In the realm of household appliances, comprehending the intricate configurations of various mechanisms is essential for effective maintenance and repair. Each device is composed of multiple elements that work harmoniously to ensure optimal performance. Familiarity with these components can greatly assist users in troubleshooting issues and prolonging the lifespan of their machines.

Accurate knowledge of the arrangement and functionality of these crucial elements empowers individuals to identify malfunctions swiftly. By grasping how each section contributes to the overall operation, users can make informed decisions regarding repairs or replacements. This insight is particularly valuable for those who prefer a hands-on approach to appliance upkeep.

Whether you are a DIY enthusiast or a professional technician, understanding the layout of these essential features fosters confidence when dealing with any challenges. A well-organized overview not only streamlines the repair process but also enhances the overall efficiency of your appliance, ensuring it continues to serve you reliably for years to come.

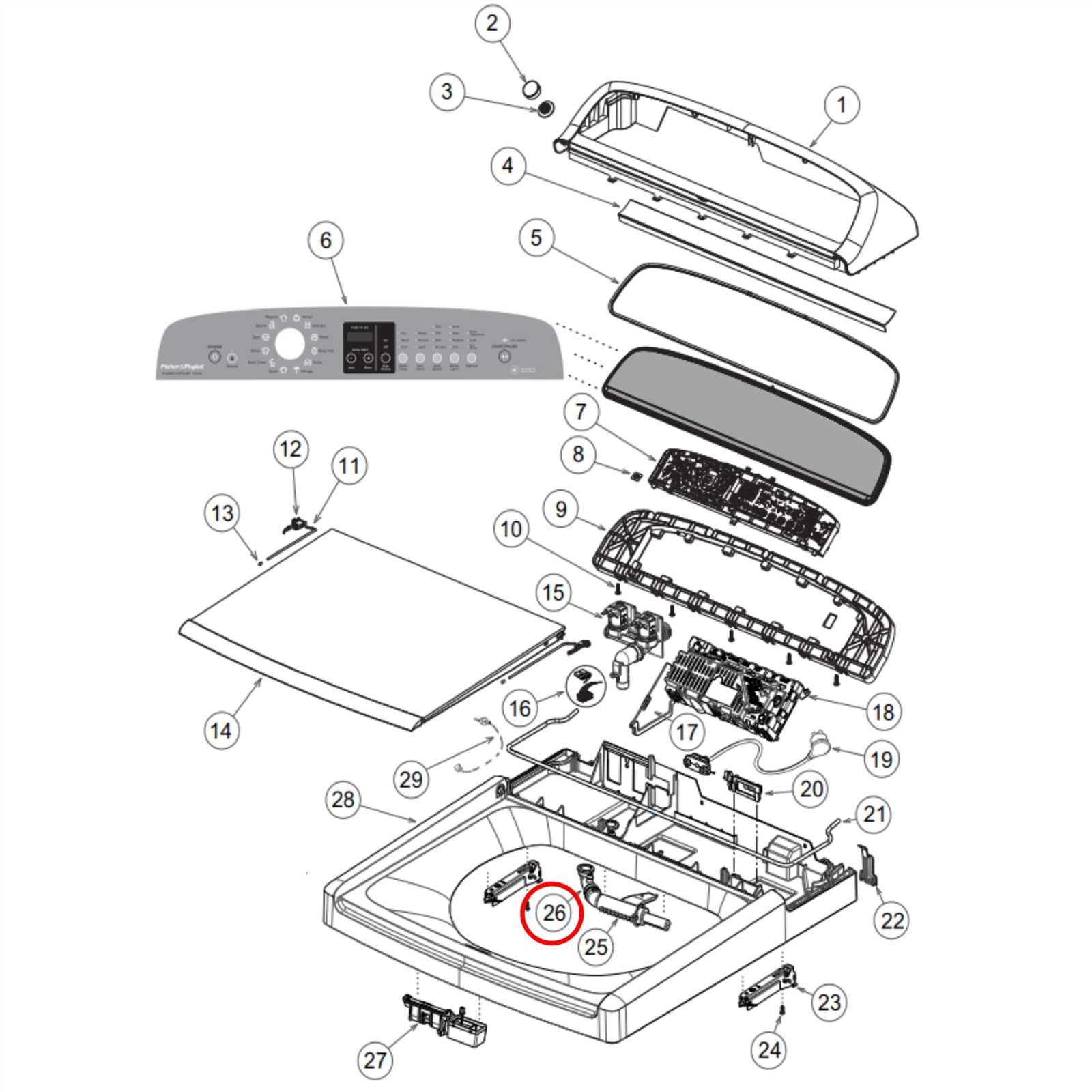

Overview of Fisher & Paykel Washer Components

This section provides an in-depth look at the essential elements that constitute the functioning of modern laundry appliances. Understanding these components is crucial for effective troubleshooting, maintenance, and ensuring optimal performance.

