When it comes to efficient outdoor maintenance, the functionality of your cleaning apparatus hinges on its various elements. Recognizing how these components interact can enhance performance and prolong the lifespan of your device. This section delves into the intricate relationships between different parts, offering insights into their roles and importance.

For optimal operation, it is crucial to grasp how each segment contributes to the overall efficacy of the equipment. A well-organized overview can assist users in troubleshooting common issues and conducting necessary maintenance. By understanding the layout and function of these elements, users can achieve greater cleaning efficiency and effectiveness.

Visual aids serve as valuable resources in this exploration, providing clarity and facilitating a deeper comprehension of assembly and functionality. As we navigate through this intricate web of components, the aim is to empower users with the knowledge needed to keep their cleaning tools in peak condition.

Understanding Ridgid Pressure Washers

When exploring high-performance cleaning equipment, it’s essential to grasp their design and functionality. These machines excel in delivering effective cleaning solutions for various surfaces and tasks, making them a popular choice for both residential and commercial use.

Key components play a vital role in ensuring optimal performance. Each element is crafted to work in harmony, contributing to the ultimate efficiency and reliability of the equipment.

Maintenance is another critical aspect. Regular checks and proper care can prolong the lifespan of the device, ensuring it operates at peak efficiency whenever needed. Understanding how each component interacts can empower users to troubleshoot and enhance performance effectively.

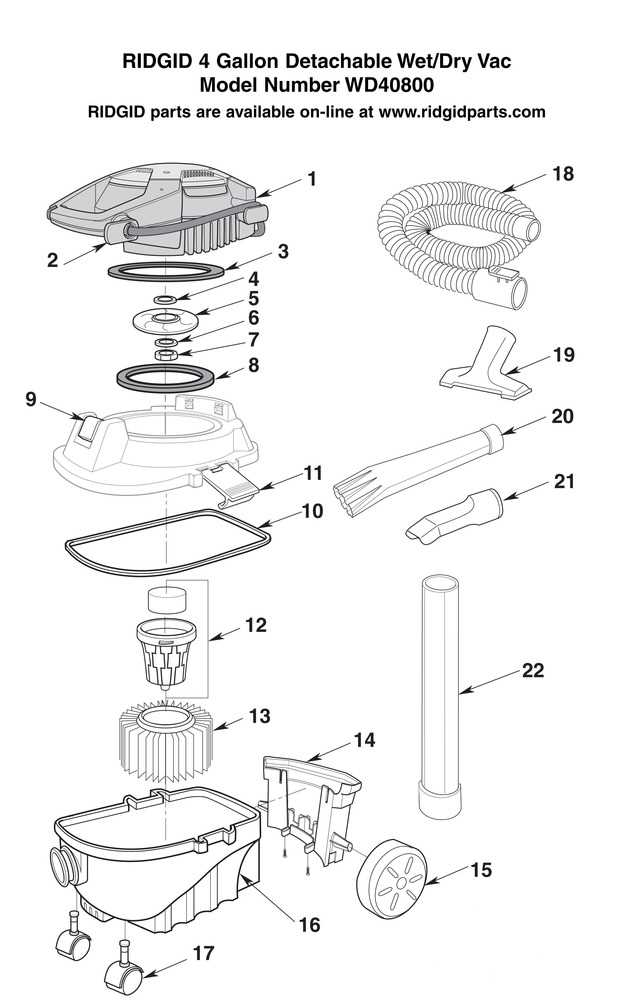

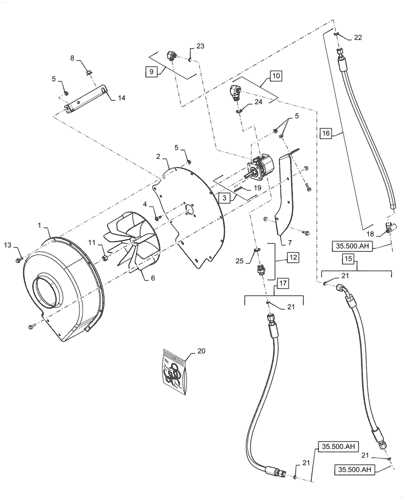

Components of a Pressure Washer

Understanding the various elements that make up a cleaning device can significantly enhance your maintenance and usage experience. Each component plays a vital role in ensuring effective operation and optimal performance, contributing to the overall efficiency of the machine.

