Understanding the internal mechanisms of your laundry equipment is essential for ensuring smooth operation and effective maintenance. Various elements within the system work in unison to provide optimal performance during each cycle. By familiarizing yourself with the essential components, you can address potential issues and keep your machine functioning efficiently.

One of the core sections of this appliance involves rotating and moving elements that contribute to the cleaning process. These components are designed to ensure proper movement and interaction with fabrics, offering the necessary force and motion for deep cleaning. Knowing how these parts interact can help in identifying common wear and tear.

In the following guide, we will explore these crucial sections and their functions, providing a detailed look at how each element plays a role in the overall system. Whether you’re troubleshooting an issue or simply aiming to better understand the inner workings, this information will equip you with the knowledge to maintain your machine effectively.

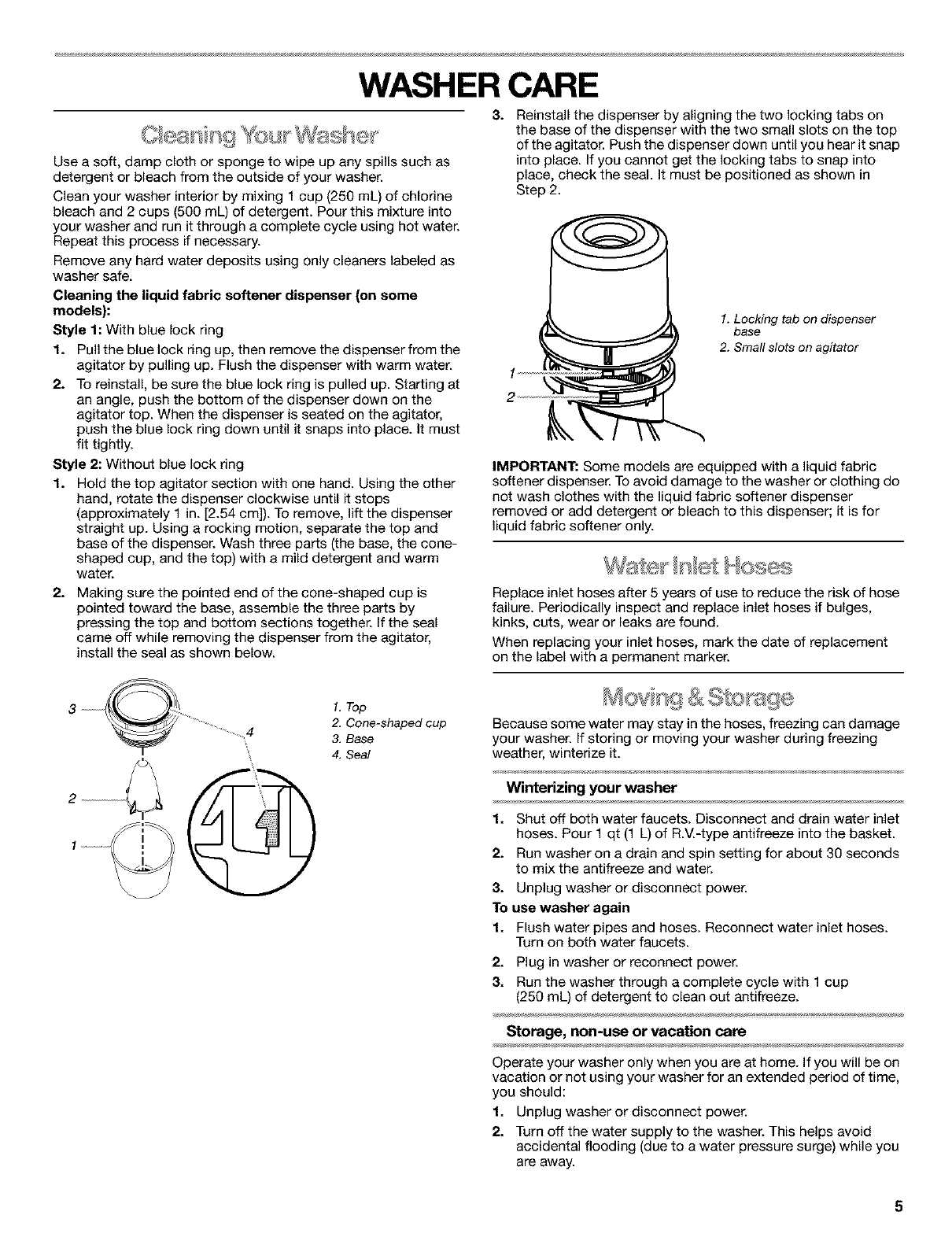

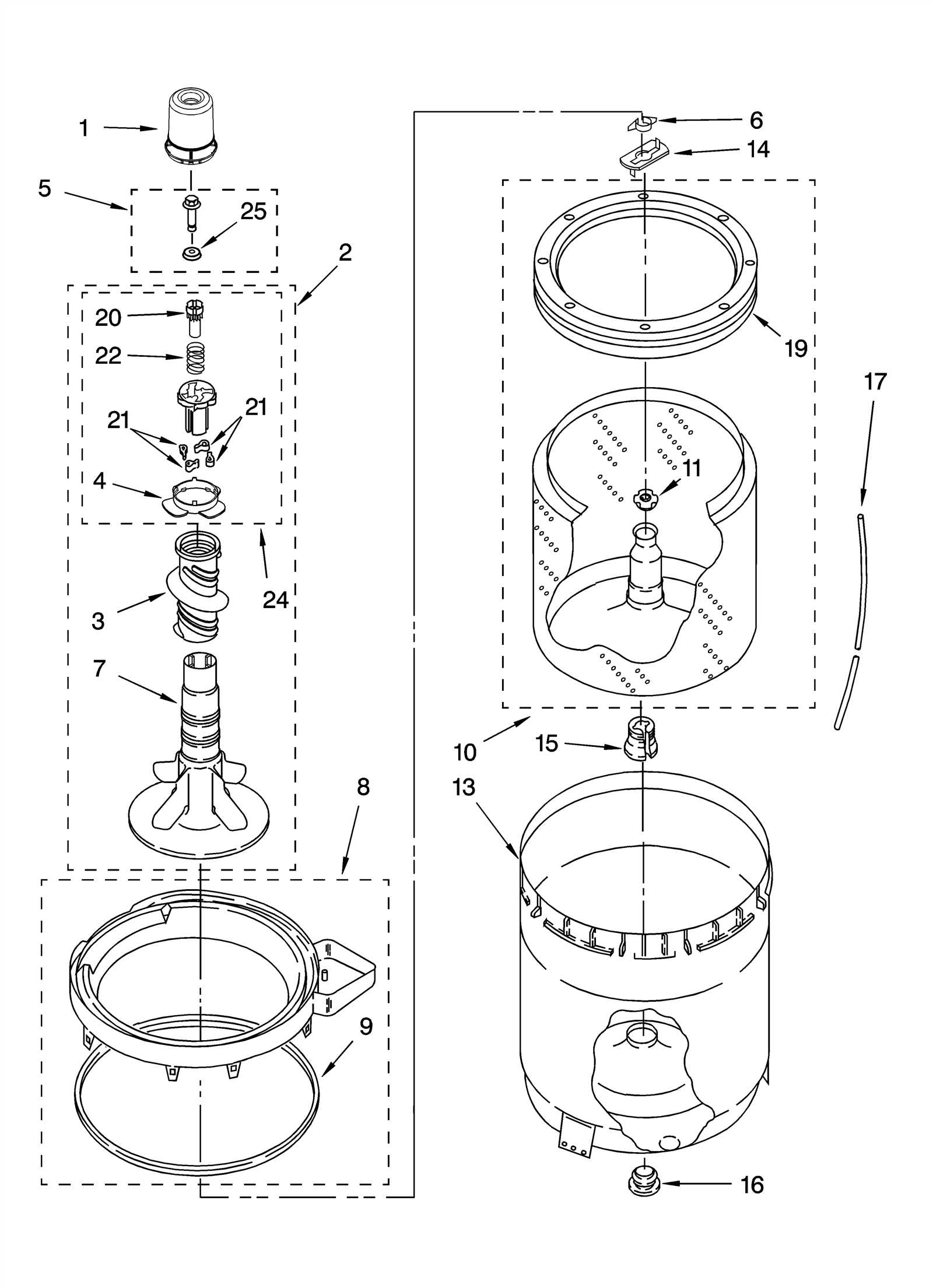

Kenmore Washer Agitator Parts Overview

In this section, we will explore the key components responsible for the efficient operation of the central mechanism in laundry machines. These elements work together to ensure effective cleaning by moving fabrics in the drum, helping to remove dirt and stains. Understanding the structure and function of these elements can assist in maintaining or repairing the appliance.

