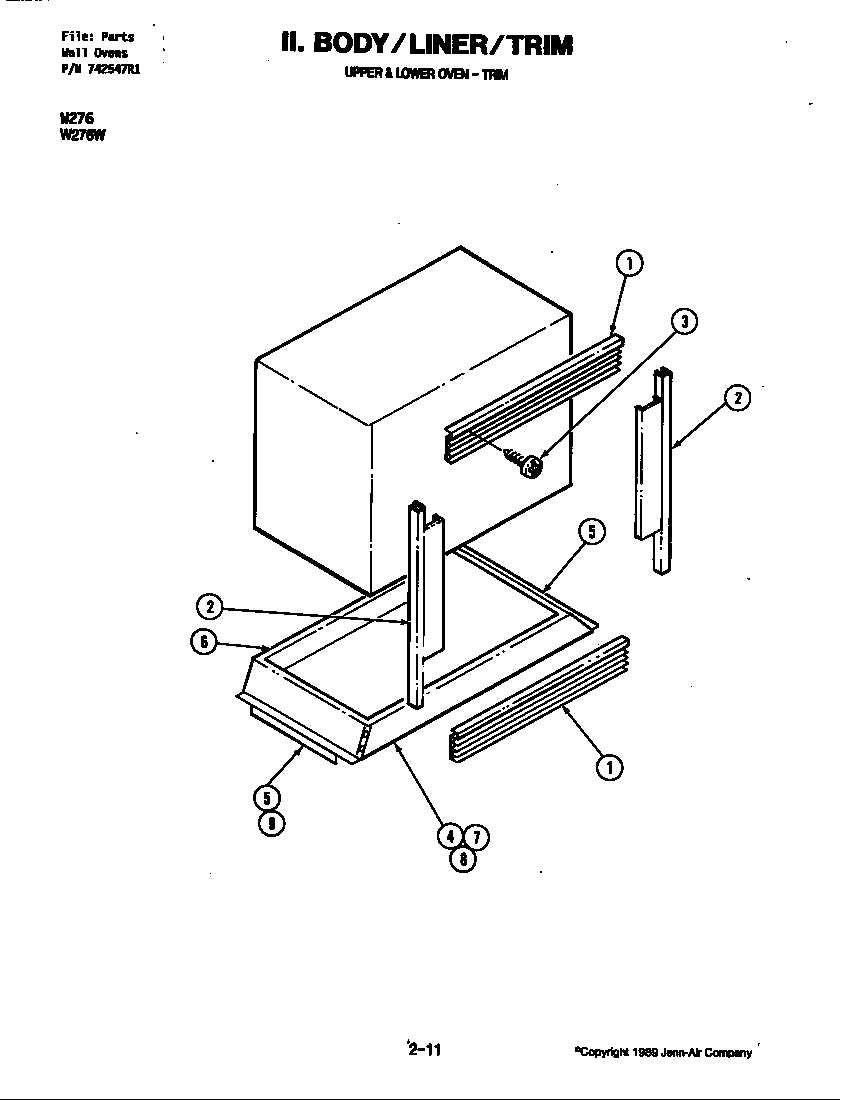

In modern kitchens, various electronic devices play a vital role in enhancing daily routines. These machines are designed to perform specific tasks, making our lives more convenient. However, like any other equipment, they consist of numerous internal and external elements that work together to ensure efficient performance. Understanding the arrangement and function of these elements can help users maintain and repair their equipment when needed.

Exploring the configuration of these appliances reveals how essential each component is for optimal operation. From the intricate connections within the control system to the mechanical structures that handle physical tasks, each part has a specific role. This section provides a detailed look into the components that make up these devices, illustrating their placement and importance in the overall mechanism. Additionally, understanding the setup of these parts can be beneficial for troubleshooting and maintenance purposes.

The internal and external elements of these kitchen devices can sometimes be overwhelming to understand. However, with the right guidance and a clear representation of their structure, even a novice user can navigate through the complexity of their appliance’s configuration. This guide aims to offer a detailed view of the setup, ensuring that users gain valuable knowledge for proper upkeep and functionality of their kitchen equipment.

