The complexity of modern machinery often necessitates a detailed exploration of their individual elements. Recognizing how each component interacts within the larger system can significantly enhance maintenance and operational efficiency. This guide aims to shed light on the intricate arrangement of parts, offering valuable insights for users and technicians alike.

By dissecting the layout of essential components, one can better appreciate the functionality and design choices made during the manufacturing process. A clear visual representation of these elements serves not only as an educational tool but also as a practical reference for troubleshooting and repairs. Understanding these arrangements can empower operators to make informed decisions regarding upkeep and modifications.

In the subsequent sections, we will delve into specific configurations, highlighting the relationships between various elements. This knowledge is crucial for anyone looking to optimize their machinery’s performance and longevity. Whether you are a seasoned professional or a newcomer to the field, grasping the fundamentals of equipment layouts is a key step toward successful operation and maintenance.

This section aims to provide a comprehensive understanding of compact construction machinery, focusing on their key components and functionalities. These versatile machines are essential in various industries, known for their agility and efficiency in completing a wide range of tasks.

Key Features of Compact Machinery

- High maneuverability for navigating tight spaces.

- Powerful lifting capabilities suited for various attachments.

- Robust design ensuring durability under tough working conditions.

Applications in Different Industries

- Construction sites for digging and material handling.

- Agricultural fields for landscaping and soil management.

- Landscaping projects requiring precise control and versatility.

Understanding the components and their functions enhances the ability to maintain and operate these machines effectively, ensuring optimal performance in diverse applications.

Key Components of Skid Steers

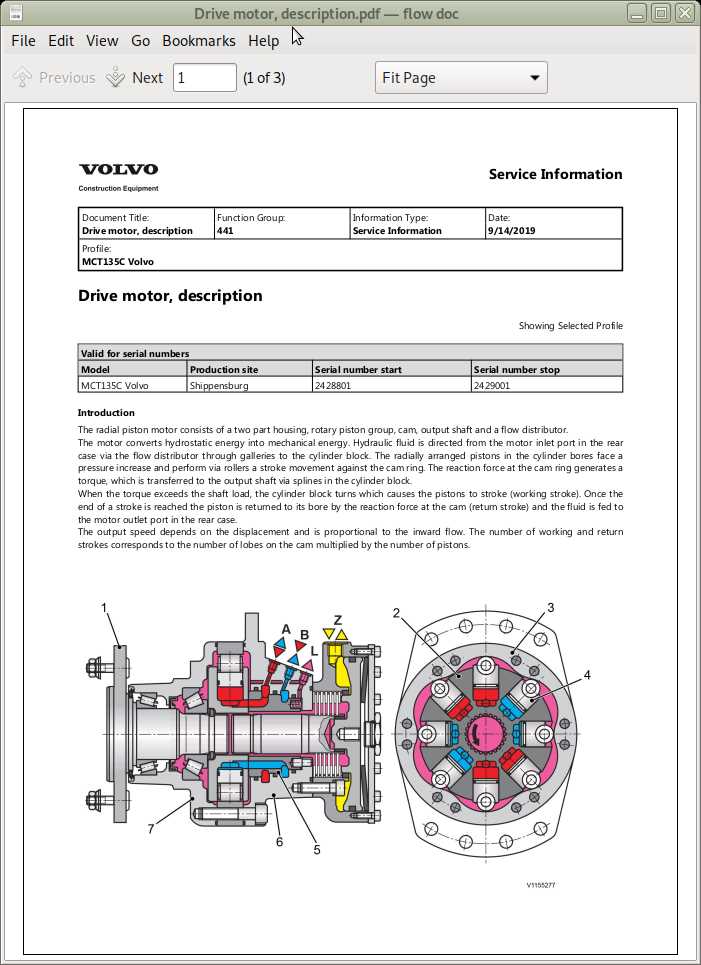

Understanding the essential elements of compact machinery is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring the equipment operates smoothly and efficiently. From power sources to movement mechanisms, these units are designed to tackle a variety of tasks across different environments.

