In any complex system designed for thermal management, a thorough grasp of individual elements is essential. Each component plays a vital role, contributing to the overall functionality and efficiency of the entire unit. Understanding these elements allows for better maintenance and troubleshooting, ensuring optimal performance.

The intricacies involved in such systems often lead to confusion. By exploring the various features and their relationships, one can demystify the inner workings and enhance operational knowledge. This exploration highlights the importance of each segment, underscoring their interdependence.

Delving into these details not only aids in identifying potential issues but also fosters a deeper appreciation for the technology behind them. Whether for repair or upgrade, recognizing the significance of every component is the ultimate step towards ensuring longevity and reliability.

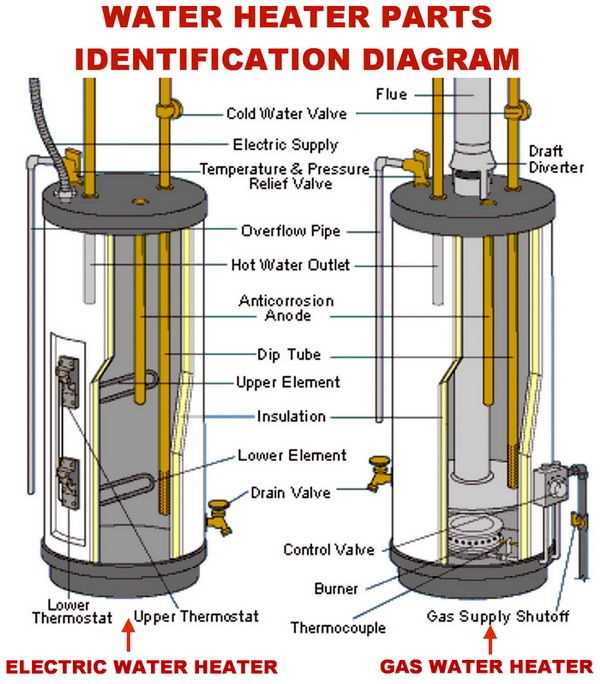

Understanding Water Heater Components

Grasping the various elements of a heating system is essential for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance, contributing to both energy efficiency and longevity. Familiarity with these components enables users to identify potential issues and understand how they work together to provide reliable service.

The primary element often found in such systems is the heating mechanism, which is responsible for elevating the temperature of the fluid. In conjunction with this, the storage unit holds the heated substance until it is needed, while the control systems regulate the temperature and pressure to ensure safe operation. Additionally, insulation materials are utilized to minimize energy loss, enhancing overall efficiency.

Other significant components include safety devices that prevent overheating and excessive pressure buildup, ensuring user safety and equipment reliability. Understanding the functions and interactions of these elements fosters a comprehensive knowledge of how heating systems operate, facilitating better maintenance practices and informed decision-making when issues arise.

Common Parts of Rheem Models

Understanding the essential components of popular appliance models can enhance maintenance and troubleshooting efforts. Familiarity with these elements ensures efficient operation and longevity.

Essential Components

- Thermostat: Regulates temperature for optimal performance.

- Heating Element: Provides the necessary heat for operation.

- Pressure Relief Valve: Ensures safety by preventing excessive pressure buildup.

- Tank Insulation: Maintains temperature and improves energy efficiency.

- Drain Valve: Facilitates easy draining for maintenance.

Additional Features

- Anode Rod: Protects against corrosion and extends lifespan.

- Control Panel: Centralized interface for settings and monitoring.

- Electrical Connections: Vital for powering various components.

Importance of Regular Maintenance

Consistent upkeep of heating systems is essential for optimal performance and longevity. By conducting regular inspections and servicing, one can ensure that all components operate efficiently, reducing the risk of unexpected failures and costly repairs.

Benefits of Routine Checks

Implementing a schedule for maintenance activities leads to several advantages, including enhanced safety, improved energy efficiency, and prolonged lifespan of the unit. Regular evaluations help identify potential issues before they escalate, promoting a smoother operation.

Key Maintenance Tasks

Essential tasks include checking for leaks, inspecting electrical connections, and cleaning filters. Each of these actions contributes significantly to maintaining efficiency and preventing damage.

| Task | Frequency | Benefits |

|---|---|---|

| Inspect Seals | Annually | Prevents leaks |

| Clean Components | Biannually | Enhances efficiency |

| Check Electrical Connections | Annually | Improves safety |

Identifying Heating Element Functions

Understanding the role of various components in a thermal system is essential for effective operation and maintenance. The heating elements are critical in generating and regulating warmth, ensuring that the system performs optimally to deliver the desired output.

