Understanding how each element works together in complex systems can be invaluable, especially when dealing with devices designed for regular use. Every detail plays a crucial role in ensuring the smooth operation of machinery. To keep such equipment functioning optimally, it’s essential to have a clear understanding of how its internal mechanisms are structured.

The focus of this guide is to explore various elements that contribute to the overall efficiency and reliability of the device in question. By identifying and examining the key components, users can better comprehend how each element interacts within the system. This knowledge allows for quicker troubleshooting and easier maintenance, ensuring long-term durability.

Through a detailed examination, we will highlight the main aspects that define the machine’s operational flow. This breakdown will offer insights into the core elements that maintain the balance between functionality and performance, providing an all-encompassing view of the internal structure.

Understanding the Layout of Whirlpool WDT750SAHZ0

The internal structure of modern home appliances can seem complex at first glance. However, by breaking it down into essential sections, the organization of components becomes much easier to grasp. This guide offers an overview of the primary elements and their arrangement, ensuring better maintenance and repair efforts.

Main Functional Areas

The design of this specific model features a logical distribution of key components, each serving a distinct role in its operation. By understanding these areas, users can more effectively troubleshoot and maintain their machine.

- Control System: Positioned at the front, this section houses the electronics that manage various cycles and user inputs.

- Water Distribution: Water management is critical, and the distribution system ensures proper flow during operation, with nozzles and channels directing water as needed.

- Cleaning Mechanism: Central to the unit, this system includes the spray arms, filters, and other components responsible for the core functionality of the machine.

- Drying Unit: Typically located near the top, this segment helps in the final stage, ensuring effective moisture removal

Main Components and Their Functions

The functionality of any modern household appliance depends on the seamless operation of several critical elements. Each of these key elements plays a specific role, ensuring smooth performance and longevity. Below, we will explore the essential units and their roles, which contribute to the overall efficiency of the device.

- Control Unit: This is the brain of the system, managing and coordinating all other functions. It interprets user commands and ensures that the different modules work in harmony to achieve the desired outcomes.

- Pump Assembly: Responsible for circulating and draining liquids, this part maintains the proper flow needed for the device to perform optimally. Its efficiency is crucial for preventing blockages and ensuring thorough cleaning cycles.

- Heating Element: This component regulates the temperature of water, ensuring that it reaches the right levels to improve performance and achieve energy efficiency. Consistent temperature control is key to optimal cleaning and drying results.

- Water Inlet Valve: It controls the water supply, allowing the necessary amount of liquid into the system. Proper regulation of water inflow

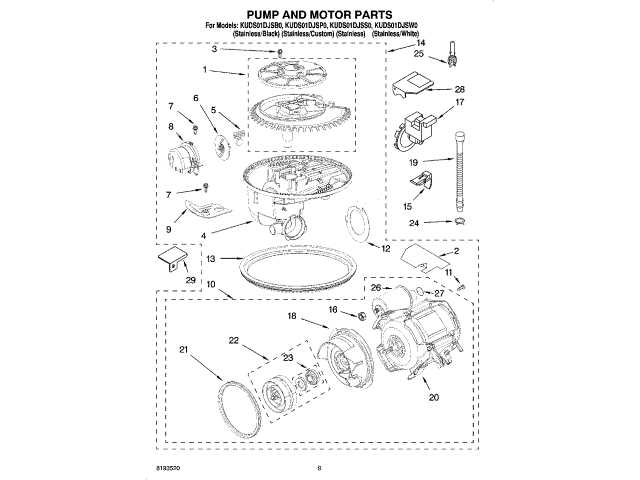

Exploring the Pump System Design

The pump system is a crucial component responsible for the efficient movement of fluids throughout the unit. Its design is essential to ensure smooth operation, facilitating the distribution and circulation of liquids, while preventing any potential blockages or flow disruptions. Understanding the inner workings of this mechanism can provide valuable insights into its overall functionality and performance.

Main Components and Functions

At the heart of the system lies a combination of key elements that work together to achieve optimal fluid circulation. The motor powers the system, driving the impeller, which in turn generates the necessary force to propel water. Seals and filters ensure that only clean liquid passes through, maintaining the integrity of the entire operation.