The core structure includes the chassis, which provides stability and houses various systems. The engine is the powerhouse, generating the necessary energy for operation. Coupled with a hydraulic system, this allows for versatile maneuvering and lifting capabilities, making the machinery adaptable to different attachments.

Another significant part is the wheel or track system, which contributes to mobility and traction. This is complemented by the control system, enabling precise handling and operation. Together, these components create a cohesive unit that enhances productivity and efficiency in a wide range of applications.

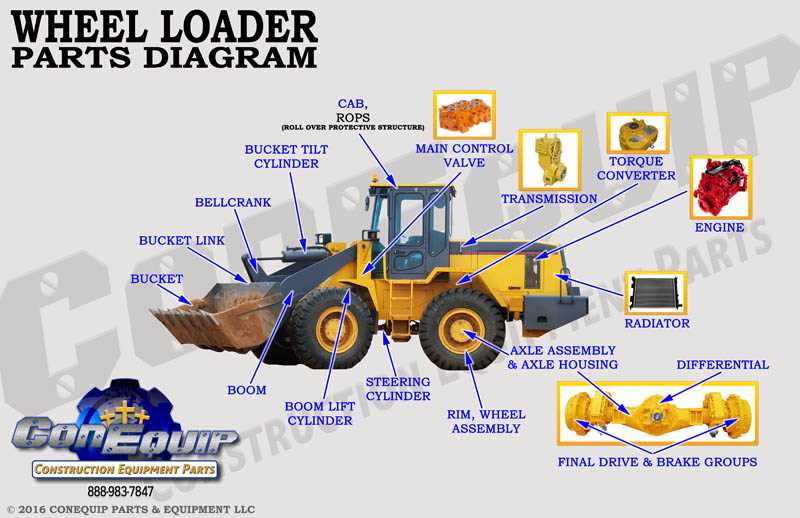

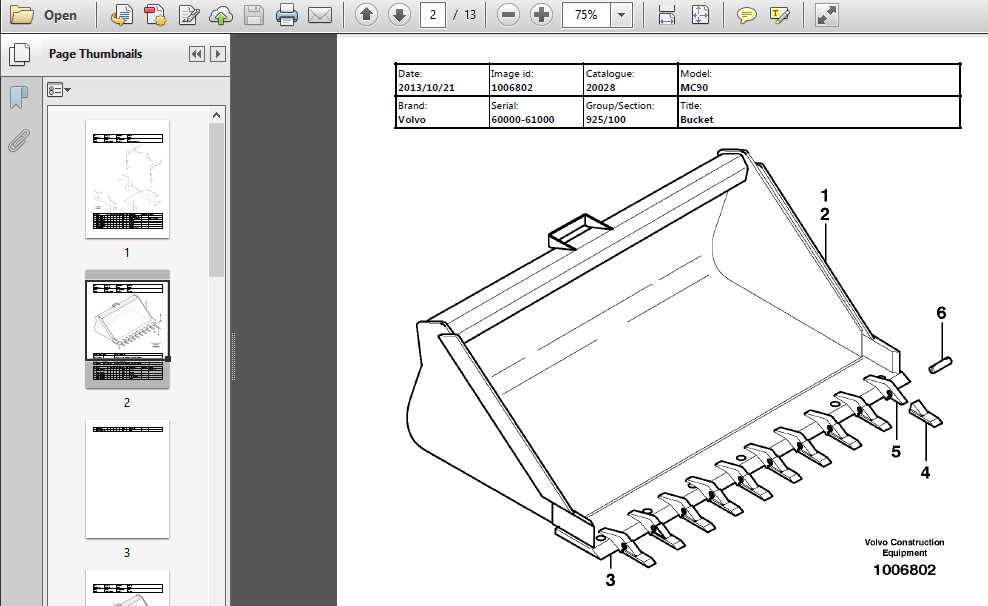

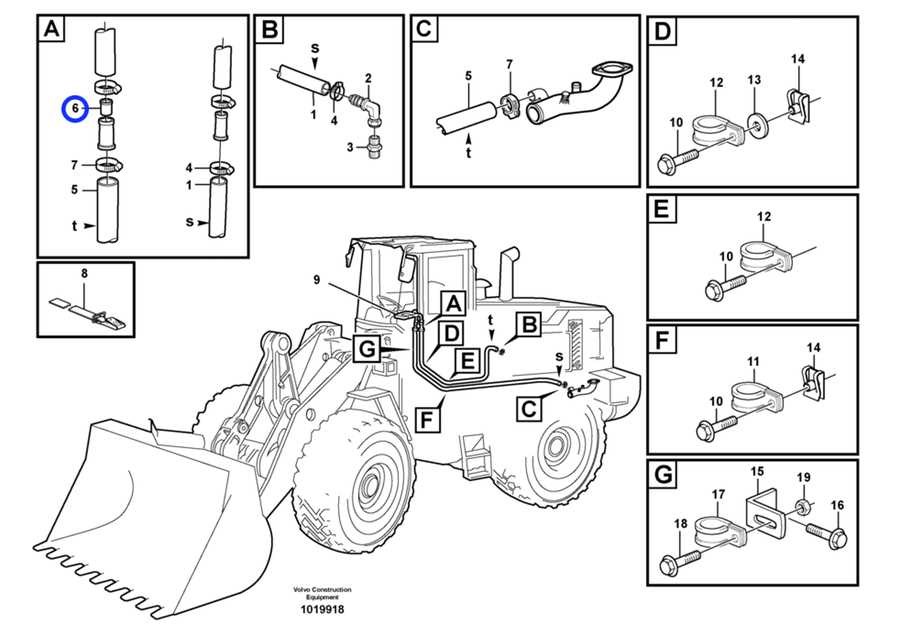

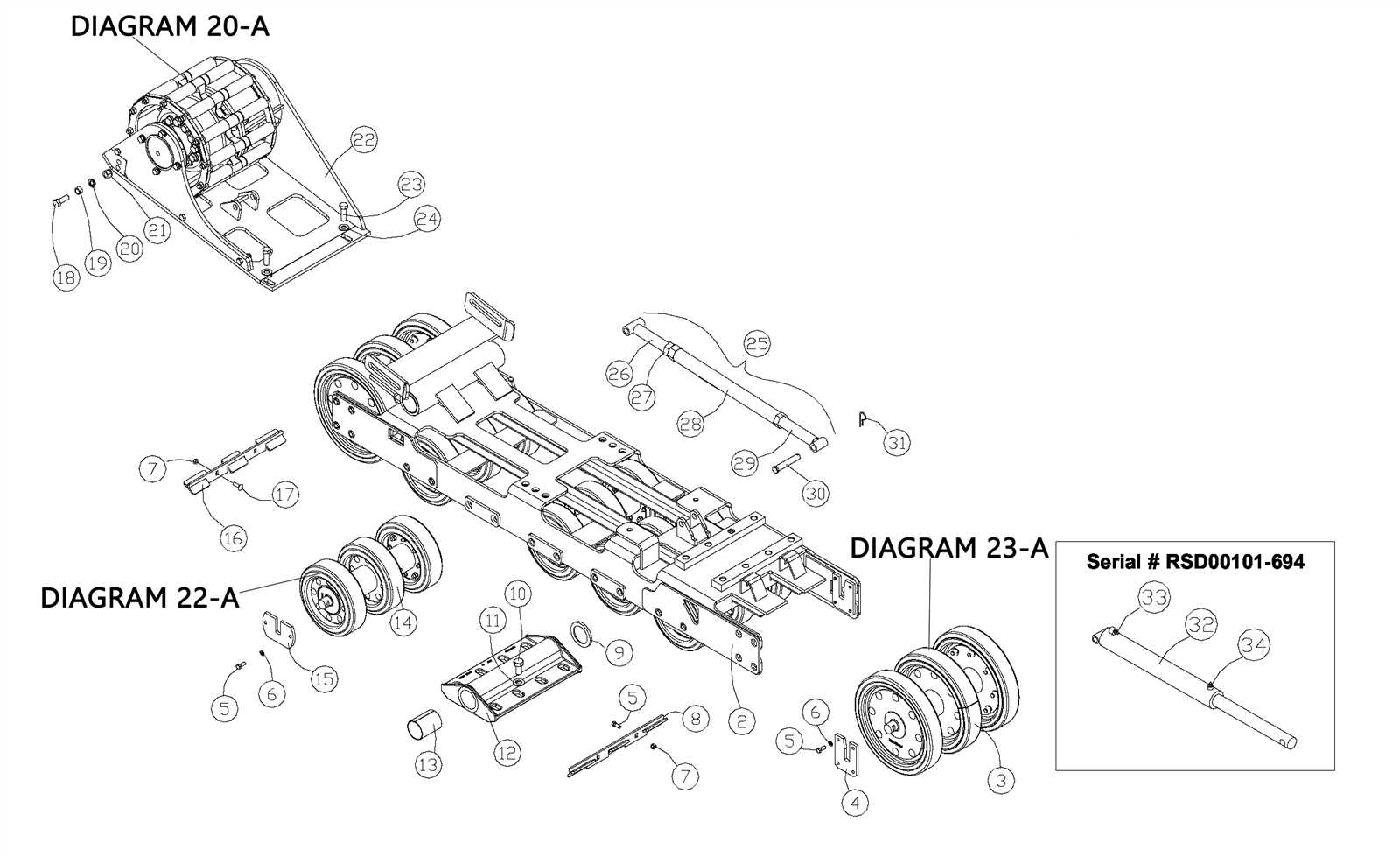

Understanding the Parts Diagram

The visualization of components is crucial for grasping the intricate relationships and functions within machinery. A detailed representation aids in identifying each element’s role and facilitates maintenance, repair, or enhancement tasks. This guide will explore how to interpret such illustrations effectively.