Core Elements

The main components include the motor, which powers the system, and the pump, responsible for generating the necessary flow and pressure of water. Additionally, there are nozzles that dictate the spray pattern, allowing for versatility in tackling different cleaning tasks. Each of these parts must work in harmony to achieve the desired results.

Supporting Features

Beyond the core elements, there are also essential accessories that enhance functionality. Hoses and connectors facilitate water delivery, while filters ensure the integrity of the fluid being used. Understanding these supporting features can help you make informed decisions regarding maintenance and upgrades.

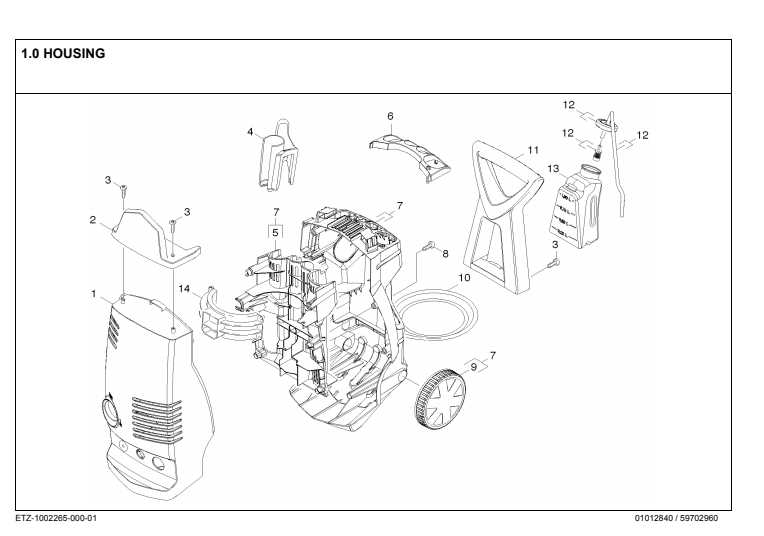

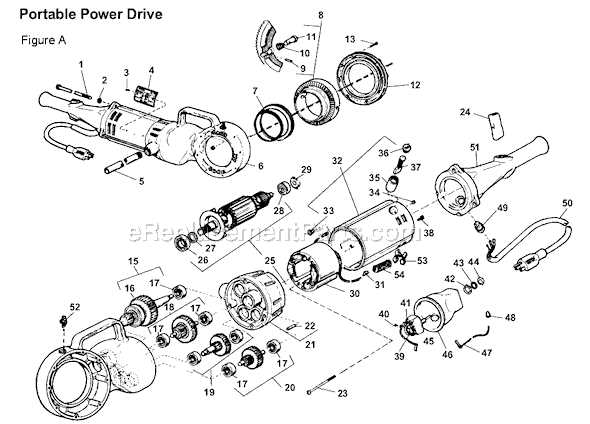

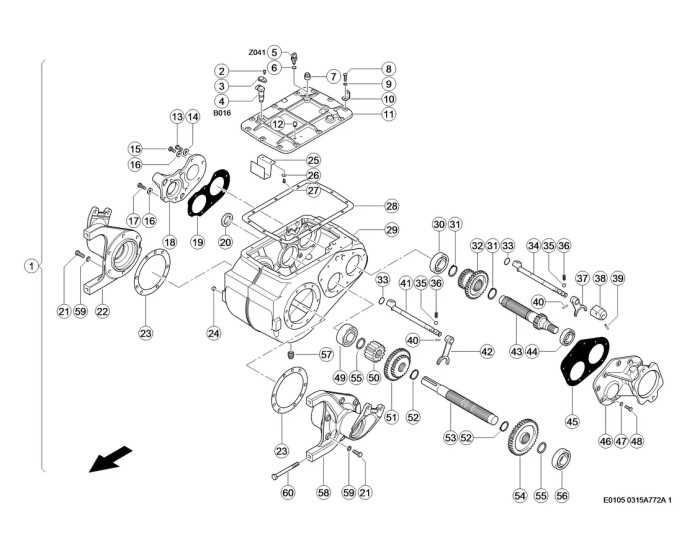

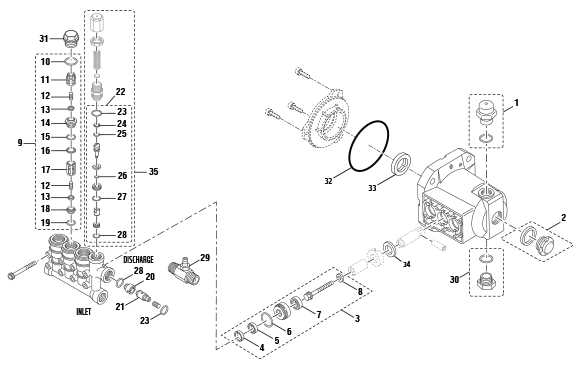

Importance of a Parts Diagram

Understanding the assembly of any mechanical device is crucial for maintenance and repairs. A visual representation of components allows users to identify individual elements and their connections. This clarity can significantly enhance troubleshooting efficiency and ensure proper reassembly after service.