Efficiency and Maintenance

Efficiency in the system’s design allows for minimal energy consumption while maximizing output. Regular maintenance of the pump, such as cleaning the filters and checking seals for wear, can significantly extend the lifespan of the system. Keeping these elements in top condition ensures that the overall unit continues to perform at its best.

How the Control Panel Operates

The control panel serves as the central interface that allows users to manage the machine’s functionality. It provides access to various settings, modes, and indicators, making it easier to customize and monitor operations. Understanding how this interface works helps in selecting the right options for efficient performance.

Main Functions of the Control Panel

- Power Management: The panel typically includes buttons or touch-sensitive areas to turn the machine on or off, ensuring proper operation and energy conservation.

- Cycle Selection: Users can choose from different programs depending on the task, such as quick cycles or intensive modes.

- Indicators: The interface provides visual cues, often in the form of lights or symbols, to indicate the current status or to alert about specific conditions like low detergent.

Customization Options

- Temperature and Speed Controls: The user can adjust settings like water temperature or cycle speed to match their preferences.

- Delay Start: This feature allows for scheduling the start time of a cycle, offering greater flexibility and convenience.

- Lock Features: Many panels include a child lock or other safety mechanisms to

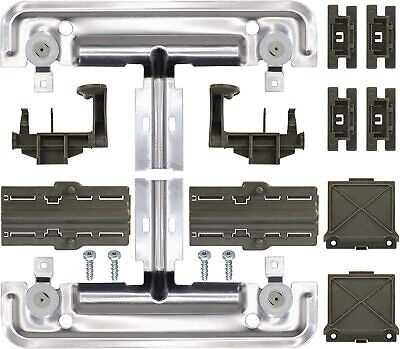

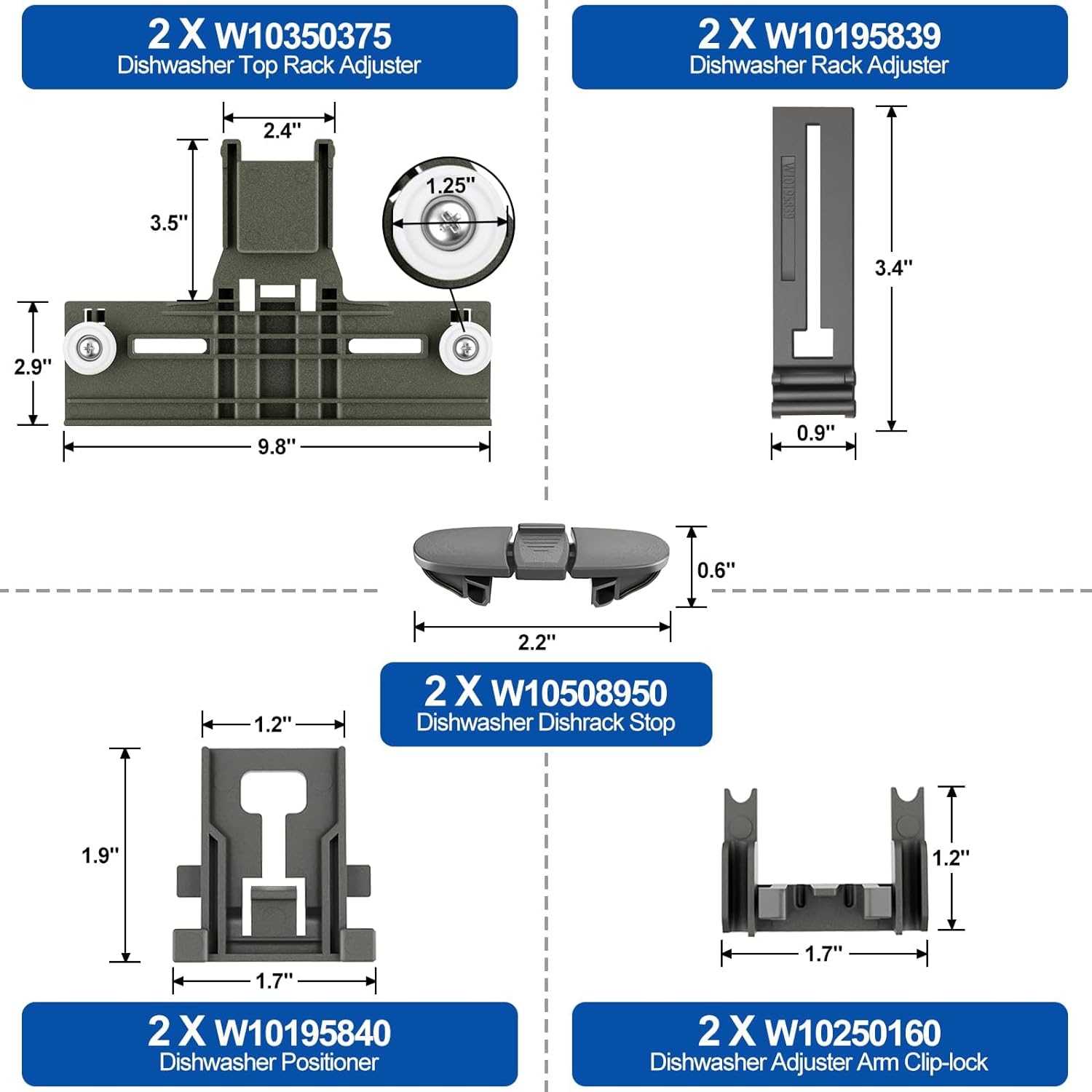

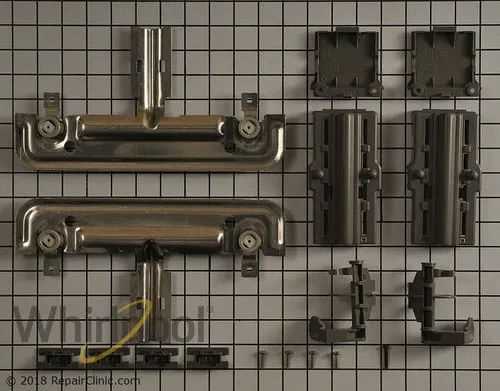

Inner Tub and Rack Assembly Overview

The internal compartment and rack structure play a critical role in the efficient functioning of modern dishwashing systems. The combination of these elements ensures proper water circulation and optimal placement of various items during cleaning. Designed to accommodate different sizes and types of dishes, the interior components maximize space utilization while maintaining stability during operation.

The inner compartment serves as the main enclosure where all cleaning activities occur. Its shape and material are engineered to resist water exposure and support the high-pressure flow of water. This design helps in ensuring thorough cleaning and durability over extended use.

The rack system complements the inner compartment by providing a well-organized layout for placing items of varying shapes and sizes. Adjustable and often removable, the racks can be configured to enhance the flexibility of the system, making it adaptable to different washing needs. Efficient spacing between the rack levels allows for better water coverage and effective drying.

