In the intricate design of automotive engineering, certain elements play a crucial role in ensuring both performance and safety. These components, often overlooked, serve as the foundation for various systems within the vehicle, contributing to its overall functionality. By exploring these vital elements, we gain insights into their significance and interconnections.

Recognizing the specific functions of these undercarriage features can enhance our appreciation for how vehicles operate. Each component has been meticulously crafted to withstand various conditions while providing support and stability. Understanding their layout and purpose is essential for anyone looking to maintain or modify their automobile effectively.

As we delve deeper into the intricacies of these essential features, we will uncover the ultimate interplay between design and functionality. This exploration will guide enthusiasts and professionals alike in making informed decisions regarding repairs and enhancements, ensuring a safer and more reliable driving experience.

Understanding Wheel Well Components

The area surrounding the tires of a vehicle houses several crucial elements that contribute to both functionality and safety. Each component plays a specific role in protecting the internal systems and ensuring optimal performance. A comprehensive grasp of these elements aids in better maintenance and enhances the overall driving experience.

In this section, we will explore the essential components found in the vicinity of the tires. Understanding their functions and interrelations is vital for any vehicle owner or enthusiast.

| Component | Function |

|---|---|

| Fender Liners | Protect the inner structure from debris and moisture. |

| Shock Absorbers | Dampen vibrations and improve ride comfort. |

| Brake Lines | Transmit hydraulic fluid to the braking system. |

| Suspension Components | Support weight and absorb road impacts. |

| Protective Covers | Shield sensitive parts from dirt and damage. |

By recognizing these components and their respective functions, vehicle owners can make informed decisions about maintenance and upgrades, ultimately prolonging the lifespan of their automobiles.

Importance of Wheel Well Maintenance

Maintaining the components surrounding the tires of a vehicle is crucial for ensuring optimal performance and longevity. Neglecting this area can lead to various issues that compromise safety and efficiency. Regular attention to this section not only enhances the overall aesthetic but also contributes to the vehicle’s structural integrity.

Preventing Damage and Corrosion

One of the primary benefits of regular upkeep is the prevention of damage and corrosion. Environmental factors such as moisture, dirt, and road salt can accumulate, leading to rust and degradation over time. Inspecting and cleaning these components can significantly extend their lifespan and reduce the risk of costly repairs.

Enhancing Safety and Performance

Proper maintenance also plays a vital role in safety. Components in this area are essential for the proper functioning of the suspension and braking systems. Ensuring they are in good condition helps maintain optimal traction and handling, ultimately protecting both the driver and passengers. Neglect can lead to malfunctions that pose serious risks on the road.

