In the world of marine propulsion systems, ensuring proper maintenance and understanding the intricate makeup of key components is essential for optimal performance. This section is dedicated to exploring the core elements that make up these systems, providing insights into how they work together to power vessels efficiently and reliably.

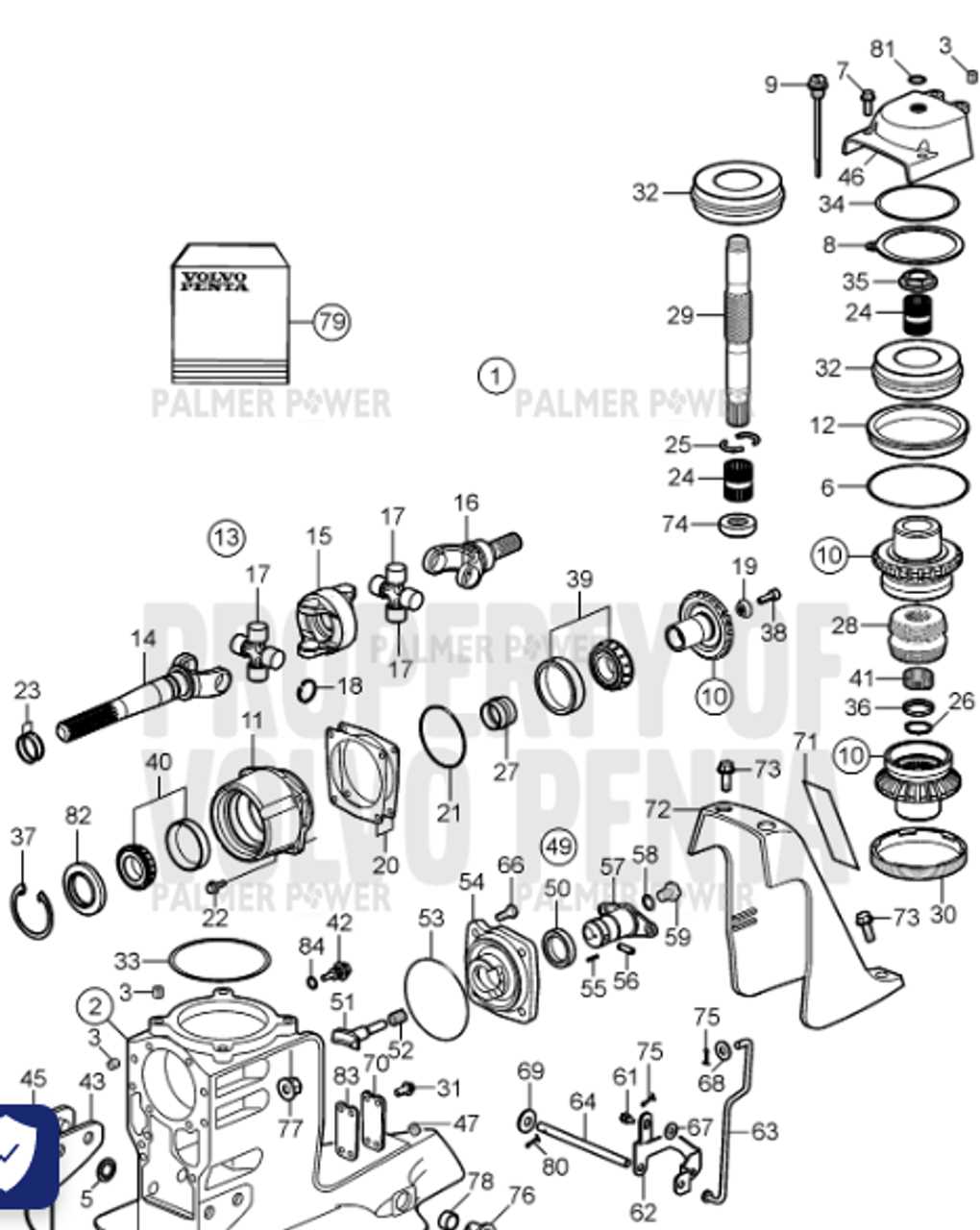

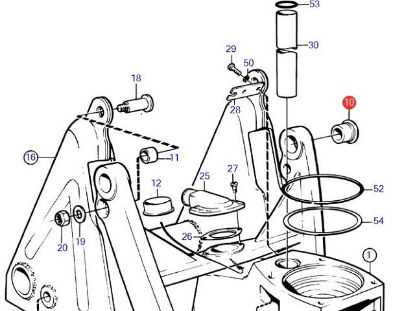

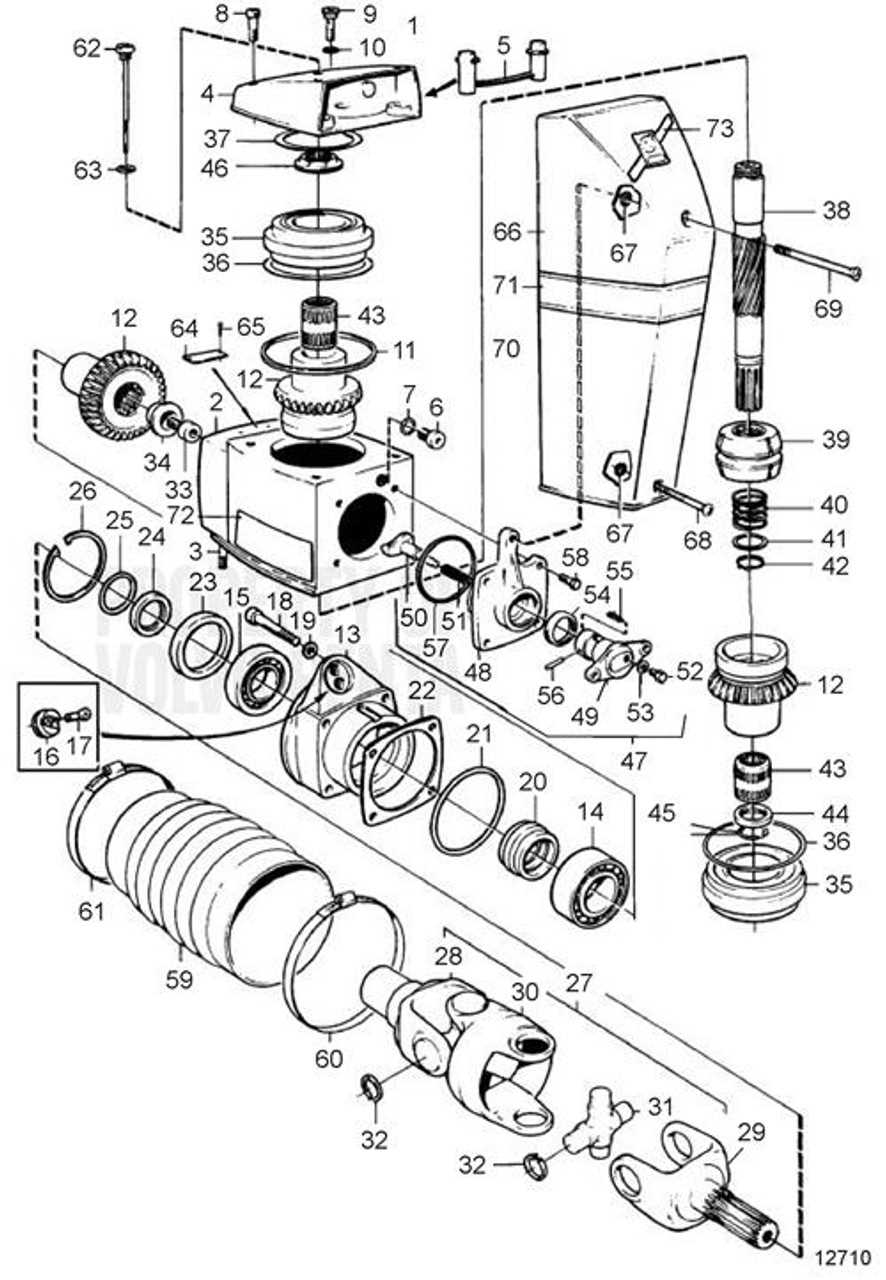

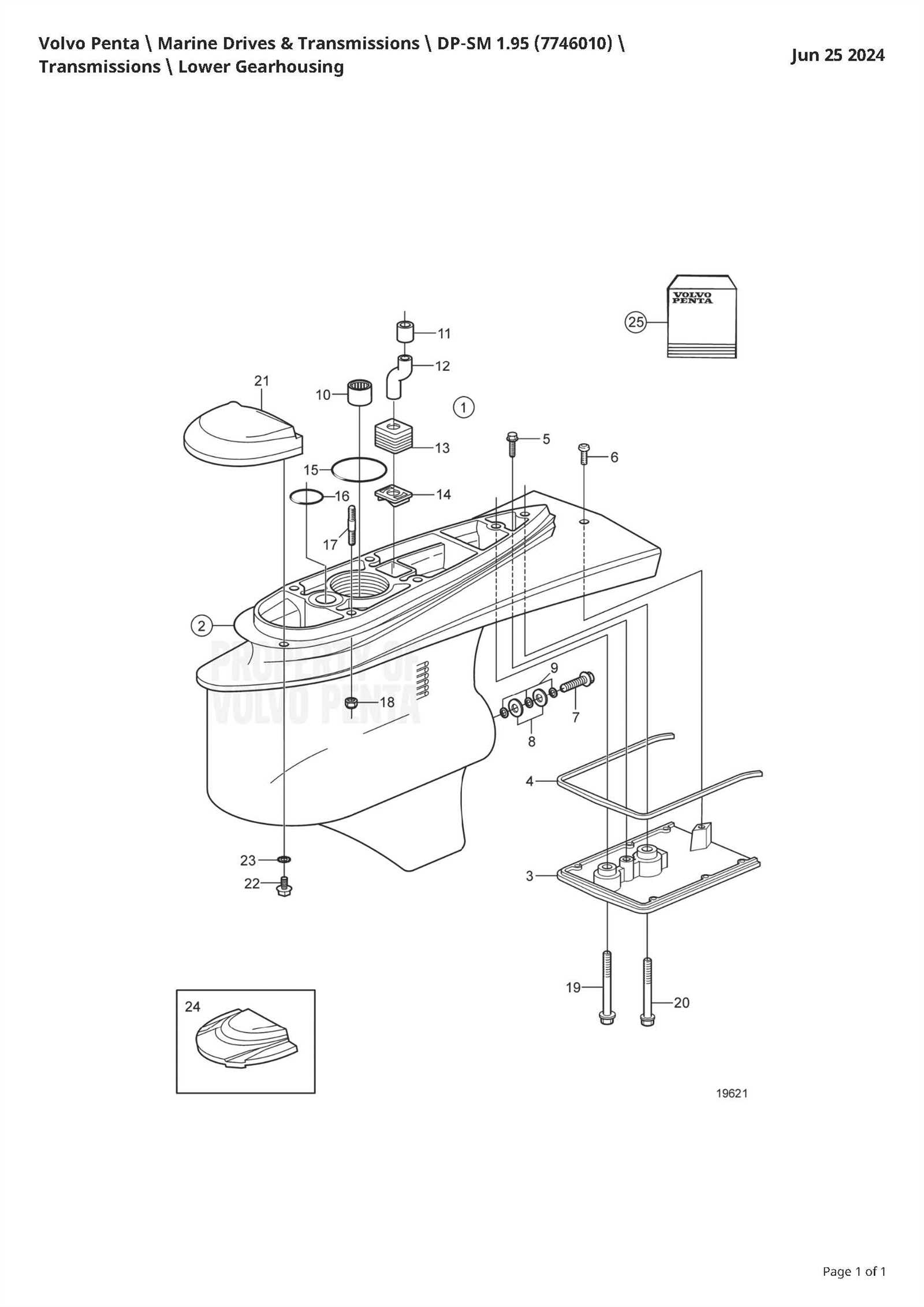

By examining detailed schematics, we can gain a better understanding of how each element interacts within the overall structure. These visuals not only highlight the connectivity of each part but also help in identifying crucial maintenance points, allowing for improved upkeep and troubleshooting.

