In the world of marine technology, the intricate mechanisms that drive vessels are crucial for optimal performance and safety. A thorough grasp of these essential elements can greatly enhance the experience of navigating the waters. By exploring the various elements involved, one can unlock the secrets behind efficient movement and control.

Each segment of the propulsion system plays a pivotal role, working in harmony to ensure smooth operation. Recognizing how these components interact can lead to improved maintenance practices and a deeper appreciation for marine engineering. Identifying each element’s function and significance allows enthusiasts and professionals alike to delve into the complexities of watercraft operation.

Ultimately, gaining insights into these mechanisms not only fosters a better understanding but also empowers individuals to make informed decisions regarding repairs and enhancements. Emphasizing knowledge in this area can elevate one’s proficiency in managing a vessel, transforming challenges into opportunities for growth.

Understanding Boat Prop Parts

The components that contribute to the propulsion mechanism of a watercraft play a crucial role in its performance and efficiency. Familiarity with these elements can enhance maintenance and optimize overall functionality. This section aims to provide insights into the various elements involved in this critical system.

| Component | Description |

|---|---|

| Hub | The central part that connects to the engine shaft, providing stability and support. |

| Blades | Flattened extensions that push water backward, generating forward thrust. |

| Nut | A fastening piece that secures the assembly, ensuring components remain in place. |

| Ring | A circular element that provides structural integrity and helps maintain alignment. |

| Clevis | A fitting that allows for the connection of the driving mechanism to the assembly. |

Understanding these components enables operators to better appreciate the mechanics of their vessel, leading to improved handling and safety on the water.

Essential Components of Propellers

The functionality of aquatic propulsion relies on various critical elements that work harmoniously to achieve optimal performance. Understanding these key components is vital for enhancing efficiency and ensuring smooth navigation.

Blades are the most prominent features, designed to create thrust by pushing water. The shape and angle of these elements significantly impact their effectiveness and the overall speed of the vessel.

Hub serves as the central part connecting the blades to the drive mechanism. It plays a crucial role in maintaining structural integrity while facilitating the transfer of energy.

Skirt, often overlooked, aids in reducing drag and improving fluid dynamics. Its design can influence how effectively the blades interact with water.

Additionally, shear pins are safety components that prevent damage by breaking under excessive stress, allowing for quick replacements without impacting the overall system.

In essence, each element contributes to the ultimate performance and efficiency of propulsion systems, highlighting the importance of proper maintenance and selection.

How Propeller Design Affects Performance

The design of a rotational thrust generator significantly influences a vessel’s efficiency and handling. Variations in shape, size, and material can lead to differing levels of performance, impacting speed, fuel consumption, and maneuverability.

- Blade Shape: Curvature and angle affect the flow of water and thrust generation.

- Diameter: A larger diameter typically increases thrust but may reduce speed.

- Pitch: The angle of the blades determines how far the vessel moves through water with each rotation.

- Material: Different materials provide varying durability and weight, affecting overall performance.

Understanding these factors is crucial for optimizing vessel operations and achieving ultimate efficiency on the water.

Common Materials Used in Prop Parts

Understanding the materials utilized in the construction of marine components is essential for ensuring durability and performance. Various substances are chosen based on their properties, contributing to the efficiency and longevity of these vital elements in watercraft operation.

Metals

Aluminum is a popular choice due to its lightweight nature and resistance to corrosion. Additionally, stainless steel offers superior strength and durability, making it ideal for high-performance applications. Both materials have their unique advantages and are widely used in the industry.

Composites

Composite materials, such as fiberglass, provide excellent strength-to-weight ratios and enhanced resistance to environmental factors. These modern substances allow for innovative designs while maintaining structural integrity, making them increasingly favored among manufacturers.

Identifying Different Types of Propellers

Understanding the various designs of rotating blades is essential for optimizing performance and efficiency in aquatic environments. Each configuration serves distinct functions, catering to different vessels and their operational needs. By recognizing these types, enthusiasts and operators can make informed decisions about the best option for their specific requirements.

Standard Blades: These are the most common designs, typically characterized by a straightforward shape and moderate pitch. They provide a balance of speed and thrust, making them suitable for general use.

High-Performance Models: Designed for speed and agility, these configurations often feature a more aggressive pitch and a streamlined design. They are ideal for racing or high-speed applications, allowing for quick acceleration and superior maneuverability.

Heavy-Duty Variants: Constructed to withstand challenging conditions, these options boast reinforced materials and broader blades. They are perfect for towing or carrying heavy loads, ensuring durability and reliability in demanding situations.