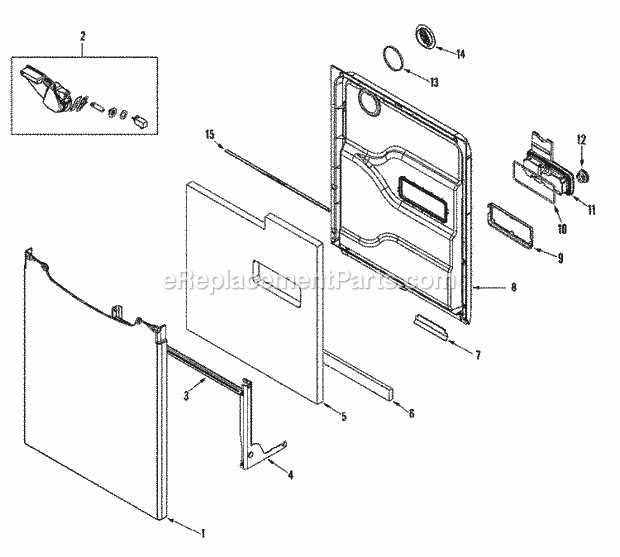

Jenn Air Dishwasher Parts Overview

This section provides an overview of the various components that make up a typical kitchen appliance designed for cleaning dishes. Understanding the essential elements helps in maintaining and troubleshooting the unit effectively.

- Pump Assembly: The mechanism responsible for circulating water within the device, ensuring efficient cleaning and draining processes.

- Control Module: The electronic unit that manages all functions and settings, allowing for customized operations and cycles.

- Water Inlet Valve: A valve that regulates the flow of water into the system, ensuring the right amount is used for each cycle.

- Spray Arms: These components distribute water evenly throughout the chamber, reaching every surface for optimal cleaning.

- Heating Element: The unit that heats water to the necessary temperature, aiding in effective washing and drying.

- Racks and Baskets: Structures designed to hold and organize dishes, utensils, and other items during the cleaning process.

These components work together to provide an efficient cleaning experience, and understanding their roles can aid in identifying issues or performing maintenance.

Key Components of Jenn Air Dishwasher

Understanding the essential elements of this kitchen appliance helps in maintaining its efficiency and ensuring proper functionality. Each element plays a specific role in the cleaning and drying process, and knowing how they work together can aid in troubleshooting and repair.

- Control Panel: This interface allows the user to select various washing and drying cycles, adjust settings, and monitor the progress of the cleaning process.

- Racks and Baskets: These components hold the dishes and utensils in place, maximizing space and ensuring that water and detergent reach all surfaces during the cycle.

- Spray Arms: Located at the bottom and middle sections, these rotating arms distribute water throughout the interior, ensuring even and thorough washing.

- Filter System: A set of filters that trap food particles and debris, preventing them from clogging the drain and ensuring the water used in each cycle is clean.

- Heating Element: This part is responsible for heating the water to the required temperature for efficient cleaning and also assists in the drying phase by generating hot air.

- Detergent Dispenser: A compartment that releases cleaning agents at the right time during the wash cycle, ensuring proper mixing and distribution.

- Float Switch: This safety mechanism monitors water levels, preventing overflows by shutting off the water supply if it reaches a critical point.

These components work in harmony to deliver a thorough and effective cleaning process. Regular maintenance and understanding each part’s function can extend the appliance’s lifespan and maintain its efficiency.