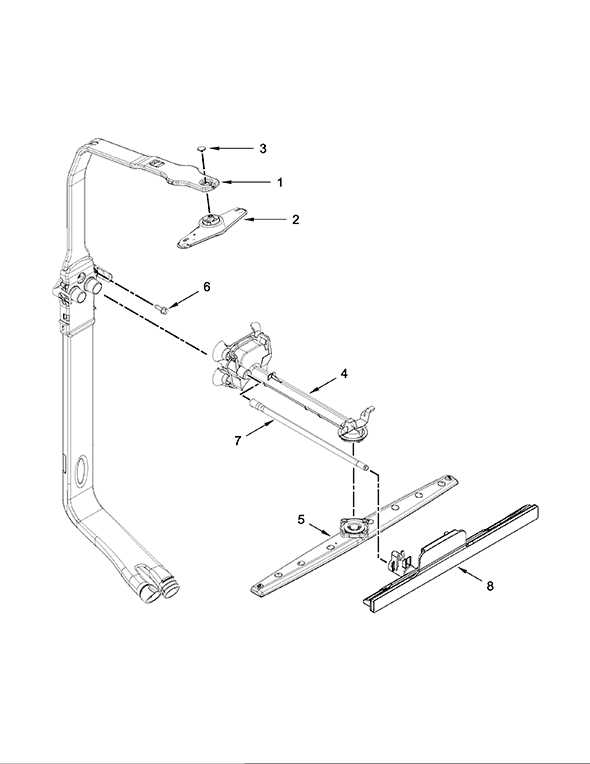

Spray Arm Mechanism Explanation

The spray arm mechanism is a crucial component in dishwashing appliances, designed to ensure efficient cleaning of dishes and utensils. This mechanism operates by utilizing a combination of water pressure and rotational motion to distribute water evenly throughout the washing chamber.

At its core, the spray arm consists of several key elements that work together seamlessly:

- Motor and Pump: These elements generate the necessary pressure to push water through the spray arms.

- Rotating Arm: The central part of the mechanism, it rotates as water flows through it, directing water jets in various angles.

- Spray Nozzles: Located at the end of the spray arm, these nozzles release water in specific patterns, optimizing the cleaning process.

The efficiency of this mechanism depends on its ability to maintain a consistent flow of water while ensuring that every surface of the items being cleaned is reached. The design allows for flexibility, accommodating different dishware sizes and shapes.

Regular maintenance of the spray arm is essential for optimal performance. Blockages in the nozzles can impede water flow, resulting in subpar cleaning results. To ensure longevity and efficiency, users should periodically check for clogs and clean the spray arm as needed.

Understanding the function and maintenance of the spray arm mechanism can significantly enhance the user experience, leading to better cleaning results and extending the lifespan of the appliance.

Heating Element Role in the Dishwasher

The heating component plays a vital part in the operation of a dish-cleaning appliance. This essential element is responsible for raising the temperature of the water used during the cleaning cycle. By ensuring that the water reaches the optimal heat level, it facilitates the breakdown of stubborn food residues and enhances the effectiveness of cleaning agents. Additionally, the component also aids in drying the dishes, providing a thorough clean and eliminating moisture from the surfaces of the items.

Importance of Temperature Control

A key function of the heating element is to maintain precise temperature control throughout various stages of the washing process. High temperatures help in dissolving grease and grime more efficiently, allowing for a more effective cleaning outcome. Moreover, by regulating heat, this component ensures that the dishwasher operates at peak performance, optimizing water usage and energy consumption.

Contribution to Drying Cycle

Beyond its role in the washing phase, the heating element also contributes significantly to the drying cycle. Once the cleaning process is complete, this component generates heat that evaporates residual water, resulting in spotless and dry dishes. By accelerating the drying process, it minimizes the chances of water spots and ensures that the items are ready for immediate use.