Understanding the layout of mechanical assemblies within maritime equipment is vital for any technician or enthusiast looking to maintain or repair their system. In this guide, we will break down the individual sections of these assemblies, explaining their functions and importance in a way that enhances both knowledge and practical application.

Exploring the Components of Volvo Penta DPS

The propulsion system under discussion is composed of multiple essential elements that work together to ensure efficient performance and handling on the water. Each component is engineered with precision to deliver reliable power, agility, and control, all while maintaining durability in marine environments. In this section, we’ll delve into the specific parts that contribute to the overall effectiveness and functionality of this mechanism.

Key Structural Elements

Among the key elements are the propeller blades, shafts, and various support structures that allow for smooth movement and stability. These components are designed to withstand significant stress, ensuring long-lasting performance in a variety of conditions. The quality of materials used in their construction plays a critical role in maintaining optimal operation.

Performance-Enhancing Features

In addition to the core structure, there are several advanced features that enhance the overall efficiency of the propulsion system. These include precision-engineered gears and hydraulics, which are crucial for managing speed and direction. Enhanced cooling systems also ensure that the engine operates within safe temperature limits, even during extended use.

Identifying Critical Sections of the DPS System

Understanding the most essential components of the drive mechanism is crucial for maintaining optimal performance and ensuring the longevity of the system. By breaking down the key areas of the setup, users can better navigate potential maintenance tasks and enhance the overall reliability of their vessel’s propulsion unit.

Core Mechanical Elements

- Propeller: Ensuring smooth and efficient movement, the propeller must be inspected regularly for wear or damage.

- Gearbox: This section manages the transfer of power, and any issues with the gearbox can affect the entire propulsion system.

- Drive Shaft: A critical link between the motor and propeller, this part must remain in good condition to prevent interruptions in power delivery.

Hydraulic and Electrical Components

- Trim Control: This mechanism adjusts the angle of the propulsion unit, affecting the overall maneuverability and efficiency.

- Steering System: Integrated with hydraulic controls, this system ensures precise directional changes.

- Electronic Sensors: These devices monitor various operational aspects,

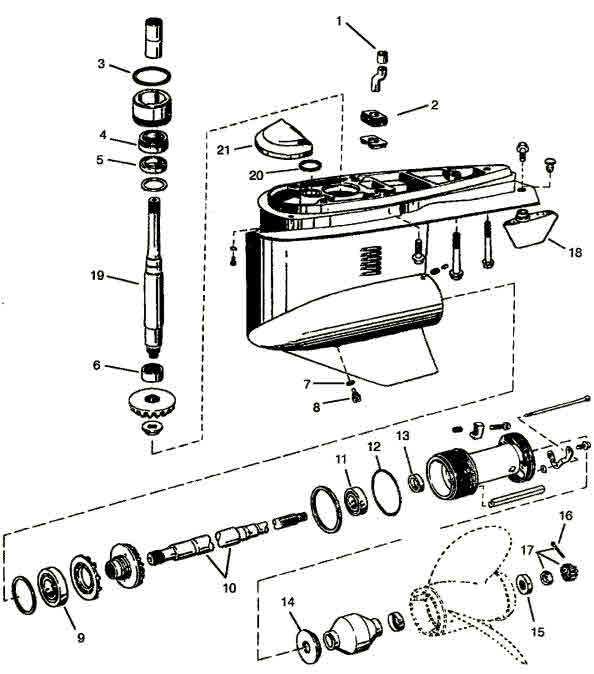

Understanding the Function of Propeller Assembly

The propeller assembly is an essential component in marine propulsion systems, designed to convert the power generated by the engine into thrust. This system ensures smooth movement through water by utilizing rotating blades, which push the vessel forward or backward. Understanding how the different elements within this assembly work together is key to maintaining optimal performance.