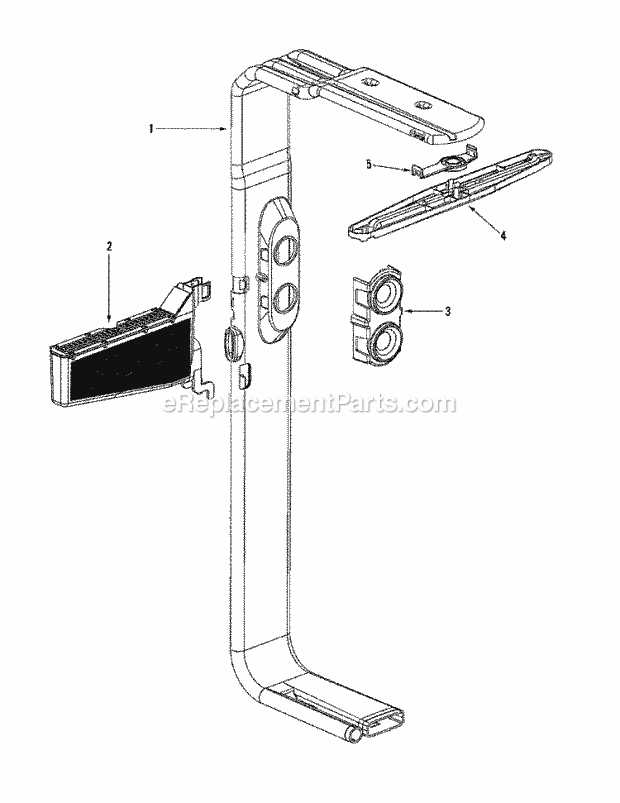

Control Panel and Interface Functions

The control panel and interface are designed to provide a seamless and intuitive experience for users. Understanding the various buttons and display features allows for efficient management and customization of the appliance’s operations. This section provides a detailed overview of the key elements and their functions, ensuring users can maximize the potential of their device.

At the center of the interface is the primary display, showing the current status and selected settings. Users can navigate through different modes and options using the dedicated buttons arranged around the display. These may include settings for cycle selection, temperature control, and additional features like delayed start or energy-saving mode.

Indicators on the display help monitor progress, notifying users of the remaining time and the current phase of operation. Some models also include alert lights to indicate specific issues, such as water supply problems or maintenance reminders, ensuring proactive management and maintenance of the appliance.

For optimal use, it is essential to familiarize oneself with each function. This will not only improve daily operations but also contribute to the longevity and efficiency of the equipment.

Spray Arms and Their Role

Spray arms are essential components that ensure effective cleaning performance in kitchen cleaning machines. They work by distributing water throughout the unit, reaching all surfaces of the items placed inside. The structure and placement of these elements influence how efficiently they perform, impacting the overall result of the wash cycle.

How Spray Arms Operate

The arms rotate during operation, directing streams of water at varying angles to cover every part of the chamber. This motion, combined with carefully positioned nozzles, guarantees that all utensils and dishware receive adequate water coverage. The process helps remove food particles and residue, ensuring cleanliness and hygiene.

Maintenance and Functionality

For optimal operation, these components must be kept clean and free from obstructions. Over time, debris can clog the nozzles, reducing water flow and affecting performance. Regularly inspecting and cleaning the arms ensures they continue to function properly. In case of any damage, it’s important to replace them promptly to maintain the efficiency of the appliance.