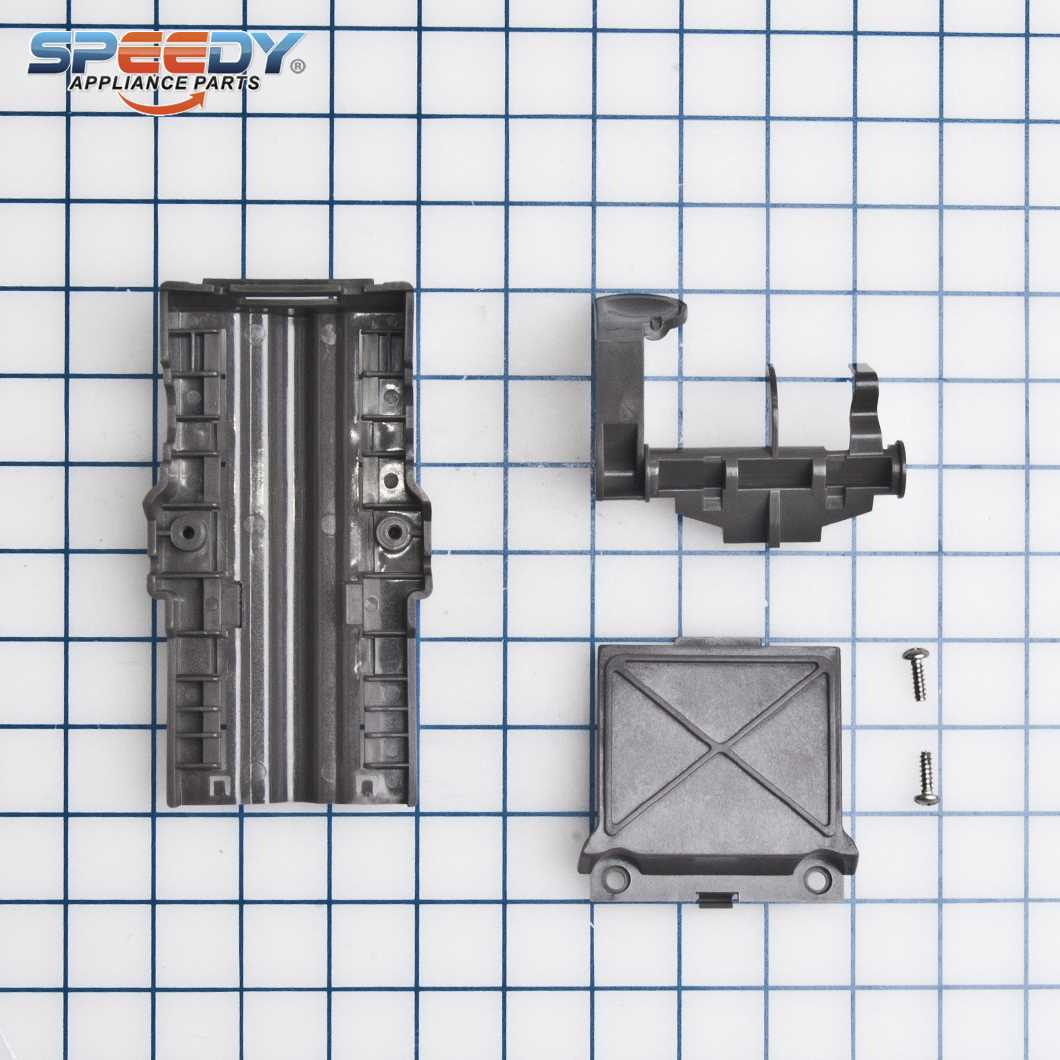

Dispenser and Detergent Delivery System

The dispenser and detergent delivery mechanism play a crucial role in ensuring optimal cleaning performance in dishwashing appliances. This system is designed to release the appropriate amount of cleaning agents at the right time during the wash cycle, thus enhancing the effectiveness of the cleaning process while minimizing wastage.

Components of the Delivery System

At the core of this mechanism are several essential components. The primary element is the dispenser compartment, which holds the detergent until it is needed. When the wash cycle begins, a series of sensors and controls activate the compartment to release the cleaning agent. Additionally, there may be a rinse aid reservoir, which ensures that dishes are not only cleaned but also rinsed effectively to prevent spotting.

Functionality and Maintenance

Regular maintenance of the dispenser and delivery system is vital for consistent performance. Users should ensure that the dispenser is free from clogs and that any sensors are functioning correctly. Periodically checking for buildup and cleaning the components can significantly enhance the efficiency of the washing process and extend the lifespan of the appliance.

