The efficiency and reliability of a powerful cleaning machine greatly depend on its individual elements. This section aims to provide a comprehensive overview of the essential components that contribute to the optimal functionality of these machines. Understanding how each piece works together will enhance your ability to maintain and troubleshoot effectively.

In this guide, we will explore the various features that make up a top-tier cleaning unit. By examining the relationships between these components, users can gain valuable insights into proper maintenance, potential repairs, and overall performance enhancement. Familiarity with these details can lead to a more satisfying and effective cleaning experience.

Additionally, this exploration will empower users to make informed decisions regarding repairs or replacements. Knowing the specific functions and interconnections of each component is crucial for anyone looking to extend the lifespan of their equipment and achieve consistent results. Embracing this knowledge will ultimately lead to greater satisfaction with the overall cleaning process.

Key Features of Simpson Pressure Washers

Modern cleaning devices are engineered with advanced technologies that enhance their efficiency and usability. These machines are designed to deliver powerful performance, making them suitable for a variety of tasks, from light household cleaning to heavy-duty commercial applications. Understanding the core attributes of these systems can help users select the most appropriate model for their needs.

Durability and Reliability

High-quality materials and robust construction ensure that these machines withstand rigorous use over time. They are equipped with reinforced frames and protective elements, making them resilient to wear and tear, even in demanding environments.

Versatile Application

These cleaning devices are capable of tackling a wide range of tasks, from removing dirt and grime from patios to cleaning vehicles. With adjustable settings, users can easily modify the intensity of the cleaning process to suit different surfaces and levels of soiling.

Identifying Common Parts and Their Functions

Understanding the essential components of a cleaning device is crucial for efficient operation and maintenance. Each element plays a specific role in ensuring the equipment functions smoothly and effectively. Familiarizing oneself with these elements can enhance user experience and prolong the lifespan of the machinery.