Main Components and Their Roles

The assembly includes several key elements such as the propeller hub, blades, and shafts. The hub holds the blades securely, allowing them to rotate in a balanced manner. The blades, shaped to maximize efficiency, are responsible for creating the thrust, while the shaft transfers energy from the engine to the propeller. These components must function in harmony to ensure smooth operation and precise control of the vessel’s movement.

Maintenance and Performance Optimization

Proper care of the propeller assembly is crucial for ensuring long-term durability and efficiency. Regular inspections and adjustments help maintain balance, preventing vibration and wear that could affect the system’s performance. Addit

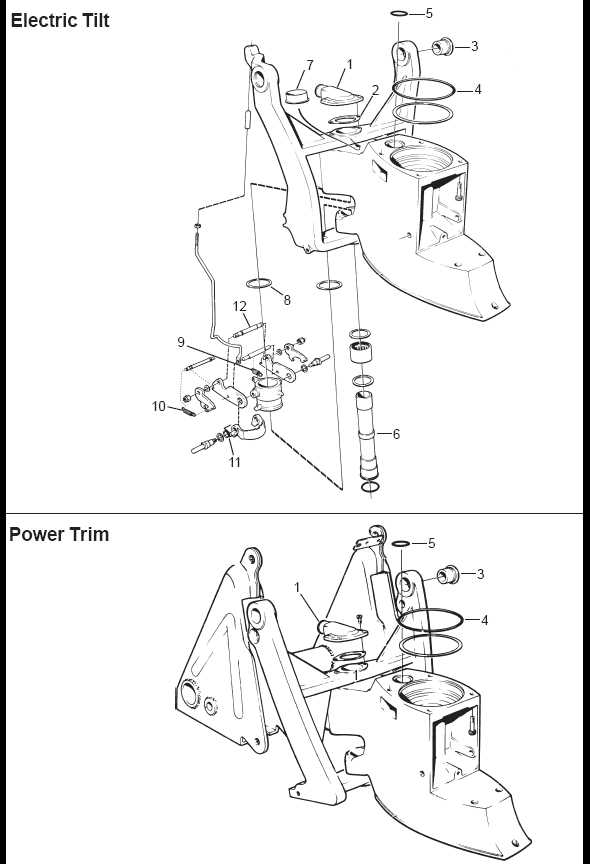

The Role of Hydraulic Cylinders in Steering

Hydraulic cylinders play a critical role in the operation of steering systems, particularly in marine environments. Their primary function is to convert hydraulic energy into mechanical force, enabling smooth and responsive control over direction. These components are essential for delivering the necessary torque to move and align the steering mechanism efficiently.

One of the key advantages of using hydraulic cylinders is their ability to handle substantial loads while maintaining precision. This ensures that even in challenging conditions, the steering remains accurate and easy to manage.

Feature Function Piston Rod Moves in response to hydraulic pressure, controlling the direction of the rudder. Cylinder Housing Encases the piston, providing a sealed environment for hydraulic fluid. Seals Inspecting the Gearbox and Its Elements

The gearbox is a crucial component that ensures smooth transmission and reliable operation of the propulsion system. Regular inspection helps prevent wear and tear, ensuring that all elements function optimally. This section outlines the key aspects to focus on during the examination process.

- Check for any unusual noise or vibration that could indicate misalignment or internal damage.

- Examine the seals and gaskets for signs of leakage or deterioration, as these can compromise efficiency.

- Inspect the oil level and quality to ensure proper lubrication of all moving parts.