Each unit consists of several key components, each serving a specific purpose:

- Drum: The central part where the clothing is placed for cleaning. It is designed to accommodate various load sizes while ensuring efficient agitation.

- Motor: This drives the drum’s rotation and is vital for both washing and spinning cycles. A reliable motor contributes to the overall performance and longevity of the unit.

- Control Panel: The interface that allows users to select different washing programs and settings. It typically includes buttons, dials, and digital displays.

- Pump: Responsible for draining water from the drum after the wash cycle. A well-functioning pump is essential for maintaining the appliance’s efficiency.

- Hoses: These facilitate water intake and drainage. Proper installation and maintenance of hoses are critical to prevent leaks and ensure smooth operation.

In addition to these primary elements, there are several auxiliary parts that enhance functionality:

- Filter: Captures debris and lint, preventing blockages in the drainage system.

- Suspension System: Keeps the drum stable during operation, minimizing vibrations and noise.

- Heating Element: Heats water to the desired temperature for effective cleaning, particularly important for certain fabrics.

Familiarity with these components not only aids in troubleshooting but also helps in understanding how the appliance operates effectively to deliver clean and fresh laundry.

Understanding the Washing Machine Mechanism

The operation of a laundry appliance is a complex interplay of various components that work harmoniously to ensure effective cleaning. Each element plays a crucial role in facilitating the washing process, contributing to the appliance’s overall efficiency and functionality.

Here are the key components involved in the mechanism:

- Drum: The central unit where the clothes are placed for cleaning. It rotates to create agitation.

- Motor: Powers the drum and controls its speed and direction during the wash cycle.

- Pump: Responsible for draining the water from the drum after rinsing, ensuring that the appliance functions smoothly.

- Control Panel: The user interface that allows for setting wash cycles, temperature, and other preferences.

- Hoses: Transport water in and out of the appliance, connecting it to the water supply and drainage system.

Understanding these components can aid in troubleshooting and maintenance, leading to improved performance and longevity of the laundry machine. Each element, from the motor to the control panel, contributes to a seamless cleaning experience, making it essential for users to familiarize themselves with their roles.

By grasping how these components function together, users can make informed decisions regarding repairs, part replacements, and overall maintenance, ensuring optimal operation for years to come.

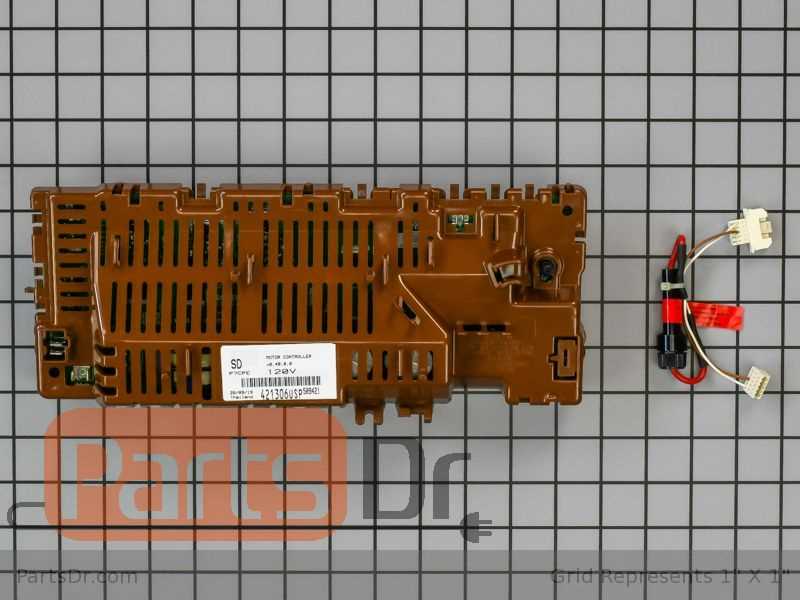

Key Electrical Components and Their Roles

Understanding the essential electrical components within a laundry appliance is crucial for effective operation and troubleshooting. Each element plays a vital role in ensuring the appliance functions correctly, contributing to overall performance and reliability.