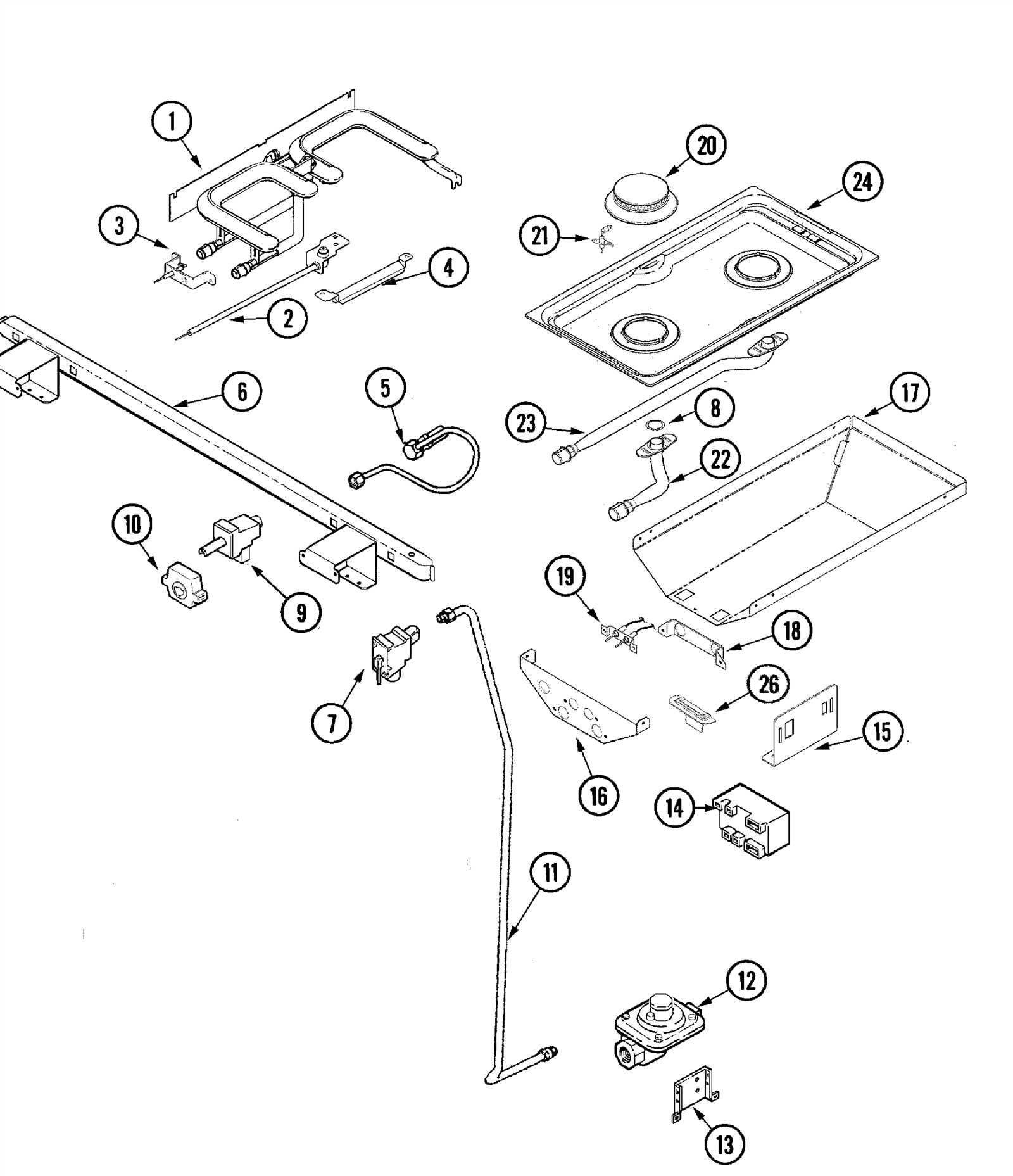

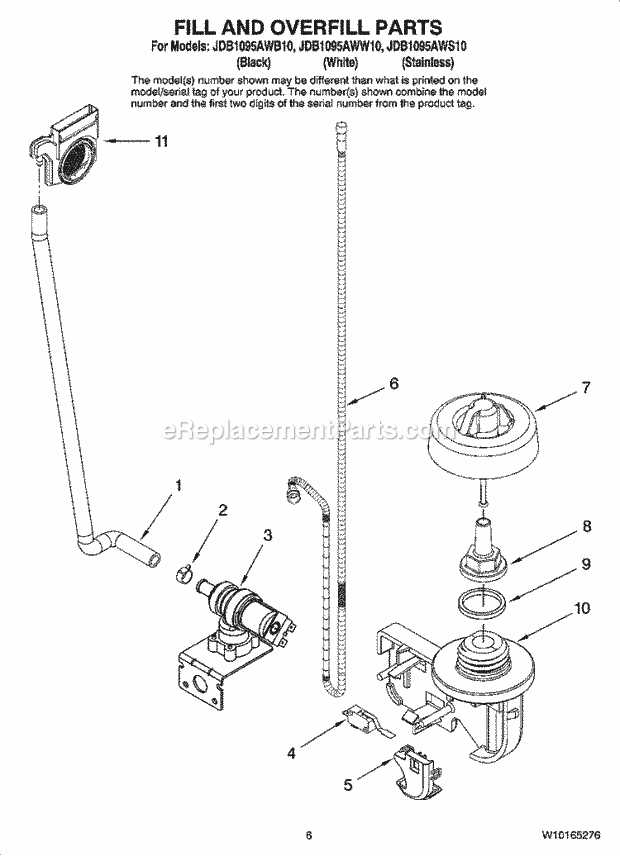

Water Inlet Valve Operation Explained

The water inlet valve is a crucial component responsible for regulating the flow of water into the appliance. Its function is to control when and how much water is allowed to enter, ensuring that the cleaning cycle operates efficiently. Understanding its operation is essential for diagnosing any issues related to water flow.

Typically, the valve operates using an electrically controlled solenoid. When the cycle begins, the solenoid receives a signal, causing it to open the valve and allow water to flow from the supply line into the system. The duration and amount of water are precisely managed to align with the cycle’s requirements.

If the valve fails, it can lead to problems such as insufficient water flow or leaking. To troubleshoot, one can inspect the solenoid for any damage or test the electrical connections to confirm proper function. Replacing a faulty valve can restore the appliance’s optimal performance.