Central Mechanism Core: The core is designed to create motion that helps in circulating clothes through the water, ensuring thorough contact with cleaning agents. It plays a crucial role in maintaining the balance between rotation and washing efficiency.

Stirring Blades: These are designed to move garments in different directions, ensuring that water and detergent reach every part of the fabric. The blades are crafted for durability, allowing for consistent performance over time.

Support Components: Various support elements, including the base and connecting joints, provide the necessary stability for the main system to function smoothly. They help reduce wear and tear on the internal machinery, extending the lifespan of the appliance.

Main Components of Kenmore Washer Agitators

The central mechanism of household cleaning machines includes several essential elements that work together to ensure efficient movement and water flow during laundry cycles. These elements are designed to create a balanced motion, promoting optimal fabric care and deep cleaning.

Core Structural Elements

- Base Platform: This foundational piece provides stability and helps distribute force evenly, ensuring smooth operation.

- Rotational Blades: Designed to generate the necessary agitation, these components shift the load within the drum, aiding in the cleaning process.

- Vertical Support Column: This piece acts as the central support, holding the other elements together and allowing rotational movement.

Additional Functional Parts

- Drive Mechanism: Powers the rotation and oscillation, providing the necessary motion for thorough cleaning.

- Clutch System: Regulates the speed and torque, ensuring that the motion is controlled and efficient during various stages of the cycle.