- Power Supply Module: This unit provides the necessary voltage and current to operate the machine, ensuring all components receive adequate energy for functionality.

- Control Board: Acts as the brain of the system, managing the operations based on user inputs and programming, thereby controlling various cycles and settings.

- Motor: Responsible for driving the drum and performing the washing and spinning motions. Its efficiency directly impacts the appliance’s cleaning effectiveness.

- Water Inlet Valve: Regulates the flow of water into the appliance, allowing for precise control over the washing process.

- Drain Pump: Facilitates the removal of water from the machine after washing, ensuring efficient drainage and preventing flooding.

- Temperature Sensor: Monitors the water temperature, allowing for adjustments to achieve the optimal heat level for various washing cycles.

- Door Lock Mechanism: Ensures safety by locking the door during operation, preventing accidental openings and potential hazards.

By recognizing the roles of these critical electrical components, users can better appreciate their importance in the functionality and safety of the appliance. Regular maintenance and awareness of these elements can enhance longevity and performance.

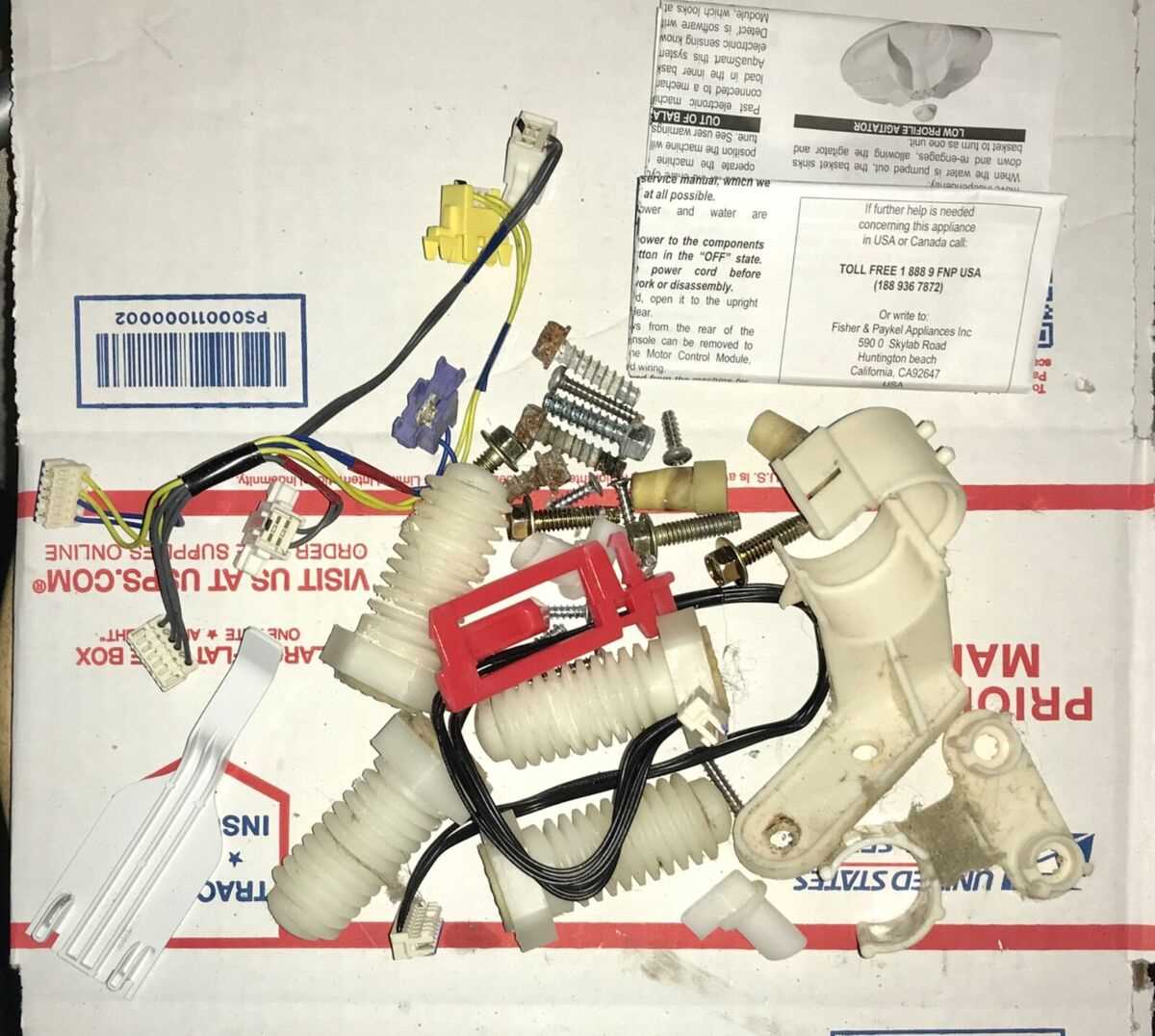

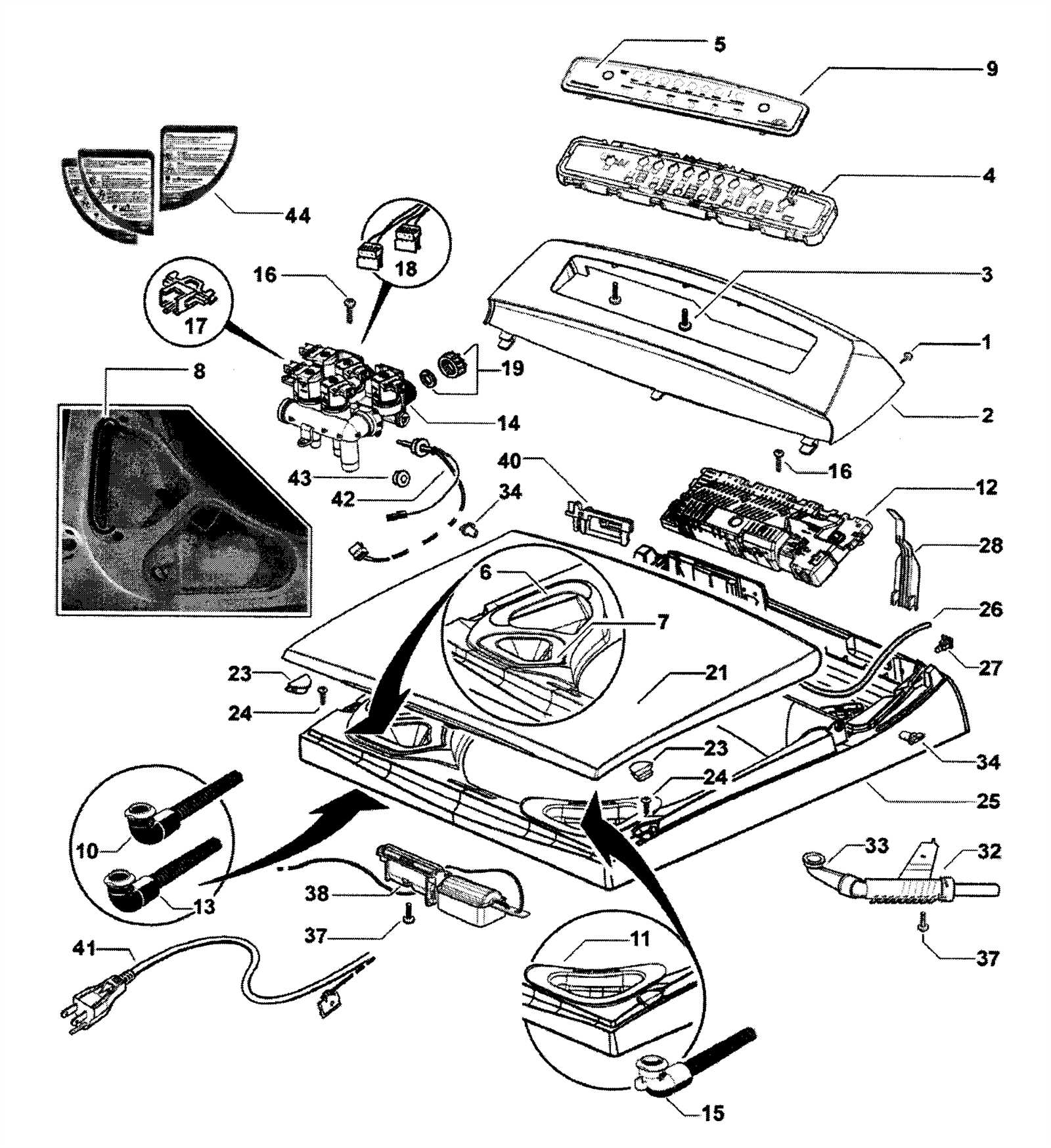

Identifying Water Inlet and Drainage Elements

Understanding the components responsible for water intake and drainage is crucial for maintaining optimal functionality in any laundry appliance. These elements play a significant role in ensuring the proper flow of water, which directly impacts the efficiency of the entire system. By recognizing these components, users can troubleshoot issues more effectively and enhance their appliance’s performance.

