When it comes to marine engines, having a clear representation of their components is crucial for maintenance and repair. A well-structured visual aid can significantly enhance your understanding of how each part interacts within the overall system. This knowledge is essential for anyone looking to ensure optimal performance and longevity of their vessel’s machinery.

In this section, we will explore the intricate layout of engine elements, offering insights into their functions and interconnections. Whether you are a seasoned mechanic or a boating enthusiast, grasping the nuances of these components can empower you to tackle repairs with confidence and precision.

By delving into this subject, you will uncover the ultimate guide to identifying various parts, allowing for effective troubleshooting and efficient servicing. Understanding these details not only saves time but also helps in making informed decisions about upgrades and replacements.

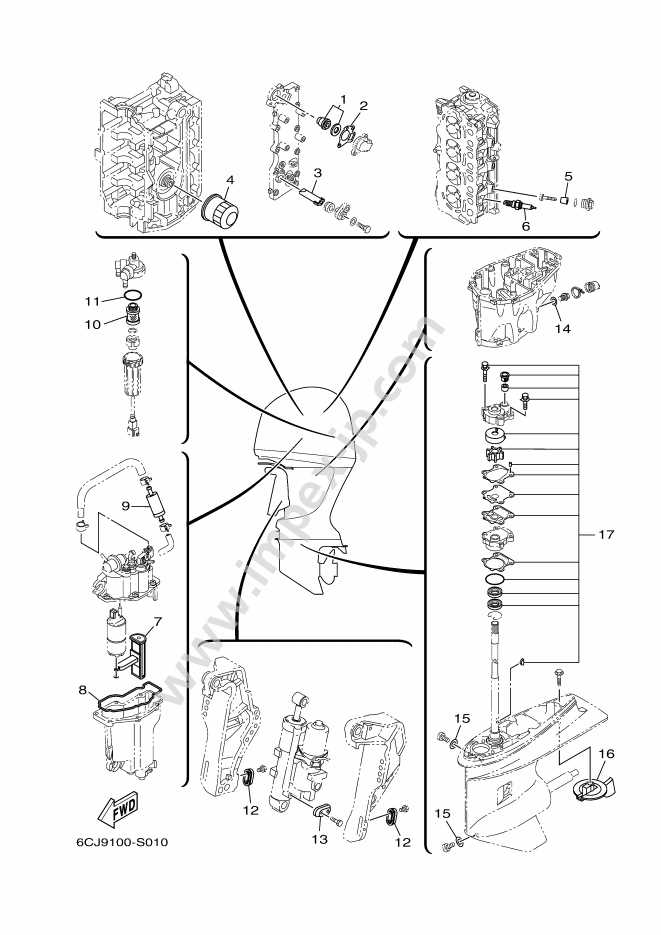

Understanding Yamaha F70 Engine Components

Exploring the intricacies of marine propulsion systems reveals the essential elements that ensure optimal performance and reliability. Each component plays a pivotal role in the overall functionality, contributing to the seamless operation of the engine. From the power unit to the auxiliary systems, understanding these parts is crucial for effective maintenance and operation.