Enhanced Troubleshooting

When issues arise, having a visual guide simplifies the diagnostic process. It helps users pinpoint the location of faults and determine which specific components require attention. This targeted approach not only saves time but also minimizes the risk of overlooking critical elements.

Streamlined Maintenance and Repair

Utilizing a schematic enables users to follow assembly and disassembly processes with confidence. It ensures that every part is accounted for, reducing the likelihood of errors during maintenance. By clearly outlining connections and functions, such guides promote better understanding and more effective handling of equipment.

In conclusion, a well-structured visual reference is an invaluable tool for anyone engaged in upkeep and repair. It fosters a deeper comprehension of mechanical systems and enhances overall operational efficiency.

Common Ridgid Pressure Washer Models

This section explores several popular models known for their reliability and performance in cleaning tasks. These units are designed for both residential and commercial use, providing versatility for various applications.

-

Model 1: A robust option favored for its powerful engine and high efficiency. Ideal for medium to heavy-duty cleaning jobs.

-

Model 2: Known for its compact design, this model is perfect for homeowners seeking ease of storage and mobility without compromising performance.

-

Model 3: This variant is equipped with advanced features that enhance usability, making it suitable for intricate tasks such as vehicle detailing.

-

Model 4: A budget-friendly choice, offering essential functionality for everyday cleaning needs while maintaining decent power.

-

Model 5: This high-end model includes additional attachments, making it versatile for various cleaning surfaces and situations.

Each model provides distinct features tailored to different cleaning requirements, ensuring users can find a suitable option for their specific needs.

How to Read a Parts Diagram

Understanding a component schematic is essential for anyone looking to maintain or repair equipment effectively. These visual representations provide crucial insights into the assembly and functionality of various elements, allowing users to identify and source individual pieces as needed.

Key Elements of a Component Schematic

When analyzing a schematic, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Each item is usually marked with a code or number for easy identification. |

| Connections | Lines or arrows indicate how components interact or connect to one another. |

| Legend | A key that explains symbols used throughout the schematic for clarity. |

Steps to Interpret the Schematic

To effectively interpret the schematic, follow these steps: begin by familiarizing yourself with the legend, then cross-reference component labels with your equipment to understand their roles, and finally, trace connections to grasp how each part integrates into the whole system.

Identifying Essential Parts

Understanding the core components of cleaning equipment is crucial for effective maintenance and operation. Each element plays a vital role in ensuring optimal functionality and performance. Recognizing these elements can significantly enhance your ability to troubleshoot issues and prolong the lifespan of the machinery.

Key components include the motor, which powers the unit, and the pump, responsible for water flow. Additionally, the hose and nozzle are essential for directing the stream to the desired area. Lastly, the frame provides structural integrity, ensuring stability during use.

Maintenance Tips for Longevity

To ensure the enduring performance of your equipment, regular upkeep is essential. By following a few straightforward practices, you can significantly extend its lifespan and enhance efficiency.

Regular Cleaning: Keep the exterior and interior components free from dirt and grime. A clean surface prevents wear and promotes optimal functionality.

Check for Wear: Routinely inspect all moving parts for signs of wear or damage. Timely replacements can prevent larger issues and costly repairs.

Fluid Maintenance: Regularly change and replenish essential fluids to ensure smooth operation. Clean fluids prevent overheating and improve overall performance.

Proper Storage: Store your equipment in a dry and sheltered environment to protect it from the elements. This simple step can greatly reduce deterioration over time.

Follow Manufacturer Guidelines: Always adhere to the recommendations provided by the manufacturer. These guidelines are designed to maximize performance and longevity.

Where to Find Replacement Parts

Finding components for your cleaning equipment can be a straightforward process if you know where to look. Various resources offer a range of options for sourcing the necessary items to keep your device functioning optimally.

Online Retailers

- Visit e-commerce platforms like Amazon or eBay, which often have a vast selection of components.

- Check specialized websites that focus on outdoor equipment and accessories for more specific needs.