Key Characteristics of Heating Elements

Heating elements are typically made from materials that can withstand high temperatures while providing efficient heat transfer. Their design often includes features that enhance durability and performance, allowing for consistent functionality over time.

Maintenance and Troubleshooting

Regular inspection of heating elements is vital to identify any signs of wear or malfunction. Preventative maintenance can extend the lifespan of these components, while addressing issues promptly can help maintain overall efficiency. Understanding how these elements function aids in diagnosing problems and implementing effective solutions.

How to Replace Thermostats

Changing temperature regulation devices is essential for maintaining optimal functioning of heating systems. This process ensures that the environment remains comfortable and energy-efficient. Here’s a straightforward guide to assist you in executing this task effectively.

| Step | Description |

|---|---|

| 1 | Turn off the power supply to the system to prevent any electrical hazards. |

| 2 | Remove the access panel to expose the regulating device. |

| 3 | Carefully disconnect the wires from the existing device, noting their positions. |

| 4 | Install the new device by connecting the wires as previously noted. |

| 5 | Replace the access panel and restore power to the system. |

Following these steps will ensure a successful replacement, leading to improved performance and reliability of the heating system.

Exploring Insulation and Safety Features

Understanding the importance of thermal barriers and protective mechanisms is essential for ensuring efficient operation and user safety in various appliances. These elements play a critical role in maintaining optimal temperatures while minimizing energy loss and preventing accidents.

Importance of Thermal Barriers

Effective insulation significantly reduces heat transfer, enhancing energy efficiency. By creating a protective layer, these materials not only help maintain the desired temperature but also lower operational costs, benefiting both the environment and the consumer’s wallet.

Safety Mechanisms

Safety features, such as automatic shut-off systems and pressure relief valves, are vital for preventing hazardous situations. These components work in tandem with insulation to ensure that any potential issues are addressed promptly, safeguarding users from risks associated with excessive heat or pressure buildup.

Common Issues with Rheem Units

Understanding the typical challenges faced by these devices is essential for effective maintenance and troubleshooting. Many users encounter similar malfunctions that can disrupt functionality and efficiency.

Temperature Fluctuations: One frequent complaint involves inconsistent temperatures, which may stem from various sources, including faulty thermostats or sediment buildup.

Noisy Operation: Unusual sounds, such as rumbling or popping, often indicate underlying problems. These noises can result from mineral accumulation or failing components that require attention.

Leakage: Water pooling around the unit is a sign of potential leaks. Identifying the source promptly can prevent further damage and costly repairs.

Inadequate Heating: Users may experience insufficient heat output. This issue might be linked to elements that are worn out or not functioning correctly, leading to poor performance.

Power Supply Problems: Devices may fail to operate due to electrical issues, such as tripped breakers or faulty connections. Regular checks can help mitigate these concerns.

Addressing these common issues can extend the lifespan of the unit and ensure reliable performance, making it essential for users to stay informed about maintenance practices.

Understanding Temperature Control Mechanisms

Effective regulation of thermal conditions is essential for optimizing performance and ensuring safety in various systems. This involves the intricate interplay of various components designed to monitor and adjust heat levels, maintaining a consistent and comfortable environment.

Control units play a pivotal role in this process. They utilize sensors to detect fluctuations in temperature, relaying information to the main system to trigger adjustments as necessary. These sensors are typically calibrated to respond to specific thresholds, ensuring precise operation.

Moreover, thermostatic devices are integral to maintaining desired thermal parameters. By activating or deactivating energy sources based on the readings from the sensors, they help sustain optimal conditions. This mechanism not only enhances efficiency but also prolongs the lifespan of the overall system.

Additionally, user interfaces allow users to set preferences easily, facilitating direct interaction with the temperature control mechanisms. Through intuitive controls, individuals can customize their experience, contributing to greater satisfaction and energy conservation.

Wiring Configurations for Rheem Models

This section explores the various electrical arrangements utilized in specific models, emphasizing the significance of proper connections for optimal performance and safety. Understanding these configurations is essential for effective maintenance and troubleshooting.