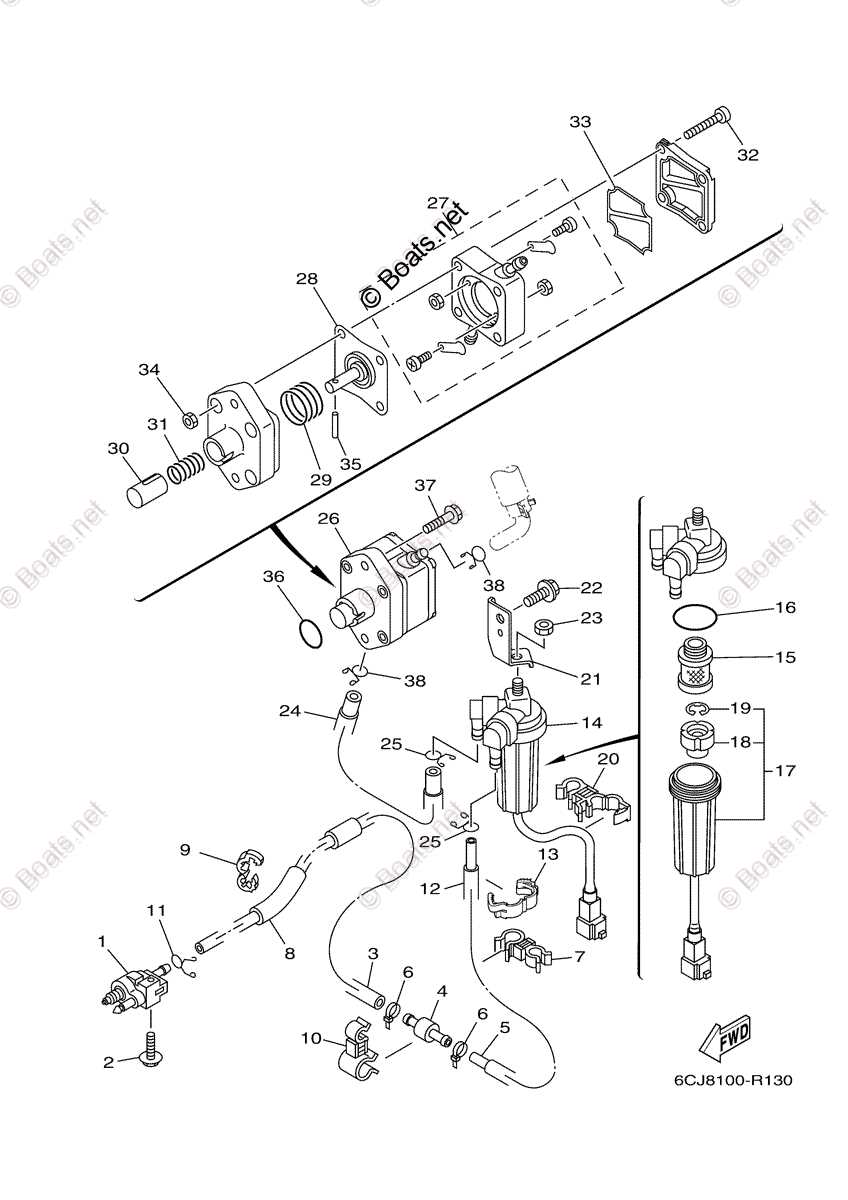

Core elements include the combustion chamber, fuel delivery mechanisms, and cooling systems. Each of these aspects interacts harmoniously to produce power while maintaining efficiency. For instance, the combustion chamber’s design affects fuel efficiency and emissions, highlighting the importance of engineering precision.

Regular inspection of the auxiliary components, such as the ignition system and exhaust systems, is vital for early detection of issues. By familiarizing oneself with these parts, operators can ensure longevity and peak performance, ultimately enhancing the overall boating experience.