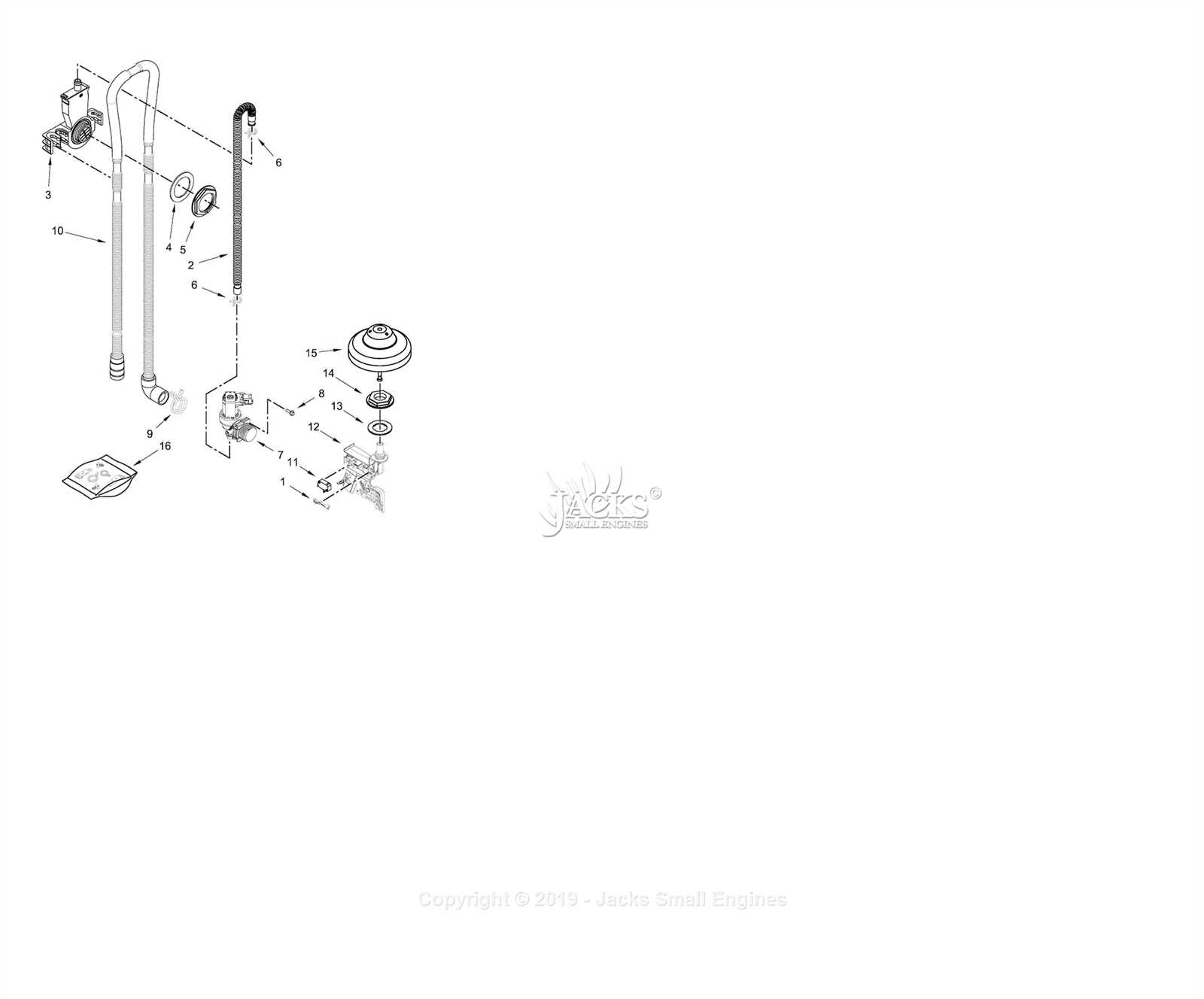

Water Inlet Valve and Flow Regulation

The water inlet valve is a crucial component in the operation of various appliances, managing the entry of water into the system. It plays a significant role in ensuring that the appropriate amount of water flows through the unit, facilitating optimal performance and efficiency. Understanding its functionality and the mechanisms involved in flow regulation can aid in troubleshooting and maintenance.

Functionality of the Water Inlet Valve

This essential device acts as a gateway, controlling the water supply based on the appliance’s requirements. When activated, it opens to allow water to enter, while closing to prevent overflow or leakage. The valve typically operates in response to signals from the control system, which assesses the need for water based on the cycle stage.

Flow Regulation Mechanisms

Flow regulation is achieved through various mechanisms that ensure a steady and consistent water supply. Key aspects include:

- Pressure Control: The valve is designed to maintain optimal water pressure, preventing fluctuations that could disrupt operation.

