When maintaining household equipment, understanding the internal structure is key to ensuring smooth operation. Proper knowledge of the various elements that come together within such systems can significantly improve the overall performance and extend the longevity of the machine. In this section, we will delve into how these elements work together in harmony, making it easier to identify and address potential issues.

Understanding the functionality of each component helps prevent unexpected breakdowns and ensures consistent, reliable usage over time. From the intricate mechanical elements to the more straightforward parts, this guide will explore each aspect in detail. By the end of this section, you will be equipped with the knowledge to make informed decisions about care and troubleshooting.

Whether you are looking to optimize the performance or troubleshoot issues, having a clear understanding of how each element contributes to the entire system is crucial. Let’s explore these key components and their role in ensuring the efficiency and durability of your household equipment.

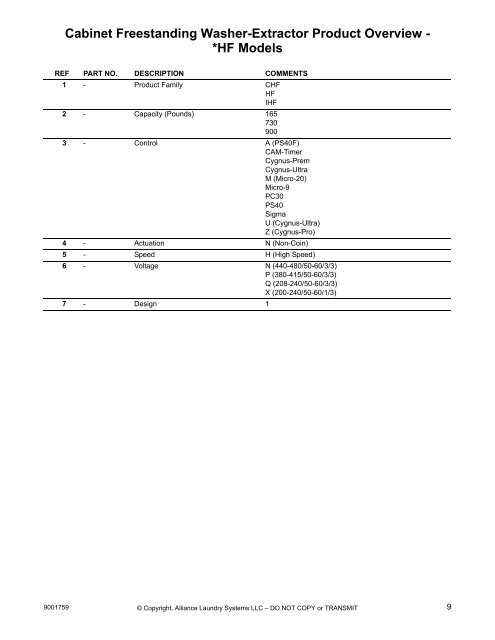

Understanding the Components of Unimac Washers

When it comes to maintaining efficient laundry systems, it’s essential to have a clear understanding of how the various mechanical and electrical elements work together. Each of these elements plays a crucial role in ensuring the smooth operation and longevity of the equipment, making it important to recognize their functions and how they contribute to the overall performance.

Key Mechanical Elements

The primary mechanisms that drive these machines include a complex network of rotating and moving parts. These components are responsible for creating the movement and force required for cleaning. Additionally, they ensure proper balance and stability during the operation, preventing excessive wear and tear on the system.

Electrical and Control Systems

The electronic control units manage the operation, enabling users to select various settings and monitor performance. These systems are equipped with sensors that detect issues, regulate power, and ensure safety. A well-maintained control system is vital for optimal efficiency and energy use.

Key Mechanical Parts of a Washer

The intricate machinery responsible for the operation of a cleaning appliance consists of several core components that work together to ensure proper functionality. Each element plays a vital role in delivering efficient and reliable performance, whether through controlling movement or managing water flow and temperature.

Main Structural Components

- Drum: The rotating chamber where items are placed. It spins to agitate clothes during the cycle, contributing to both cleaning and rinsing actions.

- Motor: This powers the drum’s rotation and adjusts the speed according to the selected cycle.

- Suspension system: A setup designed to balance the appliance during operation, reducing vibrations and ensuring smooth movement.

Water Management Systems

- Pump: Facilitates the draining of water from the machine at the end of each cycle, preventing overfilling.

- Valves: Regulate the entry and exit of water, ensuring the right amount is used for each stage of the process.

- Heating element: Warms the water to the necessary temperature for the cycle, improving the efficiency of the cleaning action.

How the Electrical System Powers the Machine

The electrical framework serves as the central force that drives the functionality of the equipment, ensuring its components work in harmony. From initiating movement to managing various cycles, this system is vital for the smooth operation of the entire process.

Energy Distribution and Control

At the core of the electrical setup is the distribution of energy. This power flow is carefully managed, ensuring that each component receives the necessary electricity to function efficiently. Control modules oversee this process, regulating the current to avoid overloading any part of the system.

Synchronization with Mechanical Components

The electrical system not only delivers power but also ensures precise synchronization with mechanical parts. Sensors and controllers work together to maintain the correct timing, making sure that all movements and operations are coordinated effectively for optimal performance.

Water Circulation and Drainage Mechanism

Efficient movement of water throughout the system is crucial for proper operation. The process relies on a combination of components that work together to manage both the inflow and removal of liquid, ensuring optimal performance.

Water Flow Path

The system initiates water intake through controlled channels, directing it to various sections. The liquid circulates through a specific route designed to maximize its reach, allowing the machine to perform efficiently while minimizing waste.

Drainage Operation

Once the cycle completes, the liquid is expelled through the drainage system. This process involves a set of valves and pumps that work in coordination to remove water from the machine, preventing any backflow or blockages.

| Component | Function |

|---|---|

| Inlet Valve | Controls the entry of water |

| Pump | Circulates and expels liquid |

| Drain Hose | Guides water out of the system |

Exploring the Drive Motor and Its Function

The drive motor plays a crucial role in the operation of various mechanical systems. It is responsible for converting electrical energy into the mechanical force needed to move and rotate components. Understanding how this essential element works helps in maintaining overall system efficiency and performance.

Core Purpose of the Drive Motor

The motor’s primary task is to generate motion, which is transferred to other parts of the machine. It works in harmony with other components to ensure smooth and precise movement, ensuring reliable performance. This process is vital for the proper functioning of the entire mechanism.

