When maintaining an off-road vehicle, it’s crucial to understand how its various components work together. Every piece plays a specific role in ensuring smooth operation, and knowing the arrangement of these elements can simplify both regular upkeep and potential repairs.

Key elements of the machine include its frame, engine, and transmission, each of which must be kept in optimal condition. Ensuring that these components function well is essential for peak performance, as even small misalignments or worn parts can lead to significant issues down the line.

Properly identifying and understanding the positioning of each part is critical for anyone looking to extend the life of their vehicle. A detailed view of the component structure can assist in ensuring that each piece is in its rightful place and functioning as intended.

Yamaha XT500 Parts Overview

Understanding the individual components of this iconic model is essential for those who seek to maintain or restore it. Each piece plays a crucial role in ensuring the reliability and performance, offering a robust foundation for both everyday rides and more adventurous journeys.

Key Components

The model features a variety of key elements designed for durability and versatility. These include systems that provide structural support, enhance maneuverability, and ensure smooth operation during different riding conditions.

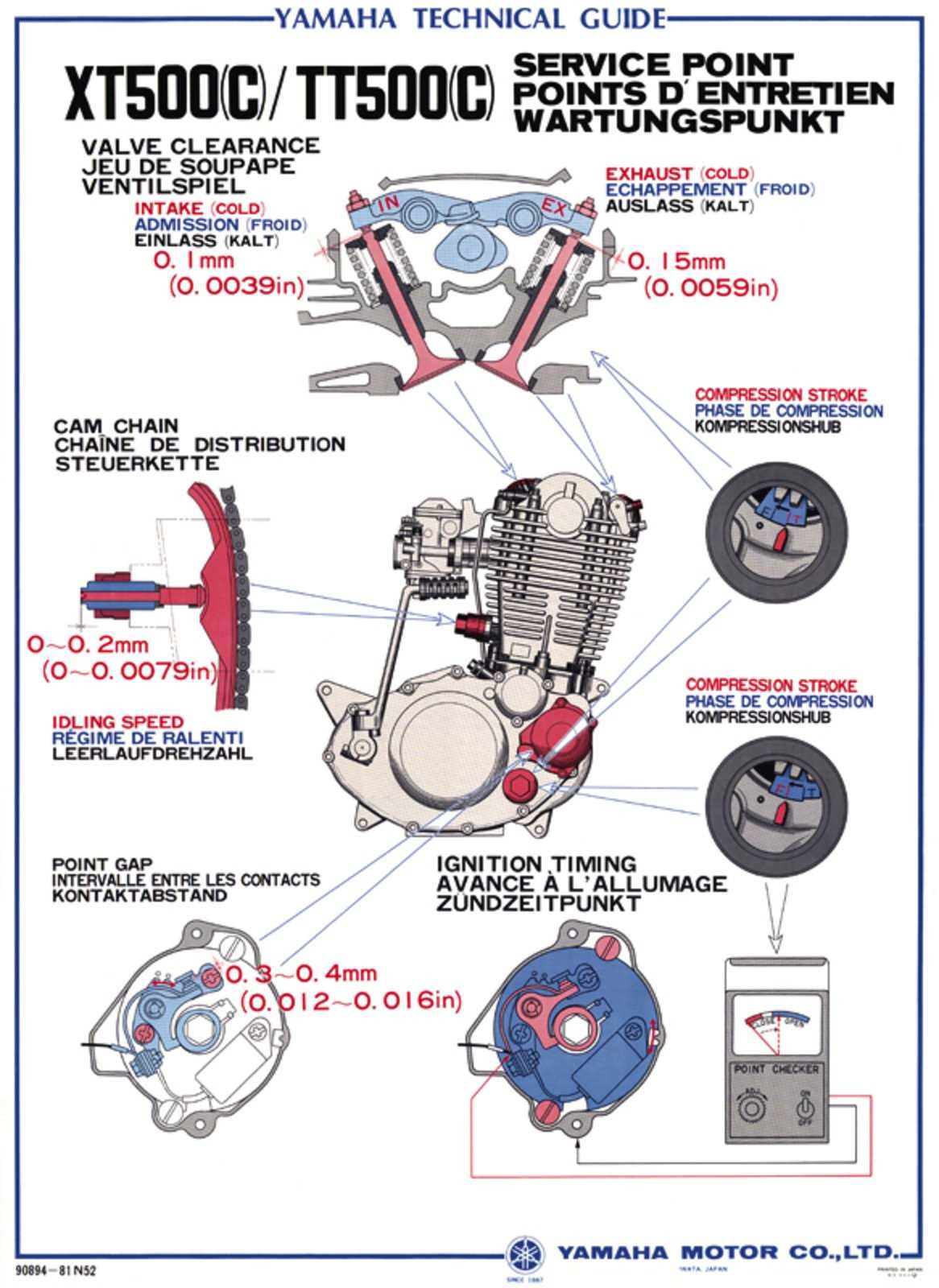

Maintenance Essentials

Regular upkeep is vital to preserve the longevity and performance. Proper care ensures that all elements remain functional and efficiently handle the stresses of varied terrains, maintaining optimal riding experience.

Engine Components Layout

The layout of key engine elements is crucial for understanding how different parts work together to ensure smooth operation. Each component plays a vital role in maintaining the engine’s performance, with some contributing to power generation, while others ensure proper cooling or lubrication.

Core elements include those responsible for combustion and power transfer. These parts are strategically placed to maximize efficiency, providing a balance between durability and power output. Secondary systems focus on regulating temperature and ensuring all moving parts function without excessive wear.

Frame Structure and Design

The framework of a motorcycle plays a crucial role in determining its overall performance and durability. It serves as the backbone, providing stability and support while enhancing the aesthetics of the machine. Understanding the composition and configuration of this vital component is essential for both enthusiasts and mechanics.

Various elements contribute to the framework’s effectiveness:

- Material Choice: The selection of materials impacts weight, strength, and resilience.

- Geometry: The design shapes the handling characteristics and comfort level.

- Welding Techniques: Proper joining methods ensure structural integrity and longevity.

A well-engineered framework not only supports the engine and other components but also influences the riding experience. Factors such as flexibility, rigidity, and weight distribution are vital in enhancing performance and control.