Variable Pitch Systems: These innovative designs allow for adjustments in blade angle while in motion, optimizing efficiency across different speeds and loads. They provide versatility, making them popular among experienced operators.

Specialized Types: Certain configurations are tailored for specific environments or uses, such as those designed for shallow waters or enhanced fuel efficiency. Recognizing these unique options can greatly impact overall performance and suitability for particular tasks.

By familiarizing oneself with these diverse types of rotating blades, operators can enhance their experience and ensure that their choice aligns with their unique navigational needs.

Maintenance Tips for Prop Components

Regular care and attention to crucial elements of your vessel can significantly enhance performance and longevity. By implementing effective maintenance practices, you can ensure these components operate smoothly and efficiently, ultimately improving your overall experience on the water.

Here are some essential tips to keep these elements in top condition:

| Tip | Description |

|---|---|

| Inspection | Regularly check for signs of wear or damage, such as cracks or corrosion. Early detection can prevent more extensive issues. |

| Cleaning | Rinse off saltwater and debris after each use to prevent build-up, which can lead to corrosion or performance problems. |

| Lubrication | Apply appropriate grease to moving parts to reduce friction and wear. This will also help protect against rust. |

| Storage | When not in use, store components in a dry, cool place to avoid exposure to moisture and extreme temperatures. |

| Professional Check-Up | Schedule regular inspections by a qualified technician to ensure everything is functioning as it should, catching any hidden issues. |

By following these guidelines, you can maintain optimal functionality and enhance the safety and performance of your vessel’s essential components.

Common Issues with Propeller Parts

Understanding the frequent challenges associated with rotational components is essential for ensuring optimal performance and longevity. Various factors can lead to complications, impacting efficiency and overall functionality.

Wear and Tear

Over time, exposure to water, debris, and varying conditions can cause significant degradation. Cracks, chips, and corrosion are common, leading to reduced effectiveness and potential safety hazards.

Alignment and Installation Problems

Improper alignment during installation can create vibrations and reduce performance. Ensuring correct fitting and torque specifications is crucial for maintaining balance and function during operation.

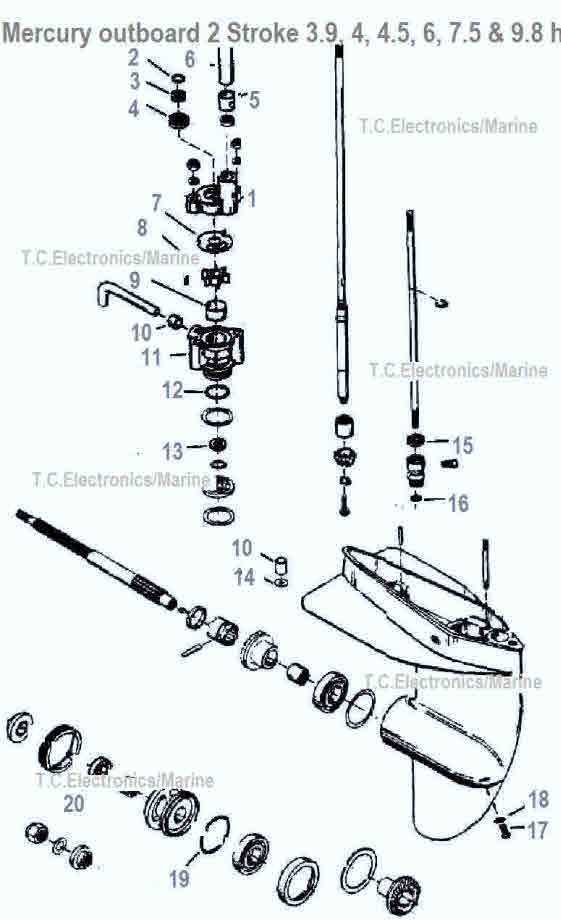

Tools Required for Prop Repairs

Proper maintenance and repair of marine components demand specific tools that ensure precision and safety. Having the right equipment at hand not only streamlines the repair process but also enhances the overall effectiveness of the work being done.

Essential Equipment

To successfully carry out repairs, you will need items such as wrenches, screwdrivers, and pliers. These tools are fundamental for disassembling and reassembling various mechanisms. A torque wrench is also crucial for ensuring that components are secured to the manufacturer’s specifications.

Safety Gear

In addition to repair tools, personal protective equipment is vital. Items like gloves and safety goggles help protect against injuries. Ensuring safety while working is as important as the repair itself, ultimately leading to a successful and hazard-free experience.

