Exploring the intricacies of assistive technology reveals a complex interplay of elements designed to enhance the user experience. Each component plays a crucial role in ensuring optimal functionality and comfort for individuals relying on these devices for mobility. Analyzing these essential features not only highlights their significance but also fosters a deeper appreciation for the engineering behind them.

Within this framework, comprehending how each section operates in harmony with others is vital. From propulsion mechanisms to supportive frameworks, every aspect contributes to the overall performance and safety of the apparatus. This examination empowers users, caregivers, and technicians to make informed decisions regarding maintenance and upgrades.

Ultimately, gaining insights into these essential components aids in navigating the landscape of mobility solutions. Whether for personal use or professional assistance, understanding the intricate designs leads to enhanced usability and a more fulfilling experience for those who rely on these remarkable devices.

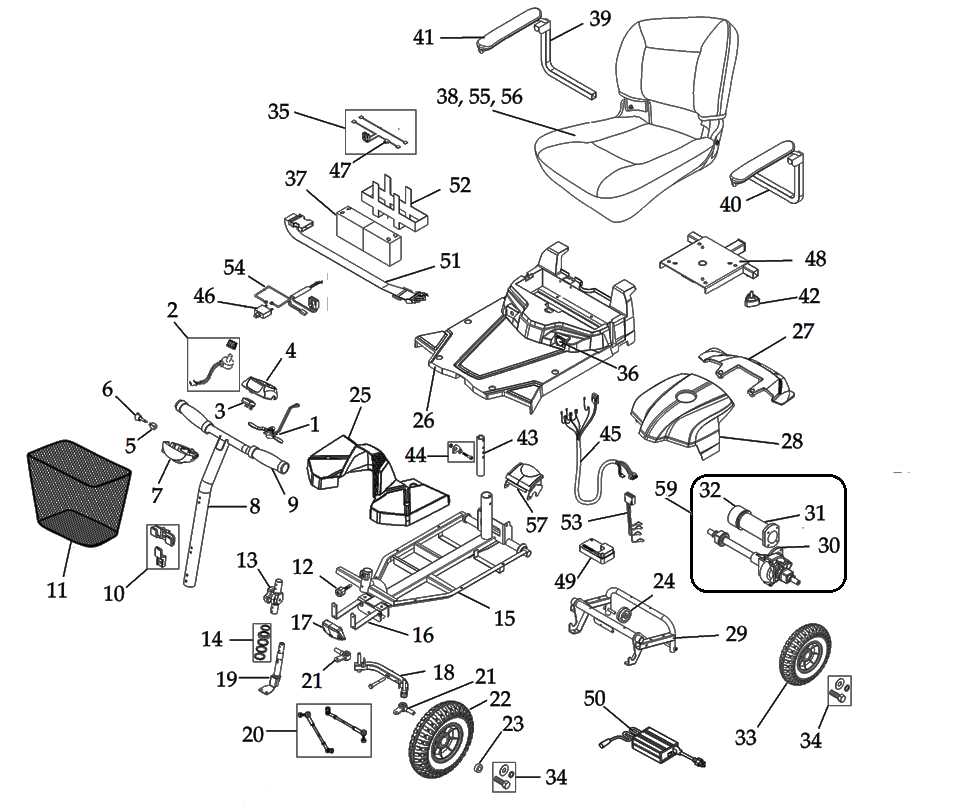

Understanding Drive Wheelchair Components

Exploring the essential elements that contribute to the functionality and performance of mobility aids provides a deeper appreciation of their design. Each component plays a critical role in ensuring smooth operation and user comfort. Understanding these features can enhance maintenance and overall user experience.

Key Elements

- Chassis: The framework that supports the entire structure, ensuring stability and durability.

- Wheels: Integral for movement, they come in various sizes and types to cater to different terrains.

- Motors: The driving force behind mobility, converting energy into motion.

- Battery: Powers the device, influencing range and efficiency.

- Control System: Enables the user to steer and navigate effectively, often equipped with intuitive interfaces.

Importance of Each Component

- Chassis: A robust frame provides the necessary support and contributes to safety during operation.

- Wheels: Selecting the right type enhances maneuverability and comfort, especially in diverse environments.

- Motors: High-quality motors ensure reliability and performance, making them crucial for long-term use.

- Battery: Understanding battery capacity can prevent inconveniences and ensure sufficient power for daily activities.

- Control System: An intuitive design promotes independence, making navigation easier for users.