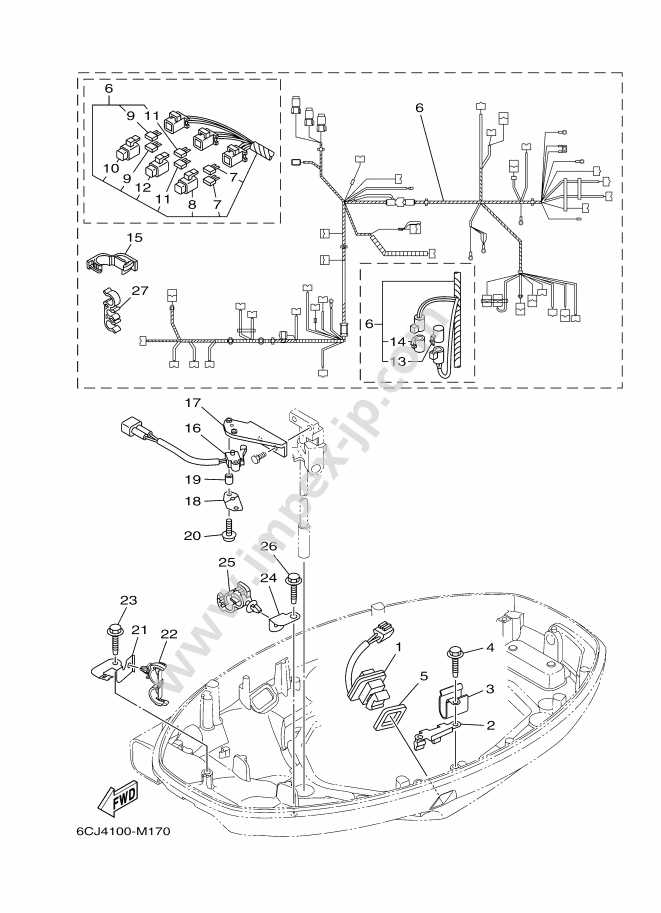

Importance of Parts Diagrams

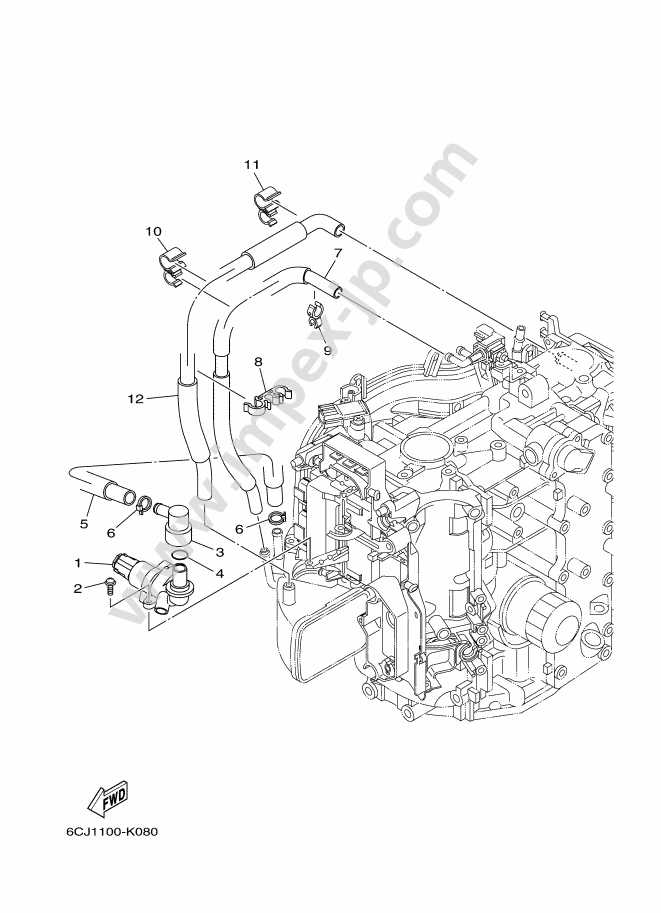

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that simplify the process of identifying individual elements and their functions. This clarity enhances efficiency and helps in preventing costly mistakes during servicing.

Utilizing these visual aids offers several advantages:

- Clarity: A well-structured visual guide helps users quickly locate and recognize different components.

- Accuracy: Proper identification of parts reduces the risk of errors during replacements or repairs.

- Time-saving: Efficient reference can significantly decrease the time spent searching for specific elements.

- Enhanced understanding: Visual aids promote a deeper comprehension of the machinery’s overall structure and operation.

- Facilitates communication: When discussing repairs or maintenance with others, these visuals provide a common language that enhances collaboration.

In conclusion, visual representations are invaluable for anyone involved in the upkeep of complex equipment. They not only streamline the repair process but also contribute to better overall knowledge and efficiency in handling machinery.

Identifying Common F70 Issues

Understanding typical problems that may arise with marine engines is crucial for effective maintenance and longevity. Many operators encounter similar challenges that can affect performance and reliability. This section highlights the most frequently reported concerns and offers guidance on how to recognize them.

