In various mechanical systems, knowing how different elements come together is essential for proper maintenance and troubleshooting. When it comes to assemblies that ensure smooth operation, understanding their interconnected parts helps in diagnosing issues and improving overall performance.

Each segment plays a vital role in the functionality of the entire system. By focusing on the arrangement of these elements, one can gain insight into how different components interact and contribute to movement and control. This knowledge is crucial for both repairs and upgrades.

Proper alignment and integration of these segments ensure that the mechanism operates effectively, reducing the risk of wear and tear. Understanding these interactions not only aids in repairs but also in optimizing performance for long-term use.

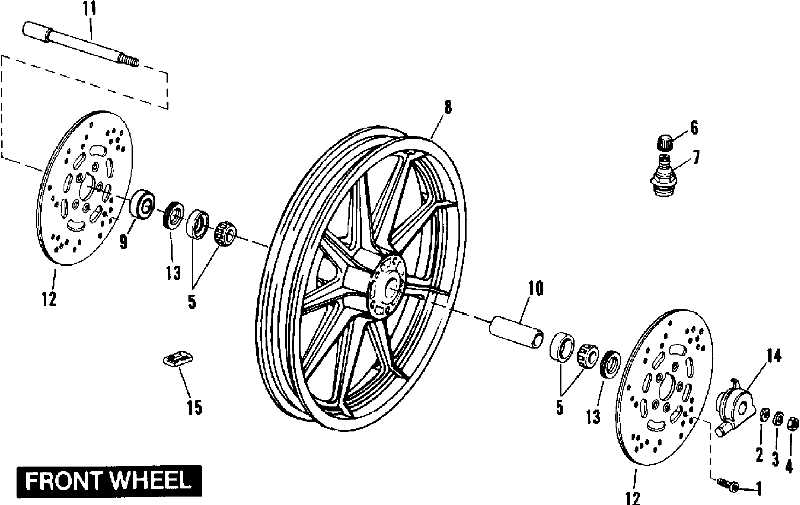

Understanding Front Wheel Components

When examining the essential elements of a vehicle’s rotating assembly, it’s important to grasp how various mechanisms work together to ensure smooth and efficient movement. These interconnected pieces are responsible for maintaining stability, steering control, and overall safety.

Main Structures and Functions

The primary mechanisms serve distinct roles, with some providing rotational power, while others offer balance and support. Each component plays a vital part in ensuring proper alignment and friction management, contributing to the durability and performance of the system.

Key Connections and Interactions

Various fasteners, bearings, and shafts connect the core elements, allowing synchronized movement and seamless operation. Proper lubrication and maintenance are crucial to avoid wear and tear, ensuring that these elements continue to function optimally over time.

