In the realm of outdoor maintenance, certain tools stand out for their efficiency and effectiveness in tackling stubborn dirt and grime. The inner workings of these cleaning machines consist of various elements, each playing a vital role in ensuring optimal performance. Grasping the function of these components can enhance the overall user experience and extend the lifespan of the equipment.

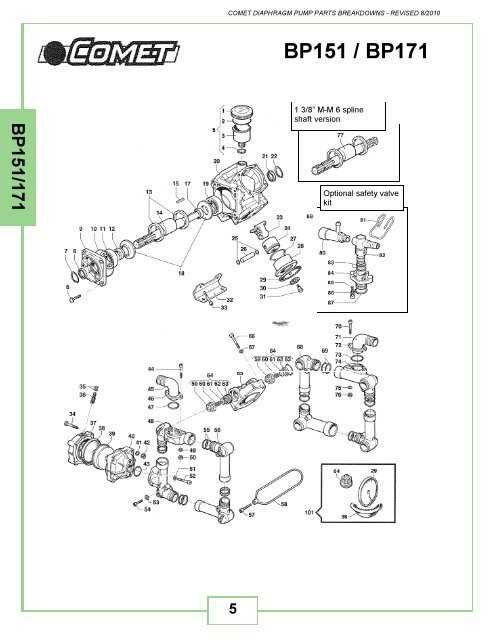

