When maintaining or troubleshooting a home appliance, having a clear understanding of its internal elements is crucial. Knowing how each section functions allows for better care and more efficient resolution of issues. This guide will provide an overview of the various elements that contribute to the overall operation of your unit, ensuring you can recognize each function and manage potential concerns effectively.

Each section of the system plays an integral role in its overall performance. From controlling the flow of energy to managing temperature settings, understanding the layout and connections can significantly enhance your ability to maintain the unit over time. By familiarizing yourself with these aspects, you can ensure that your system runs smoothly and address any malfunctions swiftly.

Understanding the Components of GE Water Heaters

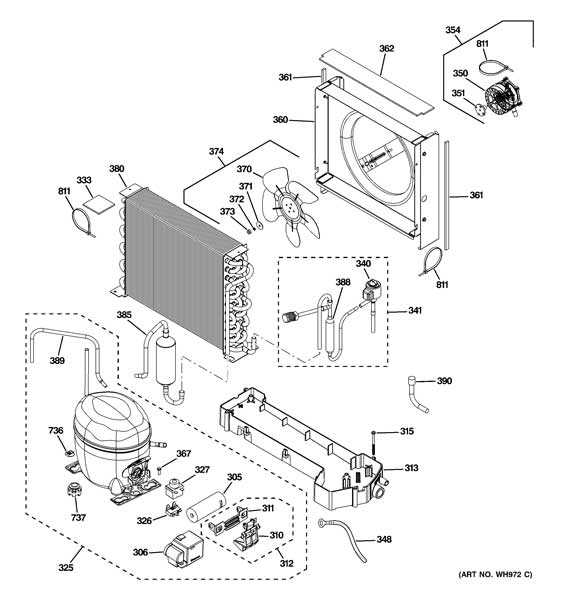

To fully appreciate how a GE system operates, it’s essential to recognize the individual elements that contribute to its functionality. Each component has a unique role in ensuring that the unit runs smoothly, delivering reliable performance over time.

These systems rely on several interconnected features that work together harmoniously. A deep understanding of these features can help in troubleshooting issues or maintaining the unit efficiently.

- Thermostat – Controls the temperature within the unit, ensuring optimal performance.

- Burner Assembly – Provides the necessary heat to the system, driving the entire process.

- Thermocouple – Acts as a safety device, shutting down the system if the flame goes out.

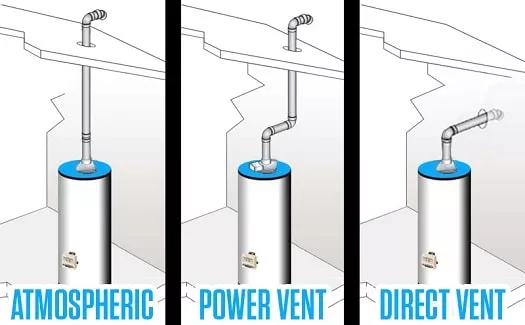

- Venting System – Responsible for the proper expulsion of exhaust gases.

- Control Valve – Regulates the flow of fuel, ensuring the unit operates efficiently.

Familiarizing yourself with these key elements not only helps in understanding the unit’s operation but also ensures better maintenance and decision-making when issues arise.