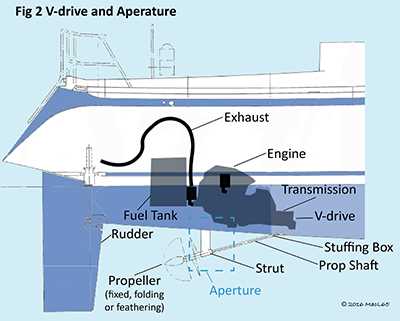

Understanding Propeller Geometry and Function

In the realm of marine engineering, the design and operation of rotating blades play a crucial role in determining performance and efficiency. The interplay of various dimensions and angles influences how effectively these components convert rotational energy into thrust, propelling vessels through water.

Key aspects of blade design include diameter, pitch, and blade area. Each of these features affects how well the device can engage with the surrounding medium, impacting speed and maneuverability. The relationship between these characteristics is vital for optimizing functionality and achieving desired operational outcomes.

The geometry of the blades also encompasses camber and rake, which contribute to the hydrodynamic efficiency. These design elements dictate how water flows around the blades, thereby influencing lift and drag forces. A well-crafted shape can enhance performance by reducing turbulence and increasing thrust.

Additionally, understanding the relationship between blade design and operating conditions is essential. Variations in speed, load, and water density can significantly alter how effectively the system functions. By carefully analyzing these factors, one can achieve a harmonious balance that maximizes overall effectiveness.

In conclusion, grasping the intricacies of blade geometry and its implications on functionality is vital for enhancing performance. A thorough comprehension of these principles ensures that vessels operate at their best, achieving optimal speed and efficiency in various conditions.

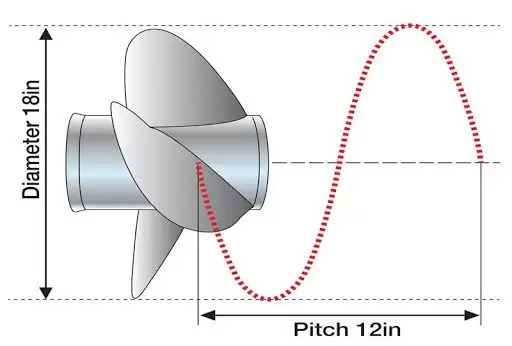

Impact of Pitch on Boat Speed

The relationship between the angle of the blades and the resulting velocity is crucial for optimizing performance on the water. Understanding this dynamic can lead to enhanced efficiency and better overall handling during navigation.

Pitch plays a significant role in determining how quickly a vessel can move through the water. A higher angle generally allows for greater thrust but may limit maximum speed, while a lower angle can facilitate faster travel but at the cost of acceleration. Finding the right balance is essential for achieving the desired outcomes.

Additionally, environmental factors such as water conditions and load weight can influence the effectiveness of the chosen angle. Adjusting the pitch based on these variables can significantly enhance maneuverability and speed. Therefore, careful consideration of pitch is vital for any mariner seeking to optimize their journey.

Upgrading Your Boat Propeller

Enhancing the performance of your vessel involves careful consideration of its propulsion system. An improved rotor can lead to better efficiency, increased speed, and enhanced maneuverability on the water. Whether you seek a smoother ride or greater power, selecting the right rotor is essential for achieving your goals.

Understanding Your Needs

Before making any modifications, assess your current requirements. Are you aiming for higher speeds, or do you need better handling in rough conditions? Understanding these needs will help you choose an upgrade that aligns with your ultimate aspirations.

Choosing the Right Upgrade

When selecting a new rotor, consider factors such as material, design, and size. Stainless steel options often provide durability and performance, while aluminum versions can offer lightweight advantages. Ensure the specifications match your vessel’s design for optimal results.

