Understanding the intricate assembly of a complex machine requires not only a solid grasp of its individual elements but also an ability to visualize how these elements fit together. By examining detailed layouts, one can gain valuable insights into the structure, functionality, and maintenance needs of the system. This information proves essential whether you are troubleshooting an issue or simply exploring the machine’s design.

Each component within the system plays a crucial role in ensuring smooth operation and optimal performance. By exploring a visual representation of these components, users can better comprehend their arrangement, relationships, and the purpose they serve. Such knowledge is fundamental for both routine upkeep and more involved mechanical work.

In this guide, we will explore the key elements that make up

Yamaha RX1 Parts Overview

When considering the key components of this high-performance machine, it’s essential to understand the intricate interplay of elements that ensure optimal functionality and durability. The vehicle relies on a combination of mechanical systems that work together, providing both power and control to the rider. Each section plays a crucial role in the overall performance and reliability.

Engine and Transmission

The core of the system lies in its engine and transmission. These two elements are finely tuned to deliver power efficiently, making it suitable for various terrains. The transmission ensures smooth shifting between gears, enhancing the ride’s overall smoothness.

- High-performance engine with reliable output

- Efficient transmission system for seamless gear transitions

- Durable components designed to withstand rigorous conditions

Key Engine Components and Their Functions

The internal structure of an engine consists of various interconnected elements, each performing a specific task to ensure the smooth and efficient operation of the system. These elements work in unison to convert fuel into mechanical energy, enabling the engine to power the vehicle or machinery it drives. Understanding the roles of these components is essential for maintaining optimal performance and diagnosing potential issues.

| Component | Function | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder | Serves as the chamber where fuel combustion occurs, producing the necessary force to move the pistons. | ||||||||||||||||||||||||||||||||||

| Piston | Moves up and down inside the cylinder, converting energy from combustion into motion that drives the crankshaft. | ||||||||||||||||||||||||||||||||||

| Crankshaft | Transforms the linear motion

Fuel System Layout and Parts IdentificationThe fuel system plays a critical role in ensuring efficient combustion by delivering the necessary fuel to the engine. Understanding how the components are arranged and their function within the system is essential for proper maintenance and troubleshooting. Each element in the layout has a specific purpose, and their interaction ensures smooth operation and optimal performance. Key Components and Their Roles