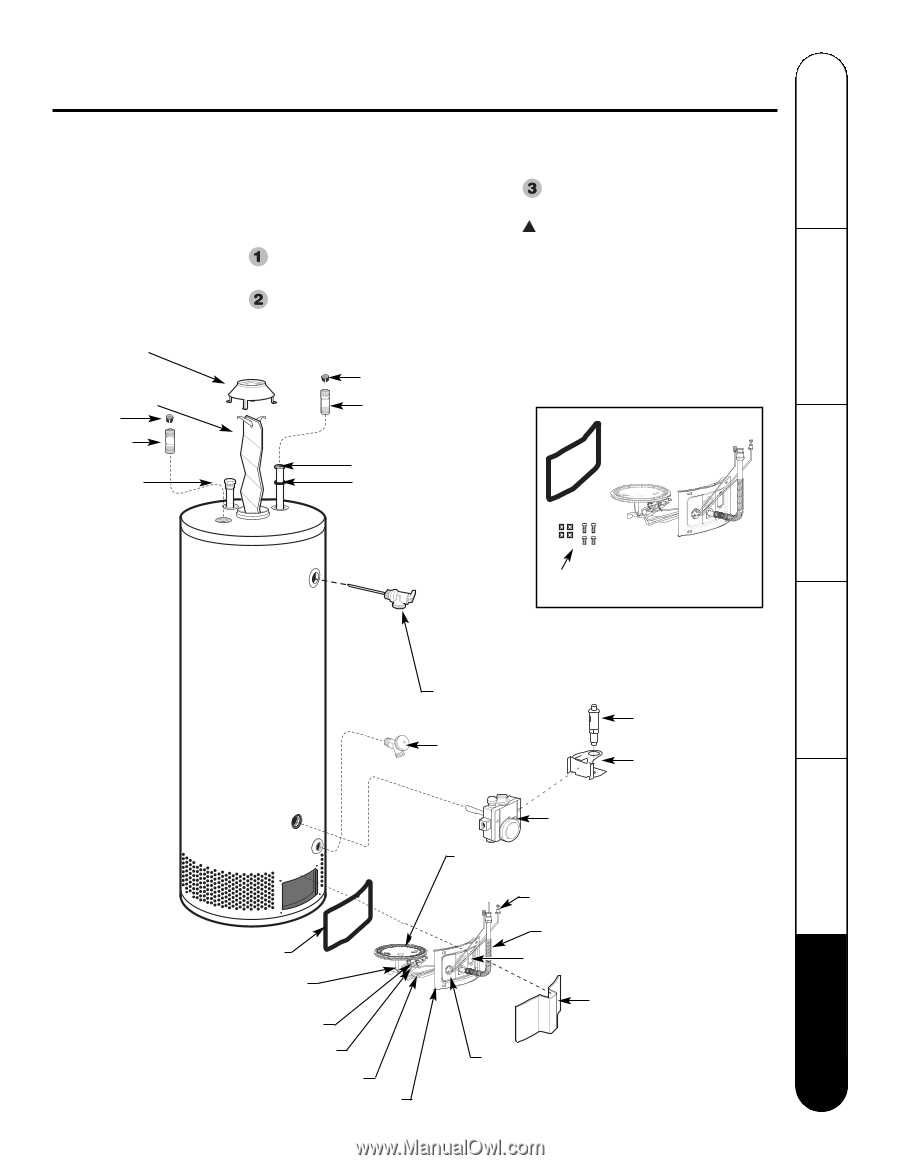

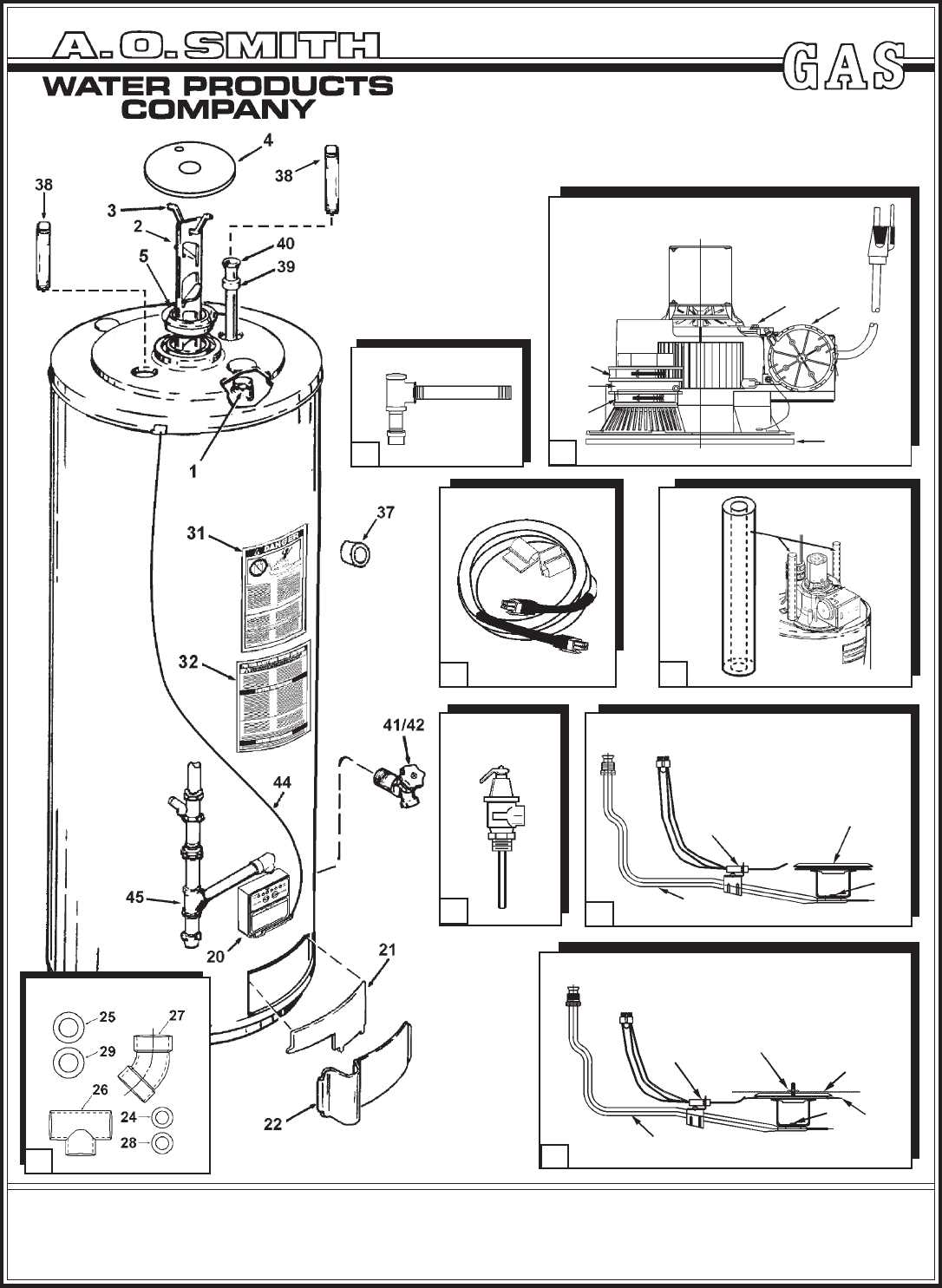

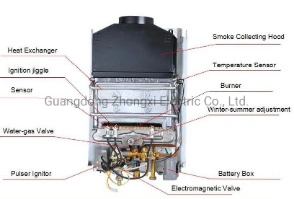

Key Parts of a Gas Water Heater

The main components of a heating system that uses fuel combustion to provide hot fluids are designed to ensure smooth operation, efficient energy transfer, and safe use. Each section plays a crucial role in the overall functionality of the device, working together to generate warmth and maintain a stable temperature.

Heating Mechanism

The burner assembly is the central element responsible for generating heat. When fuel is ignited, it creates a controlled flame that heats up the fluid circulating within the unit. This process requires a steady fuel supply and an ignition system to start the combustion process.

Temperature Control

Temperature regulation is handled by a thermostat, which monitors the fluid’s temperature. Once the desired warmth is reached, the system will shut off the burner to prevent overheating, ensuring safe and efficient operation.