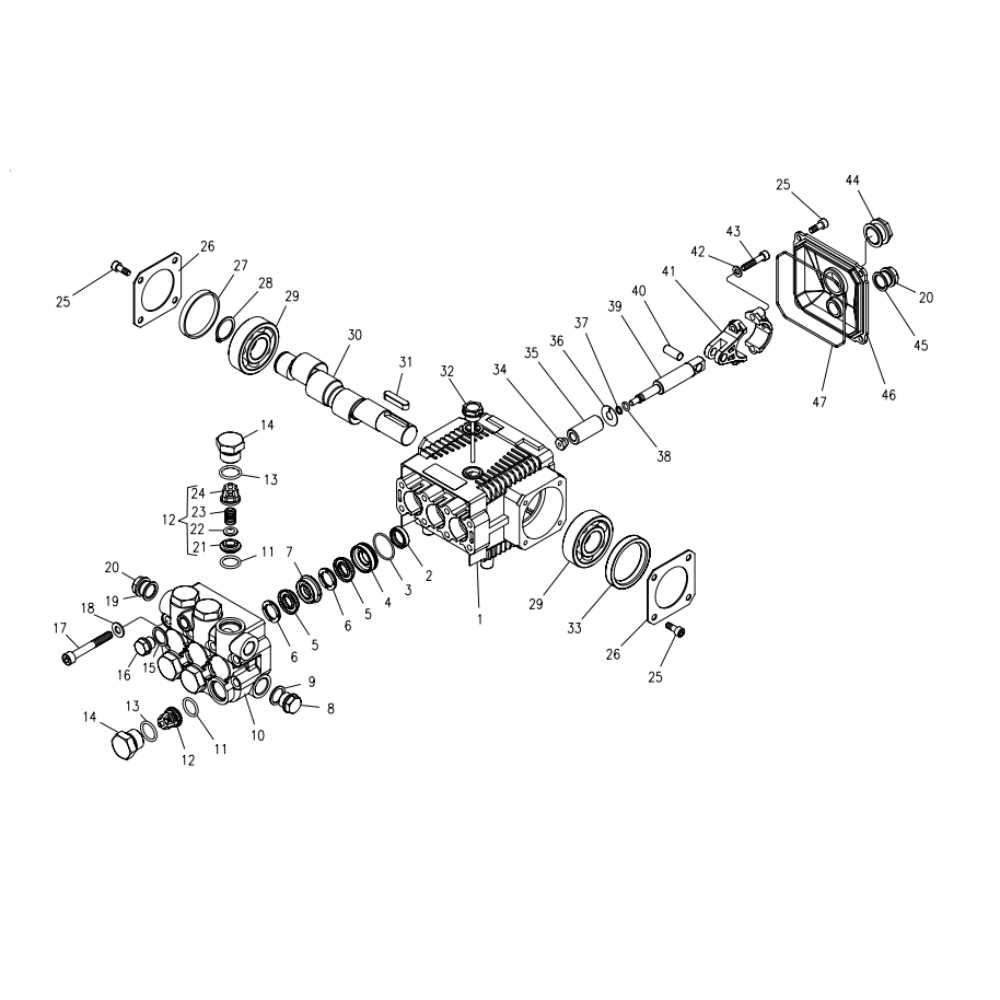

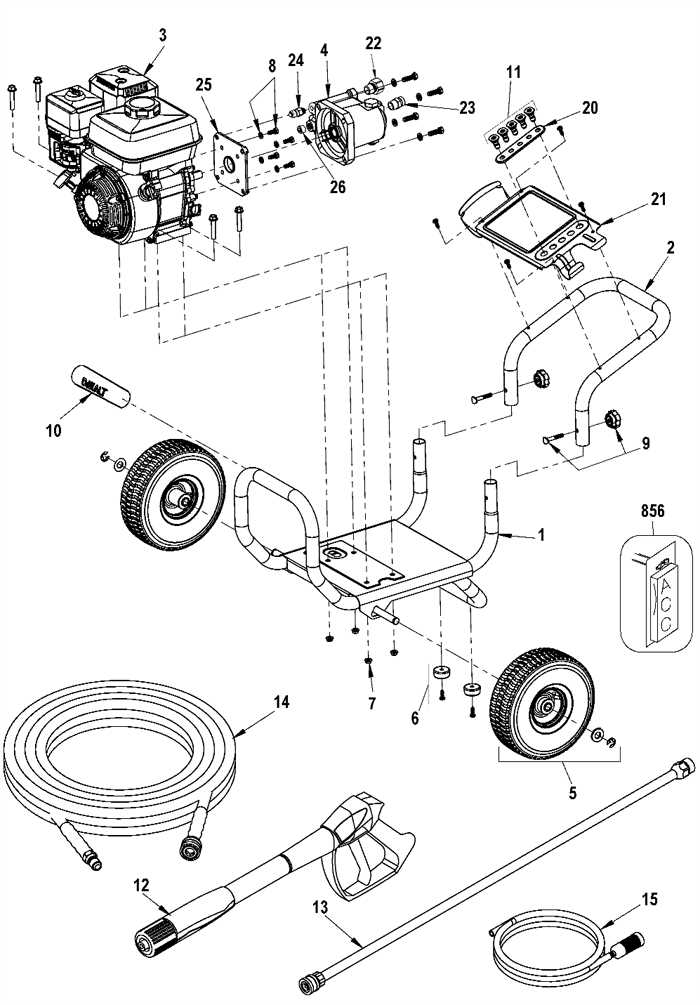

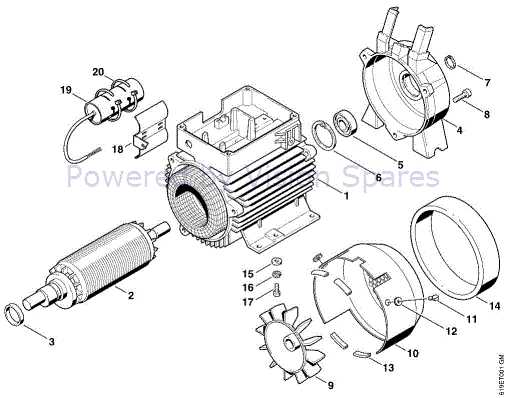

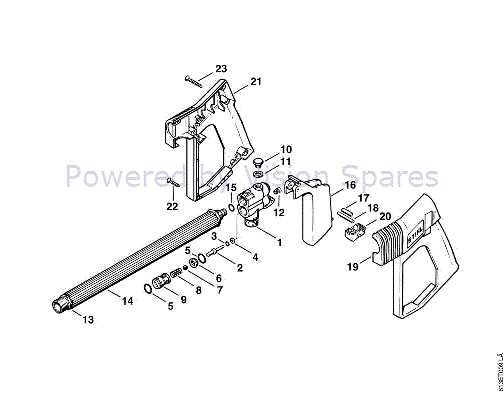

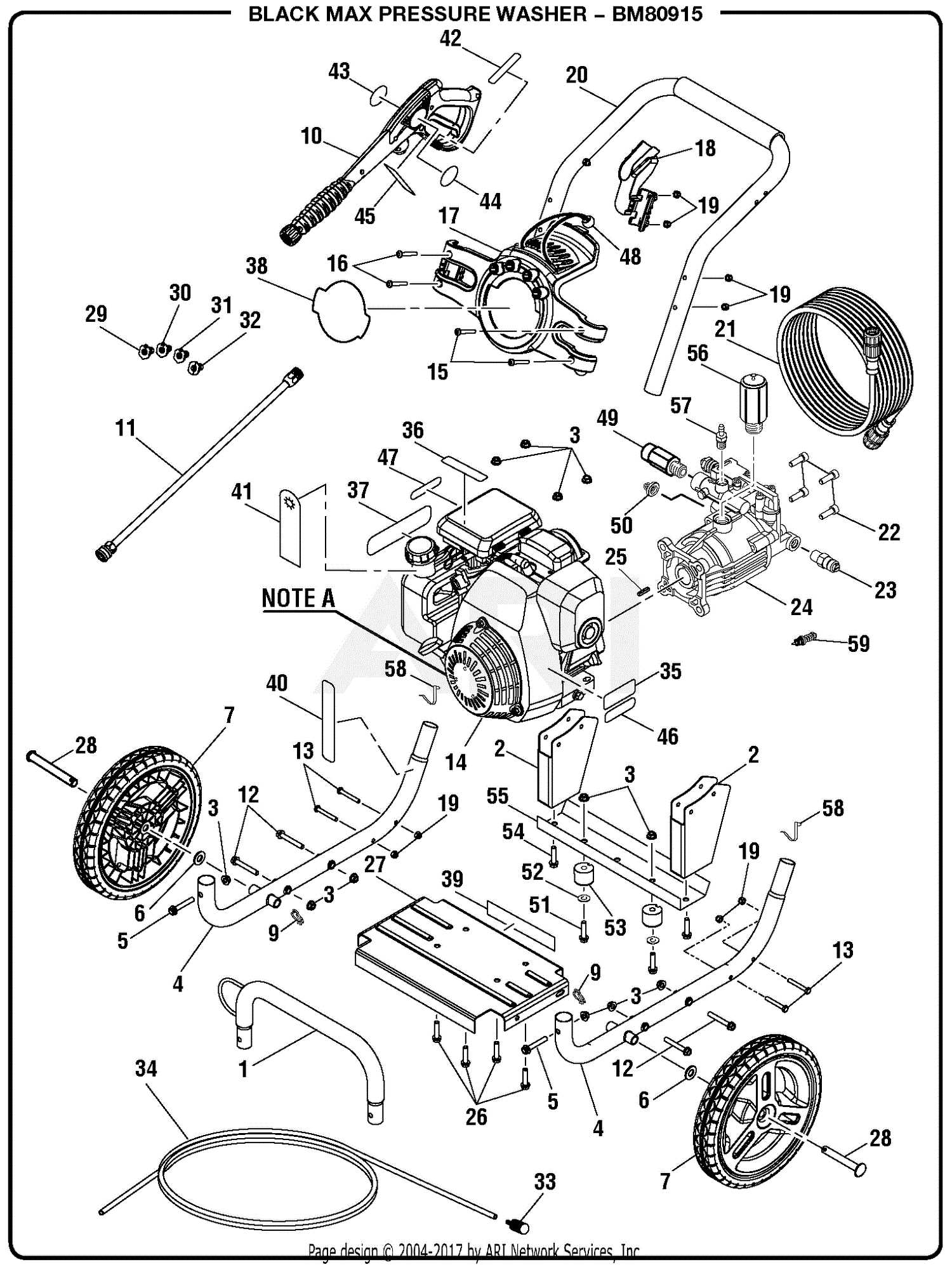

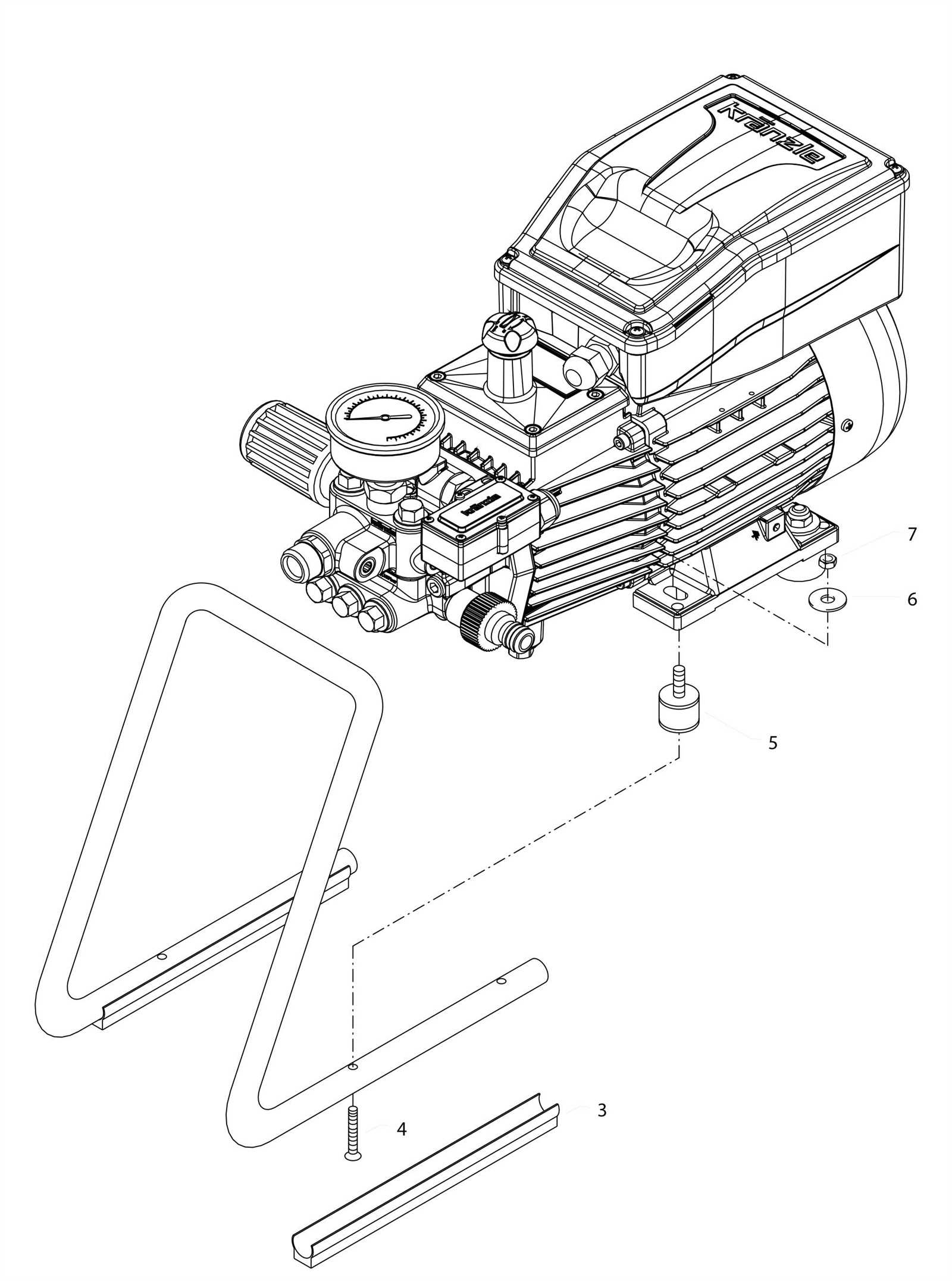

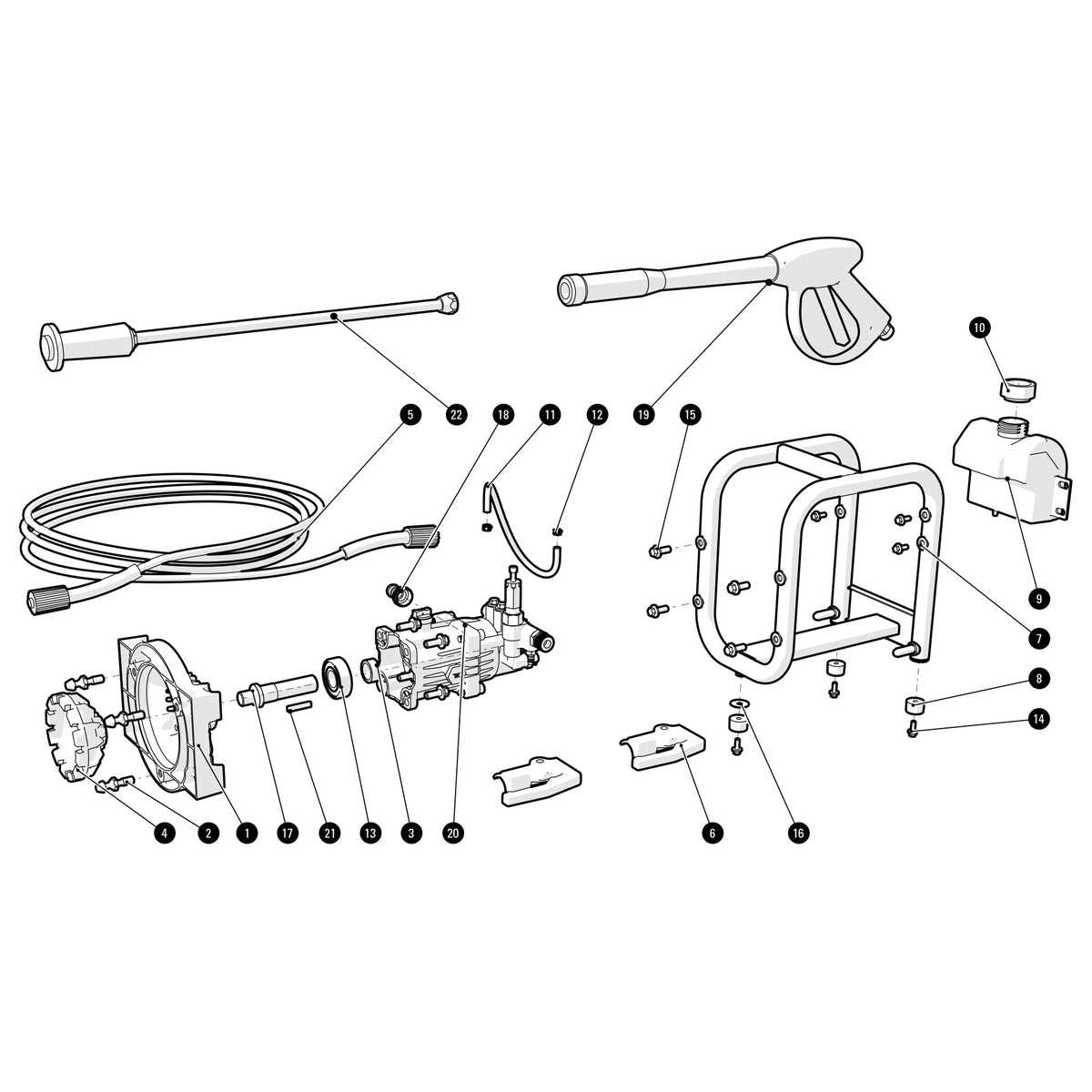

Visual representations of these crucial elements can offer insights into their arrangement and interaction. By exploring how each segment contributes to the device’s functionality, users can make informed decisions regarding maintenance and repairs. This knowledge not only fosters a deeper appreciation for the machinery but also aids in troubleshooting common issues.

Whether you are a novice or an experienced user, a comprehensive understanding of these integral parts is the ultimate key to maximizing the utility of your cleaning device. Dive into the intricacies of its construction to unlock the potential of your outdoor maintenance endeavors.

Understanding Pressure Washer Components

Every cleaning apparatus designed for high-efficiency tasks consists of several key elements that work together to achieve optimal performance. Familiarity with these components can enhance both maintenance and operational effectiveness, ensuring the device functions at its best for various cleaning needs.