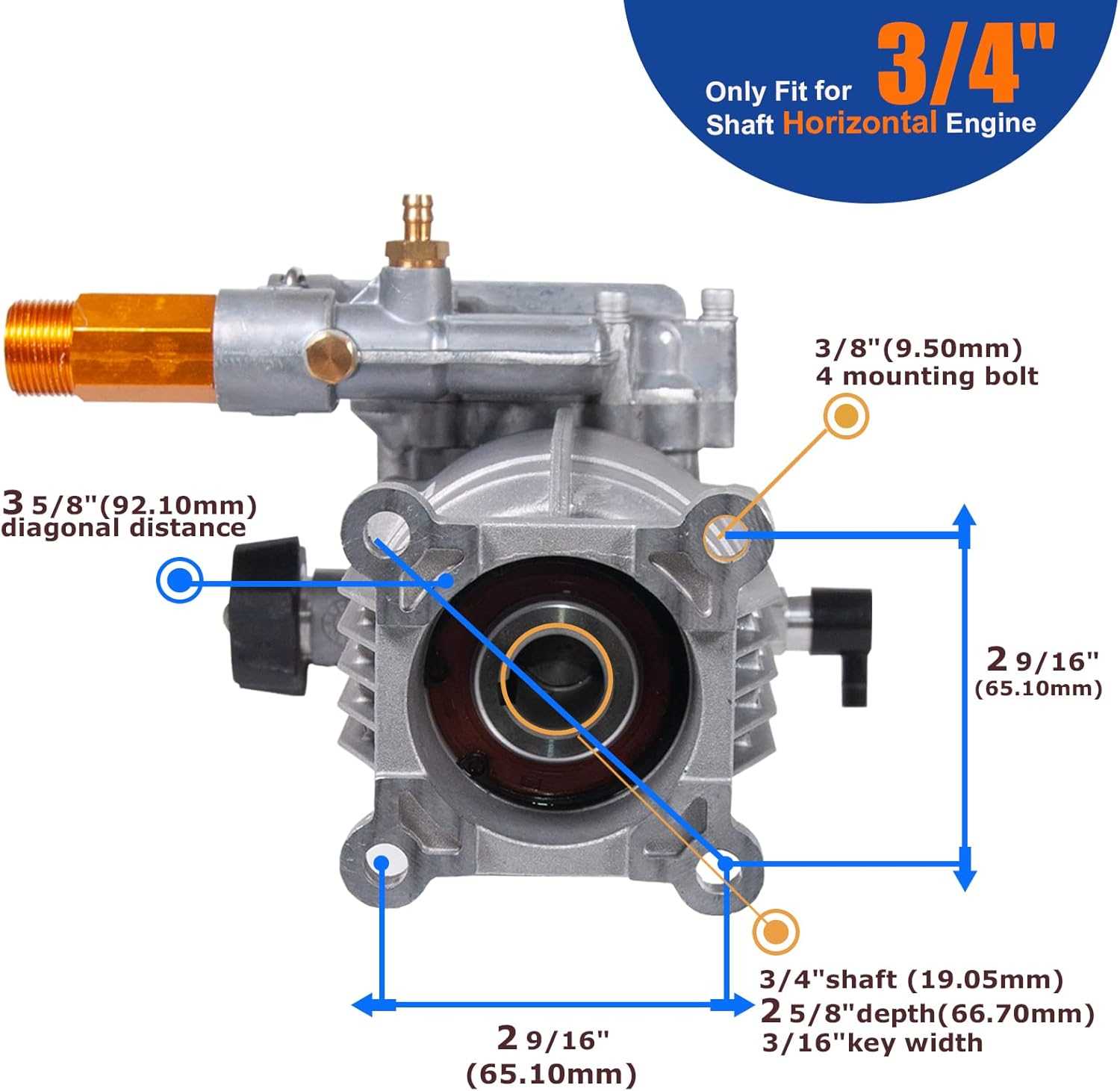

The engine serves as the heart of the system, providing the necessary power to drive the entire mechanism. Meanwhile, the pump acts as a critical intermediary, converting the engine’s energy into fluid motion, enabling effective cleaning performance. Another significant component is the spray gun, which directs the flow of water, allowing for varied pressure levels depending on the task at hand.

Furthermore, the hose is essential for delivering water from the source to the cleaning tool, ensuring flexibility and maneuverability during use. Accessories like nozzles allow users to customize their cleaning approach by altering the spray pattern and intensity. Each of these components contributes to the overall efficiency and effectiveness of the cleaning device.

Importance of Maintenance for Longevity

Proper upkeep is essential for ensuring the extended life and efficient performance of any equipment. Regular attention to maintenance tasks not only enhances functionality but also prevents unforeseen breakdowns that could lead to costly repairs. A proactive approach to care can significantly improve the overall user experience and reliability of machinery.

Routine checks and timely replacements of components are vital to sustaining optimal performance. Neglecting maintenance can result in diminished output, increased wear and tear, and potential safety hazards. By adhering to a scheduled maintenance plan, users can identify issues before they escalate, thus preserving the integrity of the equipment.

In conclusion, investing time and effort into regular maintenance activities is crucial for the longevity of machinery. Ensuring that all components are functioning correctly fosters not only operational efficiency but also enhances the lifespan of the equipment, leading to greater satisfaction and value over time.

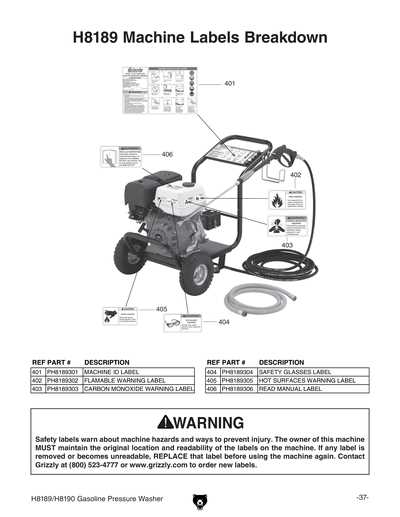

How to Read Parts Diagrams Effectively

Understanding component layouts is crucial for anyone looking to maintain or repair machinery. These visual representations provide insights into how individual elements fit together and function. By mastering the art of reading these illustrations, you can streamline your repair process and ensure the correct assembly of various components.

Familiarize Yourself with the Legend

Most visual guides include a legend that explains the symbols and notations used. Here are some steps to help you understand it:

- Locate the legend, usually positioned at the corner of the illustration.

- Identify the symbols corresponding to each element.

- Pay attention to any special notes regarding assembly or maintenance.

Follow the Sequence of Assembly

Diagrams typically display components in the order they should be assembled. To effectively navigate these instructions:

- Start from the base or main unit, then progress outward to smaller components.