Water Inlet Components

The water intake components are vital for filling the machine with the appropriate amount of water needed for each cycle. Identifying these parts can help determine if there are any blockages or malfunctions affecting water entry.

| Component | Description |

|---|---|

| Inlet Valve | Controls the flow of water into the machine. |

| Filter Screen | Prevents debris from entering the water supply. |

| Hoses | Connects the water supply to the machine. |

Drainage Elements

The drainage components are equally essential, as they ensure that used water is expelled efficiently after each cycle. Familiarizing oneself with these parts can assist in identifying potential issues related to drainage.

| Component | Description |

|---|---|

| Drain Pump | Pumps water out of the appliance. |

| Drain Hose | Channels used water to the external drainage system. |

| Drain Filter | Traps lint and debris, preventing clogs. |

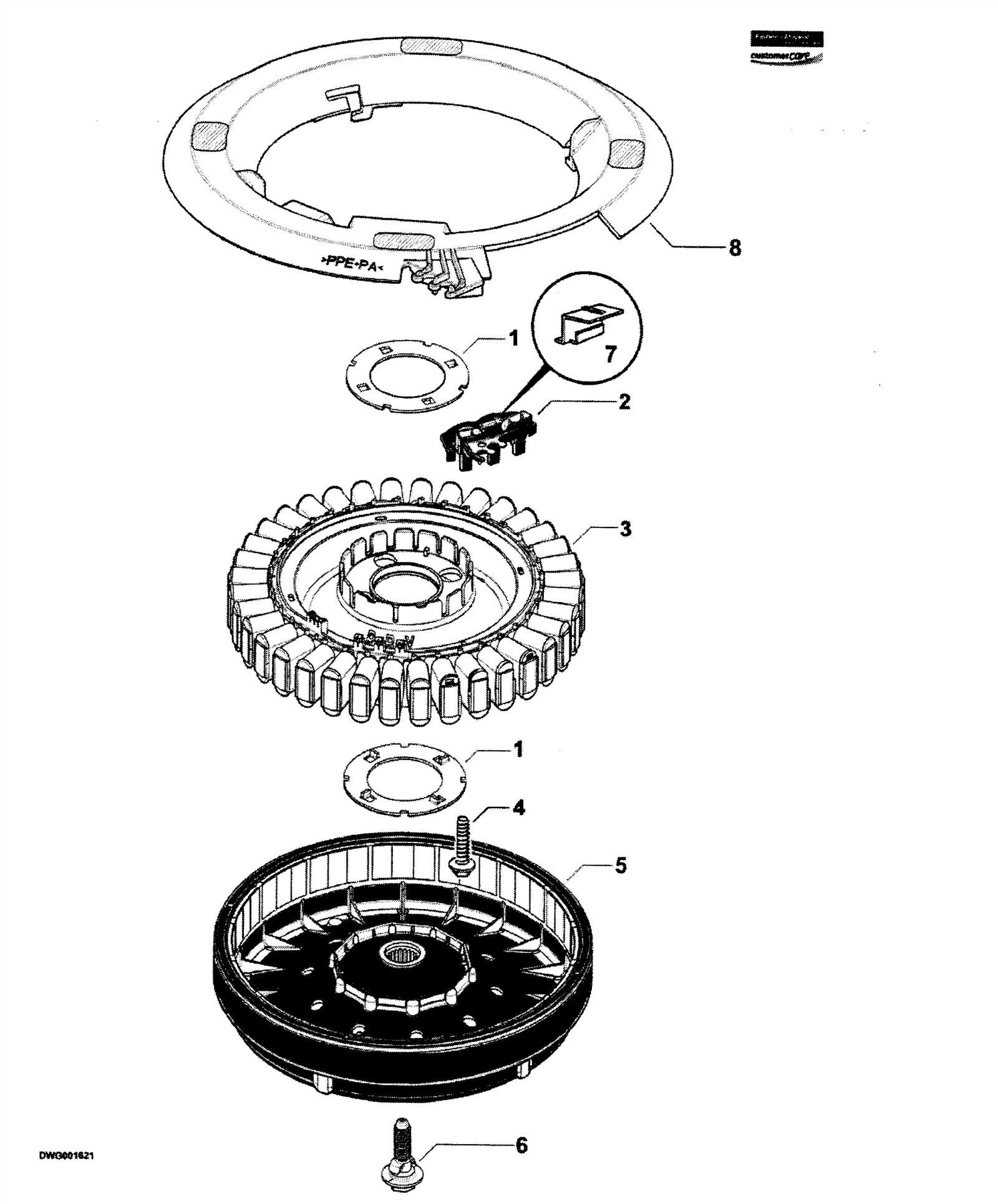

Exploring the Motor Functionality

The motor serves as the heartbeat of any laundry appliance, driving the various functions that ensure efficient cleaning cycles. Understanding its operation is essential for effective maintenance and troubleshooting. This section delves into the key aspects of the motor’s role, its components, and how they interact to facilitate optimal performance.

Key Functions of the Motor

- Agitation: The motor is responsible for creating the movement necessary to mix water and detergent, allowing for effective soil removal from fabrics.

- Spin Cycle: During this phase, the motor spins the drum at high speeds to extract water from the garments, reducing drying time.

- Control Mechanisms: Advanced motors are equipped with electronic controls that optimize energy consumption and adapt to load sizes.

Components of the Motor System

- Stator: This stationary part generates a magnetic field that drives the rotor.

- Rotor: The rotating component that engages with the drum, providing the necessary torque for motion.

- Belt and Pulley: These elements transfer power from the motor to the drum, allowing for precise control of movement.

- Bearings: Essential for smooth operation, they reduce friction and support the rotating parts.

The Importance of Seals and Gaskets

Seals and gaskets play a crucial role in maintaining the efficiency and longevity of various appliances. These components act as barriers, preventing the leakage of liquids and gases while ensuring optimal performance. Without reliable seals and gaskets, appliances may suffer from reduced effectiveness and potential damage due to the infiltration of unwanted substances.

In everyday use, the integrity of seals and gaskets is vital for proper functioning. They contribute to energy efficiency by minimizing losses due to leaks, which can lead to increased operational costs. Furthermore, high-quality seals and gaskets help protect internal mechanisms from corrosion and contamination, prolonging the lifespan of appliances.