- Look for visible wear on gears and bearings, which may require replacement if worn beyond recommended limits.

- Verify that all fasteners and bolts are securely tightened to avoid loose components during operation.

By paying attention to these factors, you can prolong the lifespan of the gearbox and maintain optimal performance.

Examining the Impact of Drive Shaft Mechanics

The mechanics of a propulsion system significantly influence overall performance and efficiency. Understanding the intricate interactions within the drive shaft assembly is crucial for optimizing functionality and ensuring durability. This section delves into the components and dynamics involved, highlighting their roles in effective power transfer and operational stability.

Key Components of Drive Shaft Mechanics

- Universal Joints: These allow for flexibility and adaptability in angles, ensuring smooth motion across varying conditions.

- Couplings: Essential for connecting segments of the drive shaft, they help mitigate vibrations and accommodate misalignment.

- Bearing Assemblies: They support the shaft and reduce friction, contributing to efficient operation and longevity.

Effects on Performance

Efficient drive shaft mechanics can lead to enhanced performance in various aspects:

- Power Transfer: A well-designed assembly ensures optimal power delivery from the engine to the propellers.

- Vibration Reduction: Proper alignment and component quality minimize vibrations, improving comfort and reducing wear.

- Durability: Robust materials and engineering contribute to longevity, reducing maintenance needs and enhancing reliability.

In conclusion, a thorough understanding of drive shaft mechanics is essential for achieving superior propulsion system performance, directly influencing operational efficiency and overall vessel functionality.

Maintenance Tips for Trim and Tilt Systems

Proper upkeep of tilt and trim mechanisms is essential for ensuring optimal performance and longevity of marine vessels. Regular attention to these components can prevent malfunctions and enhance operational efficiency, providing a smoother experience on the water.

Here are some key maintenance practices to consider:

- Regular Inspections: Frequently examine the tilt and trim assemblies for signs of wear, corrosion, or damage. Check hoses, seals, and electrical connections for integrity.

- Fluid Checks: Ensure that hydraulic fluid levels are adequate. Inspect the condition of the fluid; it should be clean and free from contaminants.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent wear. Follow manufacturer recommendations for lubricant types.

- Electronics Functionality: Test the electrical components and switches associated with the system to confirm they are functioning correctly. Replace any faulty parts as necessary.

- Debris Removal: Keep the area around the tilt and trim system free from debris and marine growth that could hinder operation.

Following these guidelines will contribute to the efficient operation of tilt and trim systems, minimizing potential issues and ensuring a reliable performance during navigation.