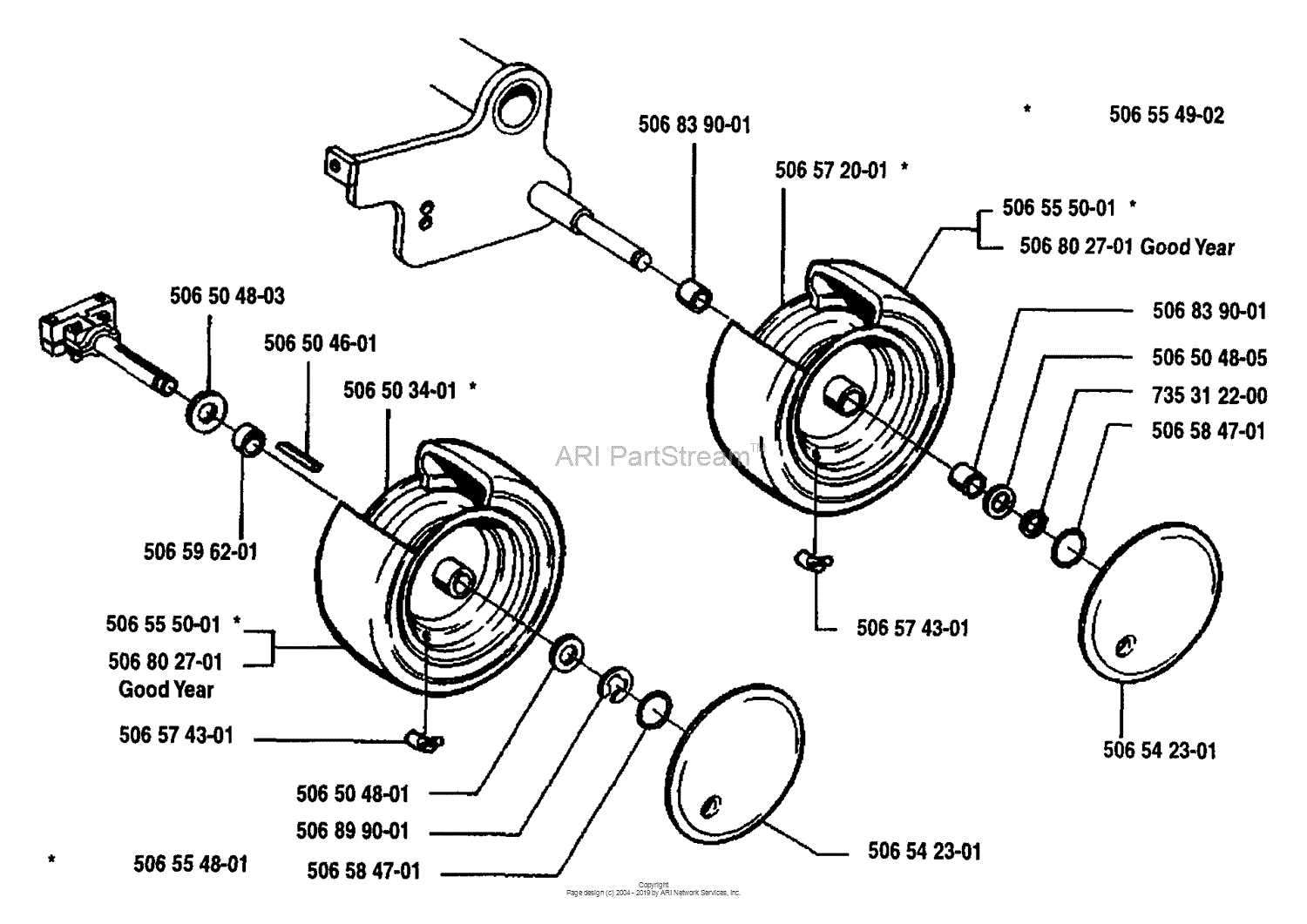

Main Structure of a Front Wheel

The primary construction of a rotating assembly involves several key components, each contributing to both movement and stability. These elements work together to support the entire framework, ensuring smooth operation and efficient control.

Key Support Components

At the core of this system is a central axis, which serves as the foundation for rotation. Surrounding this axis, multiple elements ensure that the circular component remains securely attached while still allowing for seamless movement.

External Elements and Their Functions

External features contribute significantly to handling and responsiveness. These elements are designed to withstand external forces while maintaining balance and durability, enabling consistent performance during use.