Common Symptoms

- Unusual noises during operation

- Difficulty starting the engine

- Overheating

- Inconsistent power output

Preventive Measures

- Regularly check fluid levels

- Inspect fuel lines for leaks

- Clean filters to ensure proper airflow

- Schedule routine maintenance checks

Where to Find Official Diagrams

Locating accurate technical illustrations for marine engines can greatly enhance maintenance and repair tasks. These resources provide essential visual references, ensuring users can identify and assemble components correctly. Whether you are a seasoned technician or a novice, having access to reliable schematics is crucial for successful upkeep.

Official resources are often the best starting point. Manufacturers typically offer these illustrations on their websites, usually within dedicated support or service sections. This ensures that you receive the most up-to-date and precise information directly from the source.

Additionally, authorized dealerships and service centers can be valuable resources. Many of these establishments provide customers with access to comprehensive manuals, which include detailed visual guides. Engaging with professional technicians can also lead to insights on where to find specific illustrations.

Online forums and communities dedicated to marine enthusiasts often share links to reputable sources for technical visuals. Participating in these groups not only helps in finding diagrams but also allows for the exchange of experiences and tips among users.

Lastly, consider utilizing third-party websites that specialize in marine equipment. These platforms may offer a range of illustrations and manuals, but ensure that the information is verified and accurate before use.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone looking to maintain or repair machinery. These visual representations provide essential information about components and their interrelationships, enabling users to navigate complex assemblies with ease.

Identifying Key Components

Start by familiarizing yourself with the symbols and labels used in the illustration. Each element typically corresponds to a specific part, often numbered or marked with letters. Pay close attention to the legend or key, which explains the meaning of each symbol, ensuring you can accurately identify every component.

Understanding Relationships

Next, observe how the various elements connect with each other. Lines and arrows often indicate the direction of assembly or the flow of operations. This contextual understanding will help you see how individual pieces work together, providing clarity when performing repairs or replacements.

Replacing Worn-Out Components

Maintaining optimal performance of your equipment involves timely replacement of deteriorated elements. Over time, components can wear down due to usage, environmental factors, or manufacturing flaws, necessitating attention to ensure reliability and efficiency. Addressing these issues proactively can save both time and resources in the long run.

Identifying Signs of Wear

Regular inspections are crucial for detecting signs of degradation. Look for irregular sounds, reduced efficiency, or visible damage, as these are indicators that components may need replacement.

Replacement Process

Follow these steps for a seamless replacement process:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement parts. |

| 2 | Disconnect power and ensure safety precautions. |

| 3 | Carefully remove the worn-out components. |

| 4 | Install new components following manufacturer guidelines. |

| 5 | Reconnect power and perform a test run. |

Maintenance Tips for Yamaha F70

Proper upkeep of your marine engine is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps in avoiding unexpected breakdowns. Below are some key recommendations to ensure your engine remains in excellent condition throughout its use.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil and filter to maintain lubrication and reduce wear. |

| Check Fuel System | Every 50 hours | Inspect fuel lines and filters for any leaks or blockages. |

| Inspect Cooling System | Every 100 hours | Ensure the cooling system is clear of debris and functioning properly. |

| Examine Propeller | Before each use | Check for damage or wear that could impact performance. |

| Battery Maintenance | Monthly | Inspect battery connections and charge levels to prevent starting issues. |

By adhering to these maintenance practices, you can enhance the reliability of your engine and enjoy worry-free outings on the water. Regular checks and timely servicing are key to achieving peak performance.