| Component | Function | Consequences of Failure |

|---|---|---|

| Rubber Seal | Prevents fluid leakage | Loss of liquid, reduced efficiency |

| Silicone Gasket | Provides airtight closure | Air leaks, operational issues |

| O-Ring | Creates a tight seal | Pressure loss, potential damage |

Regular inspection and replacement of these components are essential for ensuring the reliability of appliances. Investing in high-quality seals and gaskets can lead to significant savings over time, as they reduce the need for repairs and enhance overall performance.

Commonly Replaced Wearable Parts

In any appliance, certain components are prone to wear and tear due to regular use. Recognizing and addressing these frequently replaced elements can enhance the longevity and efficiency of the unit. Understanding which items are most likely to require replacement can save both time and effort during maintenance.

One of the most common components that often needs attention is the seal. Over time, exposure to moisture and friction can cause it to degrade, leading to leaks and decreased performance. Another critical part is the belt, which can wear out due to the mechanical stress of operation, resulting in inadequate function or unusual noises.

The filters also deserve mention; they capture debris and dirt but can become clogged, impacting the overall efficiency of the system. Regularly replacing or cleaning these filters is essential for optimal operation. Additionally, drum paddles, which assist in the movement of items during cycles, can suffer from wear, resulting in ineffective agitation.

Ultimately, being proactive about these commonly replaced components can significantly improve the performance and lifespan of the appliance, ensuring it operates smoothly for years to come.

Filter Maintenance and Replacement Guide

Maintaining and replacing filters is essential for ensuring the longevity and efficiency of your appliance. Regular upkeep not only enhances performance but also prevents potential issues that can arise from clogged or dirty filters. This guide provides practical steps to help you effectively manage filter care, contributing to optimal operation.

Importance of Regular Maintenance

Filters play a critical role in the functionality of your appliance. They capture debris and prevent it from entering the internal mechanisms, which can lead to malfunctions over time. Regularly inspecting and cleaning filters can significantly reduce wear and tear, ensuring your device runs smoothly and efficiently.

Steps for Filter Replacement

To maintain optimal performance, follow these simple steps for replacing your filter:

- Turn off the appliance: Always ensure the device is powered down before attempting any maintenance.