Main Elements of the System

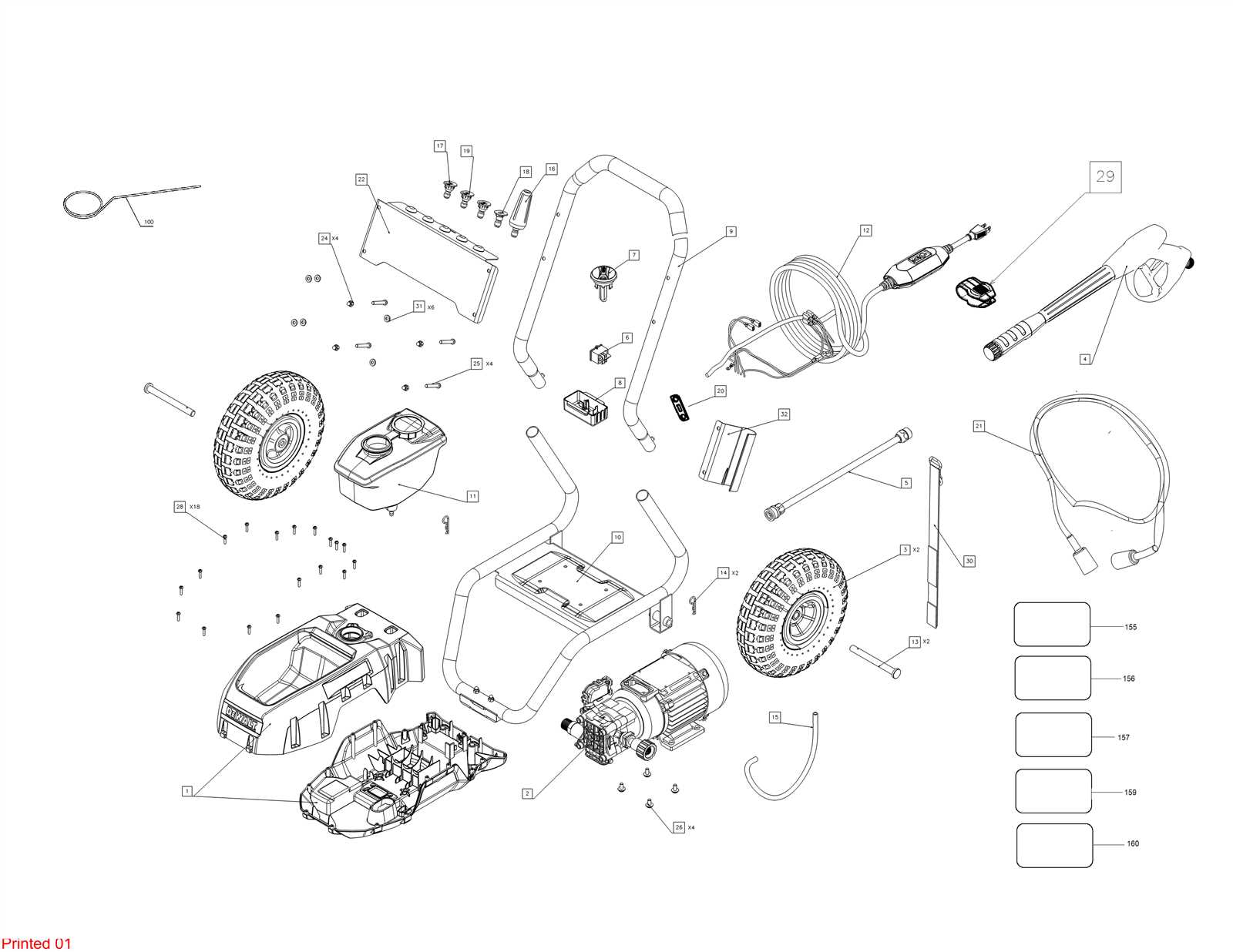

At the core of this mechanism lies the motor, which provides the necessary power to drive the entire unit. Coupled with this is the pump, a crucial component responsible for elevating water pressure. Additionally, a reliable hose facilitates the movement of water from the source to the intended area, while a nozzle regulates the flow and spray pattern, allowing for precise application during use.

Beyond the primary elements, there are numerous supportive accessories that enhance usability. Filters play an essential role in preventing debris from entering the system, thereby prolonging its lifespan. Furthermore, detergent tanks enable the integration of cleaning agents, boosting the efficiency of the cleaning process. Understanding these supportive elements is vital for anyone looking to maximize the utility of their equipment.

Essential Parts of a Pressure Washer

Understanding the key components of a cleaning machine is vital for effective maintenance and operation. Each element plays a crucial role in ensuring optimal performance and efficiency. Below are the primary components you should familiarize yourself with.

- Motor or Engine: This is the powerhouse that drives the entire system, providing the necessary force for the cleaning action.

- Pump: The mechanism responsible for drawing in water and pressurizing it, allowing for powerful spraying.

- Nozzle: This attachment determines the spray pattern and intensity, affecting how the water hits the surface being cleaned.

- Hose: A vital conduit that transports the pressurized fluid from the pump to the nozzle, available in various lengths and materials.

- Trigger Gun: The handheld device that controls the flow of water, allowing the user to start and stop the spray easily.

- Detergent Tank: An optional feature that holds cleaning solutions, enhancing the cleaning capability when mixed with water.

Familiarity with these components not only aids in better usage but also helps in troubleshooting common issues that may arise during operation.