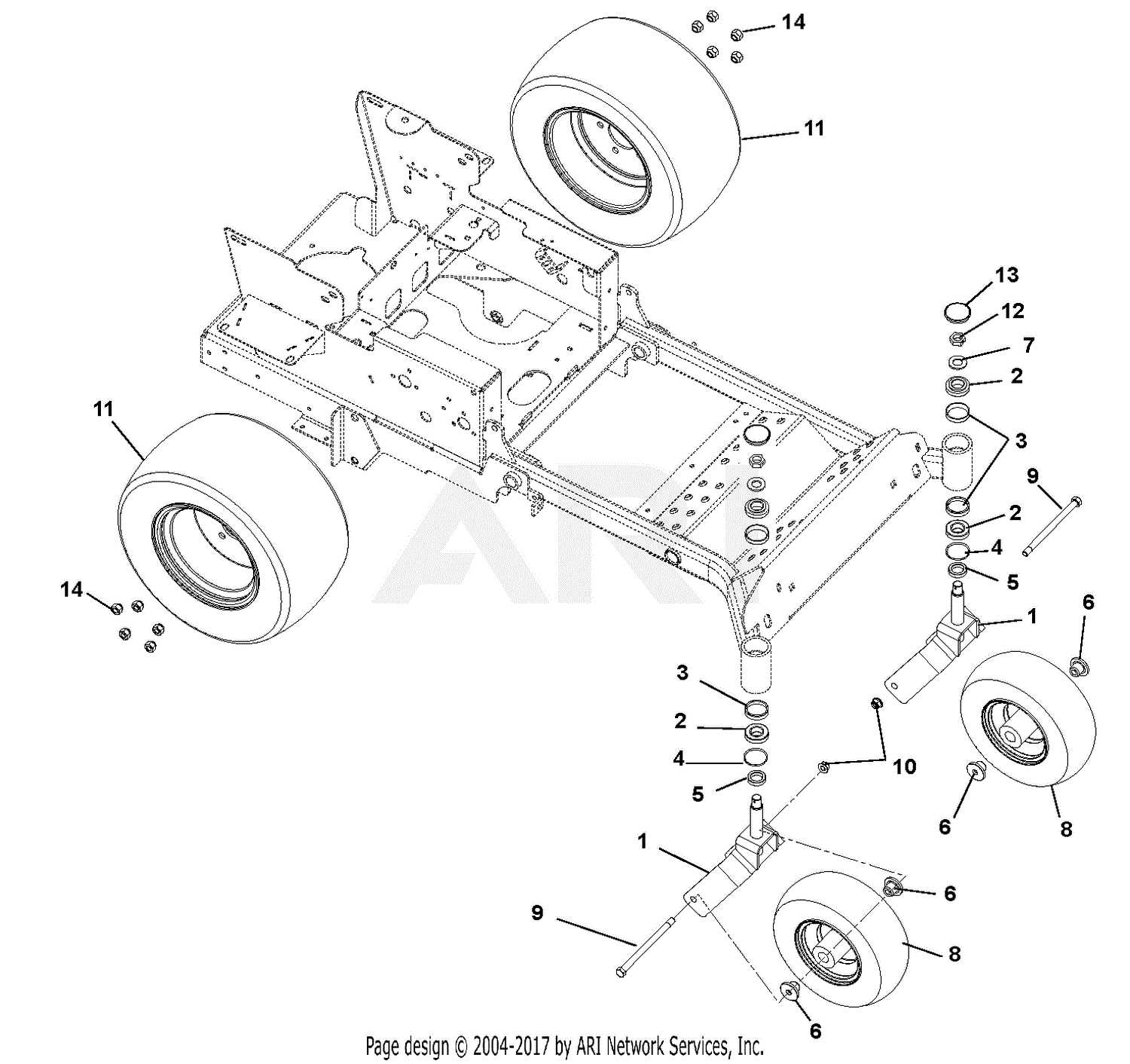

Key Elements of the Axle System

The axle structure plays a crucial role in ensuring smooth and balanced movement for any vehicle. Understanding the core elements of this system is essential for both maintenance and optimization. Below are the main components that work together to provide stability and support.

- Axle Shaft: A pivotal component responsible for transferring power efficiently, ensuring the motion of the system remains consistent.

- Bearings: These reduce friction between moving parts, allowing the system to operate smoothly and prolonging its lifespan.

- Seals: Essential for keeping lubricants in place and preventing contamination from external elements.

- Fasteners: Bolts and nuts that secure the assembly together, ensuring the components stay firmly connected.