Essential Parts of Wheelchair Drives

Understanding the key components that enable mobility for users is crucial for both users and caregivers. These fundamental elements work together to ensure smooth operation and provide support, comfort, and safety. A closer examination reveals how each piece contributes to overall functionality and user experience.

Main Components

Several critical elements play a significant role in the efficiency of mobility aids. Each of these contributes to performance, comfort, and reliability, enhancing the overall user experience.

| Component | Description |

|---|---|

| Frame | The structure that supports the entire system, providing durability and stability. |

| Wheels | Facilitate movement; their size and material can greatly affect maneuverability. |

| Brakes | Essential for safety, allowing users to stop securely and remain stationary. |

| Seating | Designed for comfort and support, ensuring proper posture during use. |

| Footrests | Provide support for the legs, enhancing comfort and preventing fatigue. |

Importance of Each Element

Each component is integral to the mobility experience. A well-constructed frame ensures that the entire unit remains reliable under various conditions. The choice of wheels affects not just ease of movement but also the terrain suitability. Effective braking systems enhance user confidence, while a comfortable seating arrangement is vital for prolonged use. Lastly, adequate foot support is necessary to prevent discomfort and potential injury, demonstrating the importance of every aspect in achieving optimal functionality.

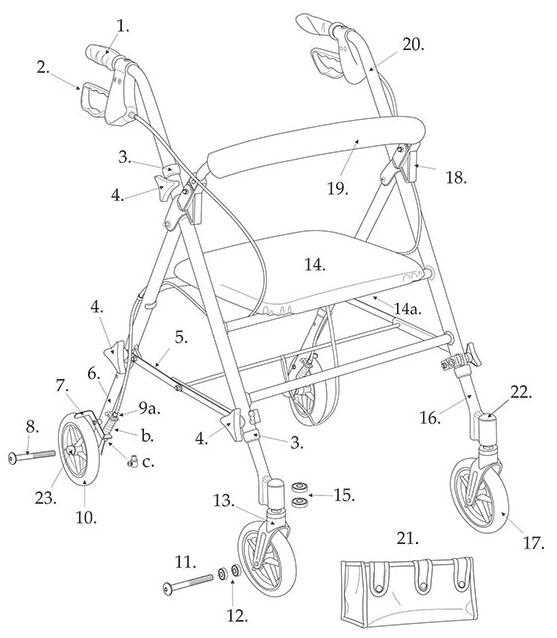

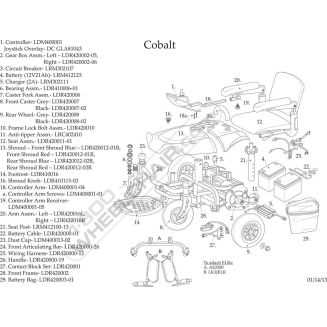

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to identify and work with various elements. Familiarizing yourself with the symbols, labels, and structure of these visuals is essential for effective navigation and problem-solving.

Key Elements to Focus On

- Symbols: Each component typically has a unique symbol. Familiarize yourself with common representations to easily recognize them.

- Labels: Descriptive titles often accompany symbols. Read these carefully to understand the function and specifications of each part.

- Connections: Look for lines or arrows that indicate how different elements interact. Understanding these connections is crucial for grasping the overall system.

Steps for Effective Interpretation

- Start by identifying the legend or key, which explains the symbols used.

- Examine the layout to understand the flow and arrangement of components.

- Take note of any annotations or notes that provide additional information.

- Cross-reference with user manuals or other resources for further clarification.

With practice, you’ll become adept at deciphering these visuals, making your repair or assembly tasks more straightforward and efficient.

Common Drive System Configurations

In the realm of mobility solutions, various arrangements of propulsion mechanisms play a crucial role in enhancing user experience and functionality. Understanding these configurations can help in selecting the most suitable system based on individual needs and environmental conditions.

Front-wheel propulsion is a popular choice, where the power source is located at the front. This setup offers excellent maneuverability, making it ideal for indoor use. However, it may struggle on uneven terrains.

Rear-wheel propulsion is another prevalent configuration. It provides stability and better traction on various surfaces. Users often appreciate the smoother ride this arrangement delivers, especially on outdoor paths.

Mid-wheel propulsion offers a unique balance by placing the power mechanism centrally. This design allows for tight turns and excellent maneuverability in confined spaces, making it suitable for both indoor and outdoor settings.