- Observe the lines connecting different elements, which indicate how they interact.

- Check for any numbered steps or arrows that guide you through the process.

By applying these strategies, you can enhance your understanding of visual representations, making your repair tasks more efficient and accurate.

Step-by-Step Parts Replacement Guide

This section provides a comprehensive approach to replacing components in your cleaning equipment. Understanding the process not only enhances the longevity of the machine but also ensures optimal performance. Follow the detailed instructions below for a successful replacement experience.

| Step | Description |

|---|---|

| 1 | Begin by disconnecting the unit from its power source to ensure safety during the replacement process. |

| 2 | Identify the specific component that requires replacement. Refer to the user manual for guidance on the location and functionality of the part. |

| 3 | Gather the necessary tools, such as wrenches, screwdrivers, and any other equipment needed for the task. |

| 4 | Carefully remove the old component by unscrewing or unfastening it, taking care not to damage surrounding parts. |

| 5 | Install the new component, ensuring it fits securely and is properly aligned with other connected parts. |

| 6 | Reconnect any hoses or electrical connections that were detached during the replacement process. |

| 7 | Perform a thorough inspection to ensure everything is correctly in place before powering on the equipment. |

| 8 | Finally, test the machine to confirm that the new component is functioning properly and that there are no leaks or issues. |

Troubleshooting Common Issues in Pressure Washers

Many users encounter difficulties when operating their cleaning devices. Understanding potential problems and their solutions can enhance performance and prolong the lifespan of the equipment. This section provides insights into frequent challenges faced by users and offers practical approaches to resolve them effectively.

Identifying Common Problems

Several issues may arise during use, often stemming from mechanical or operational factors. Recognizing these problems is the first step in rectifying them.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Low Water Pressure | Blocked nozzle, insufficient water supply, worn-out seals | Clean the nozzle, check the water source, replace seals as needed |

| Device Won’t Start | Empty fuel tank, dead battery, faulty ignition | Refill fuel, charge the battery, inspect the ignition system |

| Strange Noises | Loose components, damaged motor, debris in the pump | Tighten loose parts, replace damaged motor, clear debris |

Regular Maintenance Tips

Implementing consistent upkeep can prevent many issues from occurring. Simple actions like regular cleaning, checking fluid levels, and inspecting hoses contribute to smoother operation and efficiency.

Safety Precautions When Operating Equipment

Ensuring safe usage of machinery is essential to prevent accidents and injuries. Adopting appropriate measures enhances both personal safety and equipment longevity. It is vital to understand the potential risks associated with operating heavy-duty devices and to take proactive steps to mitigate these hazards.

Always wear protective gear, including goggles, gloves, and sturdy footwear. This equipment serves as a barrier against debris and other hazards that may arise during operation. Additionally, ensure that your clothing is suitable and does not have loose ends that could become entangled.

Before initiating any task, thoroughly inspect the machinery for any signs of damage or wear. Pay attention to hoses, connections, and electrical components. If any issues are detected, refrain from using the equipment until it has been properly repaired. Regular maintenance is key to ensuring optimal performance and safety.

Familiarize yourself with the manufacturer’s instructions and guidelines. Understanding the operational features and recommended practices is crucial for safe handling. Never operate the machinery in enclosed spaces without adequate ventilation, as this could lead to hazardous conditions.

Lastly, always keep a safe distance from others while the equipment is in use. Establish a clear work zone to minimize the risk of accidental contact and ensure that bystanders are aware of your activities. Following these precautions will contribute to a safer working environment.

Comparing Different Models in the Series

This section aims to highlight the distinctions among various models within the series, focusing on their unique features and specifications. Understanding these differences is essential for selecting the right equipment for your needs.

When evaluating models, consider the following key aspects:

- Power Output: Different units may offer varying levels of power, impacting their efficiency in tackling specific tasks.

- Design Variations: Each model may exhibit unique design elements that influence usability and storage options.

- Accessories Included: Some versions come with additional attachments or features, enhancing their versatility.

- Weight and Portability: The weight of each model can affect ease of movement and storage.

- Warranty and Support: Different units may offer varying warranty periods and customer support options, which can be crucial for long-term use.

Ultimately, a comprehensive comparison will guide users in choosing the most suitable unit, ensuring optimal performance for a variety of cleaning tasks.