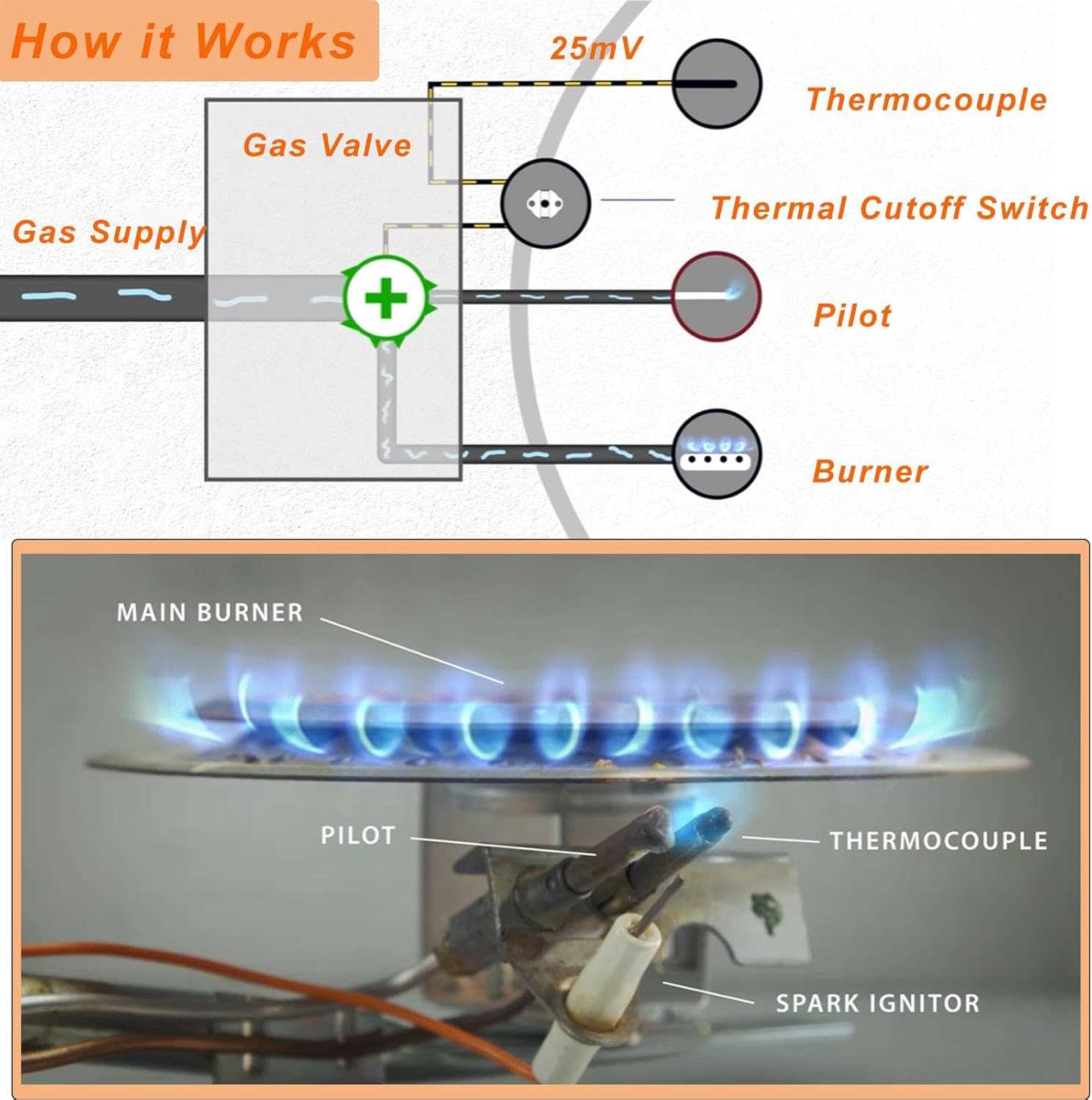

How the Ignition System Works

The ignition system plays a crucial role in initiating the combustion process. It is designed to create a spark or generate sufficient heat to start the reaction that produces the necessary energy. The system ensures that this process is both safe and efficient, allowing the device to function correctly when needed.

Typically, the ignition mechanism operates through a series of components that work together. First, a signal is sent to a spark-producing element or heating source, which then activates at the precise moment. This ensures that fuel is ignited correctly and without delay, providing optimal performance for the appliance.

Once the ignition is successfully initiated, the system monitors the ongoing process to prevent any potential issues. It continues to maintain control over the flame and fuel, ensuring that everything runs smoothly and efficiently, delivering the required energy output with minimal risk.

Importance of the Gas Control Valve

The control valve plays a crucial role in regulating the flow of energy to the unit. It ensures proper functioning by managing the release and adjustment of the fuel that powers the system. Without this component, the system would fail to operate efficiently or safely.

| Function | Impact |

|---|---|

| Regulates fuel flow | Ensures system runs smoothly and avoids overuse or underuse of energy |

| Maintains safety | Prevents fuel leaks or improper combustion, minimizing risks |

| Adjusts temperature | Provides the ability to control the system’s output based on need |

Detailed View of the Thermocouple

The thermocouple plays a crucial role in ensuring the safe and efficient operation of heating systems. It is a key component responsible for detecting temperature changes and facilitating important safety measures. Understanding its structure and function helps in identifying potential issues and performing necessary maintenance.