| Component | Function | Potential Issue |

|---|---|---|

| Solenoid | Controls the opening and closing of the valve | Failure to open or close properly |

| Inlet Screen | Filters debris from incoming water | Clogging, leading to restricted water flow |

| Valve Housing | Encases the internal components | Cracks or leaks |

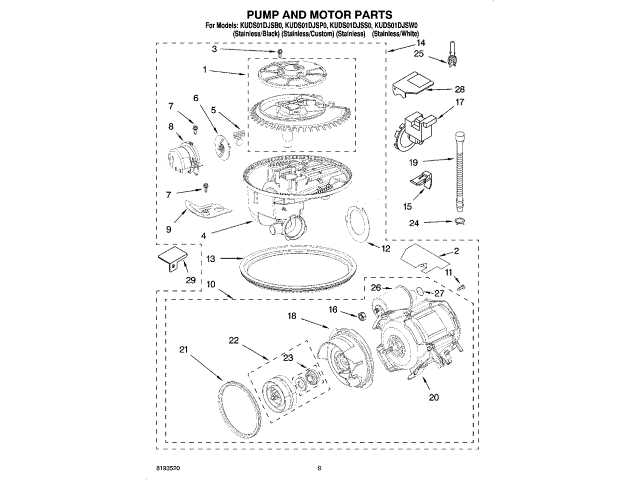

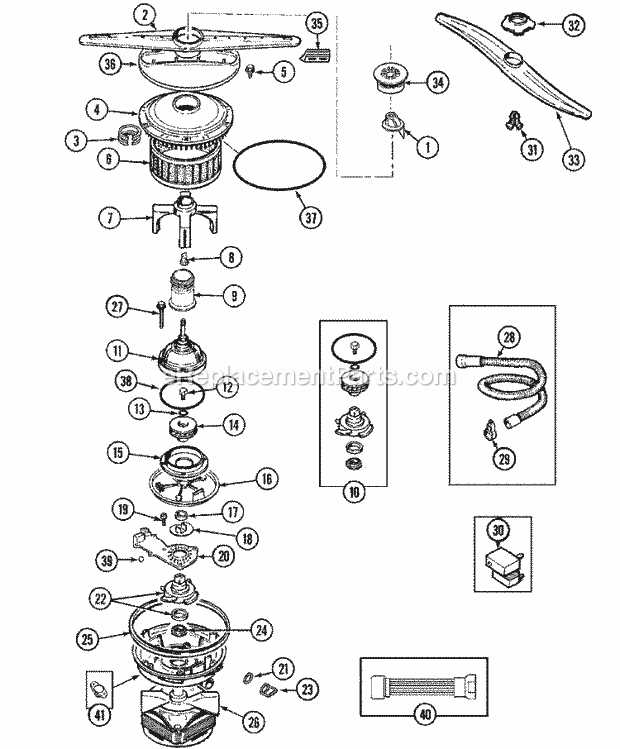

Understanding the Motor Assembly

The motor assembly is a crucial component of a cleaning appliance, playing a vital role in its overall functionality. This assembly is responsible for driving the various mechanisms that facilitate efficient operation. Understanding its structure and functionality can help in troubleshooting and maintenance tasks, ensuring optimal performance.

