Understanding the structure and functionality of key elements within your device is crucial for ensuring its optimal performance and longevity. Knowing the individual components allows users to quickly identify potential issues and replace elements as needed, contributing to smooth and efficient operation.

This guide provides a detailed breakdown of the various mechanisms and their roles within the system. From essential connectors to specialized mechanisms, each element plays a pivotal part in maintaining the device’s reliability. Familiarizing yourself with these internal workings can significantly simplify troubleshooting and upkeep processes.

In the following sections, we will explore the arrangement and function of these components, highlighting their significance for the overall operation. By gaining insight into these internal features, you can better understand how to perform routine maintenance and ensure your device runs smoothly for years to come.

Overview of the Whirlpool WDT730PAHZ0 Dishwasher

This high-performance dishwasher is designed to provide effective cleaning for a variety of dishware, offering several convenient features that ensure both efficiency and ease of use. The appliance combines advanced cleaning technology with a sleek, user-friendly design to deliver reliable results with every cycle.

Key Features and Functionality

The machine offers multiple wash cycles, allowing users to choose the optimal settings based on their load. It includes energy-efficient options that help conserve water and electricity while still achieving thorough cleaning. The interior is spacious, with adjustable racks that can accommodate larger items, making it ideal for families or those with heavy dish loads.

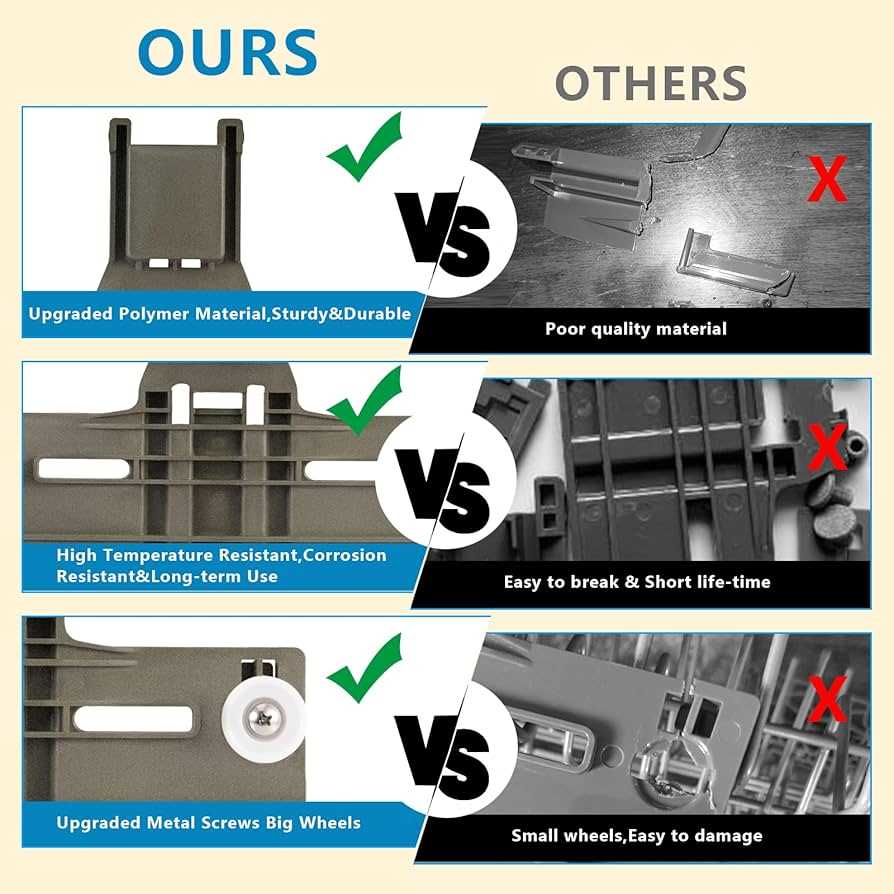

Durability and Maintenance

Built to last, the appliance uses high-quality materials and components that ensure long-term reliability. Regular maintenance is straightforward, with easily accessible filters and components that are designed for quick cleaning. For enhanced durability, this model is constructed with corrosion-resistant materials, ensuring it remains in excellent condition for years to come.

Key Components of the WDT730PAHZ0 Model

This model is known for its efficient and reliable performance, supported by a well-designed internal structure. Understanding the main components helps in maintaining and troubleshooting the system effectively. Below is an overview of the most essential elements that contribute to its functionality and seamless operation.

Internal Mechanisms

- Pump Assembly: This crucial unit manages the circulation and drainage of water, ensuring optimal cleaning and drying cycles.

- Control Panel: A user-friendly interface that allows customization of various settings and cycles for better efficiency.

- Heating Element: Responsible for regulating water temperature, improving the overall cleaning power and ensuring proper drying.

