When it comes to maintaining outdoor cleaning tools, understanding the structure and components is essential for optimal performance. A well-maintained cleaning machine ensures efficient operation and long-lasting durability, saving both time and effort. In this section, we will explore the most important elements that keep these machines running smoothly, as well as key tips for regular upkeep.

Regular maintenance not only extends the life of your cleaning device but also enhances its efficiency in tackling tough outdoor tasks. By familiarizing yourself with the key elements of the system, you can address potential issues before they become major problems. This guide will walk you through the necessary steps to keep your equipment in excellent working condition.

From the essential mechanical elements to practical care tips, this section is designed to provide a comprehensive overview of how these devices operate. Whether you’re troubleshooting a specific issue or simply aiming to improve overall performance, understanding the core structure is a great starting point for effective maintenance.

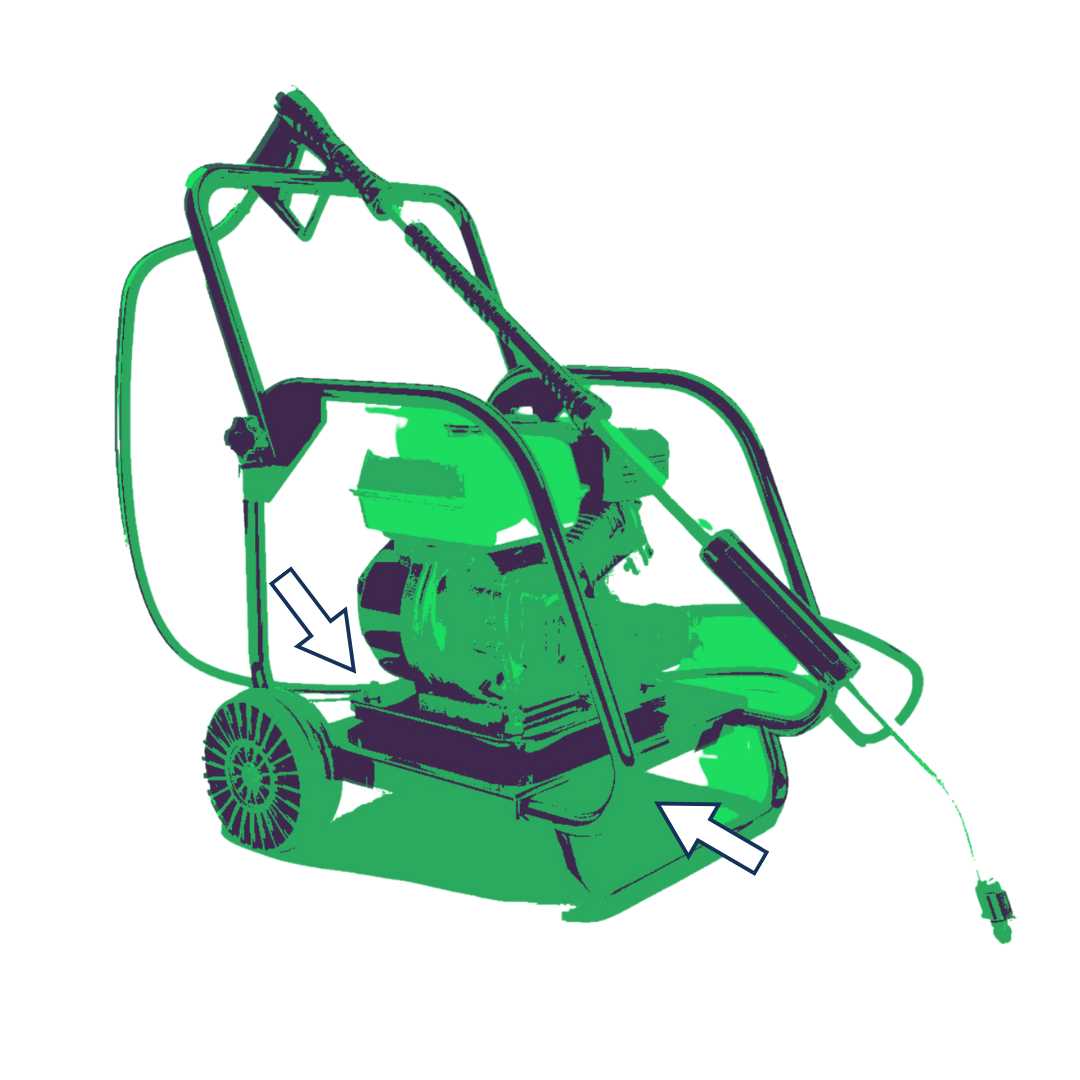

Generac 2800 PSI Pressure Washer Overview

This cleaning equipment is designed for demanding outdoor tasks, providing efficient and reliable operation. It helps tackle various cleaning projects, from removing dirt and grime from surfaces to washing vehicles or patios.