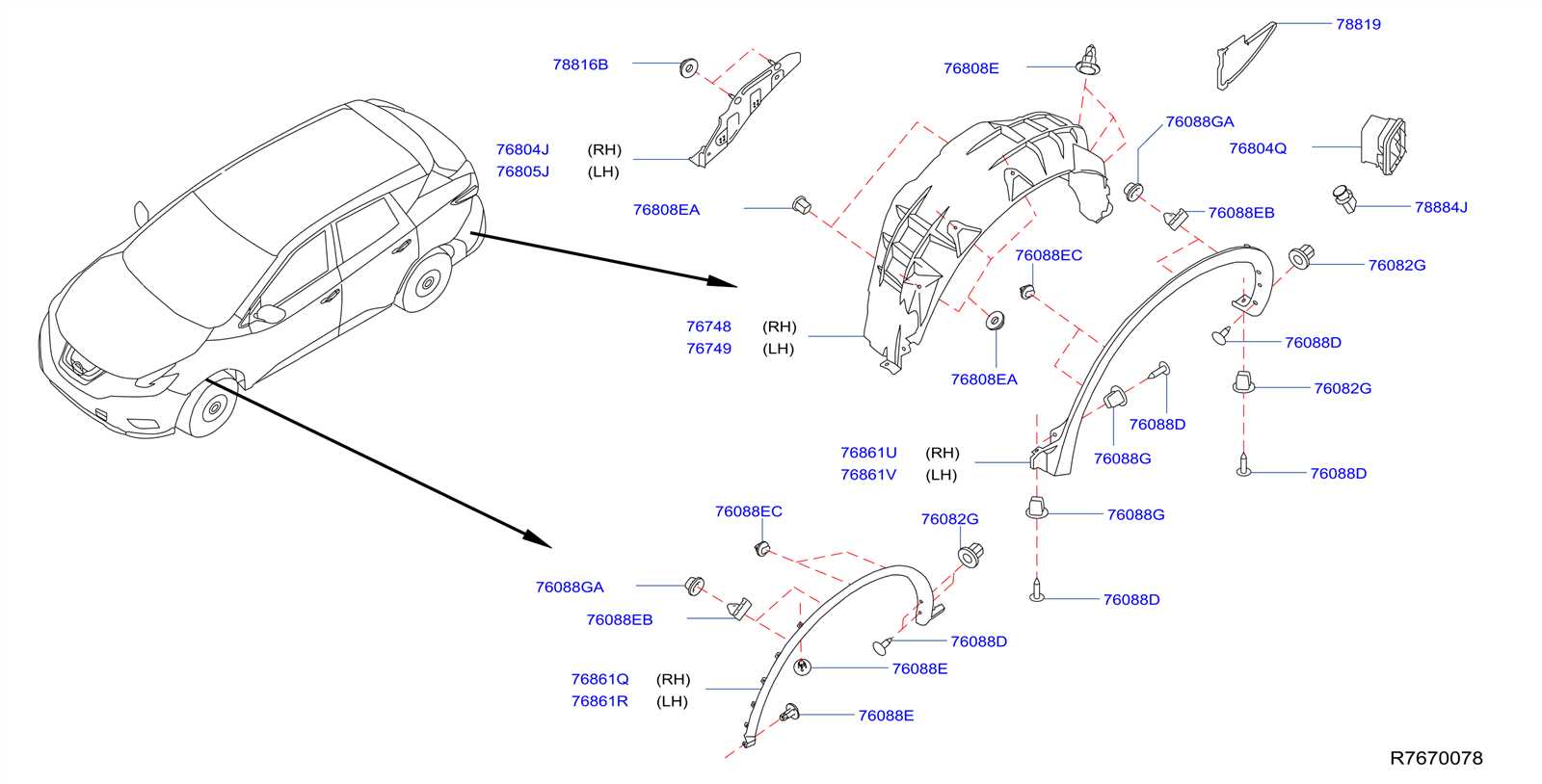

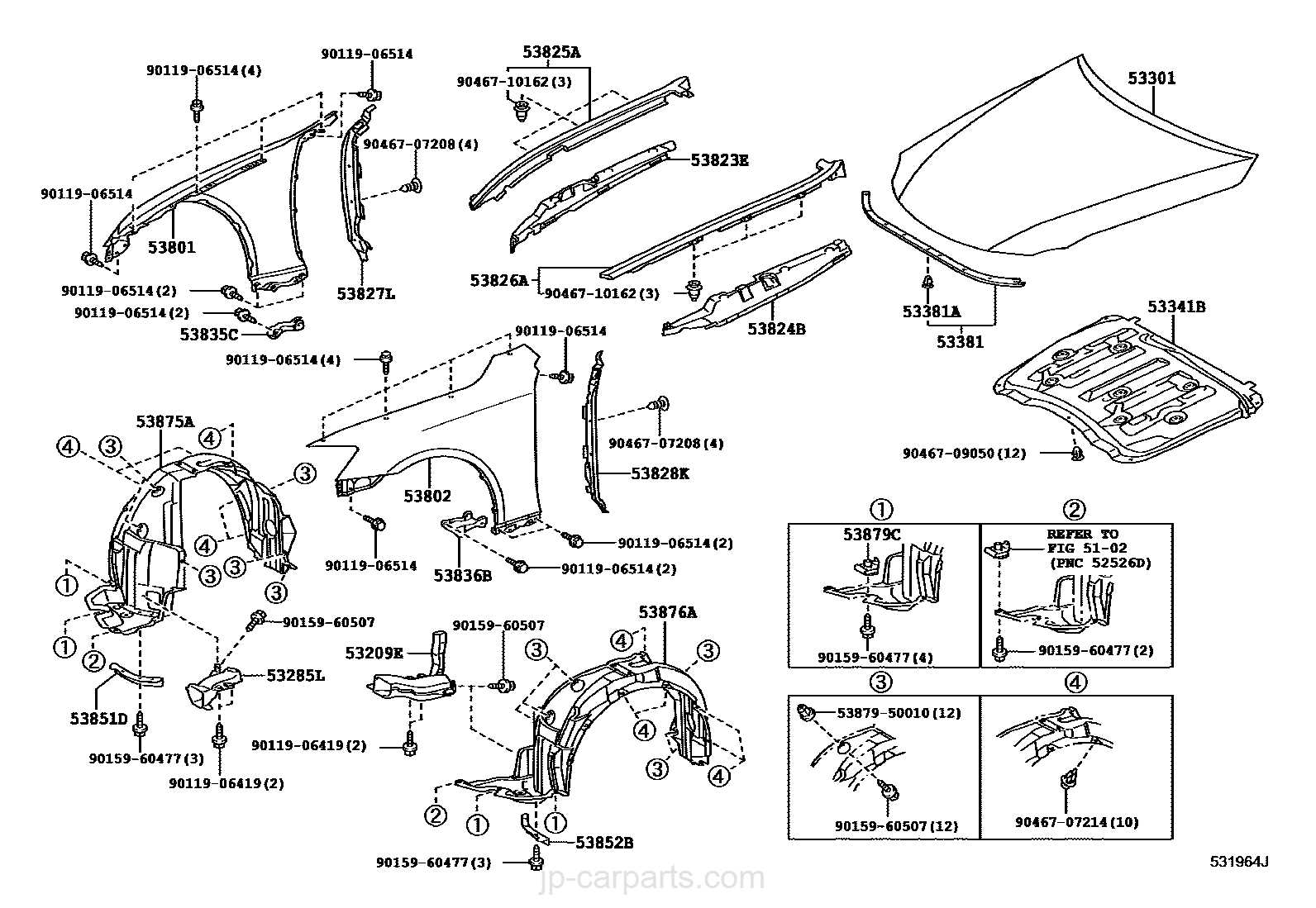

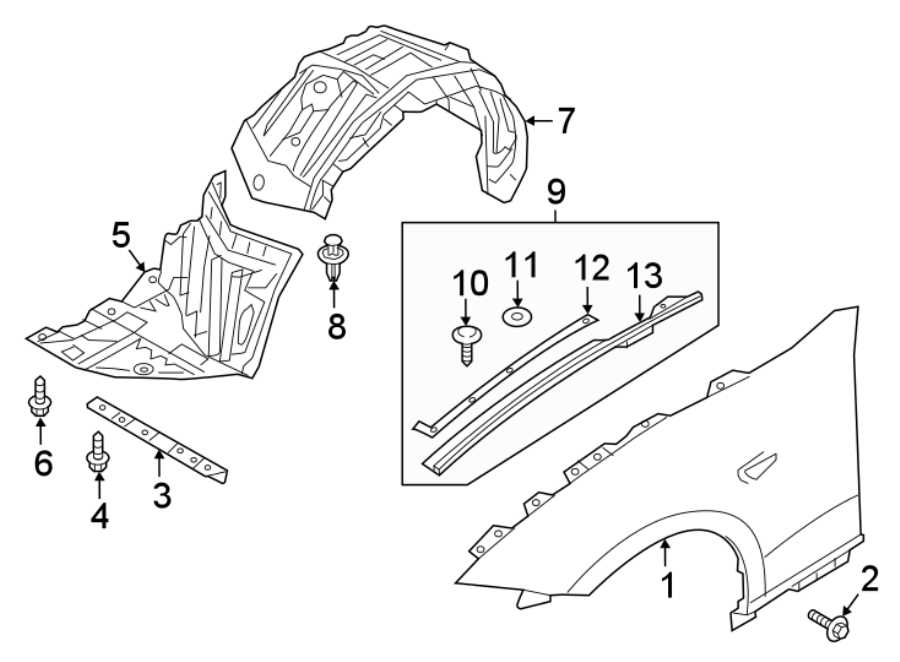

Common Parts in Wheel Wells

In the realm of automotive design, various components play crucial roles in ensuring optimal functionality and safety. These elements work together to enhance performance, provide protection, and contribute to the overall integrity of the vehicle. Understanding these essential elements helps in appreciating their significance in everyday driving experiences.

Key Components

Several vital elements are commonly found in the enclosed areas surrounding the tires. Each serves a specific purpose, contributing to both performance and maintenance.

| Component | Function |

|---|---|

| Fender Liner | Protects the inner structure from dirt and debris. |

| Splash Guard | Prevents water and mud from splashing onto sensitive parts. |

| Wheel Arch | Provides structural support and enhances aerodynamics. |

| Brake Lines | Transmits hydraulic fluid for braking efficiency. |

Importance of Maintenance

Regular inspection and maintenance of these elements are essential to ensure longevity and reliability. Neglecting any component can lead to performance issues and safety hazards, making awareness of their condition crucial for vehicle owners.