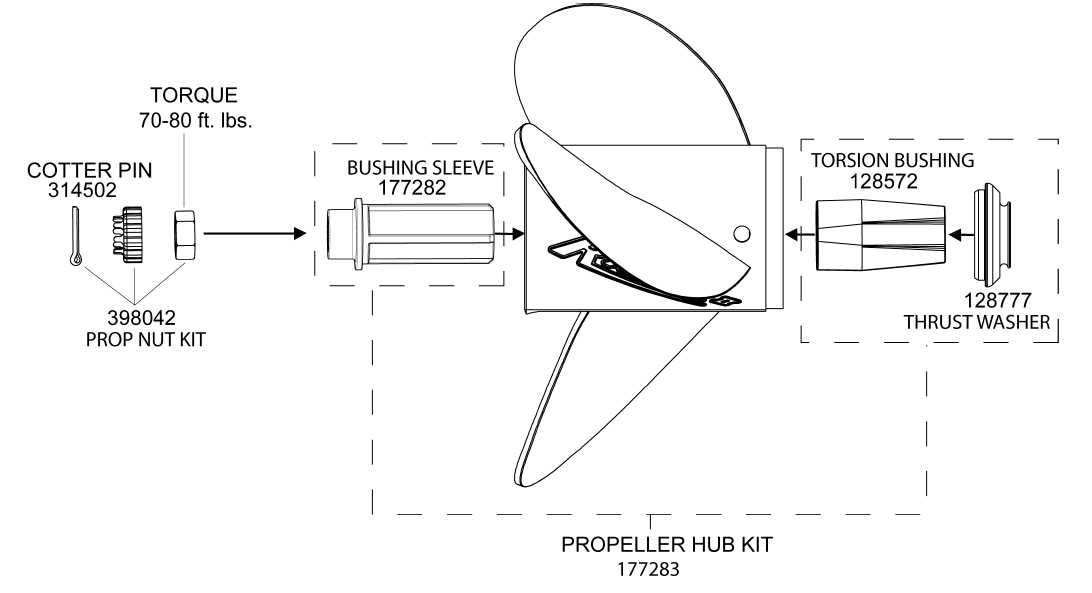

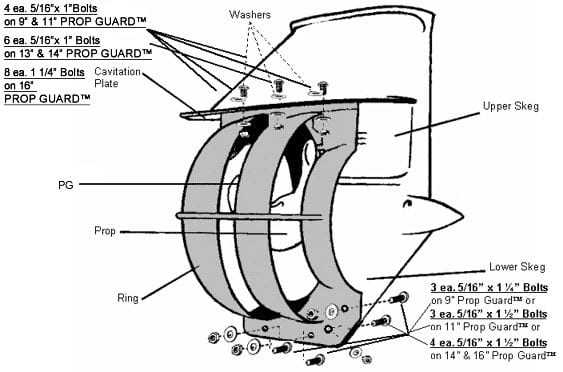

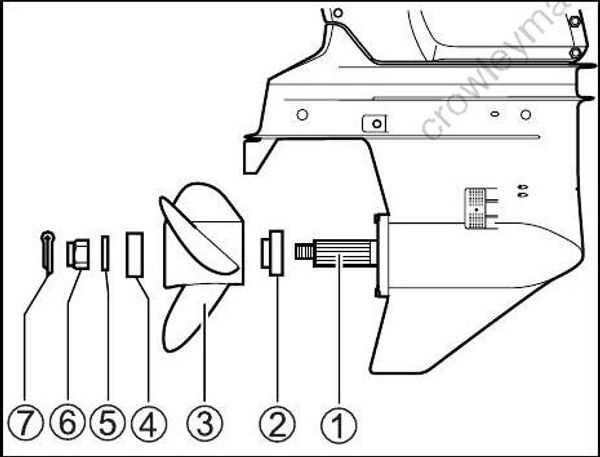

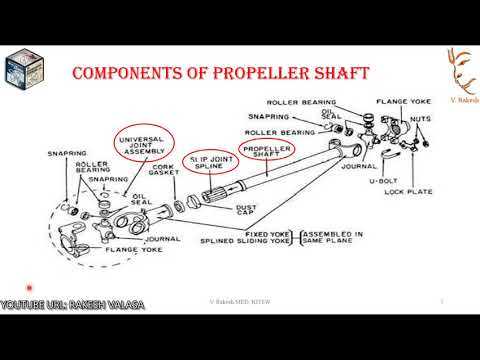

Diagramming Propeller Assembly and Parts

Understanding the intricate components involved in the rotational mechanism is essential for effective maintenance and repair. Each element plays a crucial role in optimizing performance and ensuring longevity. A clear representation of these elements can facilitate better comprehension and enhance the efficiency of troubleshooting processes.

The main components involved in this assembly include:

- Central hub

- Blades

- Spindle

- Nut and washer

- Throttle linkages

When analyzing these elements, it’s beneficial to consider their arrangement and interaction. Below is a sequential breakdown of the assembly process:

- Begin with the central hub, which serves as the anchor for all other components.

- Attach the blades, ensuring they are secured in the correct orientation for optimal thrust.

- Install the spindle, which connects the assembly to the drive mechanism.

- Secure the assembly with a nut and washer, applying the appropriate torque to prevent loosening.

- Connect any throttle linkages to facilitate control and responsiveness.

By mastering the configuration and function of these components, individuals can enhance their understanding and effectively manage the mechanical system in question.