In any home, the functionality of laundry appliances is crucial for maintaining cleanliness and convenience. A comprehensive grasp of the various components involved in these machines can significantly enhance their operation and longevity. This section delves into the essential elements that play a vital role in ensuring optimal performance.

By familiarizing oneself with the intricate layout of these essential mechanisms, users can effectively troubleshoot issues and perform necessary maintenance tasks. Knowing how different components interact not only aids in the identification of potential problems but also empowers individuals to make informed decisions regarding repairs and replacements.

Whether you are a homeowner looking to extend the life of your appliance or someone interested in understanding the inner workings of household technology, this exploration of the intricate arrangement of parts provides valuable insights. Each element contributes to the overall efficiency and effectiveness of the machine, making it imperative to recognize their significance.

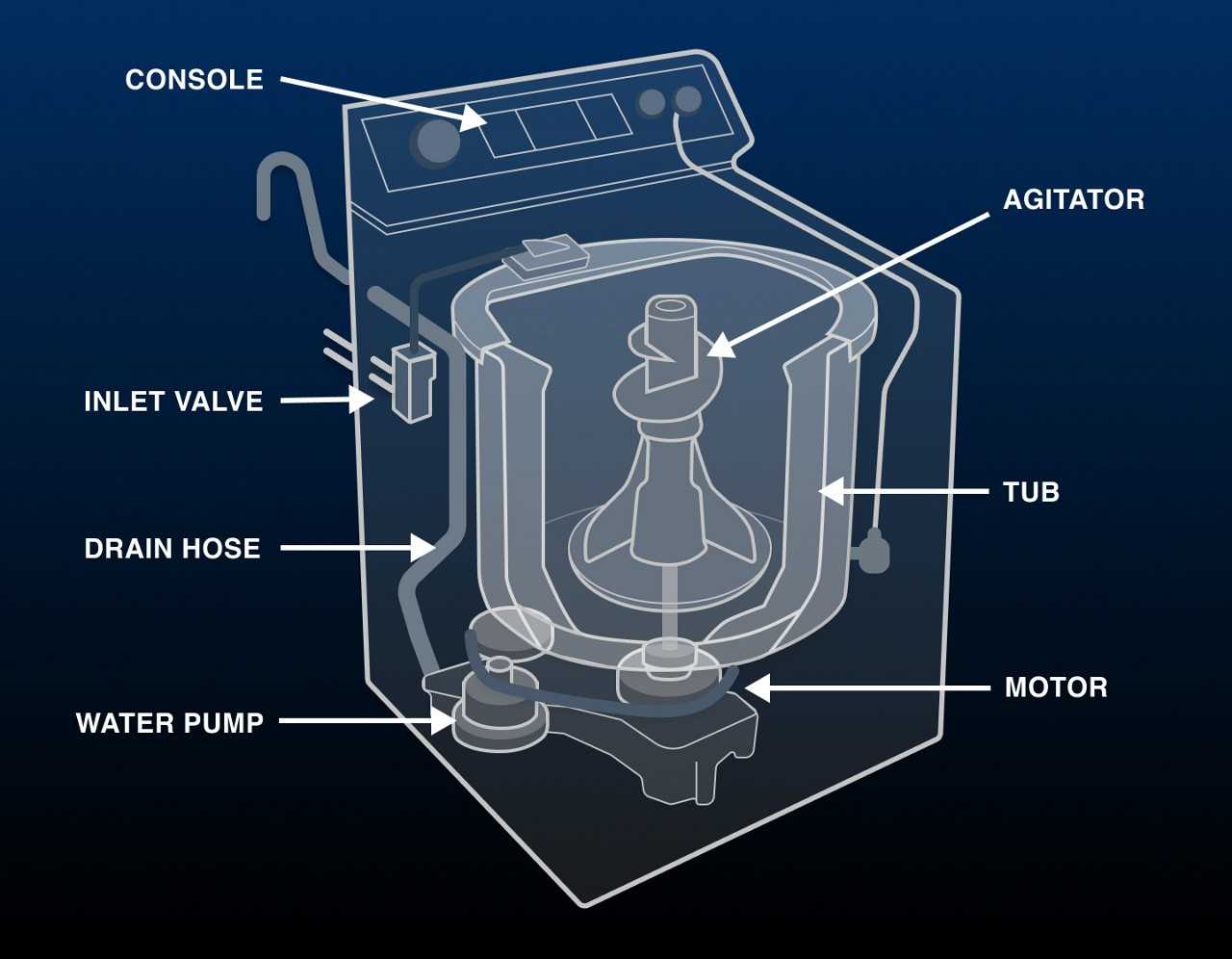

In modern households, efficient laundry machines have become essential for streamlining the cleaning process. Understanding the various components of these appliances is crucial for effective maintenance and troubleshooting. This section will delve into the intricate elements that contribute to their functionality, providing insights into their roles and interconnections.

| Component | Function |

|---|---|

| Drum | Holds and rotates the laundry during cycles, allowing for effective cleaning. |

| Water Inlet Valve | Controls the flow of water into the machine based on the selected program. |

| Drain Pump | Removes water from the drum after the wash and rinse cycles are completed. |

| Control Panel | Allows users to select settings and monitor the operation of the machine. |