How to Identify Wheel Well Issues

Understanding potential complications in the undercarriage of your vehicle is crucial for maintaining safety and performance. Recognizing early signs of damage or wear can save you from costly repairs and ensure a smooth ride. Here are some key indicators to look out for.

- Visual Inspection:

- Check for cracks or rust on the surrounding area.

- Look for any signs of loose or missing components.

- Inspect for accumulated debris that could lead to corrosion.

- Unusual Noises:

- Listen for grinding, clunking, or rattling sounds while driving.

- Pay attention to noises when going over bumps or potholes.

- Handling Issues:

- Notice if the vehicle pulls to one side during driving.

- Observe any changes in steering response or stability.

- Uneven Tire Wear:

- Check for bald spots or uneven tread wear on your tires.

- Monitor tire pressure regularly to detect possible alignment issues.

By staying vigilant and conducting regular assessments, you can address concerns promptly, ensuring your vehicle remains safe and reliable on the road.

Tools for Wheel Well Inspection

Conducting a thorough evaluation of the undercarriage components is essential for ensuring vehicle safety and performance. A variety of instruments and equipment are necessary to effectively assess the condition of these crucial areas. Utilizing the right tools can make the inspection process more efficient and accurate, helping to identify potential issues before they escalate.

Essential Equipment

There are several key items that every inspector should have on hand. These tools enable detailed examinations and facilitate the identification of wear and damage. Below is a table summarizing these important tools.

| Tool | Purpose |

|---|---|

| Flashlight | Illuminates dark areas for better visibility. |

| Mirror | Helps to see hard-to-reach spots. |

| Pry Bar | Assists in checking for loose components. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Inspection Camera | Allows for remote viewing of confined spaces. |

Safety Gear

In addition to inspection tools, personal safety equipment is vital. Proper gear protects inspectors during evaluations and minimizes risks associated with working underneath vehicles. Essential safety items include gloves, goggles, and knee pads to ensure a safe working environment.