Each configuration has its distinct advantages, and the choice depends on specific preferences, mobility requirements, and anticipated usage scenarios.

Maintaining Drive Mechanisms Effectively

Ensuring the longevity and reliability of mobility solutions requires consistent care and attention. Regular maintenance helps to prevent wear and tear, enhancing performance and safety. By implementing a systematic approach to upkeep, users can extend the lifespan of their mobility equipment and ensure optimal functionality.

Key Maintenance Practices

Establishing a routine is crucial for the upkeep of mobility systems. Here are some essential practices:

| Task | Frequency | Description |

|---|---|---|

| Lubrication | Monthly | Apply appropriate lubricant to moving components to reduce friction. |

| Inspection | Weekly | Check for any signs of damage or wear, including cables and motors. |

| Cleaning | Bi-weekly | Remove dirt and debris from surfaces to maintain performance. |

| Battery Check | Monthly | Ensure the power source is functioning correctly and holds a charge. |

Common Issues and Solutions

Understanding potential problems can aid in prompt resolution. Here are some frequent challenges and their remedies:

| Issue | Solution |

|---|---|

| No response | Check power supply and connections; replace if necessary. |

| Unusual noises | Inspect for loose components and apply lubricant as needed. |

| Stalling | Evaluate weight limits and check for obstructions in the path. |

Identifying Drive System Failures

Recognizing issues within the propulsion mechanism is crucial for ensuring optimal performance and safety. Early detection of irregularities can prevent more severe complications and enhance the longevity of the mobility aid. Understanding the common signs of malfunction helps users maintain functionality and independence.

Common Symptoms of Malfunction

Several indicators may suggest that the propulsion system is not functioning properly. Users should be vigilant about the following symptoms:

| Symptom | Description |

|---|---|

| Unusual Noises | Grinding, squeaking, or clunking sounds can indicate internal wear or misalignment. |

| Inconsistent Speed | Difficulty maintaining a steady pace may suggest issues with the motor or power supply. |

| Reduced Responsiveness | Delayed reactions to controls may point to electrical or mechanical problems. |

| Vibrations | Excessive shaking during operation could indicate imbalance or component degradation. |

Steps for Diagnosis

Once symptoms are identified, users can follow a few key steps to diagnose the problem effectively. First, inspect the system for visible damage or wear. Next, check the power source to ensure it is functioning correctly. Finally, if basic checks do not reveal the issue, consulting a professional technician may be necessary for a thorough evaluation.

Upgrading Wheelchair Drive Systems

Enhancing mobility aids can significantly improve the user experience, ensuring greater comfort and efficiency. Whether for personal use or to meet specific needs, upgrading components can lead to better performance and reliability. Understanding the available options is crucial for making informed decisions.

Benefits of Upgrading

- Improved maneuverability in various environments.

- Increased speed and responsiveness for greater independence.

- Enhanced comfort through better suspension and seating arrangements.

- Reduced maintenance costs with modern technology.

Key Components to Consider

- Motors: Higher torque and efficiency can significantly enhance performance.

- Batteries: Opt for longer-lasting options to extend usage time between charges.

- Controllers: Advanced systems provide better handling and customization of settings.

- Wheels and Tires: Selecting appropriate types can improve traction and comfort.

By focusing on these elements, individuals can tailor their mobility solutions to better meet their specific needs, enhancing both functionality and enjoyment in everyday activities.

Safety Features in Drive Components

Ensuring user protection is paramount in the design of propulsion systems. These systems incorporate various features that enhance stability and reduce the risk of accidents, making them crucial for the safe operation of mobility devices. By focusing on reliability and user control, manufacturers strive to create a secure environment for individuals relying on these innovations.

Emergency Stop Mechanisms

One of the critical safety features is the emergency stop function. This mechanism allows users to halt movement instantly, providing peace of mind in unexpected situations. The implementation of easily accessible controls ensures that individuals can quickly react to potential hazards, thereby minimizing risks associated with sudden changes in speed or direction.

Anti-Tip Systems

Another vital element is the anti-tip system, which prevents the device from overturning during operation. This feature is especially important when navigating inclines or uneven surfaces. By incorporating stability-enhancing technology, manufacturers help to maintain a safe center of gravity, ensuring that users can maneuver confidently without the fear of tipping over.