| Agitator | Facilitates the movement of garments for thorough cleaning. |

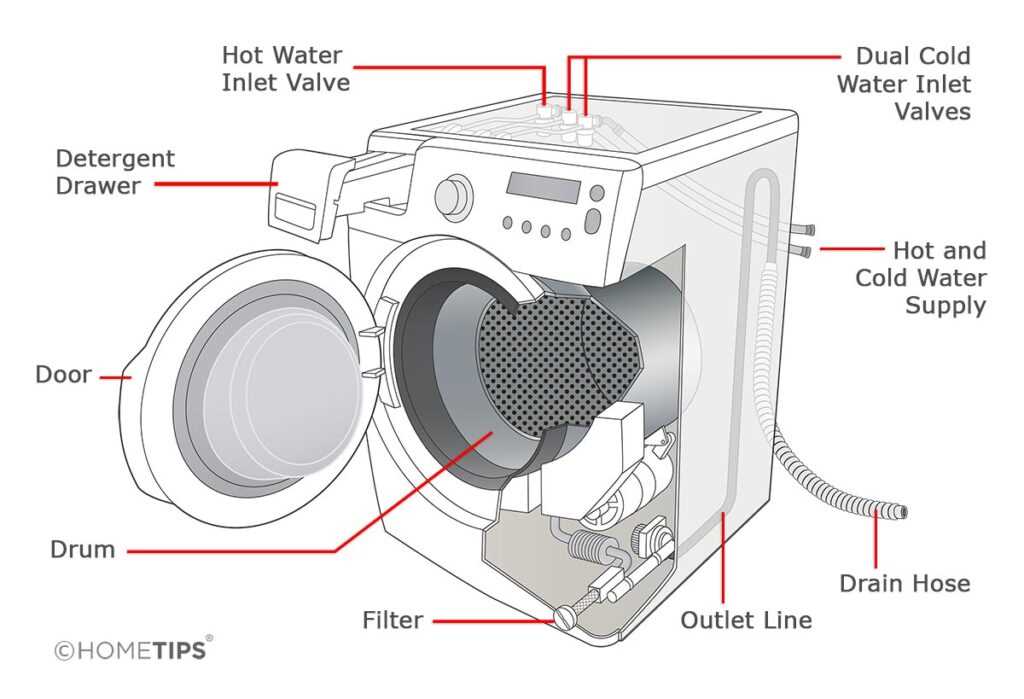

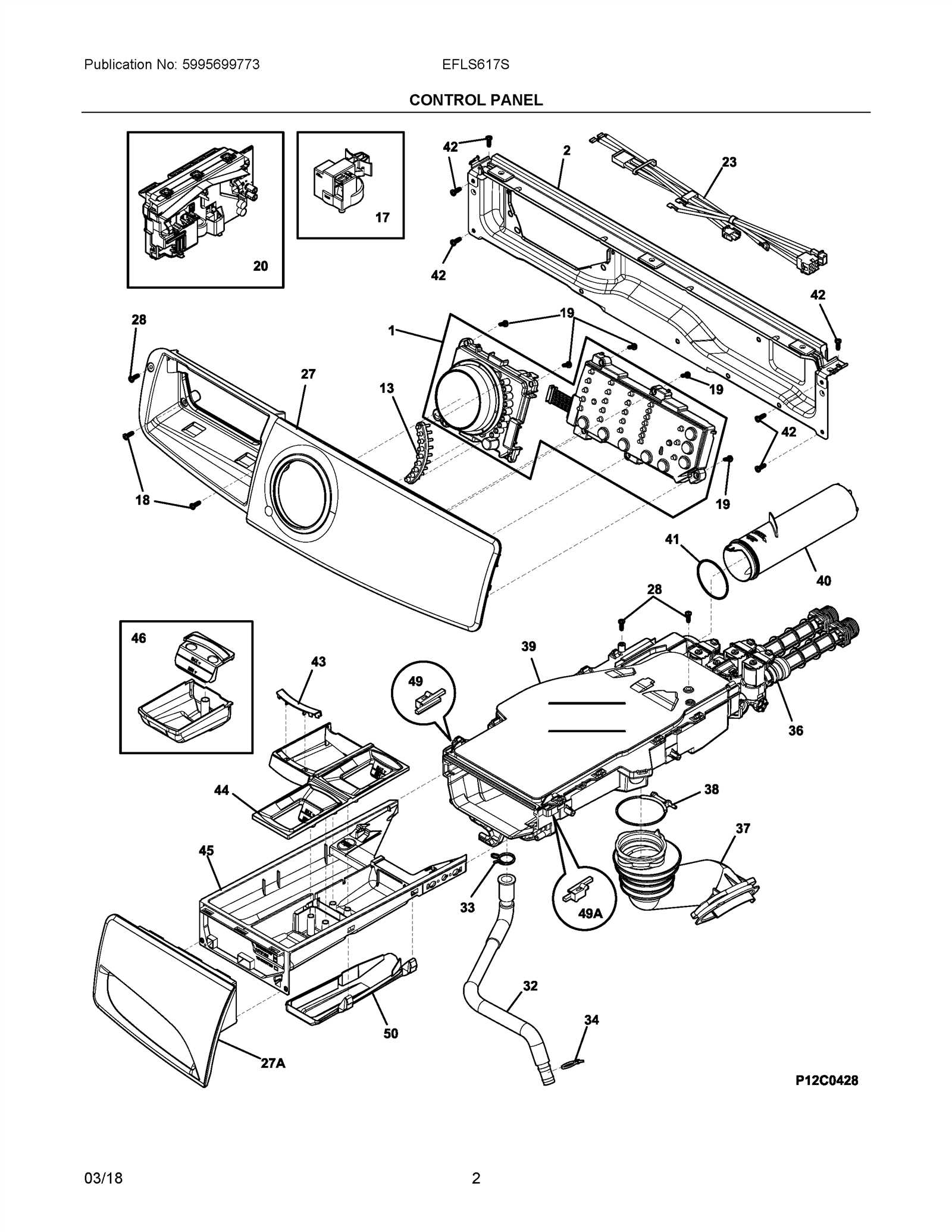

Essential Components of Front Load Machines

Understanding the critical elements of high-efficiency washing machines is essential for optimal performance and maintenance. These machines comprise various components that work harmoniously to ensure effective cleaning and user convenience. This section outlines the key features that make these appliances efficient and reliable.

Key Elements

- Drum: The cylindrical container where garments are placed for cleaning.

- Motor: Powers the drum’s rotation and ensures consistent washing action.

- Pump: Responsible for draining excess water after the washing cycle is complete.

- Control Panel: Interface for users to select washing cycles and settings.

- Hoses: Facilitate the intake of water and the drainage of used water.

Supporting Features

- Suspension System: Minimizes vibrations during operation, enhancing stability.

- Heating Element: Heats water to achieve desired temperatures for effective cleaning.

- Seal: Prevents leaks, maintaining the integrity of the machine.

- Filters: Capture lint and debris, protecting internal components from damage.

Each of these components plays a vital role in the overall functionality of washing machines, contributing to their efficiency and longevity.