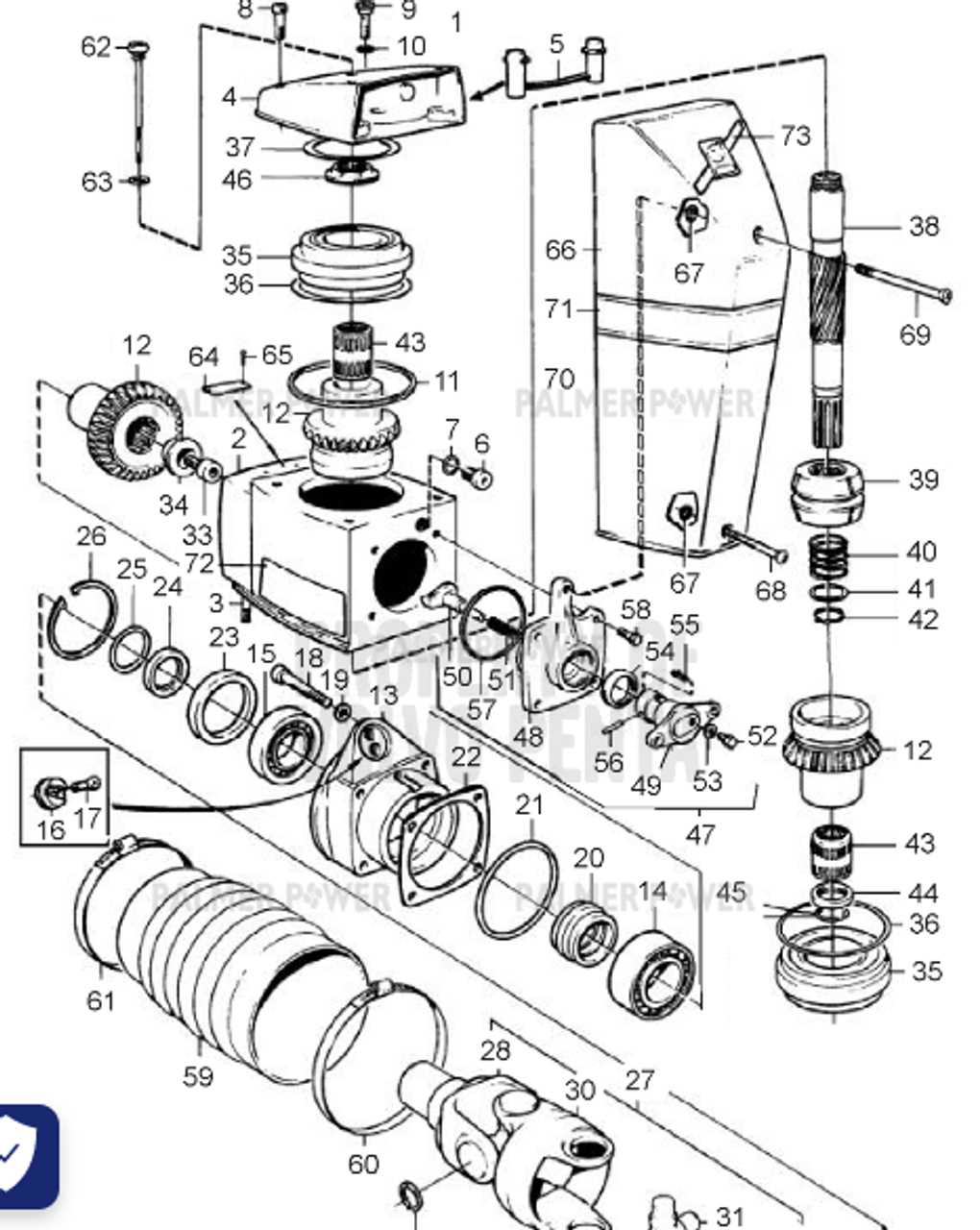

Exploring Seals and Bearings for Durability

In the realm of mechanical systems, the longevity and performance of equipment significantly depend on the quality and integrity of seals and bearings. These components play a crucial role in minimizing friction, preventing contamination, and ensuring smooth operation under various conditions. Understanding their function and maintenance can lead to enhanced reliability and reduced downtime.

Seals are designed to protect internal mechanisms from external elements while retaining lubricants. Their effectiveness is paramount in preventing leaks, which can cause operational failures and costly repairs. Different types of seals, such as lip seals and O-rings, are utilized based on the specific requirements of the application, ensuring that the right material and design are chosen for optimal performance.

Bearings, on the other hand, facilitate rotational or linear motion while supporting loads. The choice of bearing type–be it ball, roller, or sleeve–affects the overall efficiency and durability of the system. Proper lubrication and alignment of bearings are essential to reduce wear and extend their lifespan, contributing to the overall robustness of the equipment.

Regular inspections and timely replacements of these critical components can significantly enhance the performance and lifespan of machinery. By prioritizing the quality of seals and bearings, operators can achieve greater operational efficiency and lower maintenance costs.

Importance of the Upper Unit for Performance

The upper assembly plays a crucial role in the overall efficiency and functionality of marine propulsion systems. Its design and condition significantly impact the vessel’s speed, maneuverability, and fuel consumption. Understanding the significance of this component is essential for optimizing performance and ensuring reliable operation.

Key aspects of the upper unit’s influence on performance include:

- Hydrodynamics: The shape and structure of the upper unit affect the flow of water around the hull, directly influencing drag and acceleration.