- Filtration: Many valves include filtration features that help to reduce contaminants, ensuring clean water enters the system.

- Feedback Systems: Sensors may be integrated to monitor flow rates and provide real-time feedback to the control unit, enhancing precision in water management.

Regular inspection and maintenance of the water inlet valve can prevent issues related to water flow, contributing to the overall efficiency and longevity of the appliance.

Drainage System and Maintenance Tips

The effective operation of any appliance relies significantly on its drainage mechanism. Proper maintenance of this system is essential to prevent clogs and ensure smooth water flow. Regularly checking and cleaning the components associated with water removal can help enhance efficiency and prolong the lifespan of the unit.

Importance of Regular Inspections

Routine inspections of the drainage setup are crucial. Users should frequently examine hoses and connections for signs of wear or blockages. Clear any debris or buildup that may hinder water flow, ensuring that all components are functioning as intended. Identifying potential issues early can save time and money in the long run.

Cleaning Techniques for Optimal Performance

Utilizing appropriate cleaning methods can significantly improve the performance of the drainage system. For instance, using a mixture of vinegar and baking soda can effectively break down stubborn residues within the hoses. Additionally, flushing the system with warm water can help eliminate any remaining particles. Adopting these practices regularly will contribute to a more efficient water disposal process.

Filter Mechanism and Cleaning Guidelines

The filtration system within a cleaning appliance plays a crucial role in maintaining optimal performance. It ensures that debris and food particles are effectively trapped, preventing them from recirculating during the wash cycle. Regular maintenance of this component is essential for efficient operation and longevity of the device.

Understanding the Filter Mechanism: The filtration unit typically consists of multiple layers designed to capture various sizes of particles. These layers work together to enhance the cleaning efficacy while reducing strain on other internal components. Familiarity with how this system functions can help users appreciate its importance in daily operation.

Cleaning Guidelines: To keep the filtration system in top condition, it is advisable to perform regular inspections and cleanings. Begin by removing the filter according to the manufacturer’s instructions. Rinse it under warm water to dislodge any trapped debris. For stubborn residues, a soft brush may be employed to gently scrub the surface. It is essential to ensure that the filter is completely dry before reinserting it back into the appliance. Regular cleaning not only promotes better cleaning results but also extends the lifespan of the device.

In conclusion, a well-maintained filtration system is integral to the overall efficiency of a cleaning appliance. By following proper cleaning procedures, users can ensure that their device continues to perform at its best, providing spotless results with every cycle.

Wiring and Electrical Connections Overview

Understanding the intricacies of electrical configurations is essential for ensuring optimal functionality and safety in any appliance. This section delves into the key components and connections that facilitate the proper operation of the system, providing a comprehensive guide to the wiring setup.

At the core of any electrical system are the wiring harnesses, which serve as the main pathways for electrical flow. These harnesses connect various elements, such as motors, sensors, and control boards, allowing them to communicate and function seamlessly. Proper insulation and secure connections are crucial to prevent short circuits and ensure efficient power delivery.

Power Supply and Distribution: The power supply unit is responsible for converting the incoming voltage into usable energy for the appliance. It distributes power to different components, ensuring that each part receives the necessary voltage and current. A well-designed distribution network minimizes energy loss and enhances the appliance’s overall efficiency.

Control Board Connections: The control board acts as the brain of the system, interpreting signals from user inputs and sensors. It is vital to ensure that all connections to the control board are secure and free from corrosion. Regular inspections can help maintain a reliable communication pathway between the control board and other components.

Safety Precautions: It is imperative to follow safety guidelines when working with electrical connections. Always disconnect the appliance from the power source before attempting any repairs or modifications. Utilizing the correct tools and techniques can prevent accidents and ensure a safe working environment.

In summary, a solid understanding of electrical configurations and careful attention to wiring connections are fundamental for maintaining the performance and safety of the appliance. Regular maintenance and inspections can greatly enhance the longevity and reliability of the entire system.