Where to Find Replacement Parts

When your cleaning equipment requires new components, locating suitable replacements can be crucial for maintaining its performance. Various resources are available to ensure you find the right items for your needs.

Manufacturer Websites: One of the most reliable sources is the official website of the equipment’s manufacturer. These sites often provide a comprehensive catalog of available components, including detailed specifications and diagrams to assist in identification.

Authorized Dealers: Local authorized dealers are another excellent option. They typically stock a range of components and can provide expert advice on the correct replacements. Additionally, they may offer warranty services, ensuring your equipment remains in optimal condition.

Online Retailers: Numerous online platforms specialize in selling components for various types of cleaning machinery. Websites like Amazon or dedicated parts retailers often have a vast selection, allowing you to compare prices and find the best deals. Make sure to check customer reviews for quality assurance.

Repair Shops: Local repair shops can be a valuable resource as well. These businesses often have access to components and can help identify what you need. They might also offer used or refurbished items at a lower cost.

Community Forums: Engaging with community forums or social media groups dedicated to cleaning equipment can provide insights into where others have successfully sourced components. Members may share their experiences and recommend trusted suppliers.

Tips for Efficient Pressure Washing

Achieving optimal results when using a high-powered cleaning device involves several key strategies. Understanding the techniques and maintaining the equipment will ensure thorough cleaning while maximizing efficiency. Here are essential tips to enhance your cleaning experience and outcomes.

Preparation Steps

Before commencing the cleaning task, it is crucial to prepare the area and the equipment. Start by removing any obstacles from the workspace to facilitate easy access. Next, inspect the device for any issues, such as leaks or worn-out components, to ensure smooth operation.

Choosing the Right Nozzle

Selecting the appropriate nozzle can significantly impact the effectiveness of your cleaning efforts. Different nozzles create varying spray patterns and pressures, suitable for various surfaces and tasks. A wider spray pattern is ideal for larger areas, while a narrower focus is more effective for tough stains.

| Nozzle Type | Recommended Use |

|---|---|

| 0-degree | Heavy-duty cleaning (e.g., concrete, brick) |

| 15-degree | Medium-duty tasks (e.g., decks, patios) |

| 25-degree | General cleaning (e.g., vehicles, siding) |

| 40-degree | Delicate surfaces (e.g., windows, painted surfaces) |

By following these tips and utilizing the correct techniques, you will enhance the effectiveness of your cleaning sessions and prolong the life of your equipment.

Frequently Asked Questions About Repairs

This section aims to address common inquiries regarding maintenance and troubleshooting procedures. Understanding how to properly care for and fix your equipment can enhance its longevity and performance. Below are some typical questions and their corresponding answers to assist you in your repair efforts.

- What are the signs that my machine needs repair?

Common indicators include:

- Inconsistent operation

- Unusual noises

- Leaks or excessive vibrations

- How often should I perform maintenance?

Regular maintenance is recommended every few months, depending on usage. Key tasks include:

- Inspecting hoses and connections

- Cleaning filters

- Checking for wear and tear

- Can I repair my equipment myself?

Many issues can be addressed with basic tools and knowledge. However, for complex problems, professional assistance may be advisable.

- What tools do I need for basic repairs?

Essential tools typically include:

- Wrenches

- Screwdrivers

- Pliers

- Replacement parts as needed

- Where can I find replacement components?

Replacement parts can be sourced from:

- Authorized dealers

- Online retailers

- Local hardware stores

Customer Reviews and Experiences

This section highlights the feedback and insights shared by users regarding their experiences with a particular cleaning device. Understanding customer perspectives can provide valuable information for potential buyers, helping them make informed decisions based on real-world usage.

User Feedback Summary

Many customers have expressed their satisfaction with the effectiveness and reliability of the device. Here are some common themes from their reviews:

- Ease of use: Users appreciate the intuitive design, which allows for straightforward operation.

- Cleaning performance: Many reviews highlight the powerful cleaning capabilities, making tough jobs easier.

- Durability: Several customers note the robust construction and long-lasting components.

Common Complaints

Despite the positive feedback, some users have reported a few concerns:

- Maintenance issues: A number of reviews mention difficulties with routine maintenance and part replacements.

- Noise levels: Some users found the operational noise to be higher than expected.

- Customer support: A few customers expressed dissatisfaction with the responsiveness of customer service.