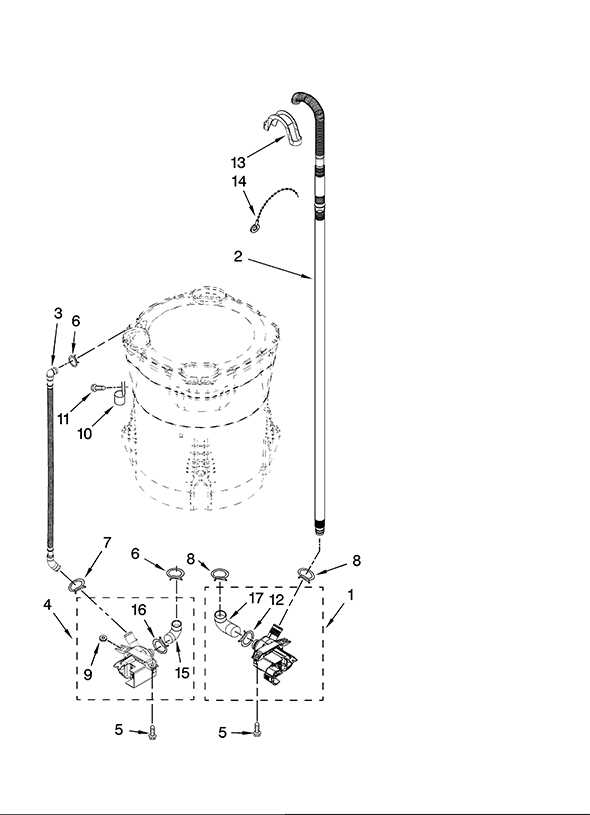

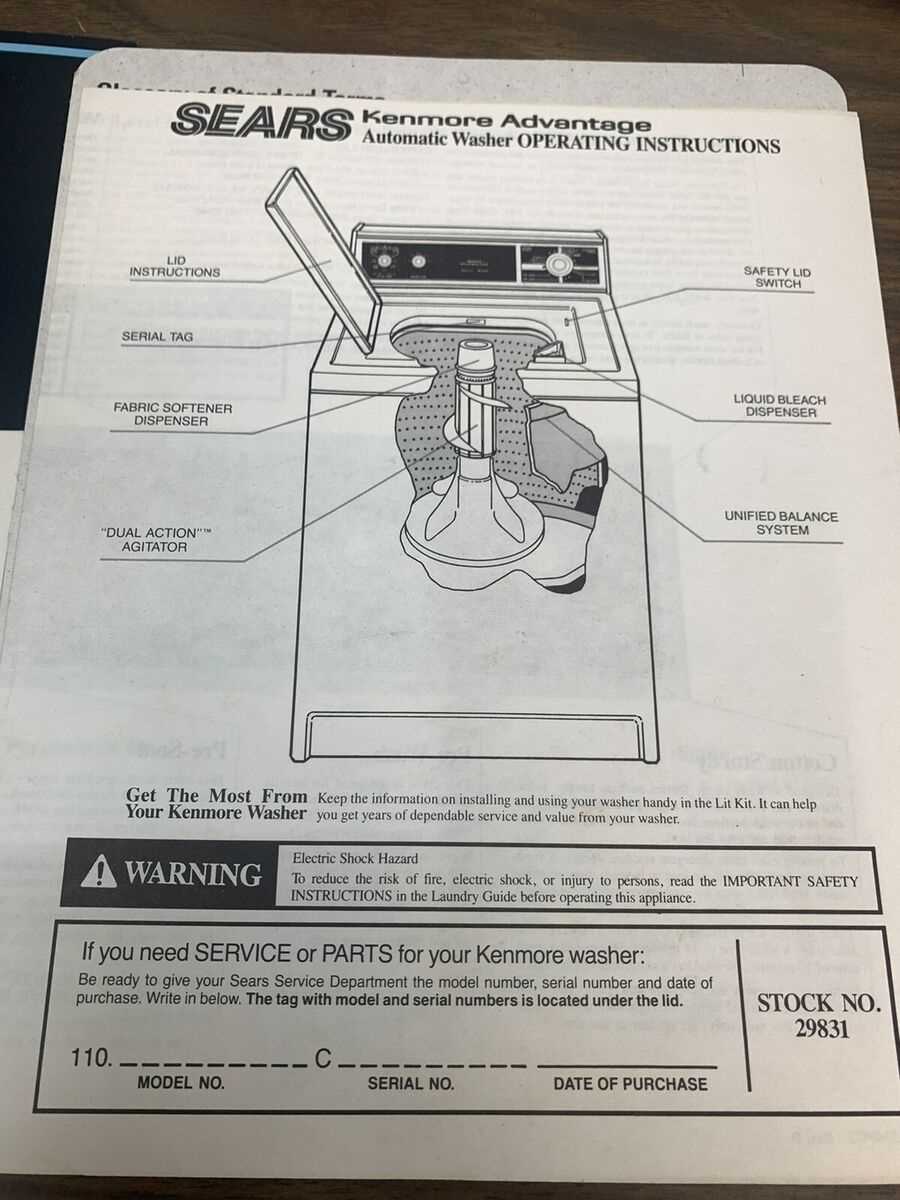

How to Identify Agitator Parts

Understanding the components of a laundry appliance is essential for effective maintenance and troubleshooting. Recognizing the different elements involved in the washing process can help in identifying issues and ensuring optimal performance. This section will guide you through the identification of these crucial components, enhancing your ability to diagnose and address common problems.

Recognizing Key Components

Begin by familiarizing yourself with the main elements found within the washing mechanism. Typically, these include various attachments and connectors that play specific roles during the cleaning cycle. Observing the arrangement and functionality of each element can aid in pinpointing any malfunctions that may arise.

Utilizing Resources for Identification

Consulting manuals or instructional resources can provide detailed information regarding the layout and function of each component. Many guides include illustrations or descriptions that can simplify the identification process. Additionally, online forums and support groups can offer valuable insights and assistance from experienced users.

Common Issues with Agitator Mechanisms

In the realm of laundry appliances, certain mechanisms can experience various complications over time. These issues often stem from wear and tear or improper usage, leading to decreased efficiency and effectiveness. Understanding these common problems can assist users in troubleshooting and maintenance.

- Insufficient Movement: One of the most prevalent issues is the lack of adequate movement during the washing cycle. This may result from worn components or obstructions within the system.

- Unusual Noises: Strange sounds during operation can indicate that parts are misaligned or damaged. Grinding or clanking noises are often a sign of mechanical failure.

- Inconsistent Performance: Variability in cleaning effectiveness can occur if the mechanism is not functioning optimally, which may be due to part degradation or misconfiguration.

- Leakage: Fluid leaks around the base of the machine can suggest seal failures, which may compromise the entire system’s operation.

- Sticking or Jamming: Components may occasionally stick or jam, preventing proper movement and leading to prolonged cycle times.

Addressing these common challenges often requires regular inspections and maintenance to ensure all components are functioning as intended. Timely interventions can prolong the lifespan of the appliance and maintain its efficiency.

Replacing Worn-Out Agitator Components

When your laundry machine begins to show signs of inefficiency, it often indicates that certain internal elements require attention. Regular use can lead to wear and tear on these components, affecting the overall performance of the appliance. Identifying and replacing these worn elements is crucial for maintaining optimal functionality and ensuring clean results with every load.