Here’s an overview of the essential features of the thermocouple:

- Material Composition: The thermocouple is typically made from two different metals that generate a voltage when exposed to heat.

- Connection Points: It is connected to a safety valve and a control system, acting as a sensor for temperature variations.

- Safety Function: The thermocouple ensures the system operates within safe temperature ranges, cutting off fuel supply when malfunctioning.

- Common Issues: Problems with the thermocouple include corrosion, breakage, or a weak electrical connection.

Regular inspection and maintenance of the thermocouple are essential to prevent system failures and ensure the longevity of the equipment.

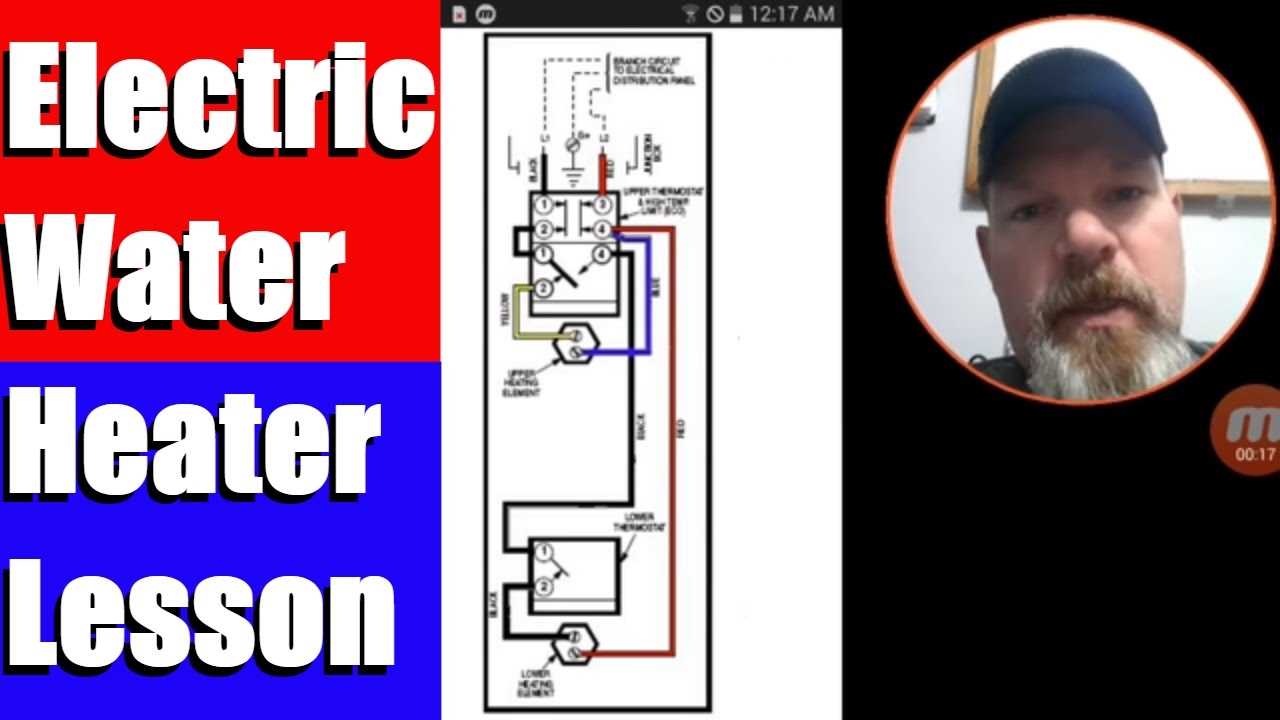

Heating Elements and Their Functions

Heating components play a crucial role in transforming energy into heat, which is essential for providing warmth in various systems. These devices are designed to convert electrical energy into thermal energy, ensuring that the desired temperature is reached and maintained efficiently. Understanding their functions helps to appreciate how they contribute to overall system performance.

Key Roles of Heating Components

- Convert electrical energy into heat for efficient temperature control.

- Provide consistent warmth through controlled heat distribution.

- Ensure safe operation by regulating temperature to prevent overheating.