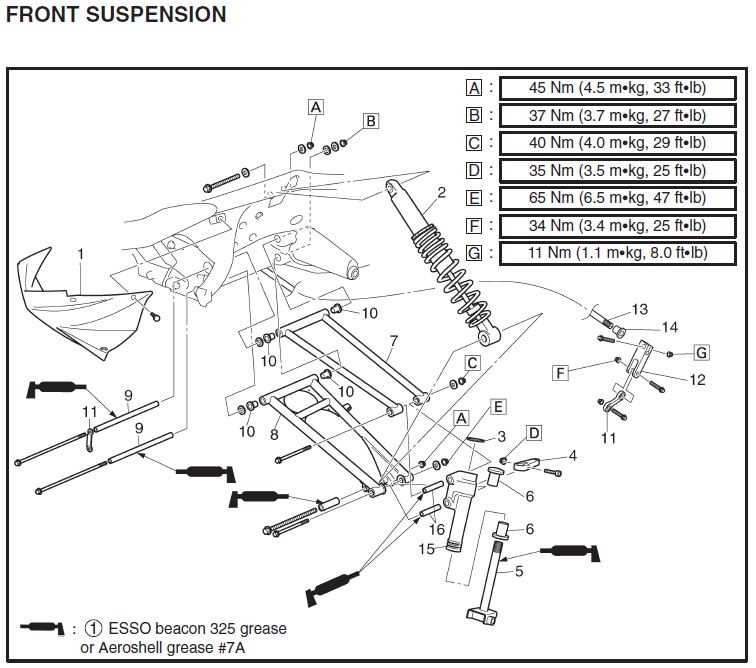

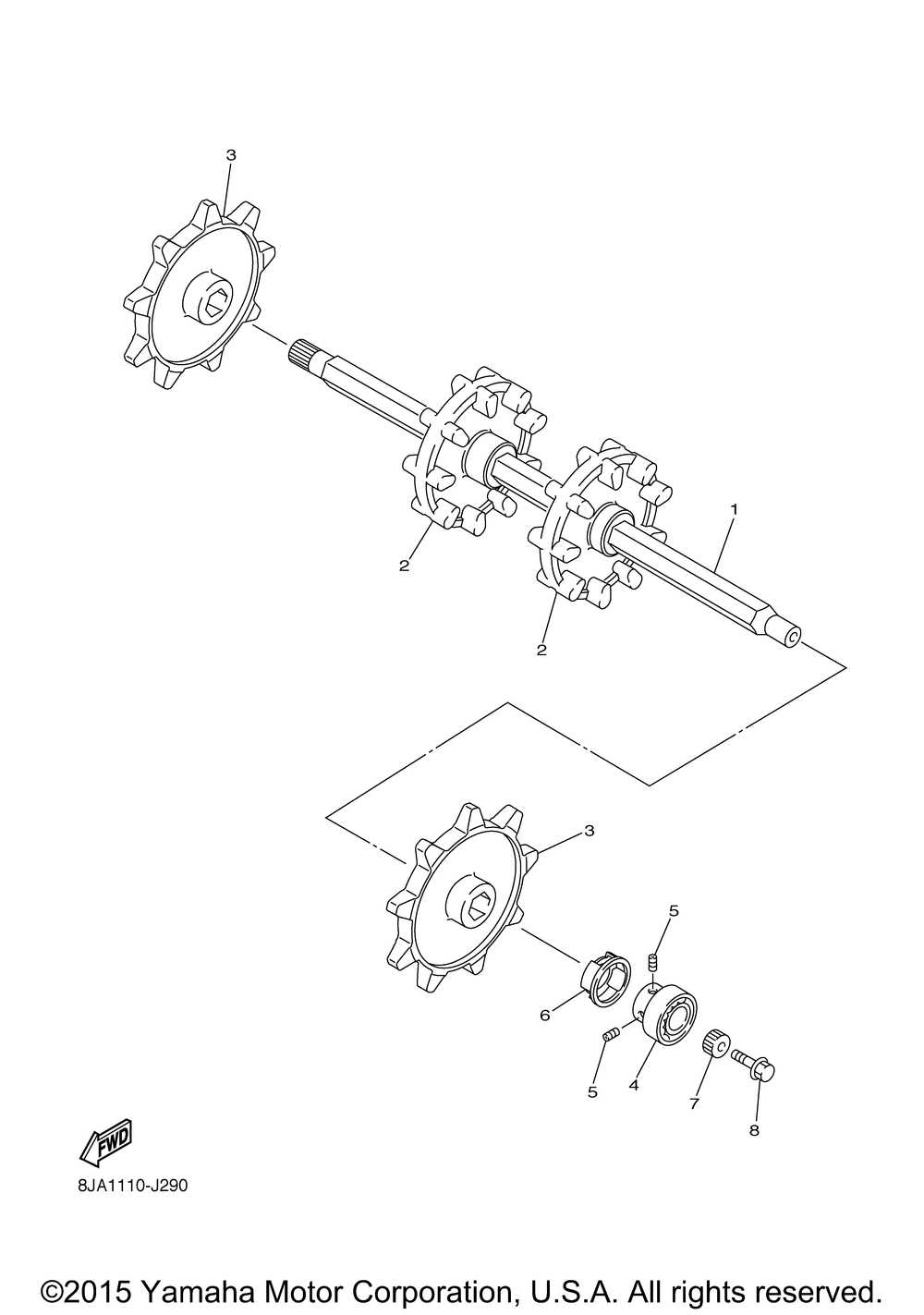

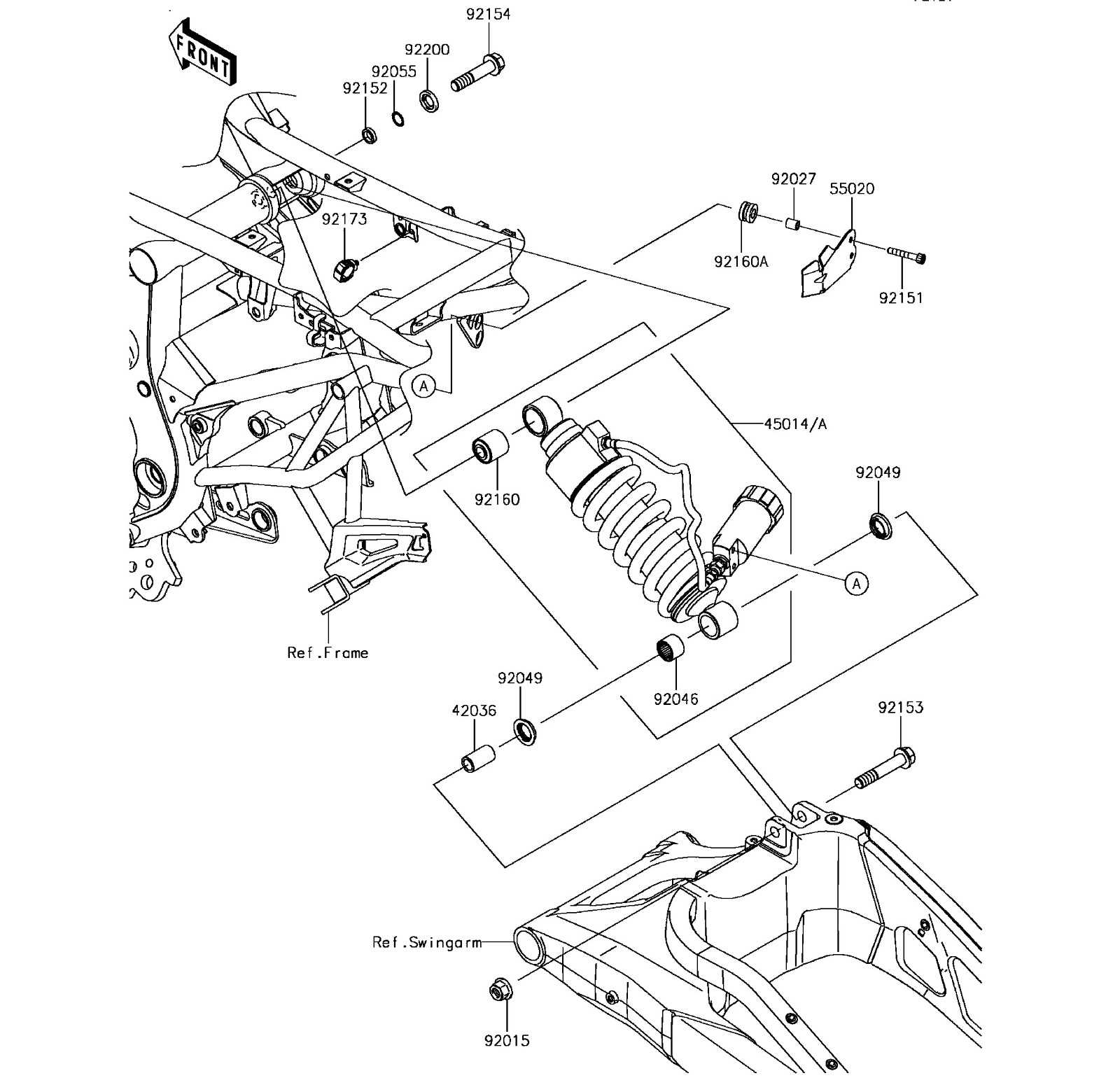

The system consists of several interconnected parts that facilitate the flow of fuel. The primary unit is responsible for drawing the fuel from the storage container, while secondary elements regulate its pressure and ensure a consistent supply to the engine. Other components include filters that prevent contaminants from entering the system, ensuring clean fuel reaches the combustion chamber. Flow Path OverviewThe fuel follows a designated route starting from the storage area, passing through a series of regulators and filters, before being injected into the engine. Along this path, each section is designed to handle specific pressures and flow rates, ensuring that the fuel reaches the engine in an Electrical Components and Wiring StructureThe electrical system is a crucial aspect of any machine, ensuring that power is distributed efficiently to various mechanisms. This section provides a comprehensive look into how the different elements of the electrical framework are interconnected and function harmoniously to ensure optimal performance. Understanding the relationships between individual components can help in diagnosing issues and maintaining the overall integrity of the system. Key Elements of the SystemThe system consists of various interconnected devices, each playing a vital role in ensuring proper electrical flow. These include power distribution units, control modules, and sensors. Together, they form a complex network that requires precise connections to operate efficiently. The careful design of these connections allows for effective