Before starting the replacement process, gather the necessary tools and new components to facilitate a smooth repair. First, disconnect the appliance from its power source and remove any coverings to access the interior parts. Carefully inspect the worn components for signs of damage, such as cracks or excessive wear. Once identified, remove these elements with the appropriate tools, taking care to follow any specific instructions related to your model.

After removing the damaged components, install the new ones, ensuring they fit snugly and securely. Reassemble any coverings or panels that were removed and reconnect the power source. Finally, run a test cycle to verify that the appliance operates smoothly and efficiently, confirming that the replacement was successful.

Where to Find Kenmore Agitator Parts

Locating components for your laundry appliance can be straightforward if you know where to look. There are various avenues to explore that offer a range of options for sourcing these essential elements.

Here are some reliable sources for finding the required components:

- Local Appliance Stores: Many retailers specialize in home appliances and may carry the necessary components or can order them for you.

- Online Marketplaces: Websites such as eBay or Amazon provide a vast selection of parts. Always check customer reviews and ratings before making a purchase.

- Manufacturer’s Website: Visiting the official site can often lead you directly to the necessary components or provide information on authorized dealers.

- Repair Shops: Local repair services often have spare components on hand or can help you locate them.

- Specialized Parts Retailers: There are retailers dedicated to appliance components that offer a wide selection and detailed catalogs.

By utilizing these sources, you can efficiently find the required items to ensure your laundry appliance operates smoothly.

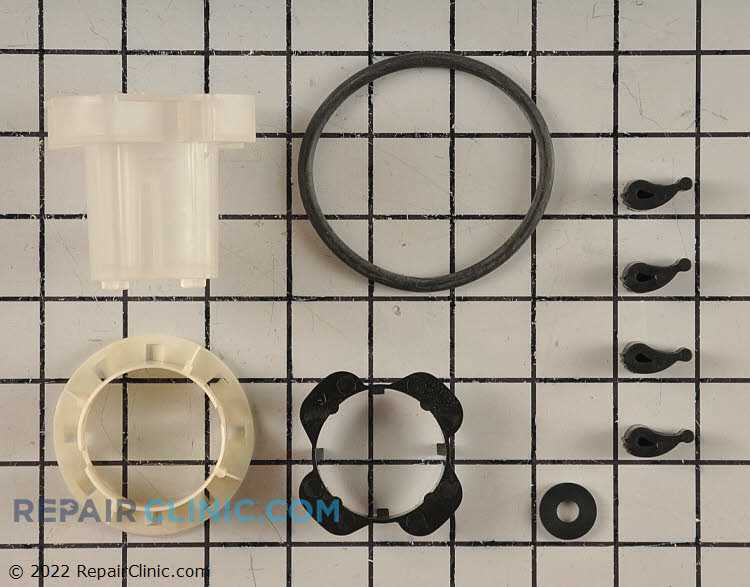

Importance of Agitator Dogs in Performance

The functionality of a laundry appliance heavily relies on various components that contribute to its efficiency. Among these elements, a specific mechanism plays a crucial role in ensuring effective movement during the washing cycle. This mechanism not only aids in the proper distribution of detergent but also enhances the overall cleaning action by facilitating the movement of textiles within the drum.

Enhancing Cleaning Efficiency

The effectiveness of the cleaning process is significantly influenced by this mechanism’s ability to create a dynamic action that dislodges dirt and stains. When functioning optimally, it ensures that garments receive even treatment, resulting in a thorough wash. Any malfunction in this mechanism can lead to subpar performance, leaving residues and not achieving the desired cleanliness.

Impact on Longevity

In addition to improving washing outcomes, the proper functioning of this component also extends the lifespan of the appliance. When all parts operate harmoniously, it reduces wear and tear on the motor and other associated elements, leading to fewer repairs and enhanced durability. Thus, maintaining this mechanism is essential not just for performance but also for the appliance’s long-term reliability.

Maintaining the Agitator for Longevity

Proper care and regular upkeep of your appliance’s mixing mechanism are essential for ensuring its durability and optimal performance. By implementing effective maintenance strategies, you can prevent wear and tear, prolonging the life of this critical component and enhancing the overall efficiency of the machine.

Regular Inspection

Conducting routine checks on the mixing mechanism can help identify any signs of damage or unusual wear early on. Look for cracks, loose parts, or any unusual noises during operation. Addressing these issues promptly can prevent more significant problems and maintain smooth functionality.