Additional Features

- Spray Arms: These components distribute water evenly across the interior, maximizing the cleaning coverage.

- Racks and Tines: Adjustable and versatile, these elements allow for flexible loading options to accommodate

Understanding the Dishwasher’s Internal Structure

The internal design of a modern dishwasher is a sophisticated system that ensures effective cleaning and efficient water use. It comprises various interconnected components that work together to deliver optimal performance during each wash cycle. Understanding how these elements interact can help in identifying potential issues and maintaining the appliance in good condition.

At the core of the system is the circulation pump, which is responsible for moving water through the spray arms. These arms distribute water evenly over the dishes, ensuring thorough cleaning. Additionally, the heating element plays a vital role by warming the water to the necessary temperature for effective washing and drying.

Other critical components include the drain pump, which removes dirty water from the machine, and the filtration system, which prevents debris from clogging the internal mechanisms. By familiarizing yourself with these key parts, you can better understand how the dishwasher operates and recogniz

Replacement Guide for the Spray Arms

The spray arms play a crucial role in ensuring the efficient cleaning performance of your dishwasher. Over time, these components may become clogged or damaged, requiring replacement to maintain optimal function. This guide provides a clear and simple approach to identifying when and how to replace the spray arms, ensuring your machine continues to operate at peak efficiency.

Identifying the Need for Replacement

Inspecting the spray arms regularly is essential to prevent any buildup of debris that could hinder performance. Look for signs of wear such as cracks, blockages in the nozzles, or a noticeable decline in cleaning results. If these issues are present, replacing the spray arms can restore the machine’s cleaning power.

Steps for Replacing the Spray Arms

Replacing the spray arms is a straightforward process that can be completed with minimal tools. First, disconnect the appliance from the power source for safety. Then, remove the lower rack and locate the spray arm assembly. Carefully uns

Common Issues with Water Inlet Valve

The water inlet valve plays a critical role in the appliance’s operation by regulating the flow of water into the system. Over time, this component may encounter a range of problems that can affect performance and lead to operational difficulties. Identifying and addressing these issues early can prevent more extensive repairs and ensure efficient function.

Blockages and Restricted Flow

One of the most frequent problems is blockages caused by debris or mineral buildup. When the valve becomes clogged, it may restrict the flow of water, leading to insufficient water levels or complete failure to fill. Regular cleaning or replacement of filters can help prevent this issue.

Valve Failure and Leakage

Another common problem involves the valve failing to close properly, resulting in water leaks. This can lead to excess water entering the system or dripping from the unit. In many cases, the valve may need to be replaced to restore proper operation. Early signs of leakage should be addressed immediately to avoid water damage.

Exploring the Heating Element Configuration

The heating component in a dishwasher plays a crucial role in ensuring optimal performance by effectively managing water temperature during cycles. Understanding the layout and functionality of this essential element can enhance maintenance practices and troubleshooting efforts. This section delves into the various aspects of the heating element setup, highlighting its significance in achieving desired cleaning results.

Key Features of the Heating Element

The configuration of the heating element typically consists of several key features that contribute to its overall efficiency. These include:

Feature Description Material Commonly constructed from durable metals that ensure longevity and heat conductivity. Placement Strategically positioned within the appliance to optimize heat distribution throughout the water tank. Wattage Varies depending on the model, with higher wattages providing faster heating capabilities. Importance of Proper Functionality

Ensuring that the heating mechanism operates correctly is vital for effective cleaning and sanitizing. Any malfunction can lead to inadequate water temperatures, compromising the entire washing process. Regular inspections and timely replacements can prevent potential issues, extending the lifespan of the appliance.

How the Circulation Pump Operates

The circulation pump plays a crucial role in the effective functioning of dishwashing machines by ensuring that water is consistently and efficiently circulated throughout the system. This component is responsible for delivering pressurized water to various spray arms, allowing for thorough cleaning of dishes and utensils during the wash cycle.

When activated, the pump draws water from the tub and propels it through a series of channels and hoses. The pressurized water is then released through the spray arms, creating a powerful stream that targets the items within the machine. This process not only helps in rinsing away food particles and debris but also contributes to the overall cleaning performance of the appliance.

Component Function Motor Drives the circulation pump, creating water pressure. Impeller Accelerates the flow of water, enhancing circulation. Housing Encases the pump and directs water flow. Inlet Allows water to enter the pump from the tub. Outlet Discharges pressurized water to the spray arms. Regular maintenance and proper operation of the circulation pump are essential for maintaining optimal performance and prolonging the lifespan of the dishwasher. Issues such as blockages or mechanical failures can significantly impact the efficiency of the cleaning process.

Identifying the Location of the Drain Hose

Understanding the positioning of the drainage tube is essential for effective maintenance and troubleshooting of your appliance. This component plays a critical role in the removal of wastewater, ensuring optimal performance. Familiarizing yourself with its location can help streamline any repair efforts or routine checks.