Components of the Motor Assembly

The motor assembly typically consists of several key elements, including the motor itself, drive belts, and gears. Each part works in harmony to convert electrical energy into mechanical motion. The motor generates power, which is transmitted through belts and gears to the working components of the unit.

Importance of Proper Functioning

A well-functioning motor assembly ensures that the appliance operates smoothly and effectively. Issues such as wear and tear, electrical malfunctions, or misalignment can lead to decreased performance or complete failure. Regular inspections and maintenance of this assembly are essential to prolong its lifespan and maintain the efficiency of the cleaning process.

Importance of the Drain Pump System

The drain pump system is a crucial component in maintaining the efficiency and performance of any appliance that relies on water drainage. It ensures that waste water is effectively removed, preventing overflow and potential damage to the unit. A well-functioning drainage system not only enhances the longevity of the appliance but also plays a significant role in delivering optimal cleaning results.

Efficiency in Water Management

A properly operating pump system optimizes water management, allowing for quick and effective removal of used water after each cycle. This efficiency minimizes the chances of water stagnation, which can lead to unpleasant odors and bacteria growth. Efficient drainage also ensures that the appliance can perform its tasks without interruptions, contributing to better overall performance.

Prevention of Damage

Another critical function of the drainage system is to prevent damage to the appliance and surrounding areas. Blockages or malfunctions in the pump can lead to leaks, causing potential flooding and water damage. Regular maintenance of the drainage components can help avoid costly repairs and ensure the appliance operates safely and effectively.

Dishwasher Door Seal Maintenance Guide

Maintaining the integrity of the closure mechanism is essential for ensuring optimal performance and preventing leaks in your cleaning appliance. This guide provides practical advice on how to care for and inspect the sealing component effectively.

Regular Inspection: Routinely examine the sealing element for signs of wear, cracks, or tears. Damage to this component can lead to moisture escaping, affecting the overall efficiency of the unit.

Cleaning Procedures: To keep the sealing area free from debris and buildup, wipe it down with a soft cloth and mild detergent. Avoid using abrasive cleaners that may damage the material.

Replacement Considerations: If you notice significant wear or damage during inspections, consider replacing the sealing element promptly. Selecting a high-quality replacement will ensure a proper fit and long-lasting effectiveness.

Proper Installation: When installing a new sealing component, make sure it fits snugly and is positioned correctly to maintain a secure closure. Misalignment can lead to further issues down the line.

Detergent Dispenser and Rinse Aid Mechanism

The effective operation of a cleaning appliance relies heavily on its components designed for dispensing cleaning agents and rinse aids. These elements work in tandem to ensure optimal performance during the washing cycle, enhancing the cleaning capabilities and improving the drying process.

The detergent dispenser is responsible for releasing the appropriate amount of cleaning solution at the right moment. It is designed to accommodate various types of detergents, allowing for flexibility in cleaning options. The rinse aid mechanism complements this function by adding a specialized agent that helps prevent water spots and enhances drying efficiency.

- Detergent Dispenser:

- Located typically on the door of the unit for easy access.

- Holds a specific quantity of cleaning solution.

- Operates through a spring-loaded mechanism that opens at designated times during the wash cycle.

- Rinse Aid Mechanism:

- Ensures a thin layer of rinse aid is distributed evenly during the final rinse phase.

- Contains a reservoir that needs regular refilling for optimal performance.

- Utilizes a siphoning action to dispense the rinse aid effectively.