Cleaning Practices

Keeping the mixing area clean is vital for preventing residue buildup that can lead to malfunctions. Regularly remove any debris or detergent residue that may accumulate. Using mild cleaning solutions can help maintain the integrity of the components without causing harm.

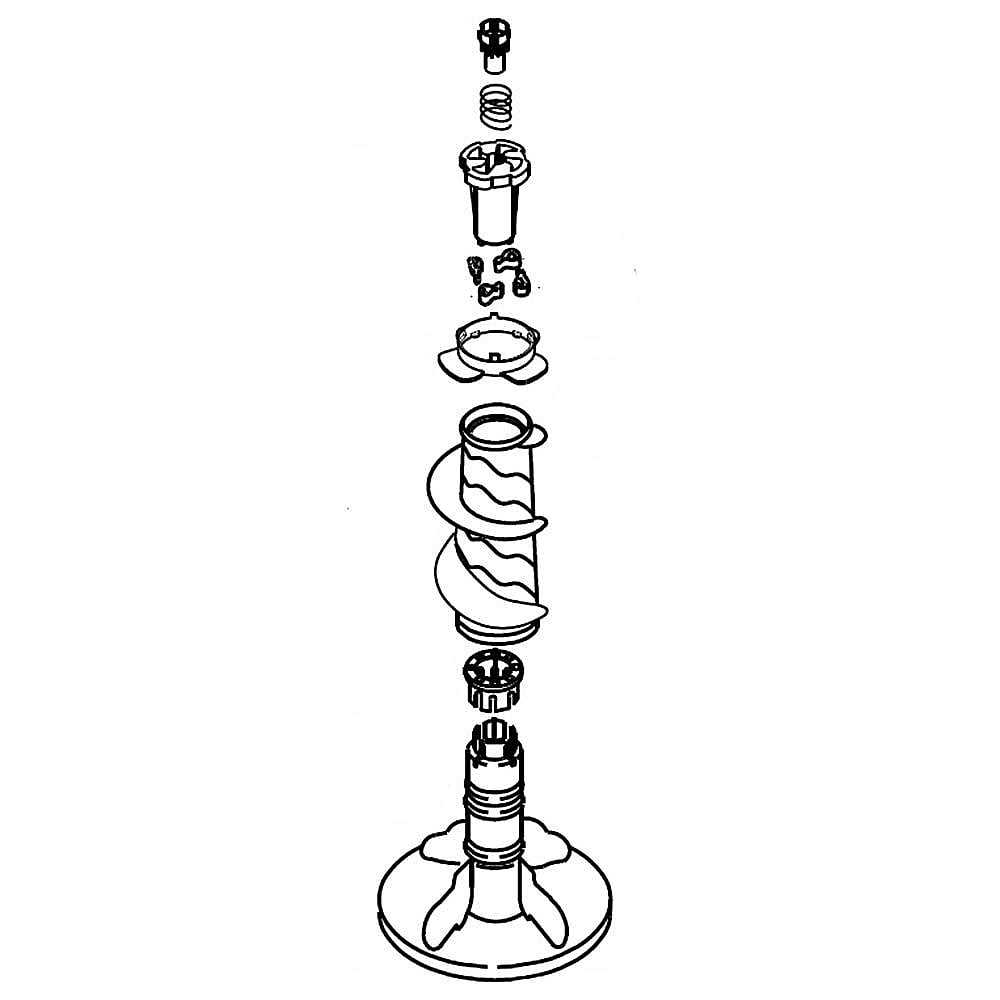

Steps to Remove and Install Agitator

To successfully detach and reattach the central mechanism responsible for the mixing process, it’s essential to follow a series of systematic procedures. This guide outlines the necessary steps to ensure a smooth and efficient transition during the replacement process.