How the Motor Drives the System

By rotating at controlled speeds, the motor enables the system to operate under different settings, adapting to varying loads and conditions. It provides the necessary torque, ensuring the appropriate level of force is applied for optimal operation. Efficient management of these dynamics is key to long-term reliability.

| Component | Function |

|---|---|

| Motor Shaft | Transfers rotational force to the mechanical system |

| Control Module | Regulates the speed and direction of the motor |

| Bearings | Ensure smooth rotation and reduce friction |

Role of the Transmission in Washer Operation

The transmission is a crucial component that facilitates the efficient functioning of laundry appliances. It serves as a mechanical link between the motor and the drum, ensuring that the device operates smoothly during various cycles. By converting the motor’s rotational motion into the appropriate speeds and torque, the transmission plays a vital role in achieving optimal performance.

In addition to power transfer, the transmission is responsible for regulating the machine’s cycle speeds. This function is essential for different stages of the cleaning process, such as agitating and spinning. A well-designed transmission enhances the effectiveness of these cycles, leading to cleaner garments and improved water extraction.

| Transmission Function | Effect on Operation |

|---|---|

| Power Transfer | Connects motor to drum for effective functioning |

| Speed Regulation | Adjusts speed for various cleaning cycles |

| Torque Adjustment | Ensures proper force is applied for different fabrics |

Regular maintenance of the transmission is essential to prevent wear and tear, which can lead to operational issues. Ensuring that this component remains in good condition not only prolongs the lifespan of the appliance but also guarantees consistent cleaning results.

Control Panel and User Interface Overview

The control interface of a laundry appliance plays a crucial role in ensuring seamless operation and user interaction. This section delves into the essential components and functionalities that make up the command center, offering insights into how users can effectively manage their laundry processes.

Key Features of the Control Interface

Modern command panels are designed to enhance usability, featuring intuitive buttons and display screens. Users can easily navigate through various settings, allowing for precise adjustments tailored to specific fabric types and load sizes. The layout often includes indicators that provide real-time feedback on the operational status, ensuring that users remain informed throughout the washing cycle.

User-Friendly Design Elements

Incorporating ergonomic principles, the interface aims to minimize user effort while maximizing efficiency. Features such as touch-sensitive controls and visual prompts guide users through the selection process. Safety measures are also a priority, with options to lock controls to prevent unintended adjustments. This thoughtful design ensures a satisfying experience, making laundry tasks less daunting.

Internal Sensors and Their Importance

In modern appliances, internal sensors play a crucial role in ensuring optimal performance and reliability. These components are designed to monitor various functions and provide critical feedback to the system, enhancing efficiency and safety.

The functionality of these sensors can be attributed to their ability to:

- Detect temperature variations

- Monitor pressure levels

- Sense moisture content

- Ensure proper water flow

By gathering real-time data, these devices enable the system to make informed adjustments, preventing potential issues and extending the lifespan of the equipment. Their presence significantly contributes to maintaining the desired operational standards.

Moreover, internal sensors enhance user experience by:

- Reducing energy consumption through optimized processes

- Providing alerts for maintenance needs

- Improving overall safety by detecting malfunctions

In summary, the integration of internal sensors is vital for achieving consistent performance, ensuring user satisfaction, and prolonging the life of the appliance.

Seals and Bearings for Smooth Performance

Effective sealing and bearing components are essential for the optimal functioning of any mechanical system. These elements work together to reduce friction and prevent leaks, ensuring longevity and efficiency. Proper maintenance and timely replacement of these components can significantly enhance overall performance.

Seals serve as barriers, preventing fluid loss and protecting internal components from contaminants. Bearings, on the other hand, facilitate smooth motion between parts, minimizing wear and tear. Understanding their roles is crucial for maintaining operational excellence.

| Component | Description | Importance |

|---|---|---|

| Seals | Devices that prevent fluid leakage and block foreign particles | Essential for maintaining system integrity and performance |

| Bearings | Components that allow rotational or linear movement between surfaces | Critical for reducing friction and enhancing durability |

Common Replacement Parts for Unimac Models

In any machinery, certain components tend to wear out over time and may require swapping to ensure optimal functionality. Understanding these essential elements can significantly improve maintenance efforts and prolong the lifespan of the equipment.

Here are some of the frequently replaced components:

- Drum bearings: Critical for smooth rotation, these need periodic inspection and replacement.

- Seals and gaskets: Essential for preventing leaks and maintaining pressure within the system.

- Drive belts: These parts can stretch or wear down, leading to inefficiencies in operation.

- Control boards: Vital for regulating functions, any malfunction might necessitate a swap.

- Filters: Keeping these clean or replacing them ensures proper operation and prevents damage.

By regularly checking these elements and replacing them as needed, users can maintain high performance and reliability in their equipment.

Preventative Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life and optimal performance of your appliances. By implementing simple maintenance practices, you can prevent costly repairs and enhance efficiency. Below are several strategies that can be easily integrated into your routine.

| Tip | Description |

|---|---|

| Routine Cleaning | Keep the exterior and interior clean to prevent buildup that can lead to malfunctions. Use appropriate cleaning solutions and avoid abrasive materials. |

| Check Hoses | Regularly inspect hoses for signs of wear or leaks. Replace any damaged hoses promptly to prevent water damage and ensure proper operation. |

| Inspect Filters | Examine filters periodically and clean or replace them as needed. Clogged filters can restrict airflow and reduce efficiency. |

| Monitor Usage | Adhere to recommended usage guidelines to avoid overloading. Proper loading ensures balanced operation and prevents strain on components. |

| Schedule Professional Service | Consider having a qualified technician perform routine inspections and maintenance. Professional assessments can identify potential issues before they become significant problems. |