Common Types of Heating Components

- Immersion elements – Direct contact with the fluid for quick heating.

- Tubular elements – Ideal for slow and steady heating in various systems.

- Flat heating units – Provide even heat distribution in specific applications.

Role of the Burner Assembly in Heating

The burner assembly plays a crucial role in the overall process of converting fuel into heat energy. It is responsible for igniting the fuel and ensuring a consistent and efficient combustion, which directly impacts the effectiveness of the entire system. Without a well-functioning burner, the heating system would fail to operate efficiently, leading to increased energy consumption and reduced performance.

Key Functions of the Burner Assembly

- Ignition of the fuel: The burner assembly is responsible for starting the combustion process by igniting the fuel source.

- Controlled combustion: It ensures that the fuel burns in a controlled manner, producing the right amount of heat.

- Efficient heat transfer: The assembly helps to direct the generated heat towards the system, facilitating effective warmth distribution.

Impact on Energy Efficiency

A well-designed burner assembly maximizes energy efficiency by ensuring complete combustion. This minimizes wasted energy and reduces the amount of fuel needed to achieve the desired heating. Regular maintenance and proper adjustments of the burner can help maintain its efficiency over time, contributing to lower energy costs and a more sustainable system.

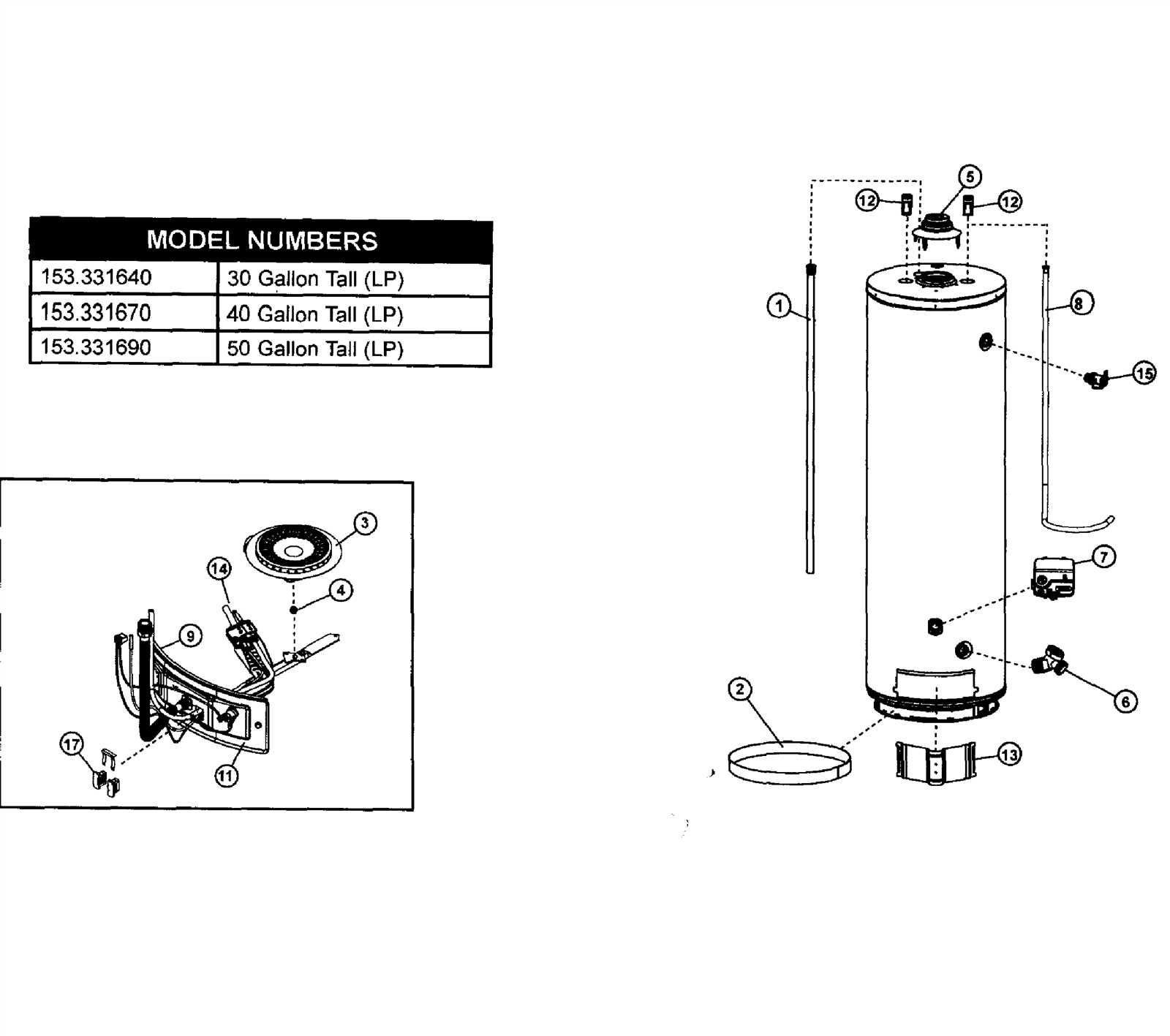

Analyzing the Tank Construction

Understanding the structure of the container used for storing heated liquids involves looking at its composition and the elements that ensure efficiency and durability. The internal and external features play a critical role in how well the system performs and how long it lasts under various conditions.

Key Components of the Storage Vessel

- Insulation: This layer is crucial for maintaining temperature, minimizing heat loss and improving overall energy efficiency.

- Exterior Shell: The outer casing is designed to protect the inner components from external damage and environmental factors.

- Internal Lining: This part protects the vessel from corrosion and extends its lifespan by preventing chemical reactions with the stored liquid.

Structural Considerations

- Material Strength: The choice of materials affects the strength, longevity, and resistance to wear and tear of the container.

- Design Efficiency: Proper design ensures that the vessel maintains uniform heat distribution, enhancing performance and safety.

- Maintenance Access: Easy access for repairs and inspections is a key factor in ensuring long-term functionality.

Safety Features in GE Gas Water Heaters