Key Areas to Check

- Rear Panel: The drain hose is often routed from the back of the appliance, making this area a primary location for inspection.

- Underneath the Appliance: Look for the hose beneath the unit, where it may be connected to the plumbing system.

- Side Compartments: In some designs, the hose can be found alongside the sidewalls, possibly concealed by insulation or panels.

Connection Points

Identifying the connection points of the drain hose can also aid in understanding its path:

- Sink Connection: The hose typically leads to a fitting under the sink or another drainage outlet.

- Clamp Securement: Check for clamps securing the hose, which may indicate where the drainage line is connected.

- Disposal Unit: In some setups, the drainage line may connect directly to a garbage disposal unit for efficient waste removal.

Control Board: Functions and Malfunctions

The control board serves as the brain of a household appliance, orchestrating its various functions and ensuring smooth operation. This central unit is responsible for processing user commands, monitoring sensor inputs, and managing the overall performance of the machine. A properly functioning control board is crucial for optimal efficiency and effectiveness in daily tasks.

Key Functions: The control board enables a range of essential tasks, such as initiating wash cycles, adjusting water temperatures, and timing the duration of operations. It communicates with other components to maintain consistent performance and energy efficiency. Additionally, it often features a user interface that allows individuals to customize settings according to their preferences.

Common Malfunctions: Despite its importance, the control board can experience issues that may disrupt its functionality. Symptoms of malfunction may include unresponsive controls, failure to start or complete cycles, and erroneous error codes displayed on the interface. In some cases, the board may suffer from electrical surges, wear and tear, or loose connections, leading to inconsistent operation. Troubleshooting and, if necessary, replacing the control board can restore the appliance’s reliability and performance.

Importance of the Door Latch Assembly

The door latch assembly plays a crucial role in ensuring the safe and efficient operation of kitchen appliances. This component not only secures the door in a closed position but also acts as a safety mechanism that prevents the appliance from functioning when the door is ajar. Understanding its significance can help users maintain their appliances effectively and ensure their longevity.

Key Functions of the Door Latch Assembly

- Safety Mechanism: Prevents accidental openings during operation, protecting users from potential hazards.

- Proper Sealing: Ensures a tight seal, which is essential for effective cleaning and drying processes.

- Durability: Designed to withstand repeated use, contributing to the overall longevity of the appliance.

Common Issues with Door Latch Assemblies

Over time, door latch assemblies may experience wear and tear, leading to several issues:

- Difficulties in Closing: A worn latch can prevent the door from closing securely, affecting appliance performance.

- Unresponsive Controls: If the latch is malfunctioning, the appliance may not start or operate correctly.

- Safety Risks: A faulty latch can create safety hazards, increasing the risk of leaks or spills.

Regular inspection and timely replacement of the door latch assembly can significantly enhance appliance performance and safety.

