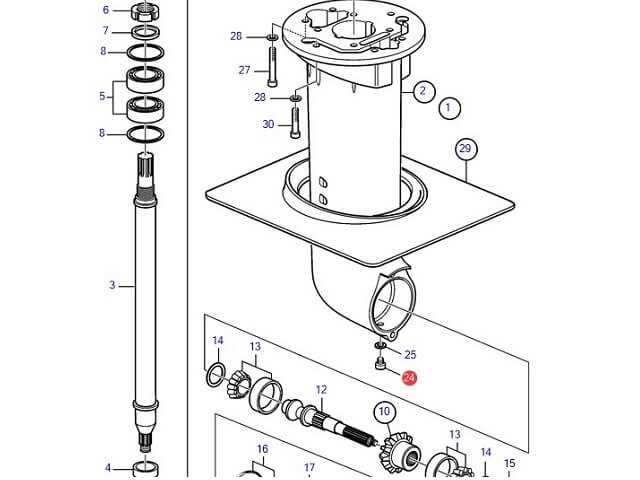

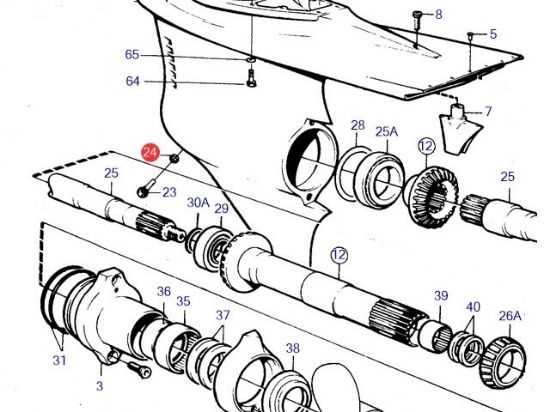

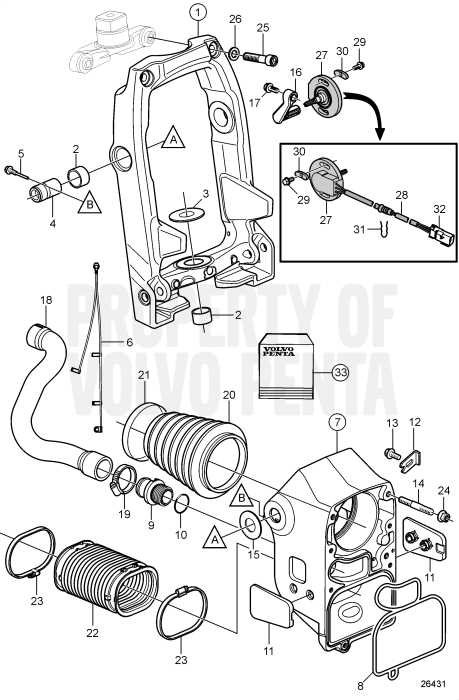

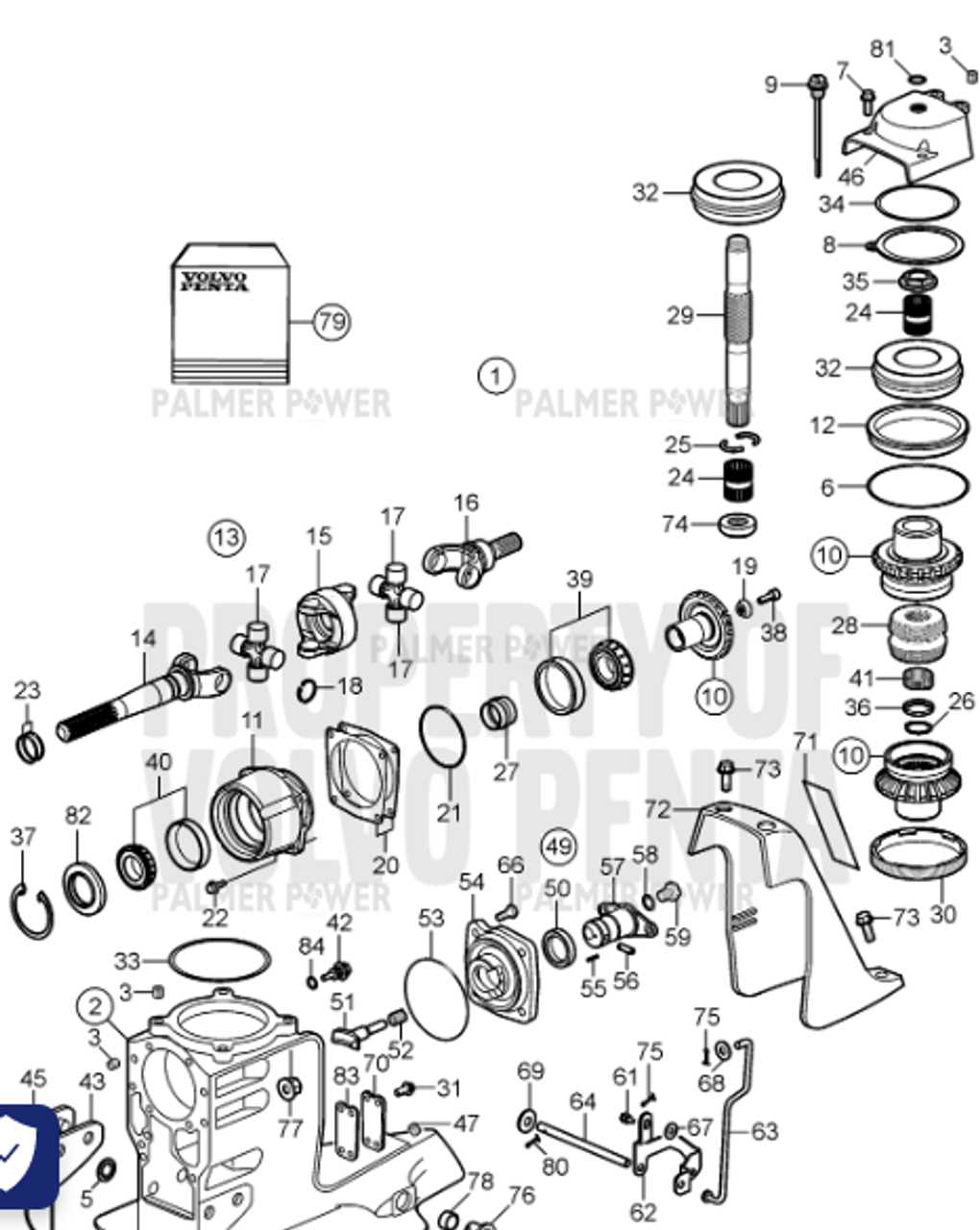

Key Components of DPS-B Parts

This section focuses on the essential elements that make up the propulsion system. Understanding these critical components is vital for effective maintenance and operation, ensuring optimal performance and longevity of the unit.

- Drive Unit: The primary mechanism responsible for converting engine power into thrust.

- Propeller: A key component that generates movement through the water, designed for efficiency and speed.

- Gimbal Ring: This element allows for a range of motion, enabling directional control while navigating.

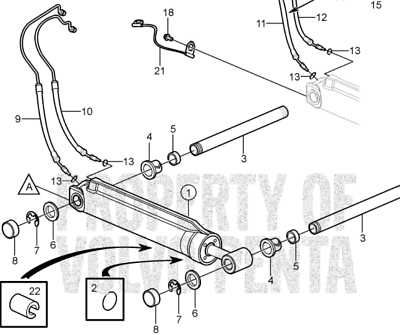

- Hydraulic System: Essential for adjusting the drive angle and providing smooth operation during turns.

Each of these components plays a significant role in the overall functionality of the system. Regular checks and maintenance of these parts are crucial to avoid potential issues and ensure seamless operation.

- Monitor the drive unit for wear and tear.

- Inspect the propeller for damage or corrosion.

- Check the gimbal ring for proper alignment.

- Maintain the hydraulic system to ensure responsiveness.

By staying attentive to these key components, operators can enhance their vessel’s performance and reliability on the water.