communication between components, reducing the risk of malfunctions. Wiring ConfigurationThe wiring layout ensures the transmission of electrical signals between the components, facilitating control and automation. Each wire is designed to handle specific voltages and is routed in such a way Drive Train and Transmission DiagramThe drive system and transmission are crucial components that ensure the effective transfer of power from the engine to the wheels. Understanding how these elements interact and function is key to maintaining optimal performance and ensuring smooth operation. The system includes a network of interconnected parts that work together to control the movement and speed, providing the necessary torque for different driving conditions. Transmission components are responsible for managing the power generated by the engine, allowing for efficient distribution and gear changes. It plays a vital role in adapting the vehicle’s power output to various terrains and driving demands. The balance and synchronization of these components ensure smooth gear shifts and consistent performance. The drive train encompasses the shafts, gears, and chains that link the transmission to the final output. These parts collaborate to transmit force effectively, ensuring that motion is efficiently converted into forward propulsion. Regular inspection of these components is essential to prevent wear and ensure that they f Brake System Assembly and Key ElementsThe braking system is a critical component for ensuring safety and control of any vehicle. It is responsible for slowing down or halting the motion of the machine, offering the rider precise handling and stability. The assembly consists of various interlinked components that work together to achieve optimal braking performance under different conditions. Key elements of the braking system include the brake calipers, which apply force to the braking surface, and the rotors, which rotate with the wheel and provide a surface for the brake pads to grip. Another crucial part is the master cylinder, which generates hydraulic pressure to engage the braking components when the lever or pedal is pressed. This pressure is transmitted through brake lines, connecting all the relevant parts and ensuring efficient force transfer. Maintaining the integrity of each part is essential for the system to function properly. Regular inspection and timely replacement of worn-out elements, such as brake pads and seals, are necessary to avoid performance degradation and ensure the system’s responsiveness. Suspension Parts Breakdown and DetailsThe suspension system plays a critical role in ensuring smooth handling and stability. It consists of various components working together to absorb shocks, maintain balance, and enhance the overall riding experience. Understanding these elements helps in the maintenance and optimization of performance under different conditions. Main Components

Key Functions

Exhaust System Structure and ComponentsThe exhaust system plays a vital role in the overall performance of a vehicle, designed to expel gases produced during combustion efficiently. This assembly not only directs harmful emissions away from the engine but also helps regulate engine sound and performance. Understanding its components is essential for maintaining optimal engine functionality and reducing environmental impact.