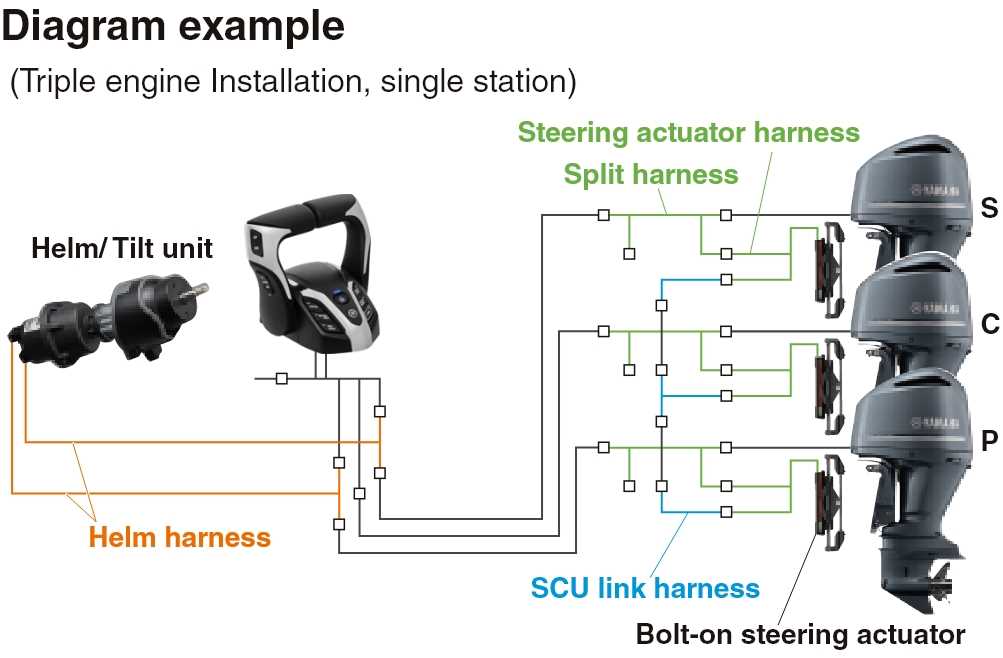

Upgrades for Improved Performance

Enhancing the capabilities of your outboard motor can significantly elevate your overall experience on the water. Various modifications can lead to better efficiency, increased speed, and improved handling, allowing for a more enjoyable journey. Understanding these upgrades helps in making informed decisions tailored to your specific needs.

Engine Tuning

Tuning the engine is essential for maximizing performance. Adjusting fuel mixtures, ignition timing, and utilizing high-quality components can lead to enhanced power output. Emphasizing regular maintenance also ensures that your engine runs optimally.

Propeller Selection

The choice of propeller can dramatically impact your motor’s performance. Opting for a high-performance propeller designed for your craft’s specifications can improve acceleration and top speed. Additionally, experimenting with different sizes and pitches can help you find the ultimate balance between speed and control.

DIY Repair Considerations

When undertaking repairs on your watercraft, it’s essential to approach the task with careful planning and a thorough understanding of the components involved. This process often requires a balance of technical knowledge and practical skills to ensure a successful outcome. Knowing what to expect can greatly enhance your efficiency and effectiveness during the repair process.

Firstly, always prioritize safety. Ensure you have the necessary protective gear and work in a well-ventilated area. Familiarize yourself with the tools required for the job, as having the right equipment can make a significant difference. It’s also advisable to gather relevant documentation or guides that can provide insights into assembly and disassembly procedures.

Furthermore, assess the complexity of the repair. Some tasks may require specialized knowledge or tools, while others can be managed with basic mechanical skills. If you encounter uncertainties, seeking advice from professionals or experienced peers can save time and prevent potential mishaps.

Lastly, maintain an organized workspace. Keep all components sorted and labeled, which will aid in reassembly and minimize confusion. By taking these considerations into account, you can ensure that your DIY repair project is both safe and successful.

Consulting a Professional Mechanic

When facing mechanical challenges, seeking the expertise of a skilled technician can prove invaluable. These professionals possess the knowledge and experience to diagnose issues accurately and recommend effective solutions, ultimately saving time and preventing further complications.

Benefits of Professional Assistance

Engaging with an experienced mechanic offers several advantages. They can provide insights into complex systems, ensuring that repairs are conducted efficiently. Additionally, their access to specialized tools and resources enhances the quality of service provided.

Choosing the Right Expert

It is crucial to select a technician who understands the specific type of machinery you are working with. Look for certifications and reviews to gauge their expertise.

| Criteria | Importance |

|---|---|

| Experience | High |

| Certifications | Medium |

| Customer Reviews | High |

| Pricing | Medium |