- High-performance engine ensures consistent power for extended use.

- Durable construction guarantees longevity even in challenging environments.

- Compact design allows for easy mobility and storage when not in use.

The equipment offers versatile functionality, making it a practical choice for both residential and commercial applications. Its user-friendly controls and robust components enhance the overall experience, ensuring a thorough and efficient clean every time.

Main Components of a Pressure Washer

A high-powered cleaning device consists of several key elements that work together to produce an efficient cleaning process. These components ensure water is pressurized and distributed effectively, enabling the removal of dirt and grime from various surfaces. Below is an overview of the essential parts that contribute to the overall functionality of such machines.

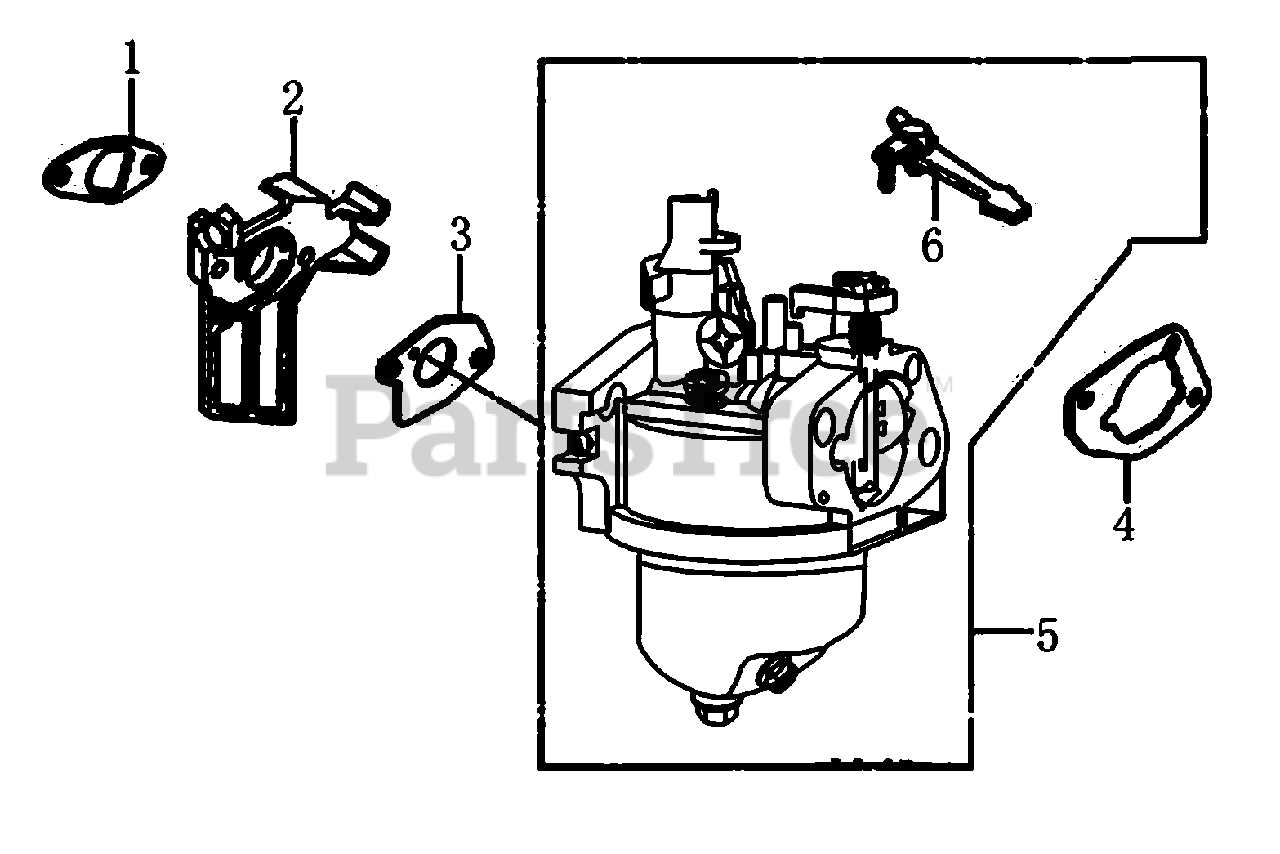

Engine or Motor

The engine or motor is the heart of the device. It provides the necessary force to pressurize the water. While electric models use motors, gasoline-powered options rely on engines to create the power needed for operation.