Importance of Each Part

The various components of a cleaning machine play a crucial role in its functionality and efficiency. Each element has a specific function that contributes to the overall performance, ensuring that clothes are cleaned effectively and the device operates smoothly. Understanding the significance of these elements can help users maintain their appliances better and troubleshoot any issues that may arise.

Key Functionalities

Motors are vital for driving the drum, allowing it to rotate and create the necessary agitation for thorough cleaning. The control panel provides users with the ability to select different cycles and customize settings based on fabric type and load size. Proper functionality of these components is essential for optimal operation.

Durability and Maintenance

Other crucial components, such as seals and hoses, prevent leaks and ensure that water is directed properly during cycles. Regular maintenance of these parts extends the lifespan of the device and enhances its overall reliability. By prioritizing the upkeep of each section, users can avoid potential malfunctions and enjoy consistent performance.

Common Issues with Washer Parts

Understanding the frequent challenges associated with various components of laundry machines is crucial for efficient maintenance and optimal performance. Identifying these common concerns can help users troubleshoot and resolve issues quickly, ensuring that their appliances operate smoothly.

One prevalent problem is leaking, which often stems from damaged seals or hoses. When these elements are worn or improperly connected, they can cause water to escape, leading to potential damage to surrounding areas.

Another issue users may encounter is excessive noise during operation. This can result from loose or worn bearings, improper leveling, or foreign objects caught in the mechanism. Addressing these factors promptly can help prevent further complications.

Electrical malfunctions are also common and can manifest as failure to start or intermittent operation. Checking the power supply and inspecting internal wiring may reveal the source of the problem, allowing for timely repairs.

Lastly, inadequate drainage is a frequent complaint, often caused by clogged filters or malfunctioning pumps. Regular maintenance and cleaning can help mitigate these issues, ensuring that the appliance remains efficient and effective.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of your home appliance. Regular maintenance can prevent unexpected breakdowns and ensure optimal performance. Implementing a few simple practices can greatly contribute to its durability and efficiency, ultimately saving you time and money.

Regular Cleaning

Keeping the interior and exterior of your appliance clean is crucial. Residue and debris can accumulate over time, leading to operational issues. It’s advisable to clean the drum, door seals, and detergent compartments frequently. This helps prevent unpleasant odors and maintains the machine’s functionality.

Periodic Inspections

Routine checks can identify potential problems before they escalate. Examine hoses, connections, and filters for any signs of wear or blockages. Addressing minor issues promptly can prevent costly repairs and extend the appliance’s life.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean drum and seals | Monthly | Prevents odors and buildup |