Common Connection Types

Several prevalent connection types are utilized across different models, each serving a unique function. Familiarity with these types aids in ensuring correct setup and repairs.

| Connection Type | Description |

|---|---|

| Line Voltage | Provides the primary power source, essential for operation. |

| Grounding | Ensures safety by preventing electrical shock and malfunctions. |

| Control Circuit | Regulates the operation and functionality of the system. |

Importance of Accurate Wiring

Maintaining accurate wiring configurations is crucial for the longevity and efficiency of the unit. Regular inspections and adherence to guidelines ensure that all connections remain secure and functioning as intended.

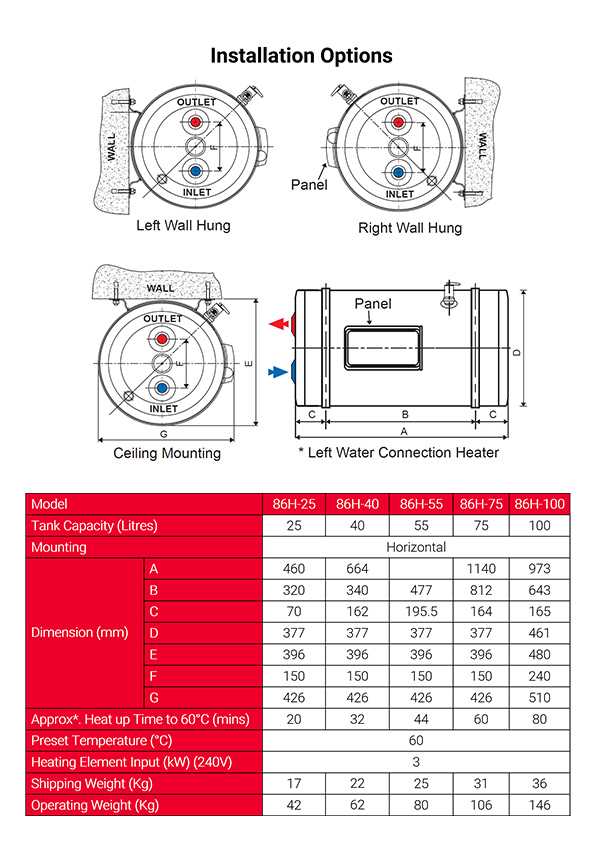

Water Inlet and Outlet Connections

Understanding the flow pathways for liquid in heating systems is essential for optimal performance. These pathways facilitate the entry and exit of fluid, ensuring efficient operation and temperature regulation.

Functionality of Fluid Entry

The inlet serves as the primary access point for incoming fluid, allowing it to reach the heating mechanism. Proper installation and maintenance of this entry point are crucial to avoid issues such as leaks or pressure drops.

Role of Fluid Exit

The outlet is equally significant, allowing heated fluid to exit the system and provide necessary warmth to designated areas. Ensuring this pathway is clear and properly connected enhances overall efficiency.

| Connection Type | Description |

|---|---|

| Inlet Valve | Controls the flow of incoming liquid. |

| Outlet Valve | Regulates the release of heated liquid. |

| Piping | Conducts fluid between entry and exit points. |

Inspecting Anode Rod Conditions

Regular assessment of protective elements within a storage unit is essential for ensuring longevity and optimal functionality. One critical component in this regard is the sacrificial rod, which helps to mitigate corrosion and enhance the overall lifespan of the system.

Signs of Degradation

When evaluating the condition of the sacrificial rod, look for signs such as significant wear or pitting. A rod that has become excessively corroded indicates it may no longer effectively serve its purpose. In such cases, timely replacement is advisable to prevent further damage to internal surfaces.

Maintenance Recommendations

To maintain the integrity of the protective rod, consider periodic inspections at least once a year. Ensuring that this component is intact and functioning properly can prevent costly repairs down the line. Additionally, consult the manufacturer’s guidelines for specific recommendations on service intervals and replacement procedures.

Energy Efficiency Tips for Homeowners

Improving energy efficiency in residences not only reduces utility bills but also contributes to a sustainable environment. Implementing simple strategies can lead to significant savings and enhanced comfort within the home.

Smart Usage Practices

- Adjust thermostat settings to reduce energy consumption when the home is unoccupied.

- Utilize programmable or smart thermostats for optimal temperature control.

- Seal any gaps or leaks around doors and windows to prevent heat loss.

Maintenance and Upgrades

- Regularly inspect and clean appliances for optimal performance.

- Consider investing in high-efficiency models when replacing older equipment.

- Insulate pipes and tanks to minimize heat loss in delivery systems.