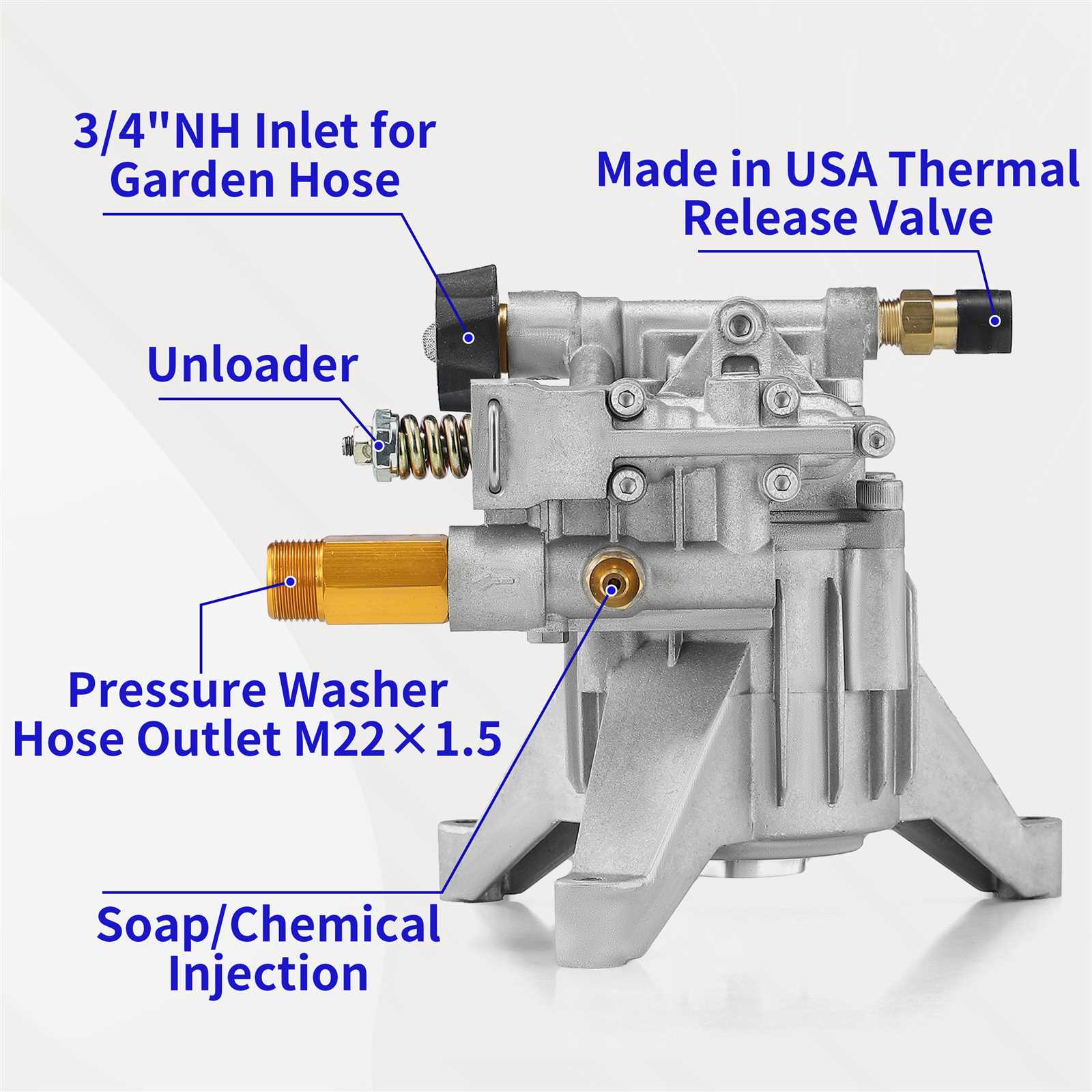

Pump

The pump is responsible for drawing in water and forcing it through the system. It plays a crucial role in building the necessary water flow for effective cleaning. Depending on the type of machine, the pump can vary in size and capacity.

| Component | Function | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hose | Transports water from the pump to the

Common Issues and Parts to ReplaceOver time, outdoor cleaning equipment may encounter various problems that affect its performance. Frequent use can lead to wear and tear of certain components, making replacements necessary to maintain efficiency. Understanding the most common issues that arise will help in identifying which parts need attention and ensuring smooth operation.