Modern units from GE are designed with several critical safety mechanisms that ensure efficient operation while minimizing risks. These systems focus on maintaining secure performance, preventing potential hazards, and offering peace of mind for users.

Thermostatic Controls are built into the system to regulate temperature and avoid overheating. This feature automatically shuts down the device if the temperature exceeds a set limit, protecting against accidental burns or excessive heat exposure.

Another important safety function is the flame monitoring sensor. This component detects whether the ignition source is functioning properly. If an issue arises, it will stop the operation, preventing dangerous situations such as the buildup of unburned fuel.

Anti-corrosion technology helps protect internal elements from wear and tear, reducing the likelihood of system malfunctions. This contributes to the overall longevity of the unit and helps avoid potential leaks that could lead to hazardous conditions.

Flow Control and Heat Distribution

The management of fluid movement and the even spread of warmth are essential for optimal performance in any system. Proper regulation ensures that every part receives the required level of energy, maintaining consistent operation and enhancing efficiency. This balance is achieved through carefully designed mechanisms that direct the flow while managing temperature fluctuations.

Efficient flow control plays a critical role in distributing heat uniformly across the entire setup. By ensuring the right volume of fluid moves through the system at the correct rate, heat is spread evenly, preventing hot spots and ensuring a stable output. The design of these components directly impacts the system’s ability to provide consistent warmth where needed.

Maintenance Tips for Long-Lasting Performance

To ensure optimal function and extend the lifespan of your appliance, regular upkeep is essential. Simple actions can prevent common issues and ensure that the device operates efficiently over time. Here are key tips to keep in mind for maintaining top performance.

Regular Cleaning

Cleaning the appliance periodically helps to remove buildup that can affect its efficiency. Pay special attention to areas that are prone to accumulation, such as vents and filters. A thorough cleaning routine prevents malfunctions and improves overall energy efficiency.

Check for Leaks

Inspecting for leaks is crucial to prevent any damage to surrounding surfaces and to maintain the appliance’s function. Small leaks can lead to larger problems if left unnoticed, so addressing them promptly ensures a longer lifespan.

Pro Tip: Always consult the user manual for recommended cleaning methods and check-ups to avoid voiding warranties or causing unintentional damage.