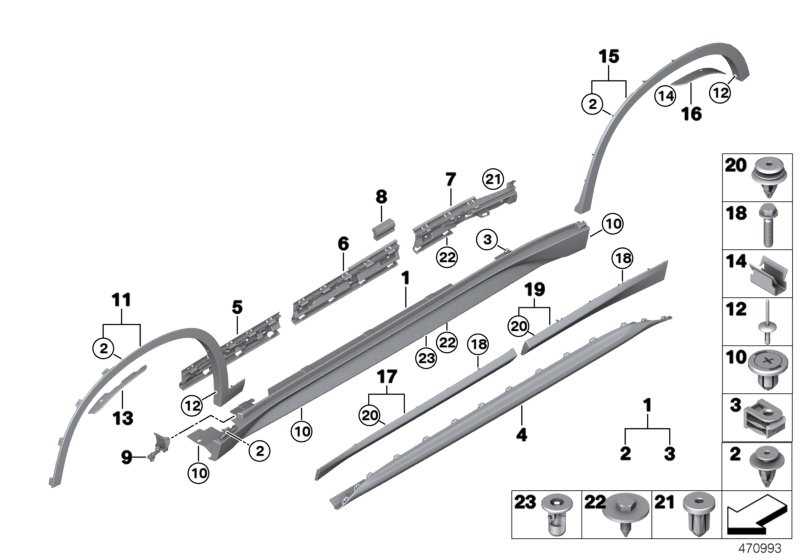

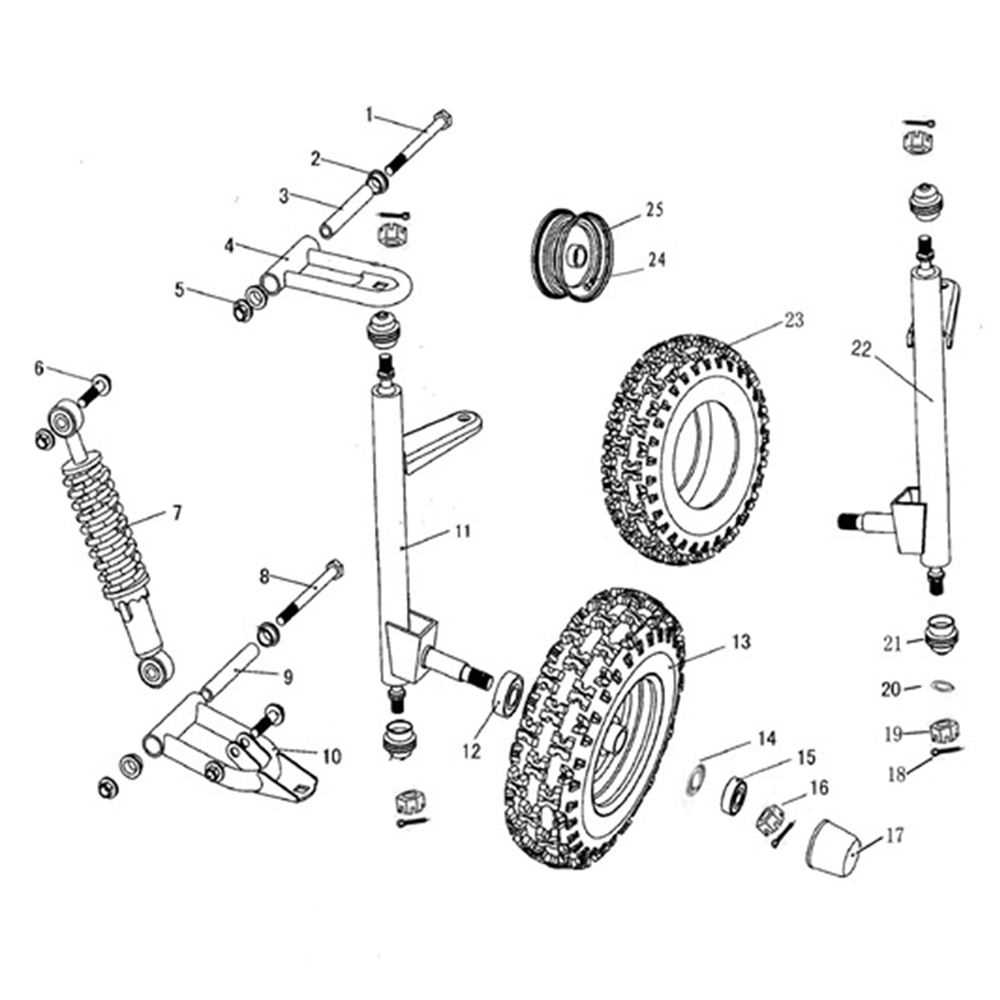

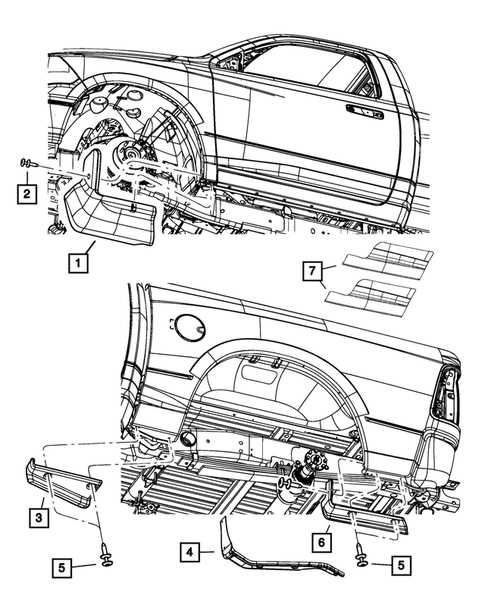

Step-by-Step Wheel Well Diagram

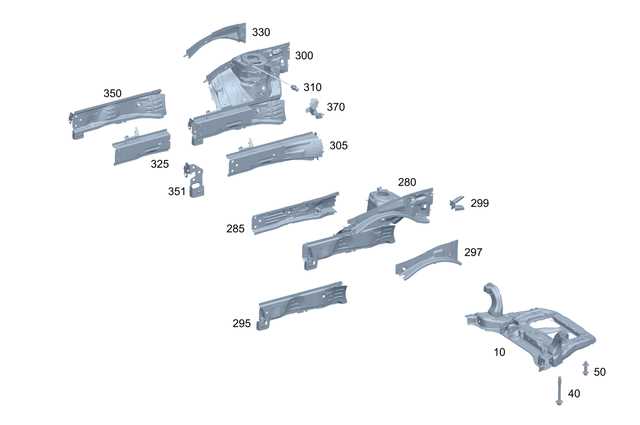

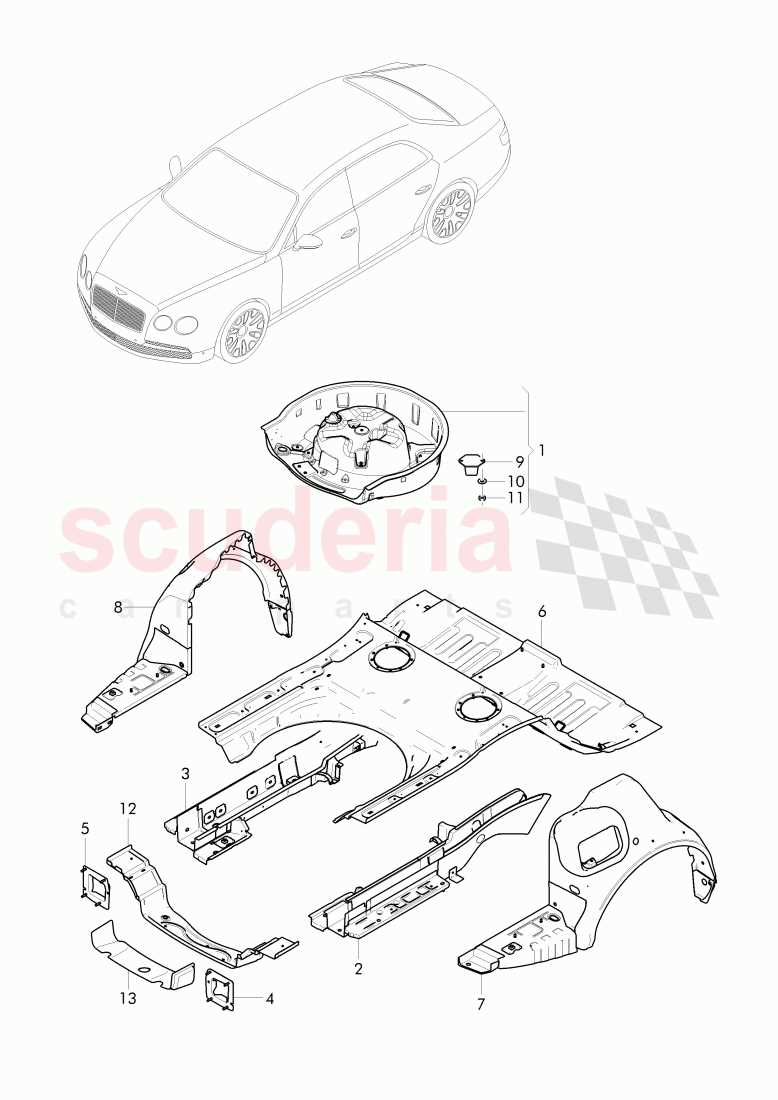

This section provides a detailed visual guide to understanding the components within a specific automotive area that houses the tires. By following each stage, you can grasp the arrangement and functionality of these crucial elements.

1. Initial Overview: Begin by familiarizing yourself with the outer framework that encapsulates the tire. Recognizing its shape and structure is essential for deeper comprehension.

2. Component Identification: Delve into the various components, such as liners and brackets. Each element plays a unique role in ensuring safety and performance.

3. Assembly Sequence: Next, observe the order in which these components are installed. Understanding this sequence will enhance your knowledge of maintenance and repairs.

4. Functional Relationships: Explore how these parts interact with one another. This understanding will lead to a greater appreciation of the entire system’s operation.

5. Final Insights: Conclude with key takeaways that highlight the importance of each element in overall vehicle performance. This comprehensive approach will provide you with the ultimate knowledge needed for effective automotive care.