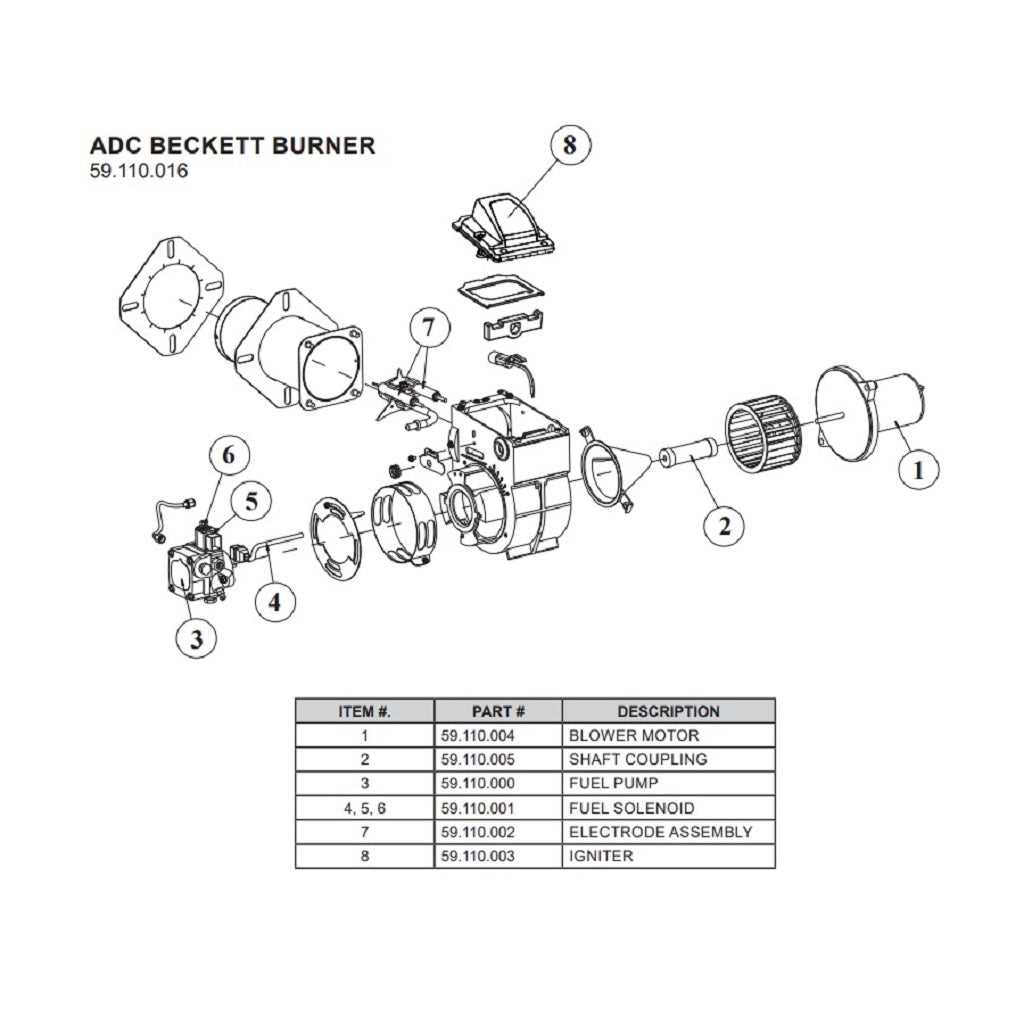

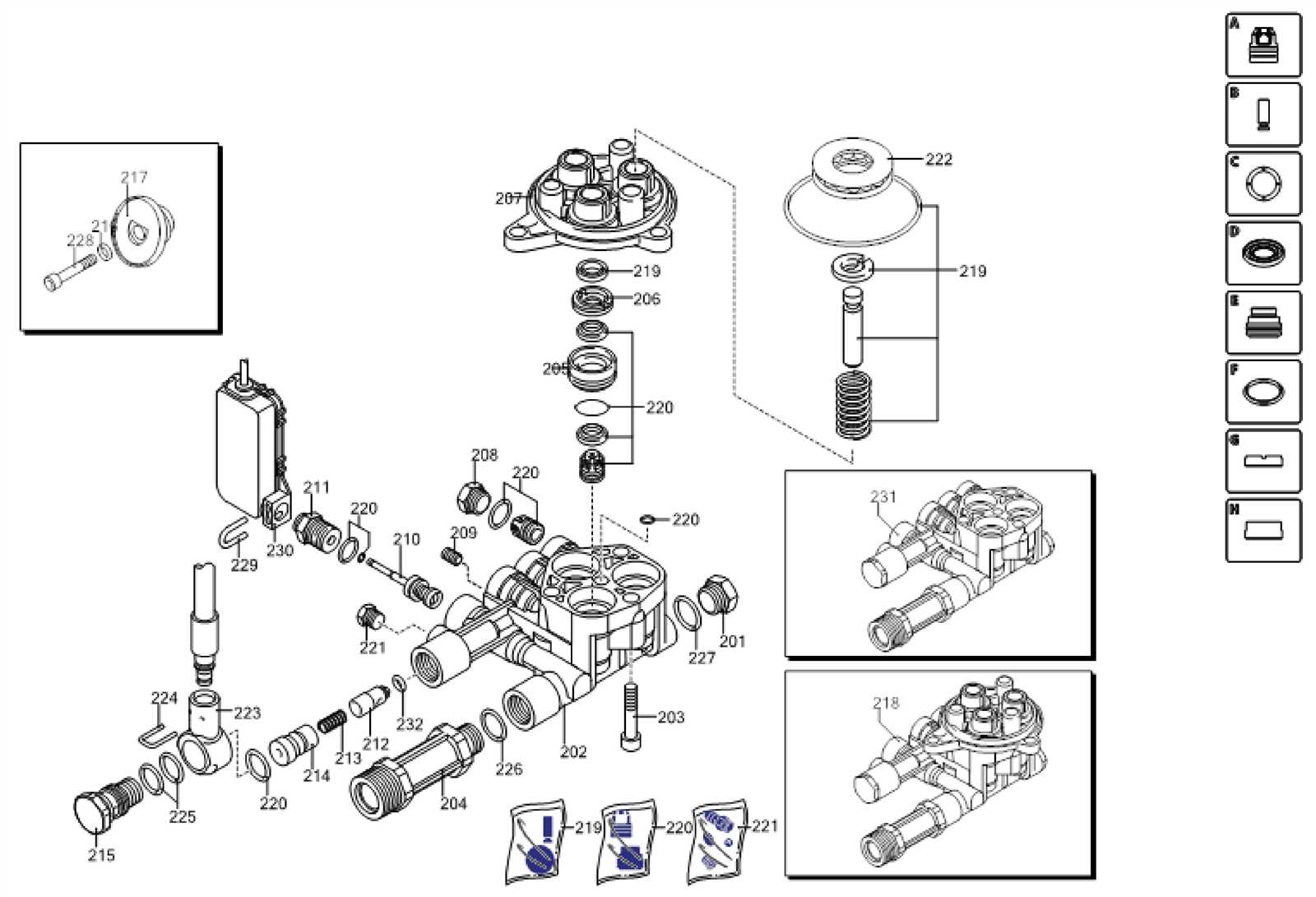

How Diagrams Enhance Repair Processes

Visual representations play a crucial role in simplifying complex repair tasks. They provide a clear overview of components, helping technicians and DIY enthusiasts understand the assembly and functionality of equipment. By offering a structured layout, these illustrations minimize confusion and streamline the troubleshooting process, ultimately leading to more efficient repairs.