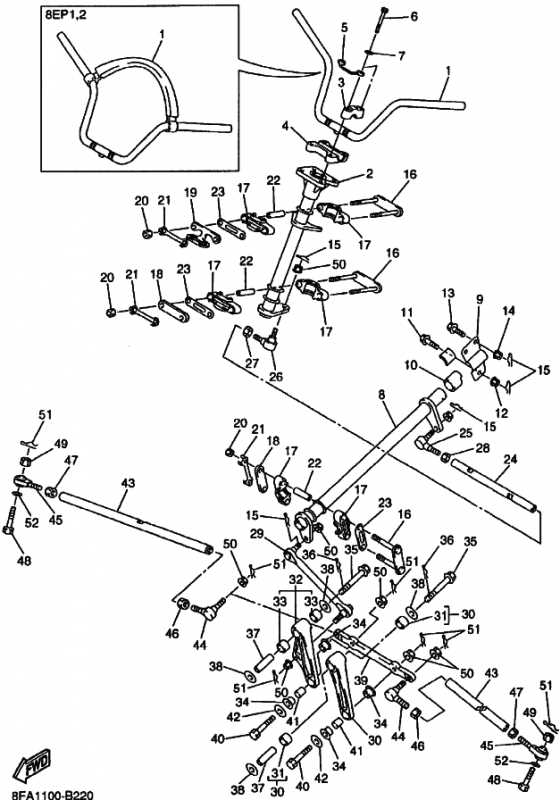

Each part is carefully designed to work in harmony, contributing to both the performance and efficiency of the engine. Regular inspection and maintenance of the exhaust system ensure that it continues to operate effectively, supporting long-term vehicle reliability and environmental responsibility. Steering Mechanism and Related PartsThe steering system plays a vital role in the handling and control of the vehicle. It includes various components that work in unison to allow precise navigation and stability. This section explores the critical elements involved in steering functionality and the associated components that ensure smooth operation. Key Components of the Steering SystemThe steering mechanism consists of several interconnected parts, each designed to contribute to the overall performance and maneuverability. From the steering column to the linkages, these components ensure that the rider can control the direction of the vehicle with ease and accuracy. The following table outlines the main elements and their roles within the system:

Importance of Regular Maintenance

Maintaining the steering components is essential for ensuring smooth and reliable operation. Regular checks of the steering column, linkages, and related elements help prevent wear and tear, ensuring the vehicle remains responsive and stable. Proper lubrication and timely replacement of worn parts are crucial to avoiding potential steering issues and ensuring safety on the road. Cooling System Components and ConfigurationThe efficiency of any high-performance machine depends heavily on its ability to regulate temperature. A well-designed cooling system ensures optimal operation by managing heat effectively, preventing overheating, and maintaining the balance between power output and temperature. The components that make up this system work in harmony to achieve the best performance in varying environmental conditions. Key Components of the Cooling SetupThe core elements of a cooling system include the radiator, water pump, hoses, and the fan assembly. These parts are responsible for circulating coolant and dissipating heat from the engine. Each part plays a vital role in ensuring that the engine operates within safe thermal limits.

Cooling System ConfigurationThe arrangement of these components forms a closed-loop system that maintains a consistent flow of coolant. Coolant travels from the engine, through the radiator, and then back into the engine. This continuous cycle prevents the engine from reaching dangerous temperatures that could cause damage. The efficiency of the cooling system is crucial in ensuring the longevity of the machine’s engine and its overall performance. Chassis Layout and Main PartsThe structure of any vehicle plays a crucial role in its overall performance, offering stability, protection, and support for various mechanical components. Understanding the layout of the frame and its key elements is essential for anyone looking to maintain or modify the vehicle effectively. The following section explores the core components that contribute to the framework and functionality of the unit.

Bodywork Panels and Fitting LocationsThe external elements of a vehicle are essential for both aesthetic appeal and structural protection. Understanding the arrangement and attachment points of these panels is crucial for ensuring a proper fit and functionality. Each section of the bodywork is designed to cover specific areas, providing both safety and visual coherence. Here are the main components of the bodywork and their corresponding fitting locations:

Each panel is fastened with specific bolts, clips, or rivets that ensure secure attachment and ease of removal for maintenance or upgrades. Regular checks of the fitting locations help in maintaining the integrity and performance of the vehicle. Clutch Assembly and Supporting ComponentsThe clutch mechanism plays a crucial role in ensuring smooth power transfer between the engine and the drive system. It includes several key elements that work together to control engagement and disengagement, allowing the vehicle to operate efficiently under various conditions. Understanding the different components of this system is essential for maintenance and troubleshooting. This section covers the main components involved in the clutch system, focusing on their functions and the interaction between them. Each piece is vital for proper clutch operation, contributing to a seamless driving experience.

|