Each of these elements contributes to the overall functionality, ensuring the system operates effectively under various conditions.

How Bearings Affect Wheel Performance

Bearings play a crucial role in enhancing the efficiency and smoothness of motion in various transportation systems. Their primary function is to reduce friction between moving parts, ensuring optimal rotation and extending the lifespan of the components. By minimizing resistance, bearings contribute to a more controlled and consistent movement, improving overall handling and speed.

Reducing Friction for Better Efficiency

One of the most significant impacts of quality bearings is their ability to decrease friction between components. By using precision-engineered materials, they allow for smoother rotations, which leads to less energy loss. This directly results in enhanced performance, as less effort is required to maintain momentum. Additionally, the reduction in friction reduces heat buildup, further preventing wear and tear over time.

Impact on Durability and Longevity

The right bearings not only improve movement but also increase the durability of the entire system. With lower friction, there is less stress on the surrounding elements, leading to fewer maintenance needs. Properly maintained bearings ensure that the mechanism remains in top condition, extending the lifespan and reliability of the structure as a whole.

Wheel Hub Assembly Breakdown

The hub assembly plays a crucial role in ensuring the smooth movement and stability of a vehicle. This component connects the rotating axle to the vehicle’s structure, allowing efficient and secure motion. Understanding its construction is key to recognizing how different elements work together to provide a reliable driving experience.

The assembly consists of various interconnected components that collaborate to provide seamless operation. Bearings ensure smooth rotation, while the housing protects the internal mechanisms. Proper alignment and installation of these elements are vital for optimal functionality and longevity of the vehicle’s suspension system.

Role of Spokes in Wheel Stability

Spokes serve a crucial function in maintaining the overall integrity and balance of a circular structure. Their design and arrangement significantly influence the performance and safety of the entire assembly. Understanding their role can help in appreciating the engineering behind these essential components.

Importance of Spokes

- Load Distribution: Spokes help in evenly distributing forces across the circular structure, ensuring that no single area bears excessive weight.

- Flexibility: They provide the necessary flexibility, allowing the structure to absorb shocks and vibrations from uneven surfaces.

- Support: Spokes offer lateral support, preventing deformation and maintaining the shape of the assembly under varying conditions.

Factors Affecting Spoke Performance

- Material: The choice of material affects strength, weight, and overall resilience.

- Tension: Proper tensioning is vital for optimal performance; too loose or too tight can compromise stability.

- Configuration: The arrangement of spokes plays a significant role in achieving balance and distributing forces effectively.