Improved Understanding of Components

With the aid of visual aids, users can easily identify various elements and their relationships within a system. This clarity allows for quicker diagnosis of issues, as technicians can see where components fit and how they interact. Such representations reduce the likelihood of mistakes during reassembly and enhance overall confidence in handling repairs.

Efficiency in Repair Processes

Visual aids not only assist in understanding but also expedite the repair workflow. By providing step-by-step guidance, they help users follow procedures systematically, ensuring that nothing is overlooked. This organized approach saves time and minimizes frustration, making the repair experience more pleasant and successful.

Common Pressure Washer Issues Explained

Maintaining a cleaning device can sometimes lead to unexpected challenges. Understanding the common problems that can arise during operation is essential for ensuring effective performance and longevity. In this section, we will explore frequent issues encountered, their possible causes, and practical solutions.

Low Water Flow

One of the most prevalent issues is inadequate water flow. This can manifest as weak or inconsistent output during use. Possible reasons include blockages in the hose or nozzle, a malfunctioning pump, or insufficient water supply. To address this, inspect the hoses for kinks or clogs, and ensure the water source is adequately supplying pressure.

Unusual Noises

Another concern is the presence of strange sounds during operation. These noises can signal various problems, such as loose components, air leaks, or wear in the internal mechanisms. To troubleshoot, examine all connections and fittings, and listen for any unusual vibrations or rattling. Regular maintenance can help prevent these issues from developing.

Importance of Regular Maintenance Checks

Conducting routine assessments is essential for ensuring optimal functionality and longevity of any equipment. These checks help identify potential issues before they escalate, ultimately saving time and resources. By implementing a consistent maintenance schedule, users can enhance performance and reduce the likelihood of unexpected failures.

Enhancing Efficiency

Regular evaluations allow for adjustments and repairs that keep machinery operating at peak efficiency. This not only improves performance but also conserves energy and resources, leading to cost savings over time.

Extending Lifespan

Proactive maintenance significantly extends the lifespan of equipment. By addressing minor concerns promptly, users can avoid major breakdowns and ensure their machinery serves them effectively for years to come.

Safety Precautions When Using Washers

Ensuring safety while operating high-powered cleaning equipment is crucial for both the user and the surrounding environment. Understanding the potential hazards and taking the necessary precautions can help avoid accidents and injuries.

Always wear appropriate protective gear, including safety goggles, gloves, and sturdy footwear. This will shield you from debris and chemical splashes that may occur during operation.

Keep a safe distance from people and pets while using the machine. Ensure that bystanders are at least 10 feet away to prevent injury from flying particles or spray.

Before starting, inspect the equipment thoroughly for any signs of wear or damage. This includes checking hoses, nozzles, and connections to ensure everything is functioning correctly.

Read the manufacturer’s instructions carefully before use. Understanding the proper operating procedures will greatly reduce the risk of accidents and enhance efficiency.

Never point the nozzle at yourself or others, even when the device is turned off. Accidental activation can lead to serious injuries.

Finally, store the equipment properly when not in use. Keeping it in a safe, dry place prevents unauthorized access and damage, ensuring it remains in good working condition for future use.