- Consider manufacturer websites, as they usually provide direct access to genuine components.

Local Stores

- Home improvement stores frequently stock essential components and may offer assistance in finding what you need.

- Check with local hardware stores that may have a selection of compatible items.

- Seek out specialty shops that cater to outdoor or cleaning equipment, as they might have unique offerings.

Using these resources can help ensure that you find the right components quickly and efficiently.

Common Issues and Solutions

When operating outdoor cleaning equipment, users may encounter various challenges that hinder performance. Understanding these frequent problems and their respective remedies can enhance efficiency and prolong the lifespan of the machinery.

1. Low Water Pressure: One of the most common complaints is insufficient water force. This can often be attributed to a clogged nozzle or hose. To resolve this, inspect the nozzle for debris and clean it thoroughly. Additionally, check for kinks in the hose that may restrict flow.

2. Engine Won’t Start: If the motor fails to initiate, it could be due to fuel issues or a faulty ignition system. Ensure the fuel tank is filled and consider replacing the spark plug if it appears worn or dirty.

3. Unusual Noises: Strange sounds during operation may indicate mechanical issues. Listen for grinding or rattling noises, which could suggest loose components. Tighten any loose screws or bolts to alleviate this problem.

4. Leaking Fluid: Any signs of leakage should be addressed immediately, as they can lead to more significant damage. Inspect seals and gaskets for wear, and replace them as necessary to prevent further leaks.

5. Excessive Vibration: If the unit vibrates more than usual, it may be unbalanced. Check that all components are securely attached and consider recalibrating any adjustable parts to ensure smooth operation.

By identifying these common issues and applying the suggested solutions, users can maintain their equipment in optimal condition, ensuring reliable performance for years to come.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right tools is essential for effective and efficient work. Proper tools not only facilitate the repair process but also ensure safety and precision.

- Screwdrivers: Various sizes and types, including flathead and Phillips.

- Wrenches: Adjustable and socket wrenches for loosening or tightening fasteners.

- Pliers: Needle-nose and standard pliers for gripping and manipulating small parts.

- Socket Set: For working with nuts and bolts, providing versatility and ease of use.

- Safety Gear: Gloves, goggles, and masks to protect against potential hazards.

Gathering these tools in advance can significantly streamline the repair process and minimize complications.