Tools for Drive Maintenance

Ensuring the optimal functionality of mobility solutions requires the right equipment. A well-equipped maintenance toolkit can significantly enhance performance and extend the lifespan of mobility aids. Understanding the essential instruments needed for upkeep is crucial for anyone involved in this field.

Essential Instruments

Basic tools such as screwdrivers, wrenches, and pliers form the foundation of any maintenance kit. These are necessary for performing routine adjustments and repairs. Additionally, specialized equipment like torque wrenches can help ensure components are secured to the manufacturer’s specifications, preventing potential failures.

Diagnostic Equipment

Incorporating diagnostic tools is vital for effective troubleshooting. Multimeters, for example, allow for precise checks of electrical systems, while tire pressure gauges help maintain optimal conditions for mobility. Keeping a stock of these instruments can facilitate swift diagnosis and repairs, ultimately improving reliability.

Comparing Manual and Electric Drives

The choice between traditional and powered mobility options can significantly impact the user experience. Each system offers distinct advantages and challenges, catering to different needs and lifestyles. Understanding these differences helps individuals make informed decisions that align with their daily activities and preferences.

Advantages of Traditional Systems

Conventional mobility solutions provide a high level of control and physical engagement. Users often find that they can navigate tight spaces with ease, and the overall maintenance tends to be simpler and less costly. Additionally, physical exertion can contribute to fitness, making these options appealing for those seeking to stay active.

Benefits of Powered Systems

Powered alternatives offer enhanced convenience, especially for those with limited upper body strength or endurance. These systems enable users to travel longer distances with minimal effort, which can be a significant advantage in daily routines. Moreover, advancements in technology have led to improved reliability and features, making them an attractive choice for many individuals.

Innovations in Wheelchair Drive Design

Recent advancements in mobility assistance technology have significantly transformed how users navigate their environments. New approaches focus on enhancing user experience through improved efficiency, comfort, and control. These developments aim to address various challenges faced by individuals, providing solutions that promote independence and ease of movement.

Smart Mobility Solutions

The integration of smart technology into mobility devices is one of the most groundbreaking innovations. Features such as automated navigation, obstacle detection, and personalized adjustments are now becoming commonplace. These enhancements not only facilitate smoother movement but also empower users to engage more fully with their surroundings, fostering greater autonomy.

Lightweight Materials and Ergonomic Design

The use of advanced materials has led to the creation of lighter and more durable mobility devices. This innovation reduces physical strain on users while improving overall performance. Furthermore, ergonomic designs prioritize user comfort, ensuring that prolonged use does not lead to fatigue or discomfort, ultimately enhancing the overall quality of life for individuals relying on these assistive technologies.

Wheelchair Drive Parts Purchasing Guide

When considering the acquisition of essential components for mobility devices, it’s crucial to approach the process with careful thought. Understanding the various elements involved ensures optimal performance and safety. This guide will assist you in making informed decisions.

Research: Begin by exploring different brands and models. Assess user reviews and ratings to gauge reliability and quality.

Compatibility: Ensure the selected components are compatible with your specific model. This prevents potential issues and enhances functionality.

Warranty and Support: Look for items that come with a warranty. Reliable customer service can provide peace of mind and assistance if issues arise.

Pricing: Compare prices across various retailers. Keep in mind that the cheapest option may not always be the best in terms of durability.

Installation: Consider whether you can install the components yourself or if professional help is required. This may influence your purchasing decision.

Reviews and Recommendations: Seek advice from peers or online forums. Personal experiences can offer valuable insights into the best choices available.

By following this guide, you can confidently navigate the selection process, ensuring that your mobility device operates at its best.

Resources for Drive System Repairs

Maintaining mobility assistance devices requires a solid understanding of their components and functionality. Having access to the right resources can make the process of repair and upkeep much smoother and more efficient. This section highlights valuable tools, manuals, and community support options available for effective maintenance.

Essential Tools and Equipment

- Socket and wrench sets for tightening and loosening hardware

- Multimeter for diagnosing electrical issues

- Lubricants and cleaning agents for optimal performance

- Replacement components specific to the model

Helpful Manuals and Online Resources

- Manufacturer’s service manuals provide detailed instructions on repair processes.

- Online forums and communities offer advice and shared experiences from other users.

- YouTube channels dedicated to mobility device repairs can provide visual guides.

- Technical support from manufacturers can assist with specific issues.

Utilizing these resources not only facilitates efficient repairs but also empowers users to take charge of their mobility solutions.