| Inspect hoses and connections | Every 6 months | Identifies leaks and damage |

| Check filters | Every 3 months | Ensures proper water flow |

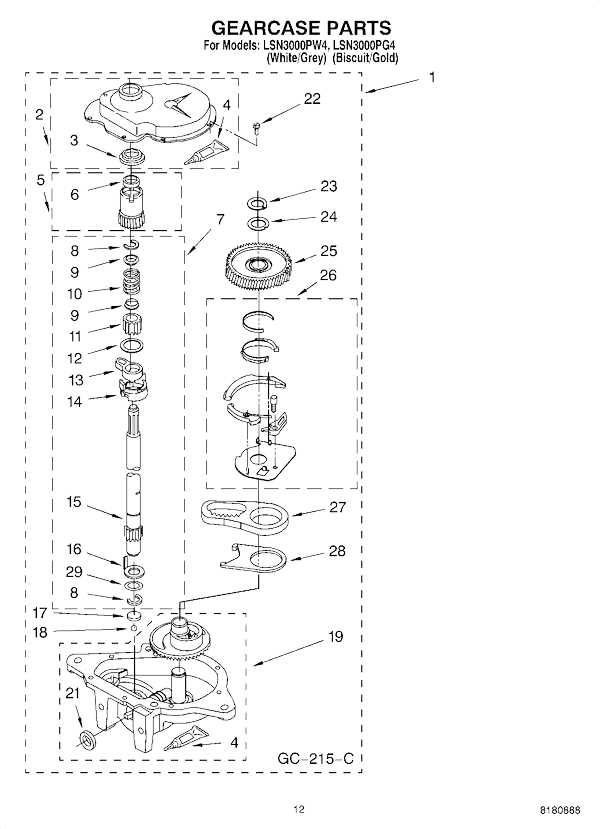

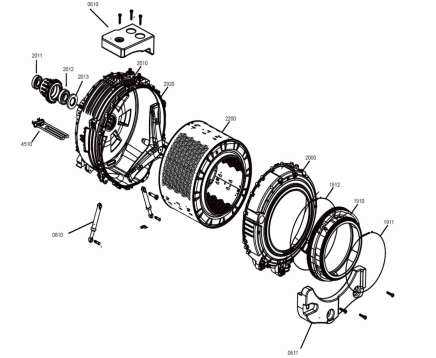

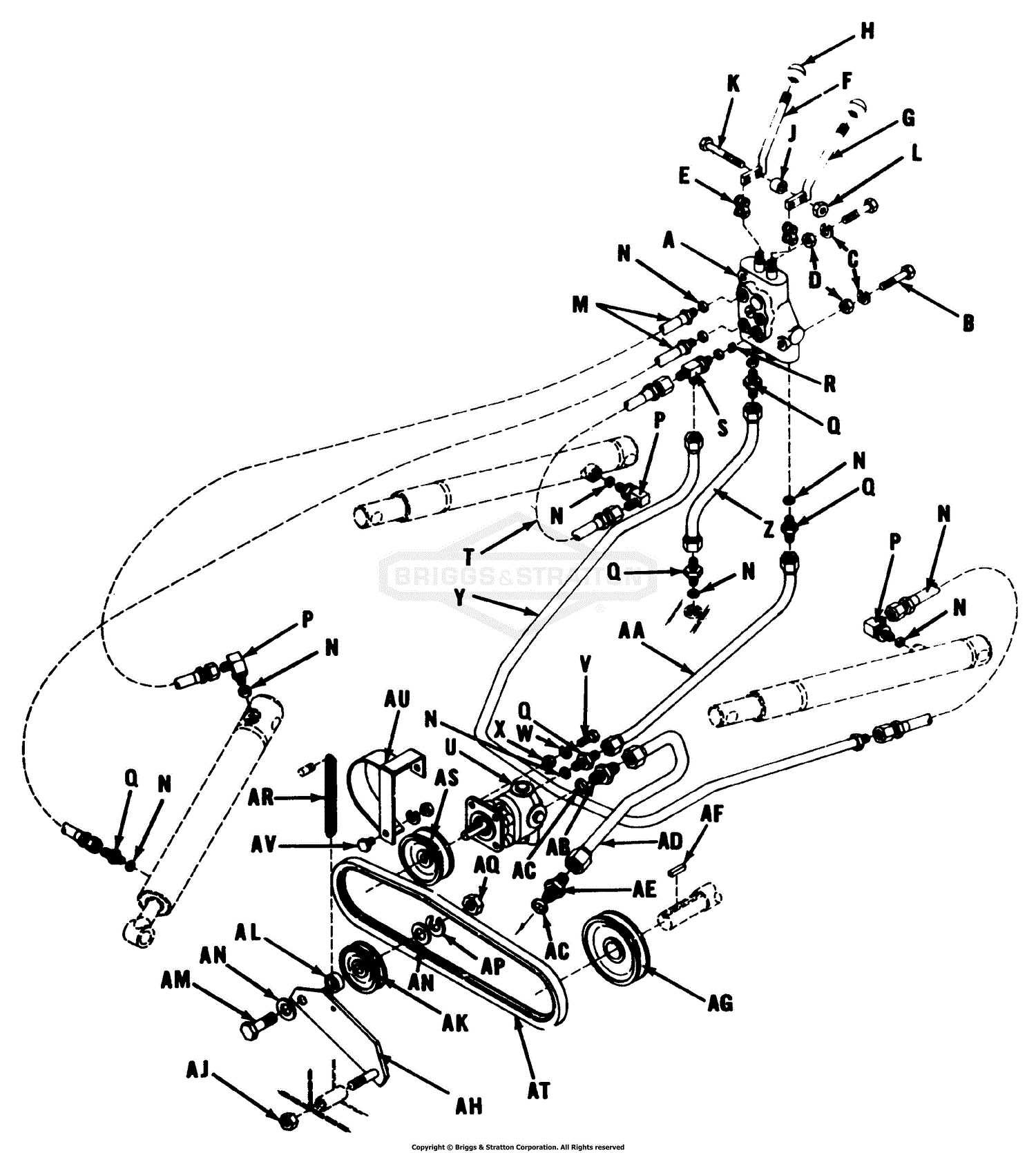

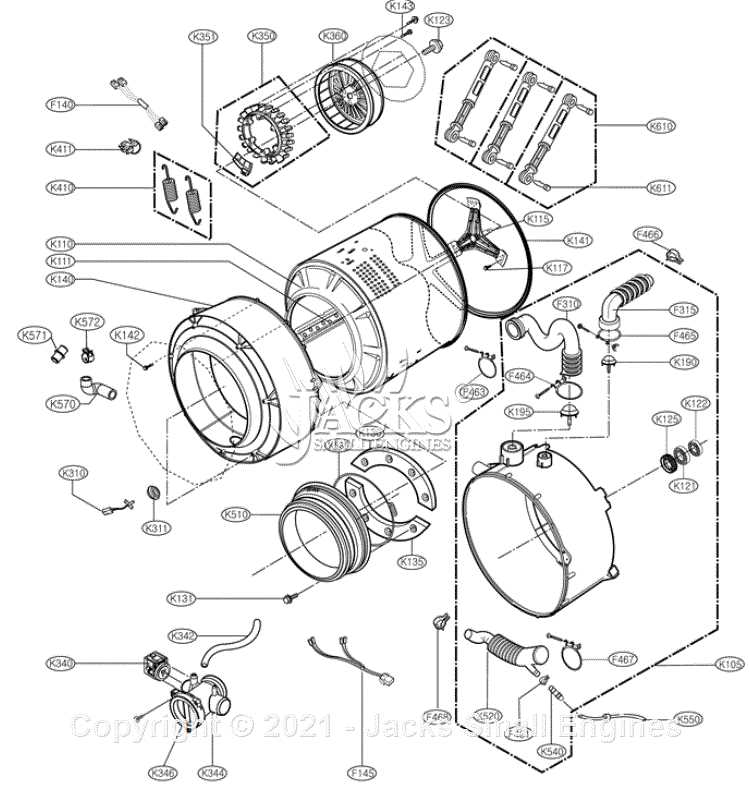

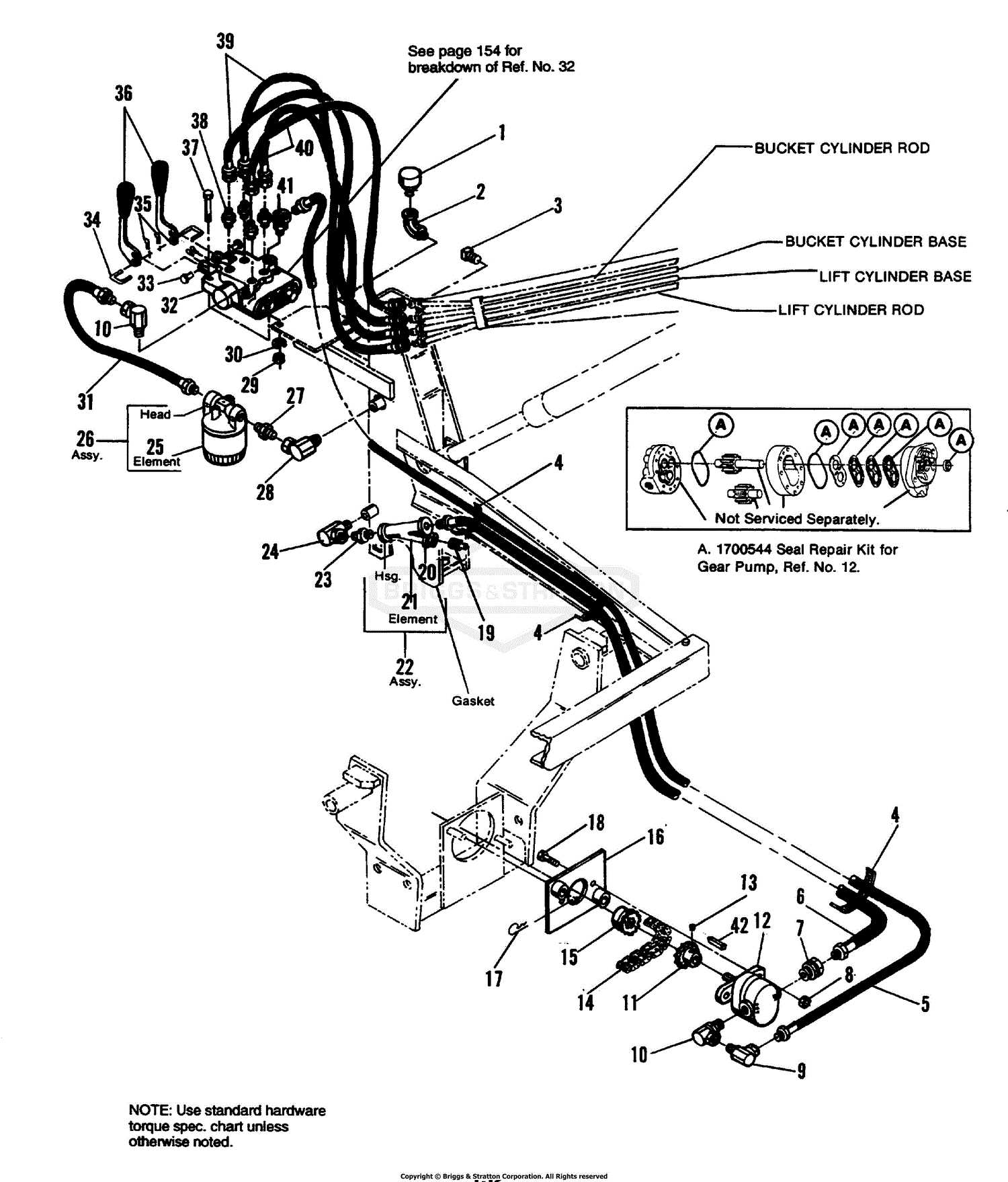

How to Read Parts Diagrams

Understanding schematic representations is essential for efficient maintenance and repair tasks. These illustrations provide a visual guide that can help users identify and locate various components within a machine. Familiarity with these visuals can significantly enhance troubleshooting and repair processes.

Identifying Components

Each symbol or section in the schematic corresponds to a specific element. It is crucial to familiarize yourself with these representations to understand their functions and relationships. Typically, components are labeled with letters or numbers, making it easier to reference them in manuals or discussions.