Key Elements to Consider

When examining a schematic, focus on symbols and labels that denote various components. Color coding often indicates different systems or categories, while numbers or letters provide specific identification. Understanding these conventions can significantly improve your ability to navigate and utilize the information presented.

Practical Applications

Comprehending the layout not only enhances troubleshooting but also empowers users to make informed decisions regarding upgrades or replacements. A thorough knowledge of the arrangement fosters confidence in handling complex machinery and ensures optimal performance.

Common Volvo Skid Steer Models

This section explores the frequently encountered machinery types known for their versatility and efficiency in various applications. Each model is designed with specific features to meet the diverse needs of operators in construction, landscaping, and agriculture.

Popular Compact Models

Among the leading compact machines, certain models stand out due to their performance and reliability. These are engineered to provide exceptional maneuverability while maintaining robust capabilities, making them suitable for a range of tasks.

High-Performance Variants

For those requiring more power, high-performance variants offer enhanced lifting capacity and advanced technology. These machines often incorporate innovative solutions that optimize productivity and ease of use, catering to demanding work environments.

Identifying Wear and Tear

Regular inspection is crucial for maintaining equipment longevity. Recognizing early signs of degradation can help prevent breakdowns and costly repairs. Paying attention to subtle changes in performance can alert operators to potential issues that require prompt attention.

- Unusual Noises: Grinding, squeaking, or other abnormal sounds often indicate a component is deteriorating and may need replacement.

- Reduced Efficiency: A drop in performance, such as slower operation or difficulty in movement, may signal wear in critical mechanical parts.

- Visible Cracks or Deformations: Regularly inspect components for any physical damage, such as fractures, bends, or rust, which could lead to failure.