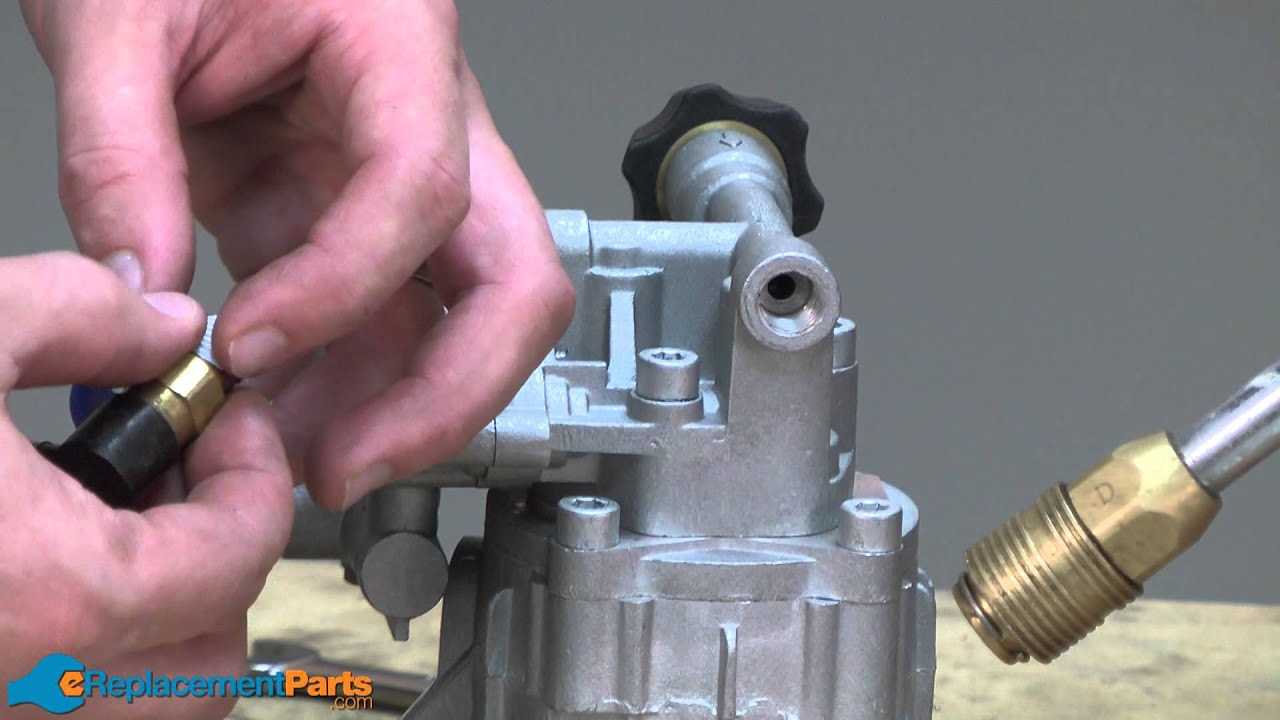

Routine maintenance and timely replacements of these key components can prolong the lifespan of the equipment and prevent larger mechanical failures. Identifying issues early on is crucial for ensuring continued reliability and functionality. Pump and Engine Relationship ExplainedThe pump and engine form the core components of many high-powered cleaning machines, working together in a coordinated manner to deliver optimal performance. Their interaction is crucial for ensuring a steady flow of water and consistent force during operation. Understanding how these two elements work in unison is key to maintaining and troubleshooting any issues that may arise. How the Engine Drives the Pump

The engine serves as the power source that drives the pump, converting fuel energy into mechanical force. This rotational energy is transferred directly to the pump, which uses it to move water through its system. Without a properly functioning engine, the pump cannot operate efficiently, making it essential to ensure both components are well-maintained. The Pump’s Role in the System