Repair Techniques for Wheel Well Damage

Damage to vehicle undercarriage areas can significantly affect performance and safety. Addressing these issues promptly is essential to maintain the integrity of the structure. Various methods exist to repair these regions effectively, ensuring both aesthetic and functional restoration.

Assessing the Damage: Before starting any repair work, a thorough inspection is crucial. Identify the extent of the harm, including rust, dents, or structural compromise. This assessment will guide the choice of techniques and materials.

Rust Treatment: For areas affected by corrosion, it’s vital to remove all rust. Use wire brushes or sandblasting to eliminate rust and debris. After cleaning, apply a rust-inhibiting primer and paint to protect against future deterioration.

Repairing Dents: Minor dents can often be addressed using a puller tool or by applying heat. For more severe damage, consider using body filler to smooth the surface before painting, ensuring a seamless finish.

Structural Reinforcement: If the damage compromises structural integrity, welding or the addition of support brackets may be necessary. This step is critical for maintaining safety and functionality.

Finishing Touches: Once repairs are made, ensure the area is properly painted and sealed. This not only enhances appearance but also provides additional protection against the elements.

Implementing these techniques can restore vehicle functionality and aesthetics, ultimately extending its lifespan.

Wheel Well Parts: Material Types

This section explores the various materials used in constructing the components found in the designated area of vehicles. Each material offers unique characteristics that influence durability, weight, and performance, making the selection process crucial for automotive design.

| Material | Properties | Common Uses |

|---|---|---|

| Plastic | Lightweight, corrosion-resistant, flexible | Inner liners, splash guards |

| Aluminum | Strong, lightweight, good thermal conductivity | Support structures, reinforcements |

| Steel | Highly durable, cost-effective, heavy | Frame components, brackets |

| Composite | High strength-to-weight ratio, resistant to harsh conditions | Advanced structural elements |

Safety Considerations During Repairs

When undertaking maintenance tasks, ensuring safety is paramount. Proper precautions not only protect the individual performing the work but also safeguard the surrounding environment and equipment. Adhering to best practices minimizes the risk of accidents and injuries.