- Gather the required tools and materials:

- Socket wrench set

- Screwdriver

- Pliers

- Replacement mechanism

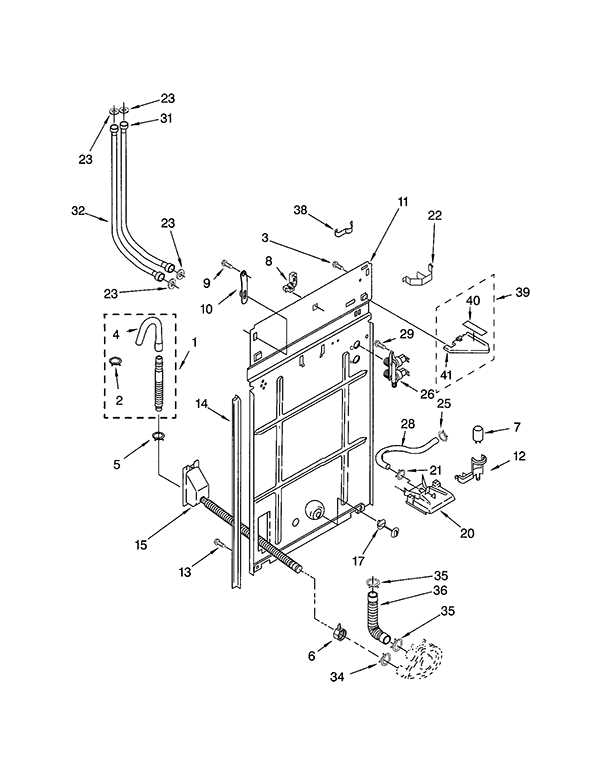

Differences Between Kenmore Agitator Models

When it comes to various types of washing machines, the mixing components play a crucial role in determining performance and efficiency. Different models feature unique designs, materials, and functionalities, impacting how effectively they clean and care for garments. Understanding these variations can help consumers make informed decisions when selecting the right machine for their laundry needs.

Design Variations

The designs of these mixing components can differ significantly between models. Some units may incorporate a dual-action design, allowing for enhanced motion and improved cleaning results. Others might utilize a more traditional single-action approach, which can affect how clothes are treated during the wash cycle. These differences often reflect the intended use and target market of each model.

Material Differences

Another key aspect to consider is the materials used in the construction of these components. While some are made from durable plastics, others may feature metal parts for added strength and longevity. This choice of materials can influence not only the lifespan of the components but also their overall performance in various washing conditions.

How to Lubricate Agitator Bearings

Proper maintenance of the rotating mechanism is essential for ensuring smooth operation and extending the lifespan of your appliance. Regular lubrication of the bearings minimizes friction and wear, enhancing performance and reducing the risk of breakdowns.

To begin the lubrication process, you will need to disassemble the unit to access the bearings. Carefully follow the manufacturer’s guidelines to remove any necessary components. Once you have access, clean the bearings to remove any accumulated dirt or old lubricant, as this will help the new lubricant adhere better.

Select a suitable lubricant that is designed for use in mechanical applications. Apply a small amount of lubricant evenly around the bearings, ensuring not to overapply, as excess grease can attract debris and lead to further issues. After lubricating, reassemble the components in the reverse order of disassembly.

Finally, run a test cycle to ensure everything functions smoothly. Regular checks and maintenance will help keep the mechanism operating efficiently and prolong its service life.

Understanding Agitator Gear Functions

The gear mechanism in laundry appliances plays a crucial role in the overall washing process. These components are designed to facilitate the movement necessary for effective cleaning, ensuring that garments are thoroughly agitated during cycles. The interaction between gears allows for the transformation of motor power into the rotational motion required for optimal fabric treatment.

Each gear serves a specific purpose, contributing to the overall efficiency and performance of the washing system. Their design and functionality directly influence how effectively items are cleaned, impacting everything from detergent distribution to the removal of dirt and stains. Understanding these functions is essential for troubleshooting and maintaining the appliance, as any malfunction can hinder the cleaning process.

In summary, recognizing the importance of gear mechanisms within laundry appliances enhances comprehension of their operation and assists users in ensuring optimal performance through regular maintenance and timely repairs.

Cleaning and Caring for the Agitator

Maintaining the core component that facilitates movement during the cleaning cycle is essential for optimal performance. Regular upkeep ensures longevity and efficiency, preventing potential issues that may arise from neglect.

Start by disconnecting the appliance from the power source to ensure safety. Remove any visible debris or residues that may have accumulated. A damp cloth with a mild detergent can effectively clean the exterior surfaces. Be cautious not to use abrasive materials that could scratch or damage the finish.

It is also important to check for any build-up inside the mechanism. A gentle brush can reach areas that are typically hard to access. Ensuring all parts are free from grime allows for smoother operation and helps prevent clogs.

Finally, regular inspections should be part of your routine. Look for signs of wear or damage, as early detection can save time and money in the long run. Keeping this crucial component clean and in good condition enhances overall cleaning results and extends the lifespan of the unit.