Proper maintenance of these components is crucial for achieving the best results. Regular checks and refills can help prevent issues such as inadequate cleaning or drying, ensuring that the appliance continues to operate efficiently.

Filtration System in Jenn Air Models

The filtration system is a crucial component in ensuring optimal performance and longevity of kitchen appliances designed for cleaning. This system plays a significant role in maintaining water clarity and preventing debris from interfering with the washing process. Proper filtration helps enhance the effectiveness of the cleaning cycle, ensuring that dishes emerge spotless and free from contaminants.

Within various models, the filtration mechanism typically consists of multiple layers, each serving a specific purpose. The initial stage often includes a coarse filter that captures larger food particles, while subsequent layers refine the water further by trapping smaller debris. This multi-stage approach not only promotes thorough cleaning but also reduces the frequency of maintenance and cleaning required by the user.

In some advanced designs, features such as self-cleaning capabilities are integrated, allowing for automatic removal of trapped particles, thus minimizing manual intervention. Regular maintenance of the filtration system is essential to ensure consistent performance. Users should consult their specific model’s guidelines for recommended cleaning intervals and procedures to keep the system functioning effectively.

Heating Element and Its Functionality

The heating component plays a crucial role in the operation of home cleaning appliances. It is responsible for raising the water temperature, ensuring that dishes are effectively sanitized and cleaned. This element is vital for achieving optimal performance, especially during heavy-duty cycles.

Here are some key functions of the heating element:

- Water Heating: The primary function is to heat the water to the required temperature for effective cleaning.

- Drying Mechanism: It aids in the drying process by providing heat that evaporates remaining moisture from the dishes.

- Sanitization: High temperatures are essential for killing bacteria and ensuring that utensils are hygienically clean.

Maintaining the heating component is essential for the efficient functioning of the appliance. Regular checks can help identify issues early, preventing potential problems such as:

- Inadequate heating, leading to poor cleaning results.

- Increased energy consumption due to inefficiency.

- Potential damage to other components if the heating element fails.

Understanding the importance of this component can lead to better maintenance practices and improved appliance longevity.

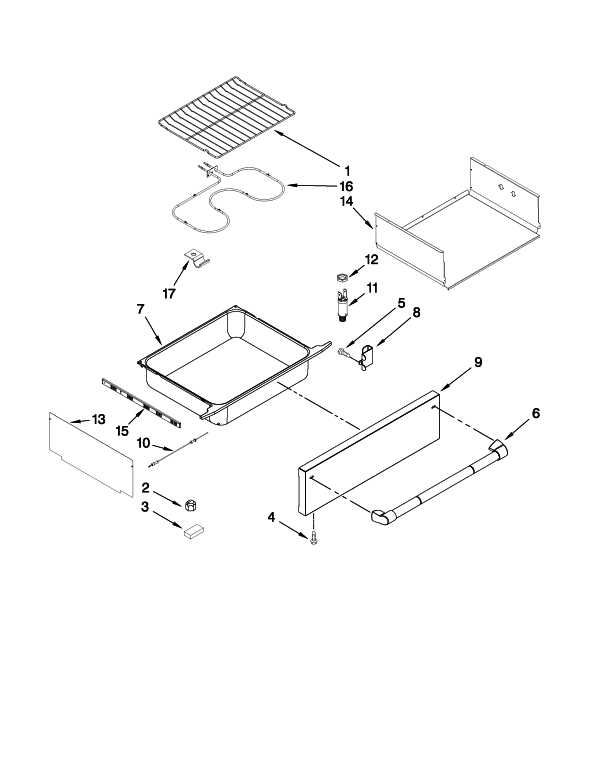

Rack and Utensil Holder Configurations

The arrangement of racks and utensil holders plays a crucial role in enhancing the efficiency of cleaning dishes and cutlery. Understanding how to effectively utilize these components can lead to better results, ensuring that every item receives the attention it deserves during the cleaning cycle. This section explores various configurations to maximize space and improve accessibility.