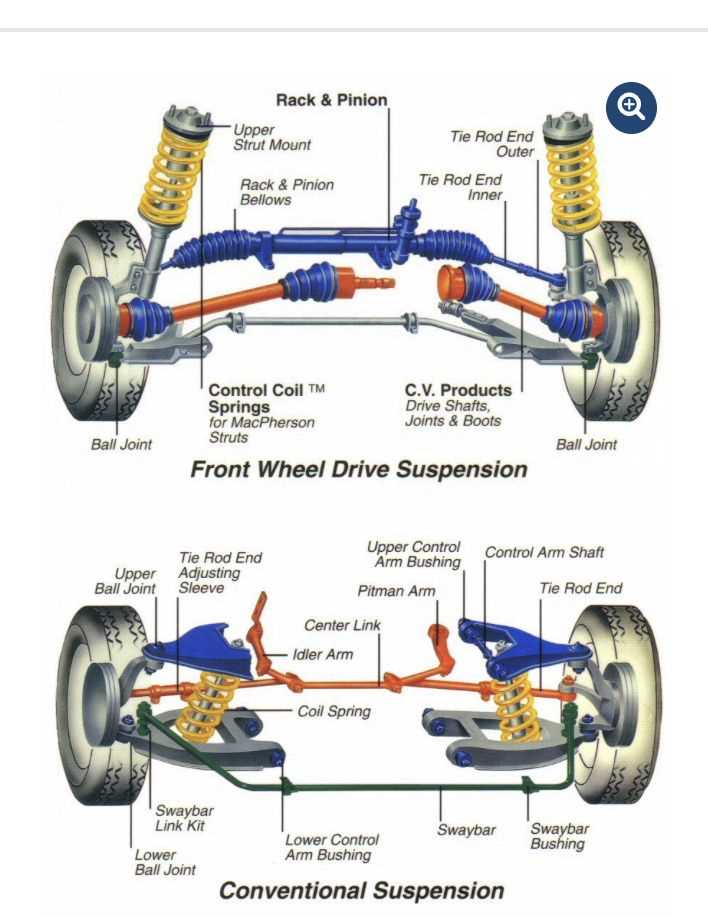

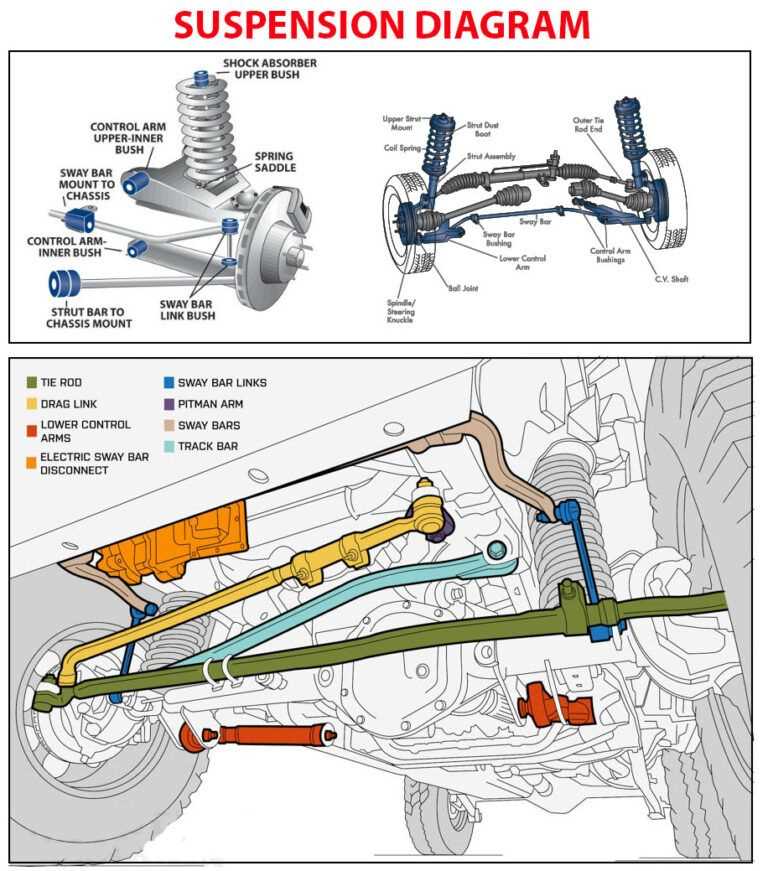

Brake System Integration with Front Wheels

The interaction between braking mechanisms and the leading axles is crucial for vehicle safety and performance. Understanding how these systems operate together ensures efficient stopping power and enhances overall driving stability. This section explores the relationship between braking components and their connection to the front suspension system.

Key Components Involved

Several elements play a vital role in the integration of braking functions with the leading axles. These components work synergistically to provide optimal performance and safety. The following table outlines the primary elements and their respective functions:

| Component | Function |

|---|---|

| Caliper | Holds brake pads and applies pressure to the disc for effective stopping. |

| Disc | Provides a surface for the brake pads to clamp down on, creating friction. |

| Brake Pads | Friction material that engages with the disc to slow down the vehicle. |

| Brake Lines | Convey hydraulic fluid from the master cylinder to the calipers. |

Importance of Proper Alignment

Maintaining precise alignment between braking mechanisms and leading axles is essential for ensuring effective braking. Misalignment can lead to uneven wear of components and decreased stopping efficiency. Regular maintenance checks and adjustments can help prevent these issues, ensuring a safer driving experience.