- Access the filter compartment: Refer to the user manual to locate the filter area.

- Remove the old filter: Carefully detach the filter, taking note of its orientation for proper installation of the new one.

- Install the new filter: Place the new filter in the compartment, ensuring it fits snugly and correctly.

- Close the compartment: Secure any access panels and power the device back on.

Regular maintenance of filters is vital for enhancing the efficiency and lifespan of your appliance. By following these guidelines, you can ensure that your device operates at its best.

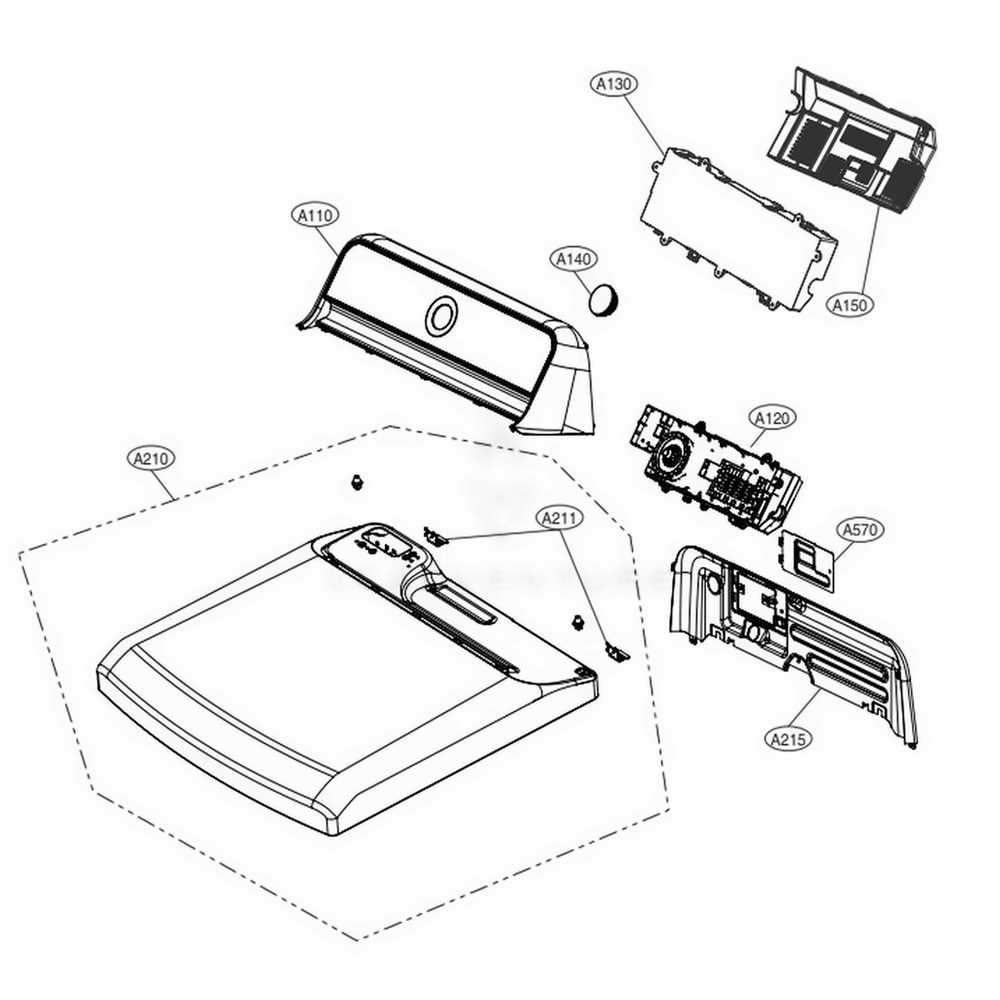

Control Panel Components Breakdown

The control interface of a laundry appliance plays a vital role in its functionality, allowing users to manage cycles and settings efficiently. Understanding the various components of this interface is essential for troubleshooting and maintenance, ensuring optimal performance and longevity of the device.

Main Functions

This section delves into the primary functionalities of the control panel. It typically includes various buttons, knobs, and indicators that allow for user interaction with the machine. Each element is designed to facilitate ease of use while offering specific operational commands.