Types of Racks

Different types of racks are designed to accommodate a variety of items. The layout of these racks can significantly influence the cleaning performance. Below are some common configurations:

| Rack Type | Description | Benefits |

|---|---|---|

| Top Rack | Ideal for smaller items like glasses and cups. | Maximizes space for fragile items. |

| Bottom Rack | Designed for larger plates and pots. | Provides ample space for bulky items. |

| Adjustable Rack | Can be modified to fit different sizes of dishes. | Offers versatility for various loads. |

Utensil Holder Options

Utensil holders are essential for organizing cutlery and small kitchen tools during the cleaning process. Different configurations can improve the effectiveness of the wash:

| Holder Type | Capacity | Optimal Use |

|---|---|---|

| Flatware Basket | Holds multiple pieces of cutlery. | Ensures thorough cleaning of silverware. |

| Specialty Holders | Designed for specific items like spatulas or whisks. | Prevents tangling and promotes efficient washing. |

| Expandable Holder | Can be adjusted to accommodate varying utensil quantities. | Provides flexibility for different cleaning needs. |

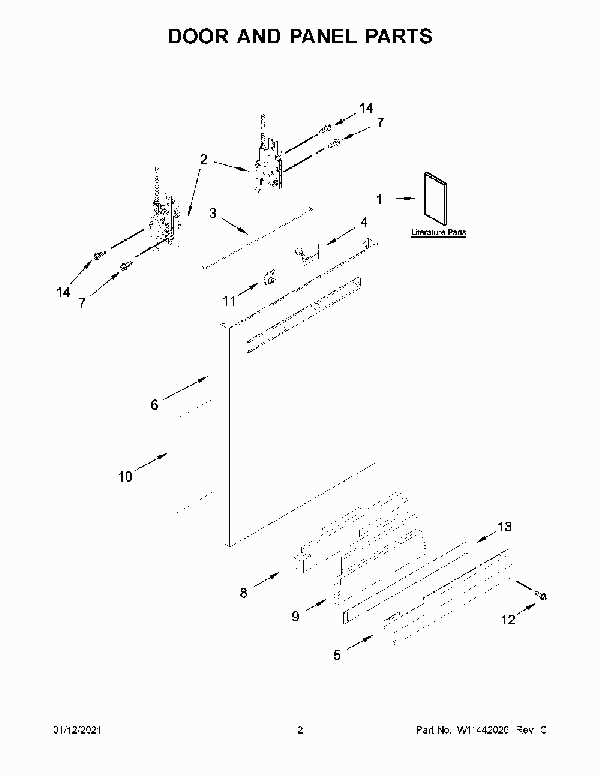

Replacing Dishwasher Electronic Control Board

The electronic control board is a crucial component in managing the various functions of your appliance. If your unit is not responding as it should, replacing this element may resolve issues such as malfunctioning cycles or failure to start. This guide outlines the steps needed for a successful replacement, ensuring your device operates efficiently once again.

Tools and Materials Needed

- Replacement control board

- Screwdriver set

- Wire cutters/strippers

- Electrical tape

- Safety gloves

Step-by-Step Instructions

- Disconnect Power: Unplug the unit from the electrical outlet or turn off the circuit breaker to ensure safety.

- Access the Control Board: Remove the outer cover by unscrewing the screws that secure it. This typically involves taking off the panel on the front or back of the device.

- Identify and Remove the Old Board: Locate the control board and carefully disconnect any wires attached to it. Note the arrangement for easier installation of the new one. Unscrew the board from its mount and take it out.

- Install the New Board: Position the new control board in place, securing it with screws. Reconnect the wires according to the previously noted arrangement.

- Reassemble the Unit: Once the new board is securely in place, reattach the outer cover and fasten it with screws.

- Restore Power: Plug the unit back into the outlet or turn on the circuit breaker.

- Test the Appliance: Run a short cycle to ensure that the new control board functions correctly and that all features are operational.

Following these steps will help you replace the electronic control board safely and effectively. Proper maintenance and timely repairs can significantly enhance the longevity of your appliance.