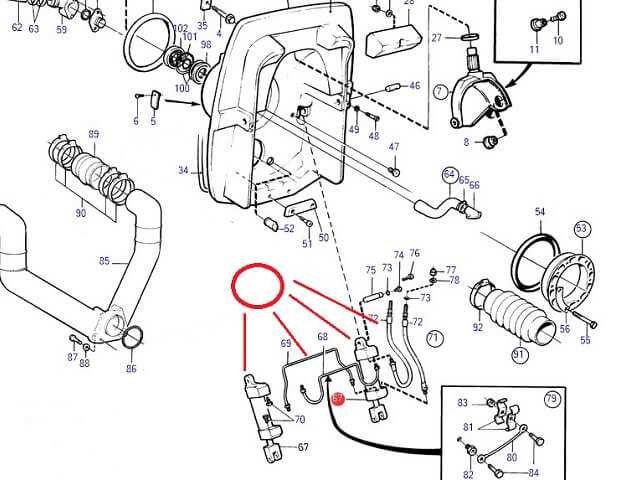

Understanding the Functionality of Each Part

Exploring the various components of a marine propulsion system reveals a complex interplay of elements, each designed to fulfill a specific role in ensuring optimal performance and reliability. By examining these individual units, one can gain insight into how they collectively contribute to the efficiency and safety of watercraft operation.

Main Components

Central to the system’s functionality are the driving mechanisms that convert engine power into thrust. This includes essential elements like the drive units and their corresponding housing, which work together to facilitate smooth movement through water. Each piece is engineered to withstand the harsh marine environment, ensuring durability and longevity.

In addition to the main driving components, various support structures play a critical role in maintaining stability and control. These include the steering apparatus and stabilization fins, which enhance maneuverability and prevent unwanted drifting. The integration of these auxiliary features is vital for achieving a balanced and responsive experience while navigating.

Common Issues and Troubleshooting Tips

Understanding potential challenges and solutions is essential for maintaining optimal performance of marine propulsion systems. By identifying frequent problems, users can take proactive measures to ensure reliability and longevity.

Frequent Problems

One common issue involves overheating, which can stem from coolant flow restrictions or faulty sensors. Regular inspection of the cooling system is vital to avoid serious damage.

Troubleshooting Techniques

For starting difficulties, check the battery and electrical connections first. Ensuring clean and secure terminals can often resolve these issues. Additionally, listening for unusual noises during operation can help pinpoint mechanical failures early.

Benefits of DPS-B for Marine Applications

The integration of advanced propulsion systems significantly enhances the performance and efficiency of marine vessels. These systems offer various advantages that cater to the diverse needs of boaters and marine operators.

- Improved Maneuverability: The design of these systems allows for exceptional control, making it easier to navigate in tight spaces and during complex maneuvers.

- Fuel Efficiency: Optimized for lower fuel consumption, these systems help reduce operating costs while maintaining high performance levels.

- Enhanced Stability: By providing better handling characteristics, these systems contribute to a smoother ride, even in challenging sea conditions.

- Durability: Built with high-quality materials, they are designed to withstand the harsh marine environment, ensuring longevity and reliability.

- Ease of Maintenance: The modular design simplifies servicing and repairs, minimizing downtime and maintenance costs.

Overall, adopting these advanced systems results in a more efficient and enjoyable boating experience, appealing to both recreational and commercial users.

Maintenance Practices for Optimal Performance

Regular upkeep is essential for ensuring that marine engines operate efficiently and reliably. Implementing systematic maintenance routines not only prolongs the lifespan of the equipment but also enhances its performance, leading to safer and more enjoyable experiences on the water.

Key Maintenance Activities

- Inspect and Replace Filters

- Check Fluid Levels and Quality

- Examine Electrical Connections

- Monitor Cooling Systems

- Clean and Test Fuel Systems

Recommended Schedule

- Daily Checks: Inspect for leaks, listen for unusual noises, and verify that all gauges are functioning correctly.

- Weekly Tasks: Clean the exterior, check battery connections, and ensure all safety equipment is in place.

- Monthly Maintenance: Replace oil and fuel filters, and inspect belts and hoses for wear.

- Seasonal Overhaul: Conduct a comprehensive inspection, including testing all systems, cleaning the cooling system, and ensuring that the engine is free of corrosion.

By adhering to these practices and schedules, users can significantly enhance the performance and reliability of their marine engines, ensuring a smooth operation throughout the boating season.

Parts Replacement: When and How

Understanding the right moments for component renewal is crucial for maintaining optimal performance and longevity of your equipment. Regular inspections and monitoring of wear and tear can help identify when a specific element needs to be addressed. Prompt action can prevent further damage and costly repairs down the line.