Utilizing the Key

Most diagrams include a legend or key that explains the symbols used. This feature is invaluable for translating the visual cues into understandable terms. By consulting this guide, you can quickly learn about the various elements depicted and their respective roles within the system.

In summary, becoming proficient at reading these illustrations can save time and reduce errors during repair tasks. By honing this skill, users can ensure a smoother and more effective maintenance experience.

Locating Replacement Parts Easily

Finding the necessary components for your appliance can often feel daunting. However, with the right approach, you can streamline the process and ensure that you acquire the correct items efficiently. By utilizing various resources, you can simplify your search and minimize downtime.

First, consider consulting the manufacturer’s website. Most brands provide comprehensive catalogs featuring detailed information on their offerings. Exploring these resources can reveal crucial details, including model numbers and specifications essential for selecting the right replacements.

Additionally, online forums and communities dedicated to appliance repairs can be invaluable. Members often share insights and recommendations on sourcing components, as well as tips on compatibility. Engaging with fellow enthusiasts can enhance your understanding and lead you to reliable suppliers.

Lastly, don’t overlook local hardware stores or specialized shops. Many of these establishments carry a variety of essential items and can assist you in identifying what you need. In-person interactions may provide you with additional guidance, ensuring you leave with the right solutions for your appliance.

Tools Needed for Repairs

When undertaking maintenance or fixing a machine, having the right instruments is essential for a successful and efficient process. Proper tools not only simplify tasks but also ensure safety and accuracy during the repair. This section outlines the essential equipment required for handling various issues effectively.