- Fluid Leaks: Oil or hydraulic fluid leakage around key areas can be a sign of seal wear or other underlying problems that require attention

Replacement Parts Availability

When it comes to maintaining heavy machinery, having quick access to necessary components is crucial for minimizing downtime. A wide network of suppliers ensures that compatible pieces are readily available, helping to keep equipment in peak operating condition. Understanding where and how to source these items can make all the difference in managing costs and efficiency.

- Online catalogs provide an easy way to identify the exact component needed for repairs.

- Authorized dealers offer reliable options for sourcing high-quality replacements.

- Local distributors can sometimes reduce wait times by offering immediate access to stock.

Additionally, manufacturers often offer special programs or partnerships with third-party suppliers to expand the availability of essential items. These networks are designed to ensure that even older models can be serviced without difficulty, keeping essential equipment running smoothly.

Maintenance Tips for Longevity

Ensuring the durability of heavy equipment depends on consistent care and proper handling. Routine inspections, timely adjustments, and preventive measures are essential for keeping machinery in optimal condition. By focusing on the overall health of your equipment, you can prevent unexpected breakdowns and extend its operational lifespan.

One of the primary steps in maintaining long-term performance is to adhere to a regular schedule of fluid checks and replacements. This includes monitoring hydraulic levels, engine oils, and coolant, all of which play crucial roles in reducing wear and tear on vital components. Always use the recommended grades to ensure efficient functioning.

In addition to fluid management, it’s important to regularly clean filters and ensure air intake systems are free of obstructions. Clogged filters can lead to reduced efficiency and even cause engine damage over time.

Safety Features of Skid Steers

Modern construction machines are equipped with a variety of safeguards to ensure the operator’s well-being and prevent accidents on the job site. These protective measures are crucial for maintaining both efficiency and security during everyday operations.

Operator Protection

The cab of these machines is designed to shield the driver from potential hazards. Reinforced structures around the seating area minimize the risk of injury in case of rollovers or other incidents. Moreover, ergonomic controls and seat restraints enhance user safety by providing better stability and reducing fatigue.

Control Systems

Advanced control technologies further contribute to safety by preventing unauthorized or improper use. These systems often include automatic shut-off functions that activate when specific conditions are not met, ensuring the machine only operates under safe circumstances. Clear visual and auditory alarms notify the operator of any immediate risks.

Safety Feature Assembly and Disassembly Procedures

The process of putting together and taking apart mechanical components requires careful attention to detail. Proper handling and organization of tools are essential to ensure smooth operations and prevent damage during the procedure. Understanding the steps involved helps streamline the work, reducing the risk of errors and unnecessary delays.

- Begin by organizing the necessary tools and equipment for the task. This preparation helps minimize interruptions during the process.

- Follow a structured approach, starting with the external components and progressively working toward the internal mechanisms.

- For disassembly, mark and group the removed pieces, ensuring that everything can be reassembled in the correct order.

- Carefully inspect each part for wear or damage before reassembly. Replace any components that show signs of wear to ensure optimal performance.

- During reassembly, refer to any reference materials or guides available to ensure accuracy at each stage.

- Finally, test the system once the assembly is complete to verify that everything is functioning as intended.

These procedures, when followed correctly, ensure the longevity and proper function of mechanical systems.

Tools Needed for Repairs

When performing maintenance or fixing any type of machinery, it’s crucial to have the right set of instruments at hand. The effectiveness of repairs often depends on the quality and suitability of the tools used. Ensuring proper equipment not only speeds up the process but also enhances safety and precision.

Basic hand tools such as wrenches, pliers, and screwdrivers form the foundation of any mechanical task. These are essential for loosening or tightening fasteners and managing small adjustments.

For more advanced work, power tools like electric drills and impact wrenches might be necessary to handle more challenging components. These tools help reduce manual effort and offer greater torque for difficult jobs.

Additionally, specialized measuring devices such as calipers and pressure gauges are vital for ensuring that components are aligned and performing within specified tolerances. Proper use of these tools ensures accuracy and long

Common Issues and Solutions

Operating heavy machinery can sometimes lead to unexpected malfunctions or wear, causing delays in work and potential safety risks. Understanding the most frequent technical challenges and having a set of clear remedies can help keep equipment in optimal condition and ensure efficient workflow.