Below is a detailed breakdown of the common components found in a control interface:

| Component | Description |

|---|---|

| Power Button | Initiates or terminates power to the unit. |

| Cycle Selector | Allows users to choose the desired wash cycle. |

| Temperature Control | Regulates the water temperature during the wash. |

| Delay Start | Enables scheduling of the wash cycle to begin at a later time. |

| Status Indicators | Lights that inform users about the current operation status. |

Exploring the Suspension and Balance System

The suspension and balance mechanism in laundry appliances plays a crucial role in maintaining stability and efficiency during operation. This system is designed to absorb vibrations and minimize movement, ensuring that the unit remains steady while handling various load weights. A well-functioning suspension system contributes to quieter performance and enhances the lifespan of the machine.

Components of the Suspension System

The key elements involved in the suspension framework include springs, dampers, and support structures. Each component is engineered to work in harmony, providing optimal support and shock absorption. Understanding these components helps in troubleshooting issues related to instability or excessive noise during operation.

Balance Mechanism Functionality

The balance system is essential for distributing weight evenly across the appliance. An imbalance can lead to uneven wear and tear, as well as potential damage to the motor and other internal parts. Regular maintenance and inspection of this system can prevent problems and ensure effective operation.

| Component | Function |

|---|---|

| Springs | Support the drum and absorb shock during operation. |

| Dampers | Control the oscillation of the drum and reduce vibrations. |

| Support Structures | Maintain the overall stability of the appliance. |

Diagnostic Tools for Fisher & Paykel Washers

Understanding the functionality of your laundry appliance is essential for maintaining its performance and longevity. Utilizing the right diagnostic instruments can significantly aid in identifying issues, ensuring that your unit operates efficiently. Whether you’re a technician or a DIY enthusiast, being equipped with proper tools can facilitate quick and effective troubleshooting.

Multimeter is a vital device for assessing electrical components within the machine. This tool enables you to measure voltage, resistance, and current, helping to pinpoint electrical failures that may disrupt operation.

Pressure Gauge plays a critical role in evaluating the water system. By checking the water pressure, you can determine if the appliance is receiving an adequate supply, which is crucial for optimal functionality.

Error Code Reader simplifies the diagnostic process by interpreting the machine’s internal error codes. This tool allows users to quickly identify specific issues and take appropriate action based on the manufacturer’s guidance.

Diagnostic Software offers advanced capabilities for in-depth analysis. Connecting your appliance to a compatible software application can provide real-time data and insights into its performance, enabling proactive maintenance.

By leveraging these essential tools, users can enhance their understanding of their laundry appliance’s workings, troubleshoot issues effectively, and ensure long-term reliability.

How to Troubleshoot Common Part Failures

Troubleshooting issues with home appliances can often seem daunting. However, by following a systematic approach, one can identify and resolve many common problems. This section will guide you through the steps to diagnose typical component malfunctions that might arise during operation.

Begin by observing the symptoms your appliance displays. Unusual noises, failure to operate, or error codes can provide valuable clues. Consult the user manual for specific indicators related to your model. Once you have a clearer understanding of the symptoms, you can begin to check individual components.

Start with the electrical connections. Loose or corroded terminals can disrupt the flow of power, causing performance issues. Ensure that all connections are secure and clean. Next, examine any belts or hoses for signs of wear or damage. Cracks or frays can lead to failures, requiring immediate attention.

If the appliance continues to malfunction, testing individual components with a multimeter can help isolate the issue. Checking fuses, switches, and motors will reveal whether they are functioning correctly. Always ensure the device is unplugged before conducting any tests to maintain safety.

By following these troubleshooting steps, you can effectively identify and resolve common issues, prolonging the lifespan of your appliance and improving its efficiency.

Recommended Parts for Performance Enhancement

Enhancing the efficiency and longevity of your appliance often requires the replacement or upgrade of certain components. By investing in quality replacements, users can experience improved functionality and better overall performance.

Here are some key components to consider for optimal operation:

- Drum Bearings: These components are crucial for smooth rotation and reduced noise. Upgrading to high-quality bearings can minimize wear and tear.

- Seals and Gaskets: Ensuring a watertight seal is essential for preventing leaks. Replacing old or worn seals can significantly enhance performance and reliability.

- Motor Coupling: This part connects the motor to the drum, facilitating efficient movement. A sturdy coupling can improve energy transfer and reduce vibrations.

- Control Module: An advanced control module can provide better precision in cycles and settings, leading to optimized washing outcomes.

- Hoses and Connections: Regularly replacing hoses can prevent leaks and ensure a steady flow of water, which is vital for effective cleaning.

By focusing on these essential components, users can significantly enhance the performance and durability of their machines, leading to a more efficient and satisfying experience.