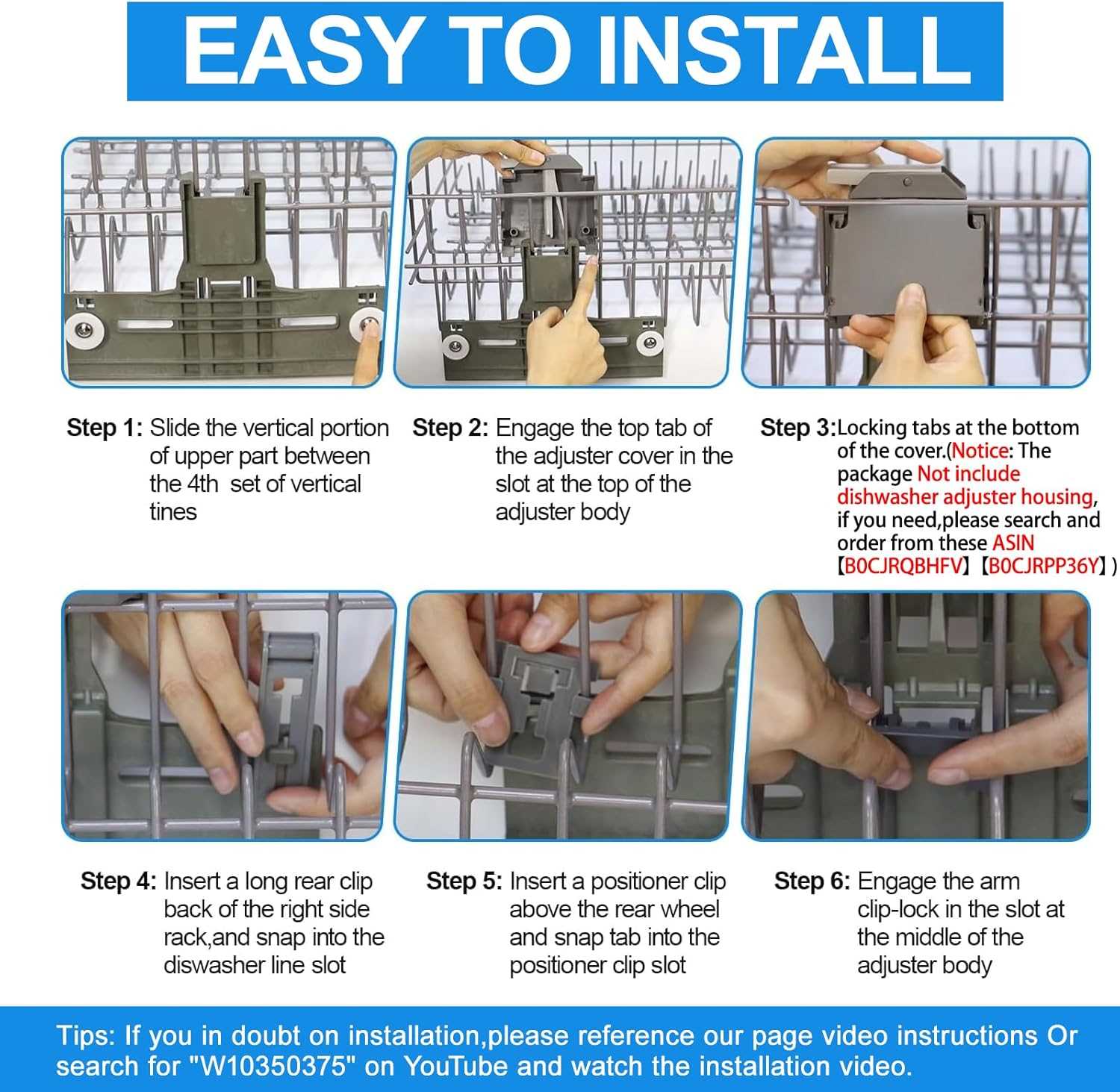

Upper and Lower Rack Adjustments

Adjusting the upper and lower racks of your dishwasher can significantly enhance its efficiency and accommodate various dish sizes. Proper configuration allows for optimal space utilization, ensuring that both small and large items are effectively cleaned. This section will guide you through the process of making adjustments to achieve the best results.

To modify the height of the upper and lower racks, follow these steps:

Step Action 1 Locate the adjustment mechanism on the side of the upper rack. 2 Lift or lower the rack according to your needs. 3 Ensure the rack is securely locked in place before closing the door. 4 For the lower rack, adjust it as necessary to accommodate larger items. By making these adjustments, you can ensure that your dishwasher operates at its highest potential, providing a thorough cleaning for all your kitchenware.

Proper Installation of the Detergent Dispenser

Ensuring the correct placement of the cleaning agent container is essential for optimal performance and efficiency of your appliance. A well-installed dispenser guarantees that the detergent is released at the appropriate times during the washing cycle, maximizing cleaning results and minimizing waste.

Tools and Materials Needed

- Flathead screwdriver

- Phillips screwdriver

- Replacement detergent dispenser unit

- Cleaning cloth

- Sealant (if required)

Installation Steps

- Start by unplugging the appliance to ensure safety during the installation process.

- Remove the front panel or door to access the compartment where the detergent dispenser will be installed.

- Carefully detach the existing dispenser by unscrewing any screws that hold it in place.

- Clean the surrounding area to remove any residue or debris, which could affect the seal.

- Position the new dispenser in place, ensuring it aligns with the existing openings.

- Secure the dispenser using the screws and verify it is tightly fitted to prevent leaks.

- If necessary, apply sealant around the edges for added protection against moisture.

- Replace the front panel or door and reconnect the appliance to the power source.

- Run a test cycle to ensure the detergent is dispensed correctly during operation.

Maintaining the Filter and Chopper Assembly

Proper upkeep of the filter and chopper unit is essential for ensuring optimal performance of your kitchen appliance. Regular maintenance not only extends the lifespan of these components but also enhances the efficiency of the entire system. This section outlines the key practices for keeping these crucial parts in top condition.

Begin by routinely checking the filter for debris and blockages. Accumulation of food particles can hinder the functioning of the system and lead to operational issues. Clean the filter with warm, soapy water and a soft brush to remove any buildup.

Equally important is the care of the chopper assembly. This component plays a vital role in processing waste and requires regular inspection. Ensure that the chopper blades are sharp and free of obstructions. Lubricate moving parts as recommended to prevent wear and tear.

Consider the following maintenance schedule for optimal results:

Task Frequency Inspect and clean the filter Monthly Check chopper assembly for damage Every 3 months Lubricate moving parts of the chopper Every 6 months By following these guidelines, you can ensure that the filter and chopper assembly operates effectively, contributing to the overall functionality of your appliance.