- Hydraulic Leaks: Leaks in the hydraulic system can be caused by damaged seals, worn hoses, or loose connections. Regularly inspect components for wear and promptly replace any faulty parts to prevent pressure loss.

- Overheating: High temperatures often result from clogged radiators or insufficient coolant levels. Cleaning cooling systems and monitoring fluid levels can prevent overheating during extended use.

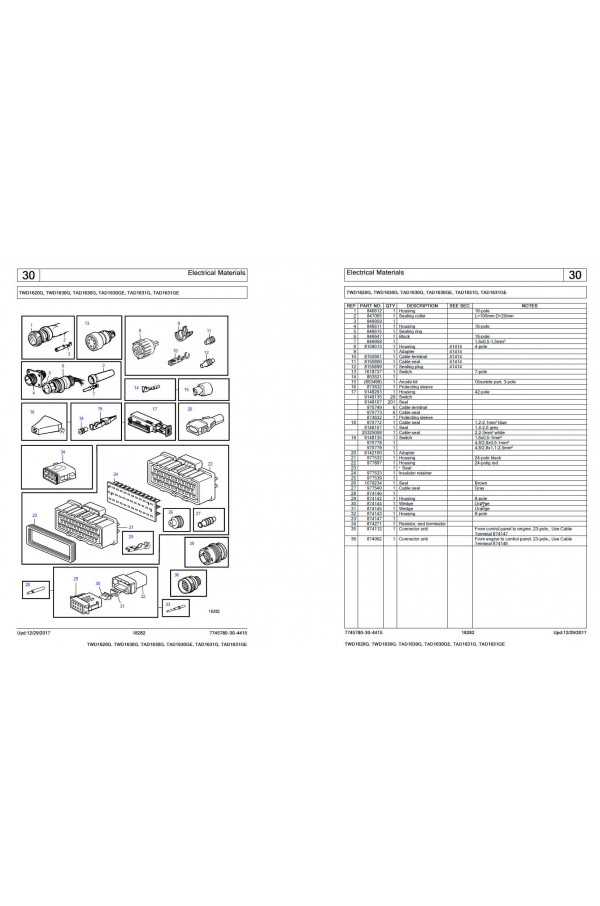

- Electrical Failures: Issues such as dead batteries or malfunctioning lights may stem from corroded terminals or faulty wiring. Ensuring proper maintenance of electrical connections and

Benefits of Genuine Parts

Choosing original components for your equipment offers significant advantages. The quality and precision provided by these parts help to ensure the machine runs efficiently, reducing the risk of breakdowns and extending the lifespan of the equipment. With genuine components, you gain reliability and performance that meet the manufacturer’s exact standards.

Advantage Description Longevity Authentic parts are designed to last longer, reducing the frequency of replacements and downtime. Compatibility Original components fit perfectly, eliminating issues caused by incorrect dimensions or materials. Warranty Protection Using certified parts often maintains the manufacturer’s warranty, protecting your investment. Technical Support Resources

Reliable support is crucial for ensuring the long-term efficiency and performance of any machinery. Access to comprehensive resources allows users to address issues quickly, minimizing downtime and maintaining productivity. Whether troubleshooting common problems or seeking detailed guidance, having access to the right tools and information can make a significant difference.

Online Documentation

A wide range of manuals, guides, and step-by-step instructions is often available through official websites or dedicated platforms. These resources provide users with the knowledge required to handle various tasks, from routine maintenance to more complex repairs. Having this information readily accessible online ensures that help is available whenever it’s needed.

Customer Support Services

When online resources are not enough, professional assistance can be obtained through dedicated support teams. These experts are available to offer personalized help, answering specific questions and providing insights into more challenging situations. With knowledgeable professionals on hand, complex issues can be resolved efficiently, reducing