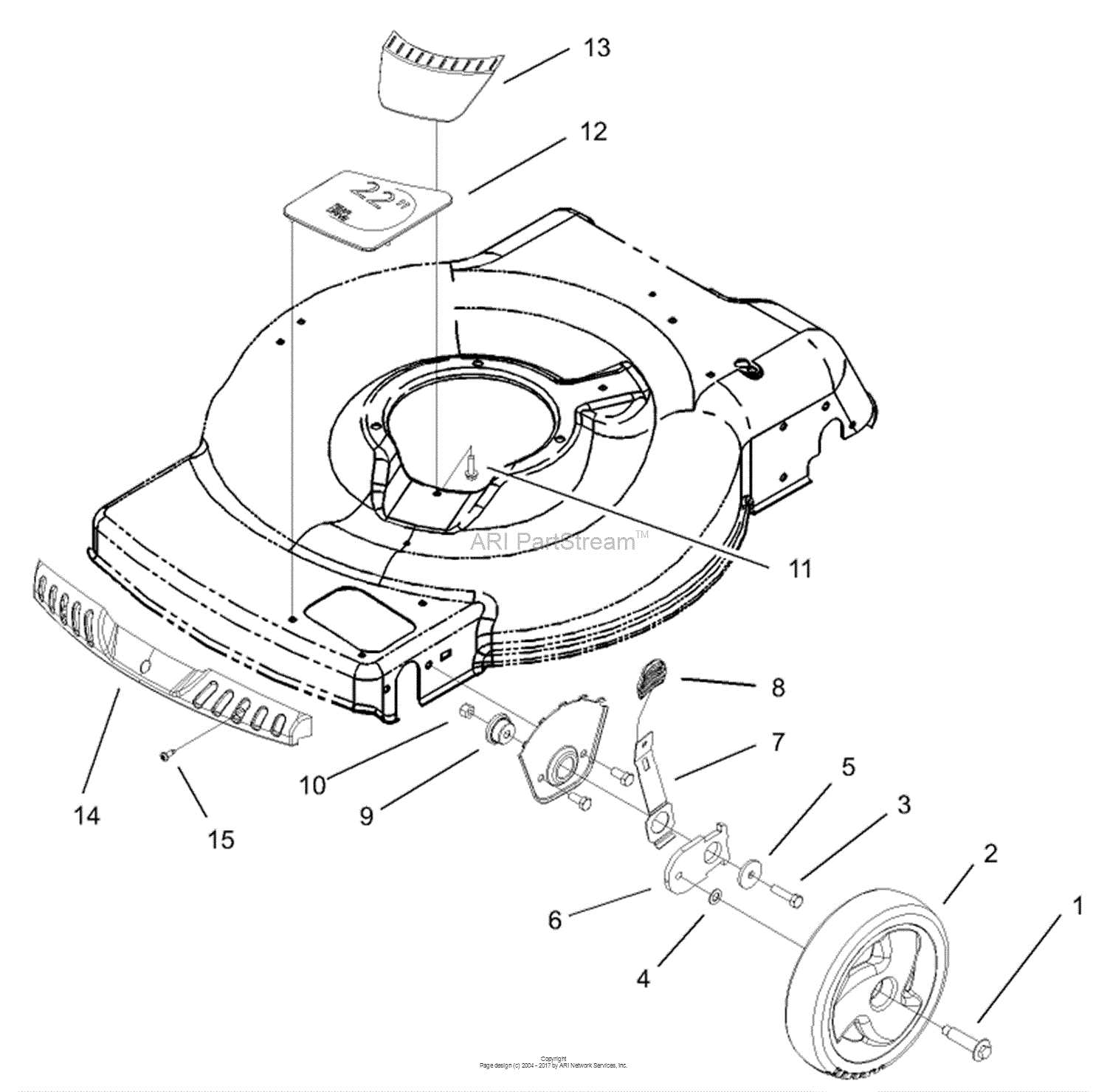

Detailed Look at the Rim and Tire

The circular components play a crucial role in ensuring a vehicle’s optimal performance and safety. This section will delve into the characteristics and functions of these essential elements, highlighting their significance in maintaining stability and control while on the move.