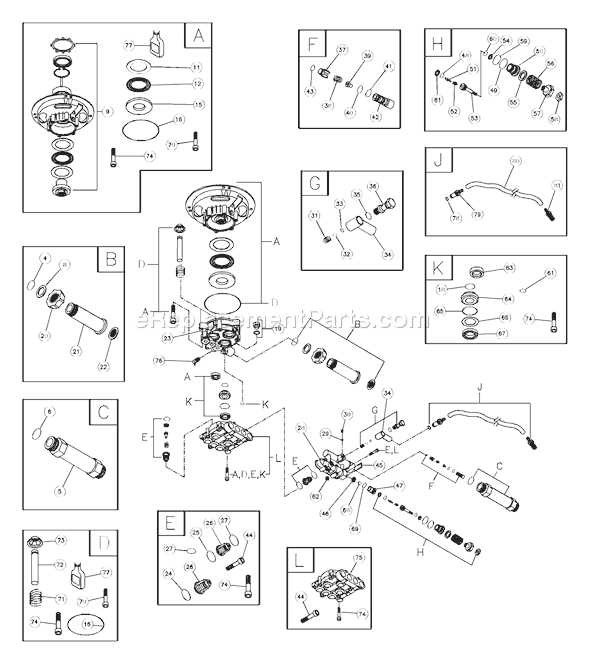

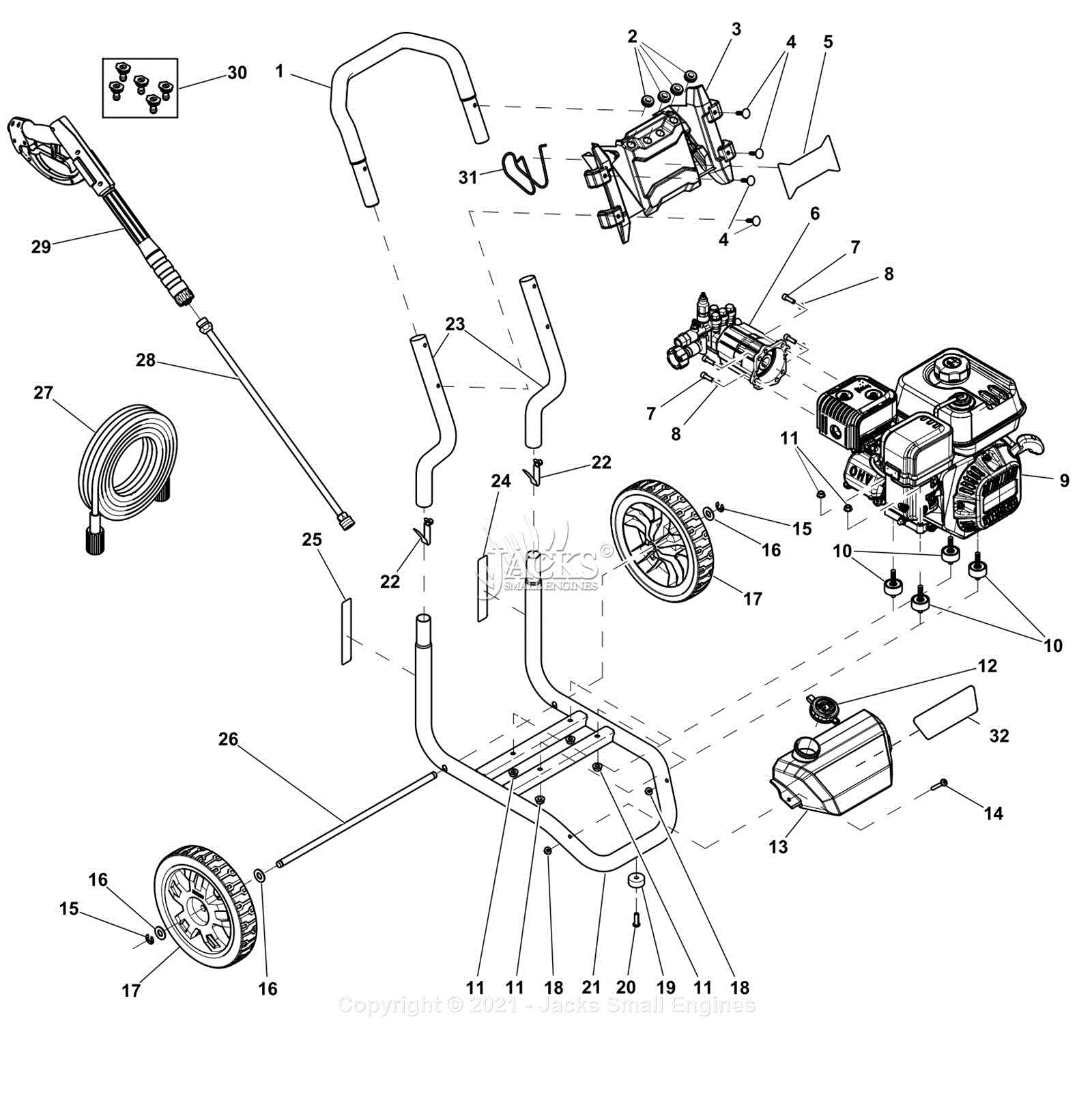

The pump, receiving its energy from the engine, is responsible for pressurizing and controlling the flow of water. It works by drawing water in and then forcing it out at a high rate, ensuring that the cleaning system performs effectively. A balance between the engine’s power and the pump’s capacity ensures that the machine operates at its peak potential. Identifying Key Parts in the DiagramUnderstanding the structure and components of this type of equipment is essential for effective operation and maintenance. The diagram provides a visual breakdown of the machine, helping users pinpoint critical elements and their functions. By reviewing each section, you can familiarize yourself with the main units and their roles in ensuring the equipment works smoothly. Pump assembly is at the heart of the machine, responsible for driving the water through the system. This component is crucial for maintaining flow and pressure consistency during use. The engine serves as the power source, converting energy into mechanical force. Proper care of this part is vital for the overall longevity and performance of the device. Various connectors and hoses link different parts of the equipment together, facilitating the movement of water and ensuring the correct distribution of power. Additionally, safety features, such as the trigger mechanism, play an important role in controlling the machine, allowing users to start and stop the flow when necessary. Hose and Nozzle Configuration Guide

This section provides essential information on how to optimize the configuration of hoses and nozzles for efficient cleaning tasks. Understanding the right combination can significantly enhance performance and ensure that the equipment operates at its best. When selecting hoses and nozzles, consider the following factors:

Regarding nozzle types, different configurations serve various purposes:

By carefully selecting and configuring hoses and nozzles, users can achieve optimal results and prolong the lifespan of their cleaning equipment. Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged performance and efficiency of your cleaning equipment. By following some simple maintenance practices, you can extend the lifespan of your device and minimize the risk of unexpected breakdowns. Routine Inspections

Conducting periodic inspections is vital for identifying potential issues before they escalate. Check all components for signs of wear, leaks, or damage. Ensuring that all connections are secure and that the fluid levels are adequate can prevent costly repairs. Cleaning and Storage

After each use, make sure to clean the equipment thoroughly to remove dirt and grime. Storing it in a dry, sheltered area protects it from harsh weather conditions and helps maintain its functionality. Proper maintenance not only enhances performance but also contributes to a cleaner environment. Pressure Regulation and Control MechanismsEffective management of force within a cleaning apparatus is crucial for optimal performance and safety. This involves various components designed to ensure that the flow and intensity of the liquid are maintained within desired limits. Understanding how these mechanisms function can enhance the user experience and prolong the lifespan of the equipment. Key Components of Regulation

Several vital elements contribute to the control of liquid dynamics in a cleaning device. These parts work together to modulate the output, ensuring that the machine operates efficiently without risk of damage or inefficiency.

Importance of Control MechanismsControl features are essential for enhancing the usability and safety of the device. By ensuring that liquid is delivered at a consistent rate, these mechanisms help prevent accidents and ensure effective cleaning results. Regular maintenance and understanding of these components can significantly impact the efficiency of the apparatus. Water Intake and Filtration Components