Maintenance and upgrades to the structure can significantly affect the overall functionality and safety. Regular inspections and modifications may be necessary to adapt to different riding styles and conditions.

Exhaust System Breakdown

The exhaust system plays a crucial role in enhancing the overall performance of a motorized vehicle. It is responsible for directing gases away from the engine while reducing noise and emissions. Understanding the components that make up this essential system can lead to better maintenance and improved functionality.

Key Components:

- Header: This part collects exhaust gases from the engine’s cylinders and directs them toward the rest of the system.

- Mid-pipe: Serving as a connecting section, it channels gases from the header to the muffler, ensuring a smooth flow.

- Muffler: Designed to minimize noise produced by the exhaust gases, this component helps create a more pleasant riding experience.

- Exhaust tip: The visible end of the system, it often enhances the aesthetic appeal and can influence the sound emitted.

Regular inspection and maintenance of these components are essential for optimal performance. Proper care can prevent issues such as blockages or leaks, which can adversely affect efficiency.

Fuel Tank and Related Parts

The fuel reservoir is a vital component of any motorcycle, serving as the primary storage for the necessary energy source. Understanding its structure and associated elements is crucial for effective maintenance and optimal performance.

- Reservoir: This is where the fuel is held before being directed to the engine.

- Cap: A secure closure that prevents fuel leakage and maintains pressure within the tank.

- Fuel Petcock: A valve that controls the flow of fuel from the tank to the engine.

- Fuel Filter: An essential component that removes impurities from the fuel, ensuring clean delivery to the engine.

- Fuel Lines: Hoses that transport fuel from the tank to the engine, requiring regular inspection for wear and leaks.

- Mounting Brackets: Hardware used to secure the fuel tank to the frame of the motorcycle.

Regular checks and maintenance of these elements can enhance the longevity of the motorcycle and ensure a smooth riding experience. Proper installation and functioning of the fuel reservoir and its related components are key to avoiding potential performance issues.

Suspension and Shock Absorbers

The suspension system plays a crucial role in maintaining a smooth ride by absorbing bumps and vibrations from the road. Effective dampers and springs work together to enhance stability and comfort, ensuring a balanced experience during travel.

Components of the suspension system include various elements that contribute to the overall performance. The choice of shock absorbers significantly affects how the vehicle handles different terrains, providing a blend of flexibility and firmness.

Regular maintenance of these components is essential for optimal functionality. Inspecting for wear and tear helps in identifying issues before they escalate, thus prolonging the lifespan of the entire suspension system.