Understanding the Structure

The design of the outer component consists of various features that contribute to its effectiveness. Key aspects include:

- Material Composition: Typically crafted from aluminum or steel, each material offers unique advantages in terms of weight, durability, and aesthetics.

- Width and Profile: The dimensions directly influence handling and ride comfort, impacting the overall driving experience.

- Bead Seat Design: This area ensures a secure fit for the tire, preventing slippage during operation.

Functionality and Maintenance

Regular attention to these components is vital for longevity and performance. Consider the following maintenance tips:

- Inspect for cracks or deformation regularly to avoid potential failures.

- Maintain proper inflation levels to enhance fuel efficiency and prevent uneven wear.

- Clean the surface to remove debris and brake dust that can cause corrosion.

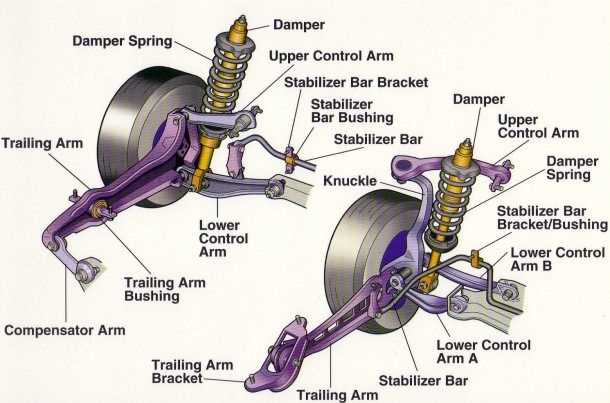

Front Wheel Suspension: Parts and Functions

The suspension system at the front of a vehicle plays a crucial role in maintaining stability and comfort during travel. It comprises various components that work together to absorb shocks and provide a smooth driving experience. Understanding the individual elements and their respective roles helps in grasping the overall functionality of this essential mechanism.

Key Components of the Suspension System

Among the vital components are the shock absorbers, which mitigate the impact of road irregularities, ensuring a stable ride. Additionally, control arms connect the assembly to the vehicle’s frame, allowing for controlled movement and alignment adjustments. Furthermore, sway bars enhance stability by reducing body roll during cornering.

Functionality and Importance

The proper functioning of this system is essential for vehicle safety and performance. Each component, from struts to mounts, contributes to effective load distribution and vehicle handling. A well-maintained suspension enhances tire longevity and improves overall driving dynamics, making it imperative for vehicle owners to monitor and service these elements regularly.