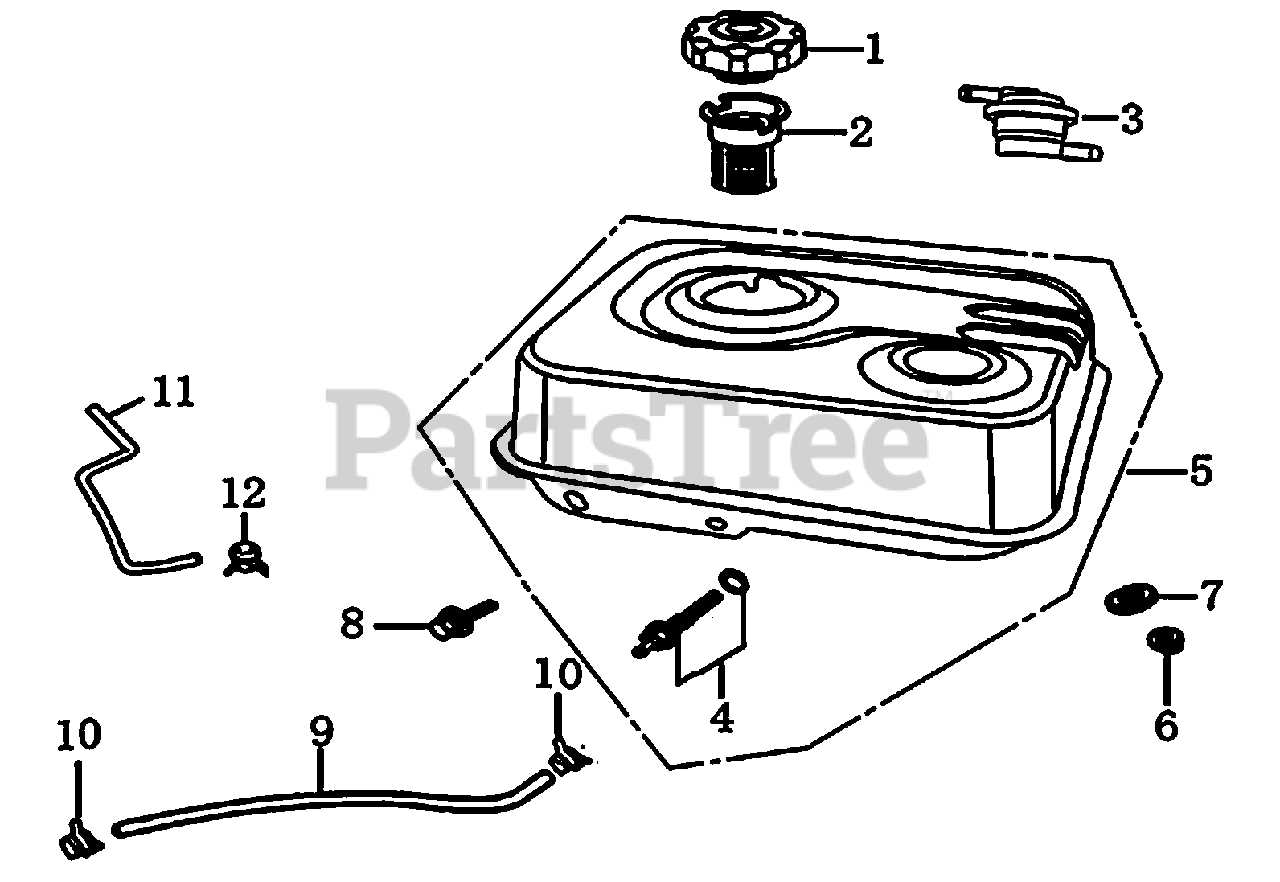

The efficiency of any cleaning system heavily relies on its water intake and filtration mechanisms. These components play a crucial role in ensuring that water flows smoothly into the device while preventing contaminants from causing damage. Understanding their functionality helps users maintain optimal performance and extend the lifespan of the equipment. Functionality of Water IntakeThe water intake system serves as the entry point for liquid to enter the cleaning apparatus. This component is designed to create a consistent flow, allowing for effective operation during use. Properly functioning intake parts minimize air pockets and ensure that the device operates efficiently, maximizing cleaning capabilities. Importance of Filtration

Filtration is a vital aspect of any cleaning system. It prevents dirt, debris, and other particles from entering the machinery, which can lead to wear and tear. High-quality filtration components capture impurities, ensuring only clean water is utilized for the cleaning process. Regular maintenance and timely replacement of these parts are essential for sustained performance. Frame and Support Components