Here are essential safety measures to keep in mind:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is well-lit and free of clutter to prevent tripping hazards.

- Utilize tools and equipment designed for the specific task to avoid misuse and potential injuries.

Before starting any repair work, consider the following:

- Review the manufacturer’s guidelines to understand recommended procedures and safety tips.

- Disconnect power sources and secure the area to prevent accidental activation.

- Have a first aid kit readily available in case of emergencies.

By following these safety considerations, individuals can create a safer environment, enabling efficient and successful maintenance activities.

Upgrades for Enhanced Wheel Performance

Improving the functionality and efficiency of your vehicle’s rolling components can significantly enhance overall driving experience. Various modifications can be employed to maximize performance, handling, and durability. This section will explore some key enhancements to consider.

Tires Selection

Choosing the right rubber can dramatically affect grip, comfort, and fuel efficiency. Performance-oriented options often provide better traction and responsiveness in various conditions.

Suspension Tuning

Optimizing the suspension system can lead to improved stability and control. Adjustments can be made through upgraded shock absorbers, springs, or bushings to suit driving preferences.

| Upgrade Type | Benefits |

|---|---|

| Tire Quality | Enhanced grip and handling |

| Suspension Upgrade | Improved stability and ride quality |

| Alignment Services | Better tire wear and handling |

| Brake System Enhancements | Shorter stopping distances and better control |

DIY vs. Professional Wheel Well Service

When it comes to maintaining the undercarriage of your vehicle, there are two main approaches: tackling it yourself or enlisting the help of a specialist. Each option has its own set of advantages and challenges that can influence the decision-making process for vehicle owners.

Advantages of DIY Maintenance

Opting for a do-it-yourself approach can save money and provide a sense of accomplishment. Many enthusiasts enjoy the hands-on experience and the opportunity to learn more about their vehicle. With the right tools and research, performing basic maintenance tasks can be both rewarding and effective.

Benefits of Professional Service

On the other hand, relying on a professional offers expertise and efficiency. Specialists have access to advanced tools and extensive knowledge, ensuring that all aspects of maintenance are addressed properly. This option can also save time and reduce the risk of potential mistakes that may occur with a DIY approach.

Cost Analysis of Wheel Well Repairs

Understanding the financial implications of repairing critical components of vehicles is essential for both owners and service providers. Various factors contribute to the overall expense, including labor, materials, and the complexity of the work involved. This section aims to provide a clear breakdown of these costs to aid in informed decision-making.

Factors Influencing Repair Costs

Several key elements affect the total cost of repairs. These include the type of damage, accessibility, and the need for specialized tools or parts. Additionally, regional labor rates can significantly impact the final bill.

Estimated Cost Breakdown

| Cost Component | Estimated Range |

|---|---|

| Labor | $50 – $150 per hour |

| Materials | $100 – $300 |

| Specialized Equipment | $50 – $200 |

| Total Estimated Cost | $200 – $600 |

Ultimately, a thorough analysis of these factors will help vehicle owners budget effectively for necessary repairs and maintain the integrity of their vehicles.

Future Trends in Wheel Well Design

The upcoming developments in the design of vehicle enclosures will focus on enhancing efficiency and performance while addressing environmental concerns. Innovations will likely prioritize lightweight materials and advanced aerodynamics, ultimately contributing to fuel economy and reduced emissions.

Moreover, integration of smart technologies will pave the way for improved monitoring systems, providing real-time data on component condition and performance. This proactive approach can enhance safety and prolong the lifespan of critical elements.

Additionally, sustainability will become a cornerstone, with manufacturers exploring eco-friendly materials and recycling methods. This trend reflects a broader commitment to minimizing the ecological footprint of automotive production.

Finally, customization options will evolve, allowing consumers to personalize their vehicles more extensively, thereby enhancing user experience and satisfaction. These trends indicate a significant shift towards innovation and responsibility in future vehicle designs.