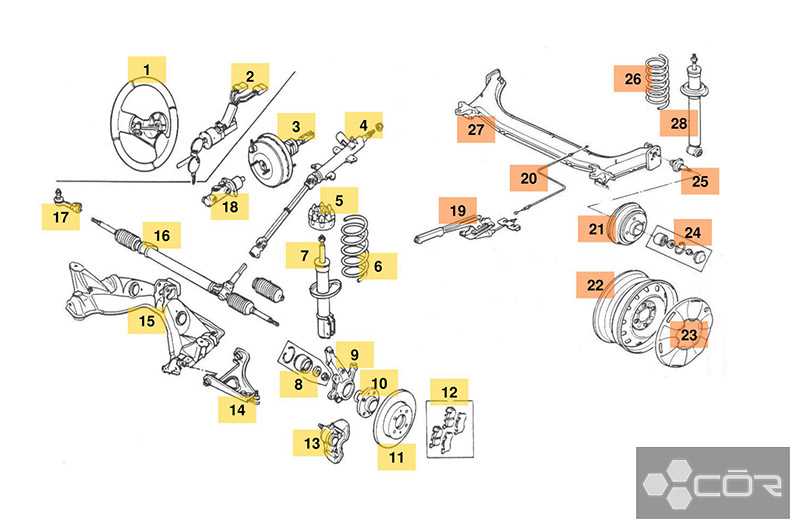

Steering Mechanism and Its Interaction with Wheels

The steering mechanism plays a crucial role in vehicle dynamics, enabling precise control and navigation. It serves as the interface between the driver’s intentions and the movement of the vehicle, influencing how it responds to steering inputs. This section explores the various components involved in steering and their relationship with the rolling elements, highlighting the importance of coordination for optimal performance.

Components of the Steering System

At the heart of the steering assembly are several key components that work in unison. These include the steering wheel, column, and gear mechanism, which translate the driver’s movements into directional changes. Additionally, the linkage connects these components to the rolling elements, ensuring accurate alignment and responsiveness.

Impact on Vehicle Maneuverability

The interaction between the steering mechanism and the rolling elements significantly affects maneuverability. A well-designed assembly allows for smooth turning and stability at various speeds. Any misalignment or wear in the system can lead to compromised handling, resulting in decreased safety and performance. Maintaining this critical connection is essential for effective navigation and control.

Fastening Methods for Front Wheels

Proper attachment techniques are crucial for maintaining stability and safety in any vehicle. Various methods ensure that components remain securely in place, providing optimal performance and durability. Understanding these fastening methods is essential for effective maintenance and repair.

Types of Fasteners

Different types of fasteners are utilized in securing components, including bolts, nuts, and clips. Bolts are commonly used due to their strength and reliability, while nuts complement bolts by providing a secure grip. Clips are often used for lighter attachments, offering quick installation and removal.

Installation Techniques

Effective installation is vital for the longevity of any assembly. Techniques such as torque application and proper alignment play a significant role in ensuring that fasteners function correctly. Torque application involves using a specific amount of force to tighten fasteners, preventing them from loosening during operation. Additionally, proper alignment ensures that all components fit together seamlessly, reducing wear and tear.

Common Wear and Tear in Wheel Parts

The longevity and performance of automotive components can significantly impact the overall functionality of a vehicle. Understanding the typical deterioration patterns of these components is crucial for maintenance and replacement schedules.

Indicators of Deterioration

Regular inspection can reveal several signs of wear. One common issue is friction-related damage, which may lead to reduced efficiency and increased noise. Additionally, components may exhibit cracking or deformation due to stress over time.

Maintenance Tips

To prolong the lifespan of these components, it is essential to perform routine checks and adhere to recommended service intervals. Regular lubrication and prompt replacement of damaged items can help mitigate potential issues, ensuring smoother operation and enhanced safety.

Maintenance Tips for Front Wheel Components

Proper upkeep of your vehicle’s critical components is essential for ensuring a smooth and safe driving experience. Regular inspections and maintenance can help identify potential issues early, preventing costly repairs and enhancing overall performance.

Regular Inspections: Frequently check the condition of the key elements for any signs of wear or damage. Look for cracks, corrosion, or loose fittings that may compromise functionality.

Lubrication: Keep the moving parts well-lubricated to minimize friction and wear. Use high-quality lubricants specifically designed for automotive applications to ensure optimal performance.

Tightening Fasteners: Ensure that all bolts and nuts are properly tightened according to the manufacturer’s specifications. Loose fasteners can lead to misalignment and increased wear on surrounding components.

Cleaning: Regularly clean the assembly to remove dirt and debris that can accumulate over time. A clean surface allows for better inspection and can prevent premature wear.

Timely Replacement: If you notice any components that are nearing the end of their lifespan, replace them promptly. Ignoring worn parts can lead to more severe damage and unsafe driving conditions.