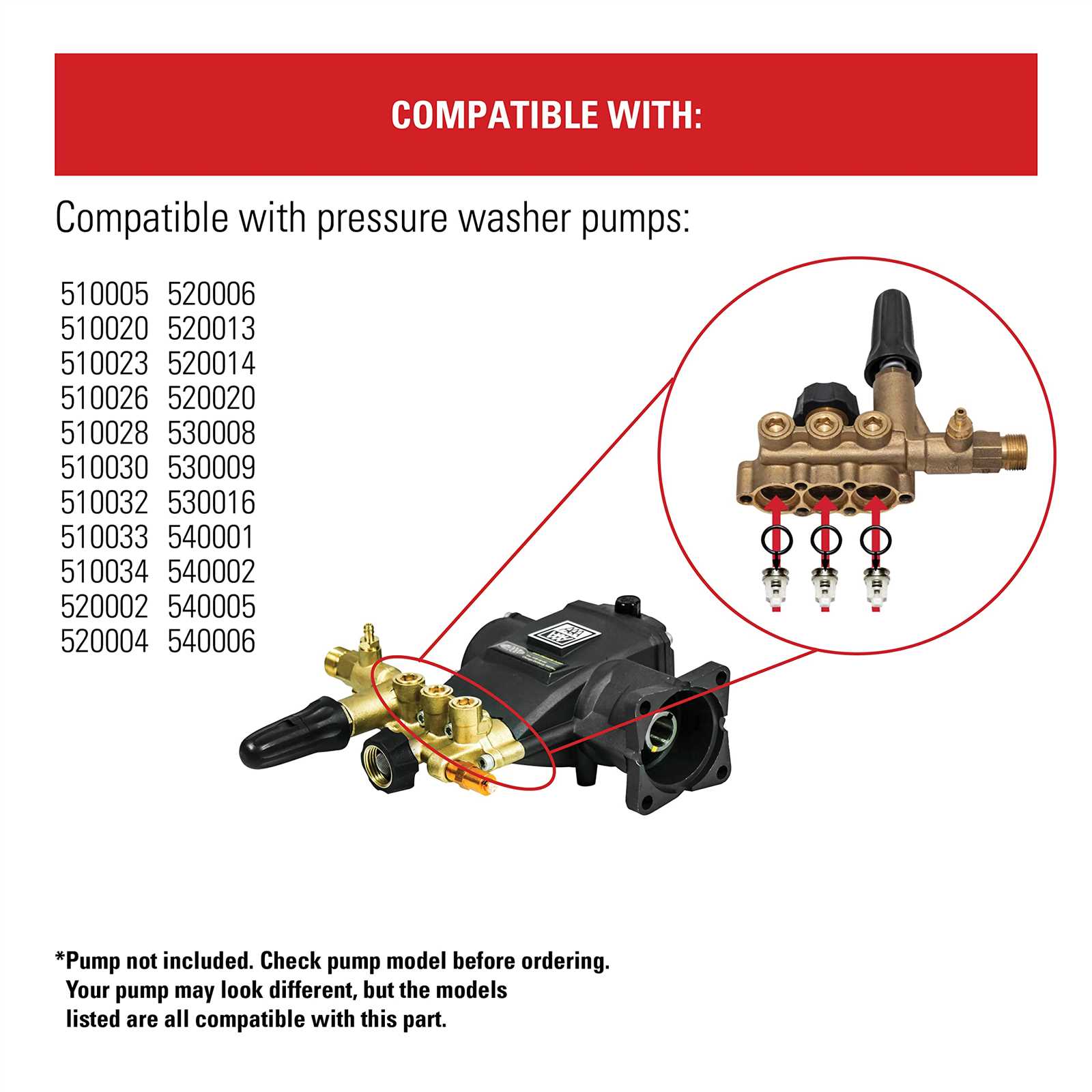

Choosing the Right Parts for Repairs

When it comes to maintaining your equipment, selecting the appropriate components is crucial for ensuring optimal performance and longevity. Understanding the key factors in making these decisions can greatly enhance the efficiency of your restoration efforts.

Assessing Compatibility

Before purchasing any component, it is vital to verify its compatibility with your specific model. Check the manufacturer’s guidelines and specifications to avoid any mismatches. Consulting resources such as user manuals or online forums can provide valuable insights.

Quality Over Cost

While it may be tempting to opt for cheaper alternatives, investing in high-quality components often leads to better results. Durability and performance should be prioritized, as subpar options may result in further issues down the line. Make informed choices to ensure the ultimate success of your repairs.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to safely dismantling equipment for maintenance or repair. Following these steps will ensure that each component is handled properly, minimizing the risk of damage.

- Preparation:

- Gather necessary tools, including wrenches and screwdrivers.

- Ensure the device is unplugged and fully cooled down.

- Initial Inspection:

- Examine the exterior for any visible damage or wear.

- Identify any screws or fasteners that need to be removed.

- Remove Outer Housing:

- Unscrew and detach any panels carefully.

- Keep screws organized for reassembly.

- Access Internal Components:

- Identify key elements that require inspection or replacement.

- Disconnect any electrical connections gently.

- Final Disassembly:

- Remove individual components as needed.

- Document each step for later reference.

By following these detailed instructions, you’ll be equipped to tackle the disassembly process efficiently and effectively.

Tools Required for Pressure Washer Repair

Maintaining and fixing cleaning equipment demands a specific set of instruments to ensure efficiency and effectiveness. Understanding which tools are essential can significantly simplify the repair process, allowing for timely and reliable restoration of functionality.

Essential Hand Tools

Basic hand tools, such as wrenches, screwdrivers, and pliers, are fundamental for disassembly and assembly tasks. Having a variety of sizes is crucial to accommodate different components.

Diagnostic and Cleaning Equipment

Utilizing multimeters for electrical issues and compressed air for cleaning out debris ensures thorough diagnostics and maintenance. These tools enhance precision in identifying and resolving problems effectively.

DIY vs. Professional Repair Services

When it comes to addressing equipment malfunctions, individuals often face the choice between tackling repairs themselves or enlisting the help of experts. Each approach has its advantages and drawbacks, influencing the outcome and efficiency of the restoration process.

Do-It-Yourself (DIY) solutions appeal to those seeking cost savings and the satisfaction of self-sufficiency. By delving into repair manuals and online tutorials, enthusiasts can often resolve issues without financial strain. However, this route requires a certain level of skill and the right tools, and mistakes can lead to further complications.

On the other hand, professional services offer the ultimate convenience and assurance. Trained technicians bring expertise and specialized tools, often resulting in quicker and more reliable fixes. Yet, this option typically comes with a higher price tag, which can be a significant consideration for many.

Ultimately, the decision between DIY and professional assistance hinges on individual comfort levels, available resources, and the complexity of the problem at hand.

Where to Find Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process if you know where to look. Numerous online platforms offer a wide selection of replacements, ensuring you can maintain your machinery effectively. Here are some reliable sources to consider when searching for these essential items.

| Website | Description |

|---|---|

| Amazon | A vast marketplace with a variety of brands and user reviews to help make informed choices. |

| eBay | A great option for finding both new and used items, often at competitive prices. |

| Manufacturer’s Website | The best place for original components, ensuring compatibility and quality. |

| Home Improvement Stores | Many retail chains have online catalogs, offering easy access to common replacements. |