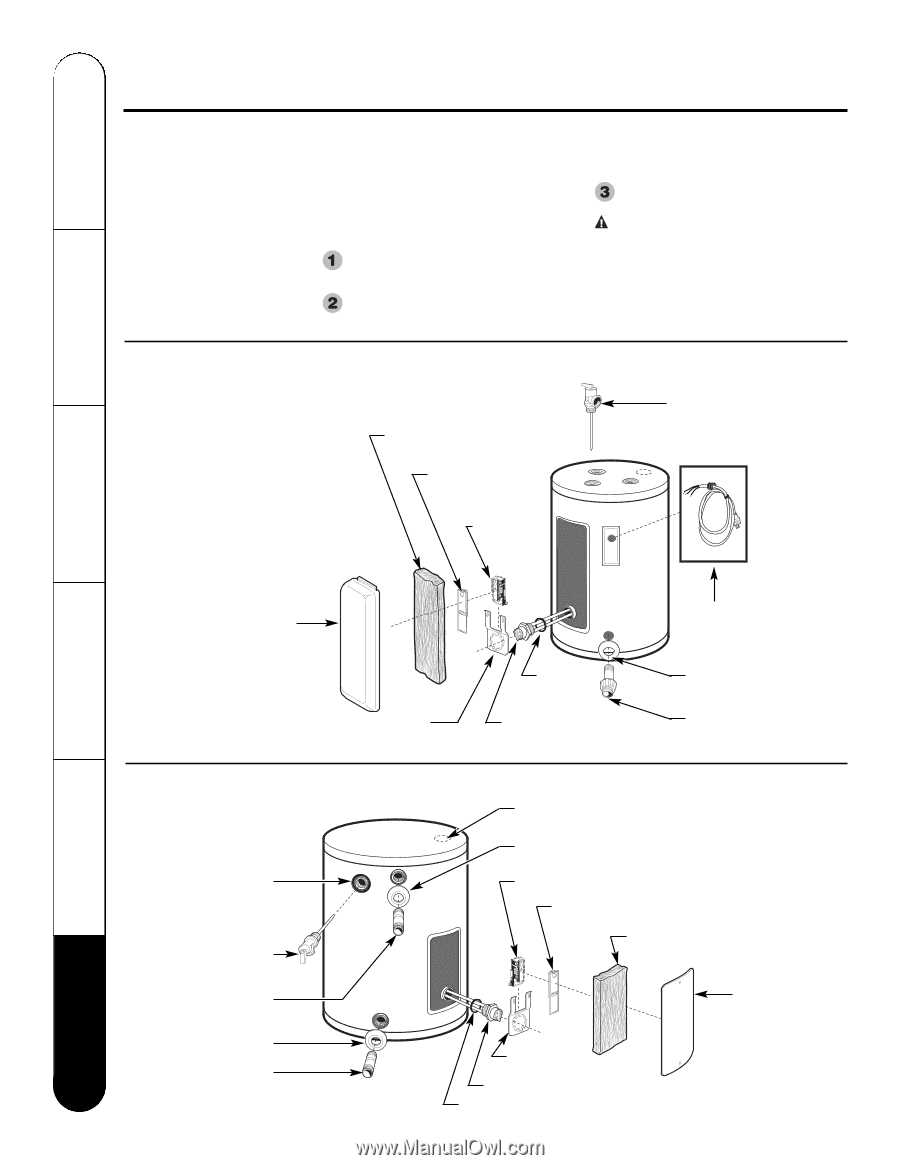

Replacing Components in Your Heating System

Maintaining the efficiency of your heating system involves timely replacement of certain elements. Over time, certain components may wear out or malfunction, leading to reduced performance. Identifying and replacing these crucial elements can restore the system’s functionality and ensure a steady flow of warmth throughout your space.

Here are some essential steps to consider when replacing these critical elements:

- Turn off the main supply to avoid any electrical or fluid hazards.

- Drain any remaining liquid if necessary to ensure a safe working environment.

- Identify the worn-out components by inspecting for leaks, unusual noises, or heating issues.

- Choose high-quality replacement items that are compatible with your system for optimal performance.

- Install the new components carefully, following the manufacturer’s guidelines.

- Test the system to confirm that everything is functioning as expected.

Regular maintenance and timely replacement of these elements are key to prolonging the life of your system and avoiding more costly repairs down the line.