When it comes to the replacement process, it’s essential to follow a structured approach. Start by consulting the manufacturer’s guidelines to determine the correct specifications for the replacement item. Gather all necessary tools and ensure you have a suitable workspace. Take your time during removal to avoid damaging surrounding components, and carefully install the new element, ensuring a secure fit and proper alignment.

After replacement, conduct a thorough check to confirm everything is functioning as intended. Regular maintenance and timely updates can significantly enhance the overall efficiency of your system, ensuring it operates at its best for years to come.

Compatibility with Other Models

This section explores the interconnectivity and shared components among various marine engine systems, emphasizing how certain elements can enhance overall functionality. Understanding compatibility can lead to improved maintenance and performance across different units.

Shared Components

- Engines: Many models share similar engine designs, allowing for easier upgrades.

- Transmission Systems: Certain systems utilize interchangeable gears and drive components.

- Cooling Systems: Components like heat exchangers can be found across multiple variants.

Benefits of Compatibility

- Simplified Maintenance: Access to a broader range of parts reduces downtime.

- Cost Efficiency: Shared components can lower repair and replacement costs.

- Enhanced Performance: Utilizing compatible parts can improve system reliability.

Tools Required for Repairs and Upgrades

Successful maintenance and enhancement of marine propulsion systems require a variety of essential instruments. Having the right tools on hand not only streamlines the repair process but also ensures safety and efficiency. From basic hand tools to specialized equipment, understanding what is needed is crucial for any technician.

Essential Hand Tools

Basic hand tools like wrenches, screwdrivers, and pliers are fundamental for performing routine tasks. Socket sets and torque wrenches are particularly important for securing components to manufacturer specifications, ensuring optimal performance. Additionally, a multimeter can be invaluable for electrical diagnostics.

Specialized Equipment

For more complex repairs, specialized tools such as alignment fixtures and pressure gauges are necessary. These tools enable technicians to achieve precision during upgrades or replacements, contributing to the longevity and reliability of the system. Investing in quality equipment can make a significant difference in the ultimate outcome of repair projects.

Cost Considerations for DPS-B Components

When evaluating the financial aspects of marine propulsion elements, it’s essential to account for various factors that can influence overall expenses. Understanding these costs helps in making informed decisions regarding maintenance, replacement, and upgrades.

Several key factors should be considered when estimating the costs associated with these components:

- Initial Purchase Price: The upfront cost of acquiring new components can vary significantly based on brand, quality, and specifications.

- Installation Expenses: Professional installation may be necessary, adding to the total expenditure. Labor rates can differ based on location and complexity of the installation.

- Maintenance Costs: Regular upkeep is crucial for ensuring longevity. Consider the frequency and cost of routine maintenance, as well as potential repairs.

- Availability of Parts: The ease of sourcing components can impact costs. Items that are readily available may be more affordable than rare or specialized parts.

- Compatibility Issues: Upgrading to newer models may require additional modifications, which can lead to increased costs. It’s vital to ensure compatibility with existing systems.

In summary, a comprehensive analysis of these financial factors will enable owners to budget effectively and make strategic decisions regarding marine propulsion systems.

Where to Purchase Genuine Parts

Acquiring authentic components is crucial for ensuring optimal performance and longevity of your marine equipment. Seeking reliable sources can make a significant difference in both quality and reliability.

Authorized Dealers

One of the most effective methods to obtain original components is through certified dealers. These establishments are equipped with knowledgeable staff and can offer products that meet strict quality standards.

Online Retailers

Another convenient option is exploring reputable online platforms that specialize in marine supplies. Always ensure that the retailer is recognized for offering genuine items to avoid counterfeit alternatives.

Future Innovations in Volvo Penta Technology

Advancements in marine technology are set to revolutionize the way vessels operate, enhancing efficiency, safety, and sustainability. The focus on integrating cutting-edge solutions is paving the way for a new era in the maritime industry.

Key Areas of Development

- Electric Propulsion Systems

- Autonomous Navigation

- Smart Connectivity

- Eco-Friendly Fuel Alternatives

Impact on the Industry

The integration of these innovations promises to improve operational performance and reduce environmental impact. With smarter designs and greener technologies, the future looks promising for maritime operations, aligning with global sustainability goals.