Understanding the relationship between the springs and shock absorbers is vital. While springs support the weight of the vehicle, shock absorbers control the rate at which the springs expand and contract, enhancing safety and control during rides.

Braking System Components

The braking system is a crucial aspect of any two-wheeled vehicle, ensuring safe and reliable stopping capabilities. It comprises various elements that work together to achieve optimal performance and responsiveness during braking maneuvers.

Key Elements of the Braking System

Understanding the primary components involved in the braking system can enhance maintenance practices and overall functionality. Each part plays a vital role in ensuring effective deceleration and control.

| Component | Description |

|---|---|

| Brake Pads | Friction materials that press against the rotor to create stopping power. |

| Brake Rotor | A metal disc that rotates with the wheel, where brake pads clamp to slow down the vehicle. |

| Brake Caliper | Holds the brake pads and houses the pistons that push them against the rotor. |

| Brake Line | Flexible tubing that transfers hydraulic fluid from the master cylinder to the calipers. |

| Master Cylinder | Generates hydraulic pressure to engage the braking mechanism when the lever is pulled. |

Maintenance and Care

Regular inspection and timely replacement of worn components are essential for maintaining the effectiveness of the braking system. Ensuring that each part is in good condition will enhance safety and improve overall performance.

Handlebars and Control Elements

The steering system and accompanying control mechanisms play a crucial role in the overall functionality and handling of a two-wheeled vehicle. Understanding the components involved can enhance the riding experience and ensure optimal performance.

Components Overview

Essential parts of the steering assembly and control elements include:

- Grip handles

- Control switches

- Clutch and brake levers

- Throttle mechanism

- Instrument cluster

Functionality and Maintenance

Each component serves a specific function that contributes to safe and effective navigation. Regular inspection and maintenance of these elements are necessary to prevent wear and ensure responsiveness:

- Check for loose connections in control switches.

- Inspect grips for wear and replace if necessary.

- Ensure levers operate smoothly without resistance.

- Verify throttle response for accurate acceleration.

Maintaining these components not only improves safety but also enhances the overall riding experience.

Electrical Wiring and Connectors

This section focuses on the essential components related to the electrical system of the vehicle. Proper connections and wiring play a crucial role in ensuring the functionality and reliability of various systems. Understanding how these elements interact can greatly enhance maintenance and troubleshooting efforts.

Wiring Harness: The wiring harness serves as the backbone of the electrical system, connecting various components and allowing for the transmission of power and signals. It is vital to ensure that the harness is intact, with no fraying or damage that could lead to malfunctions.

Connectors: Connectors are pivotal in maintaining secure and efficient electrical connections. Regular inspection of connectors for corrosion or looseness is essential. Keeping these components clean and well-connected prevents electrical issues and enhances overall performance.

Grounding: Proper grounding is crucial for the electrical system’s efficiency. A solid ground connection helps prevent electrical interference and ensures that all systems function as intended. It is important to regularly check ground points for corrosion or loose connections.

In summary, attention to the electrical wiring and connectors not only improves the vehicle’s reliability but also aids in the longevity of its components. Regular maintenance and inspections are key to preventing potential issues and ensuring optimal performance.

Transmission and Gearbox Parts

The transmission and gearbox assembly plays a crucial role in ensuring smooth power delivery and optimal performance in motorcycles. This section focuses on the various components that contribute to the effective operation of these systems, providing insights into their functions and interconnections.

Key elements include the shifting mechanism, which facilitates gear changes, and the main shaft, which connects the engine to the gearbox. Additionally, various bearings and seals are essential for reducing friction and preventing leaks, ensuring longevity and reliability. Understanding these components can enhance maintenance practices and improve overall efficiency.

Moreover, the layout of the gears within the gearbox determines the motorcycle’s acceleration and top speed. Each gear’s size and arrangement are meticulously designed to balance torque and speed, optimizing the riding experience. Regular inspection and timely replacement of worn parts are vital for maintaining peak performance.

Wheel Assembly and Tires

The wheel assembly plays a crucial role in the overall performance and handling of a vehicle. It consists of various components that work together to ensure stability and smooth operation on different terrains. Understanding the different elements involved in this assembly helps in maintaining and optimizing functionality.

Tires are the primary contact point with the ground, and selecting the right type is essential for effective traction and control. Factors such as tread pattern, rubber composition, and tire pressure significantly influence performance. Regular inspection and proper maintenance of both the wheel assembly and tires are vital for safe and efficient rides.