- Gear Ratios: Proper gear ratios within the assembly enhance power transfer from the engine to the propeller, impacting torque and speed.

- Durability: A well-maintained upper unit withstands harsh marine environments, reducing the risk of breakdowns and enhancing longevity.

- Alignment: Accurate alignment of the upper unit ensures smooth operation, minimizing vibration and wear on connected components.

Regular inspection and maintenance of this crucial element can lead to improved performance and greater reliability during operation. By prioritizing the upper unit’s integrity, boat owners can enhance their vessels’ overall efficiency and enjoyment on the water.

Guidance on Replacing Wearable DPS Parts

When it comes to maintaining marine propulsion systems, addressing the replacement of components subject to wear is crucial for ensuring optimal performance. Regularly assessing these elements helps prevent costly breakdowns and extends the lifespan of the overall system.

1. Identifying Components: Begin by determining which elements require attention. This may include seals, bearings, or other mechanisms that experience friction or stress during operation. Recognizing the signs of wear, such as leaks or unusual noises, is essential.

2. Gathering Tools and Materials: Ensure you have the necessary tools for the task at hand, including wrenches, screwdrivers, and replacement items. Having everything prepared before starting the process will streamline your efforts.

3. Safety Precautions: Always prioritize safety. Use protective gear and ensure the system is deactivated before attempting any replacements. This precaution protects you from potential injuries during the repair process.

4. Follow Manufacturer Guidelines: Consult the relevant manuals for specific instructions on disassembly and reassembly. Adhering to these recommendations will facilitate a smoother process and help avoid mistakes.

5. Testing the System: Once replacements are made, conduct thorough testing to verify that everything functions correctly. This step is vital to ensure that the repairs are successful and that the system operates as intended.

Insights into Cooling System Components

The efficiency and reliability of any marine propulsion system significantly depend on the functionality of its cooling system. This essential setup is designed to manage the temperature of critical engine components, ensuring optimal performance and longevity. Understanding the various elements involved can provide valuable insights into maintaining and troubleshooting these systems effectively.

Key Elements of the Cooling Mechanism

At the heart of the cooling apparatus are several crucial components that work together seamlessly. The heat exchanger plays a vital role in transferring heat from the engine coolant to the surrounding water, allowing for efficient thermal management. Additionally, thermostats are critical for regulating the temperature, opening and closing to maintain optimal operating conditions. Furthermore, the circulation pump ensures a continuous flow of coolant, preventing overheating and promoting stable engine performance.

Importance of Regular Maintenance

To ensure the longevity and effectiveness of the cooling system, regular inspections and maintenance are paramount. Components such as hoses and gaskets should be checked for wear and tear, as any leaks can lead to significant issues. Moreover, periodic flushing of the cooling system helps eliminate debris and contaminants, maintaining the overall health of the engine and its components. By staying proactive with maintenance, operators can avoid costly repairs and ensure reliable operation.

Best Practices for Routine DPS Inspection

Regular examination of marine propulsion systems is essential for maintaining optimal performance and ensuring safety. A structured approach to these assessments not only extends the lifespan of components but also enhances overall efficiency during operation. By following specific guidelines, owners and operators can identify potential issues before they escalate into serious problems.

Conduct Thorough Visual Checks

Begin each inspection with a comprehensive visual examination of the system. Look for signs of wear, corrosion, or damage to visible components. Pay close attention to seals and gaskets, as these areas are often susceptible to deterioration. Document any irregularities to track changes over time, helping to prioritize repairs and maintenance tasks.

Monitor Fluid Levels and Quality

Regularly check the levels and condition of essential fluids, such as lubricants and hydraulic fluids. Contaminated or low fluids can lead to increased wear and tear on moving parts. Perform fluid changes according to manufacturer recommendations to ensure optimal performance. Additionally, consider using high-quality fluids that meet the required specifications for better protection against wear and breakdown.