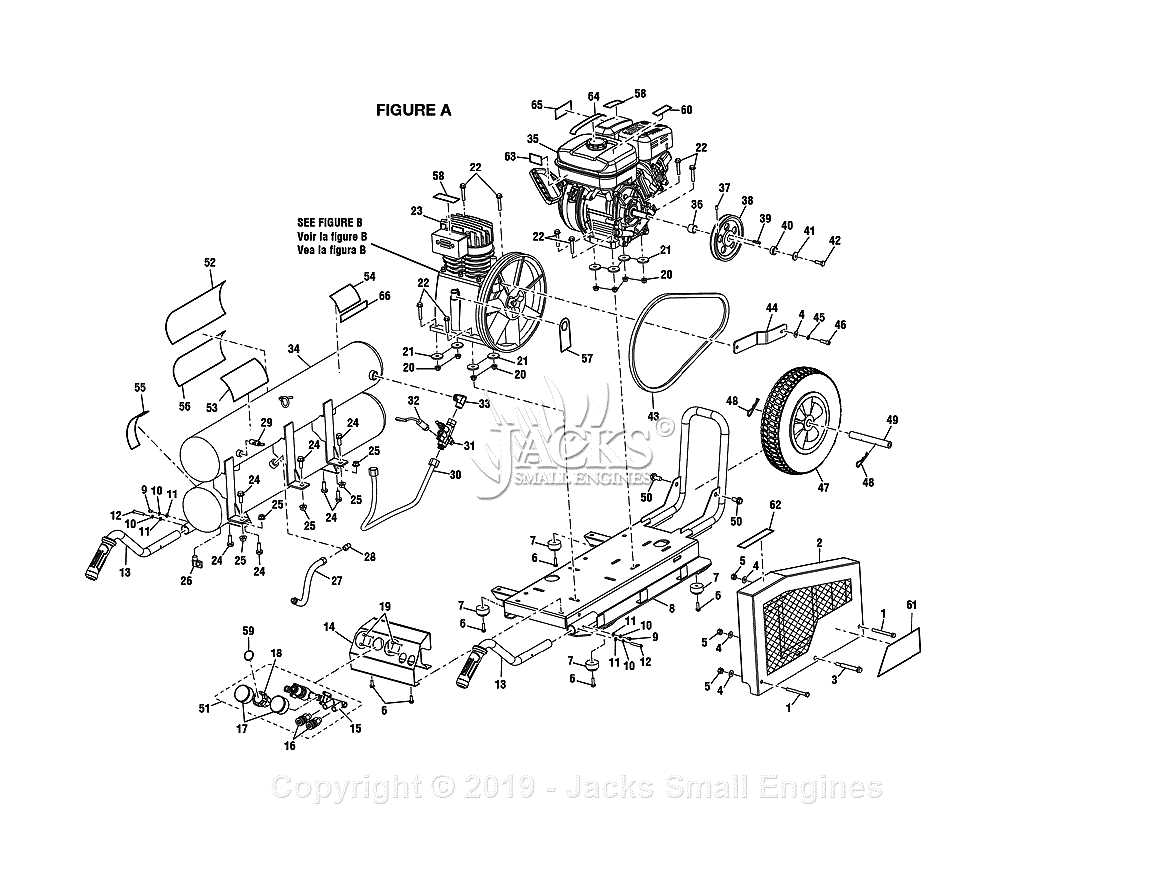

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing common issues encountered with high-efficiency cleaning machines. By following each step carefully, you can restore optimal functionality and extend the lifespan of your equipment.

Begin by ensuring safety; disconnect the machine from any power source. Gather all necessary tools and replacement components to streamline the process. Carefully examine the unit to identify visible signs of wear or damage, taking note of any specific areas needing attention.

Next, consult the relevant schematic to understand the layout and connections within the system. This will help you locate the components that require servicing. Proceed to disassemble the machine methodically, documenting each step to avoid confusion during reassembly.

Once disassembled, clean each component thoroughly, removing any debris or buildup that may hinder performance. Replace any worn or damaged pieces with new, compatible items. Reassemble the unit, ensuring all connections are secure and aligned properly.

Finally, reconnect the machine to its power source and perform a test run to confirm everything operates as expected. Address any remaining issues before concluding the repair, ensuring your equipment is ready for use.

Upgrading Your Pressure Washer

Enhancing your cleaning equipment can significantly improve its efficiency and effectiveness. By selecting the right components and accessories, you can transform your machine into a more powerful tool, making tasks easier and faster. This section explores various upgrades that can elevate your device’s performance.

1. Nozzle Selection: Choosing the right nozzle can dramatically affect your cleaning experience. Different nozzles create varying spray patterns and pressures, allowing for tailored approaches to specific surfaces. Consider upgrading to nozzles that offer adjustable settings for versatility in your cleaning tasks.

2. Hose Improvements: Upgrading to a high-quality, flexible hose can enhance mobility and reduce the risk of kinks or leaks. Look for options with increased durability and a longer reach, which can save time and effort while working on larger areas.

3. Detergent Dispensers: Adding or upgrading a detergent system can facilitate more efficient cleaning. Look for dispensers that allow for the use of various cleaning solutions, ensuring you can tackle tough stains and grime with ease.

4. Motor Enhancements: Consider upgrading the motor for improved power and reliability. A more robust motor can increase cleaning efficiency and reduce downtime, enabling you to complete tasks quicker.

5. Accessory Kits: Investing in comprehensive accessory kits can provide you with additional tools that enhance your cleaning capabilities. From surface cleaners to extension wands, these tools can help you tackle a wider range of projects.

By thoughtfully selecting upgrades, you can significantly enhance the functionality and performance of your cleaning equipment, ensuring that it meets your evolving needs.

Benefits of Genuine Ridgid Parts

Using authentic components for your cleaning equipment ensures optimal performance and longevity. Genuine items are specifically designed to work seamlessly with your machine, providing reliability and efficiency that aftermarket alternatives often cannot match.

Here are some key advantages of choosing original components:

- Quality Assurance: Authentic components are manufactured to stringent standards, guaranteeing durability and effectiveness.

- Perfect Fit: Designed for specific models, these components ensure a precise fit, reducing the risk of malfunction or damage.

- Enhanced Performance: Genuine items contribute to the overall efficiency of your equipment, improving cleaning capabilities.

- Warranty Protection: Utilizing original components often helps maintain your warranty, providing peace of mind in case of future issues.

- Availability of Support: When you choose authentic items, you gain access to customer service and technical support that may not be available with aftermarket alternatives.

In summary, opting for genuine components not only improves the functionality of your equipment but also ensures a longer lifespan and better overall user experience.