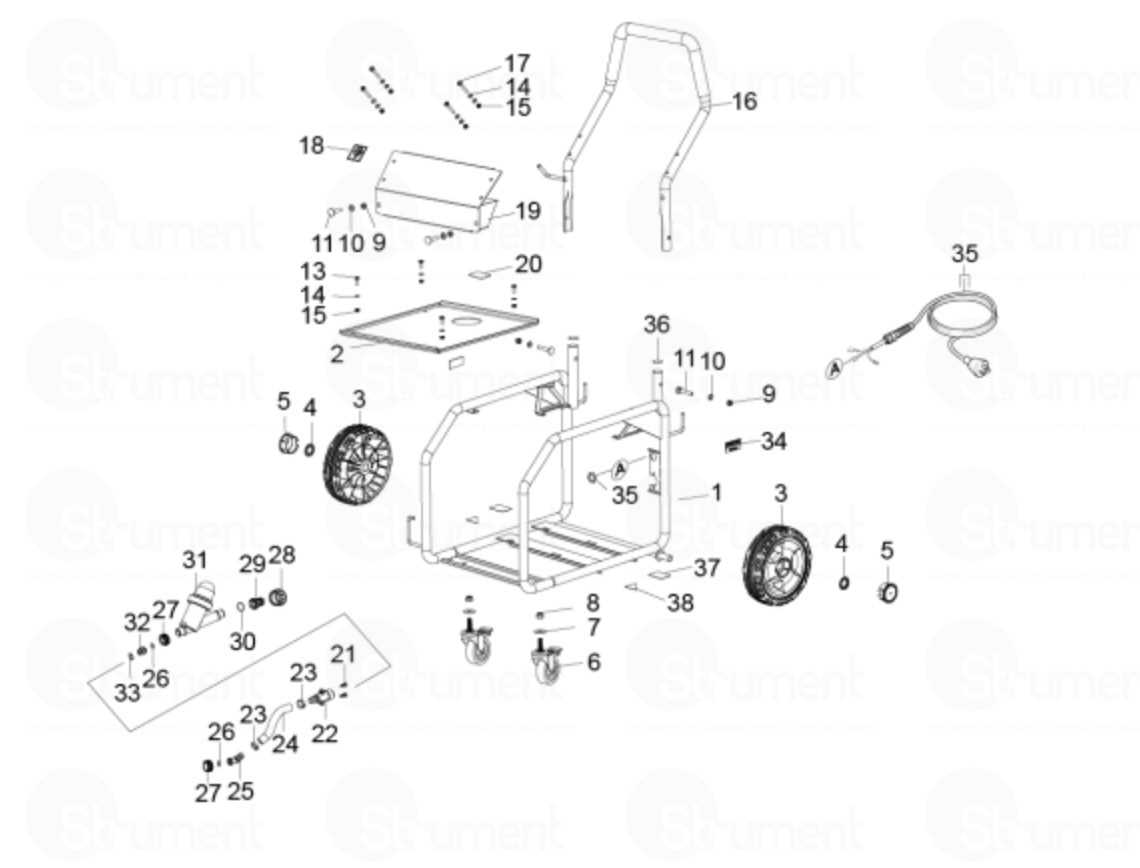

In any cleaning machine, the structure and support components play a vital role in ensuring stability and durability. These elements are designed to provide a robust foundation that allows for efficient operation, while also enhancing the overall user experience. Understanding the various structural components is essential for maintenance and effective usage. Key Structural Elements

The main framework is typically constructed from high-quality materials, designed to withstand wear and tear from regular use. It encompasses the base and supports that uphold the entire assembly, ensuring that the device remains stable during operation. The strength of these components is crucial for minimizing vibrations and preventing damage. Support Mechanisms

Support mechanisms often include wheels and handles that facilitate mobility and ease of use. These features allow users to maneuver the unit effortlessly, while also providing stability when stationary. A well-designed frame with integrated support features significantly contributes to the effectiveness and longevity of the equipment. Safety Features and Protective ElementsEnsuring user safety is a paramount consideration in the design of cleaning equipment. Various protective mechanisms and features are integrated to prevent accidents and enhance the overall experience. These elements not only safeguard the operator but also contribute to the longevity of the device, making it more reliable during use. Among the essential safety components are automatic shut-off systems, which deactivate the machine when not in use, reducing the risk of accidental activation. Additionally, pressure relief valves help manage excess pressure, preventing potential hazards during operation.

|