Basic Hand Tools

Every repair technician should have a set of basic hand tools, including screwdrivers, wrenches, and pliers. These items are crucial for loosening and tightening components as well as for removing and securing various elements of the appliance. Additionally, a reliable set of socket wrenches can significantly speed up the process of accessing hard-to-reach fasteners.

Specialized Equipment

In some cases, specialized tools may be necessary to address specific issues. For example, a multimeter can assist in diagnosing electrical problems, while a belt tension gauge is useful for adjusting drive mechanisms. Having these specialized instruments on hand will enhance your ability to perform thorough repairs and ensure the longevity of the appliance.

Identifying Malfunctioning Components

Understanding the various elements of your appliance is crucial for diagnosing issues that may arise during operation. By recognizing signs of malfunction, you can efficiently address problems before they escalate, ensuring the longevity and optimal performance of your machine.

Common Signs of Failure

When components begin to fail, several symptoms may become apparent. These indicators often serve as warnings that something is not functioning correctly. Familiarizing yourself with these signs can aid in quicker diagnosis and repair.

Key Components to Inspect

Regularly examining specific components can help identify potential issues early on. Below is a table listing crucial parts and their typical failure signs:

| Component | Symptoms of Malfunction |

|---|---|

| Drive Belt | Strange noises, vibrations |

| Pump | Water not draining, leaks |

| Motor | Inconsistent operation, overheating |

| Door Seal | Visible wear, water leaks |

Safety Precautions During Repairs

When conducting maintenance or repair work on household appliances, it is crucial to prioritize safety to prevent accidents and injuries. Taking the necessary precautions can significantly reduce the risk of harm while ensuring effective handling of the task at hand.

Power Disconnection

Always disconnect the appliance from the power source before starting any repair work. This step is essential to avoid electric shocks and ensure that the device is completely inactive during the process. It is advisable to unplug the unit or switch off the circuit breaker dedicated to it.

Use of Proper Tools

Utilizing the correct tools is vital for safe and efficient repairs. Ensure that you have the right equipment for the job to prevent unnecessary strain or injury. Additionally, wearing appropriate personal protective equipment, such as gloves and safety goggles, can further enhance your safety during the repair process.

Cost of Replacement Parts

The expense associated with the substitution components in a laundry appliance can vary significantly based on several factors, including the type of equipment, the manufacturer, and the specific component needed. Understanding these costs can help users budget for necessary repairs and maintenance to ensure the longevity of their devices.

| Component Type | Average Cost | Price Range |

|---|---|---|

| Drum | $200 | $150 – $300 |

| Motor | $150 | $100 – $250 |

| Control Board | $120 | $80 – $200 |

| Door Seal | $50 | $30 – $80 |

| Pump | $70 | $50 – $120 |

It’s essential for users to compare prices from different suppliers to find the most economical options. Additionally, considering warranty options and potential labor costs for installation can further impact the total expenditure for replacing these essential components.

DIY vs Professional Repairs

When it comes to fixing household appliances, individuals often face the choice between tackling the task themselves or hiring an expert. Each option has its own set of advantages and drawbacks, making it essential to weigh them carefully before making a decision. Understanding the nuances of both approaches can lead to a more effective and satisfying repair experience.

Advantages of DIY Repairs

Many homeowners opt for do-it-yourself fixes for several reasons. First, it can be significantly more cost-effective, as it eliminates labor costs associated with hiring a technician. Additionally, undertaking repairs independently can foster a sense of accomplishment and enhance one’s skills. However, it is crucial to possess a basic understanding of the appliance’s mechanics to avoid exacerbating issues.

Benefits of Professional Services

On the other hand, enlisting the help of a trained technician ensures that the repair is conducted safely and efficiently. Professionals come equipped with the necessary tools and expertise to handle complex problems. Moreover, relying on their services often comes with warranties, providing peace of mind regarding the durability of the fix. This option, though more expensive, may ultimately save time and stress.

| Criteria | DIY Repairs | Professional Repairs |

|---|---|---|

| Cost | Generally lower, no labor fees | Higher, includes labor costs |

| Skill Required | Basic knowledge helpful | Professional expertise needed |

| Time Investment | Variable, may take longer | Typically quicker |

| Warranty | No warranty | Often includes warranty |