The intricate world of marine engines is marked by a variety of essential components that work harmoniously to ensure optimal performance. This section aims to delve into the specifics of one popular engine model, highlighting its various elements and how they interact. By examining these components, enthusiasts and professionals alike can gain valuable insights into maintenance and functionality.

Familiarizing oneself with the arrangement and role of each part can significantly enhance troubleshooting skills and the overall understanding of engine mechanics. From the fuel system to the ignition components, every piece plays a vital role in the effective operation of the vessel. As we explore the configuration of these elements, it becomes clear that knowledge is key to successful engine care.

Moreover, recognizing the interplay between different systems can lead to improved efficiency and longevity of the engine. Whether you are an experienced technician or a novice boat owner, comprehending the layout and function of these crucial parts is indispensable. Let’s embark on this journey to unravel the complexities of marine engine design.

Overview of Volvo Penta 5.7 GI

This section provides a comprehensive look at a popular marine engine model, highlighting its key features, specifications, and applications. Designed for durability and performance, this engine is widely used in various watercraft, making it a preferred choice among boating enthusiasts.

Key Features

The engine is known for its robust construction and reliable performance. It boasts a powerful output, ensuring efficient propulsion while maintaining fuel economy. Additionally, the design incorporates advanced technology for enhanced throttle response and smoother operation, making it suitable for both recreational and commercial vessels.

Applications and Benefits

This engine variant is particularly well-suited for inboard motorboats, offering excellent maneuverability and stability on the water. Its compatibility with various hull designs and configurations allows for versatile usage across different types of watercraft. Furthermore, the focus on ease of maintenance and availability of support ensures that owners can enjoy their vessels without prolonged downtime.

Key Components of the Engine

Understanding the essential elements of a marine propulsion unit is crucial for optimal performance and maintenance. Each part plays a vital role in the overall functionality, ensuring efficiency and reliability during operation.

Core Elements

The heart of any engine includes components such as the cylinder block, which houses the cylinders and provides structural integrity. Additionally, the crankshaft converts linear motion into rotational energy, driving the vessel forward.

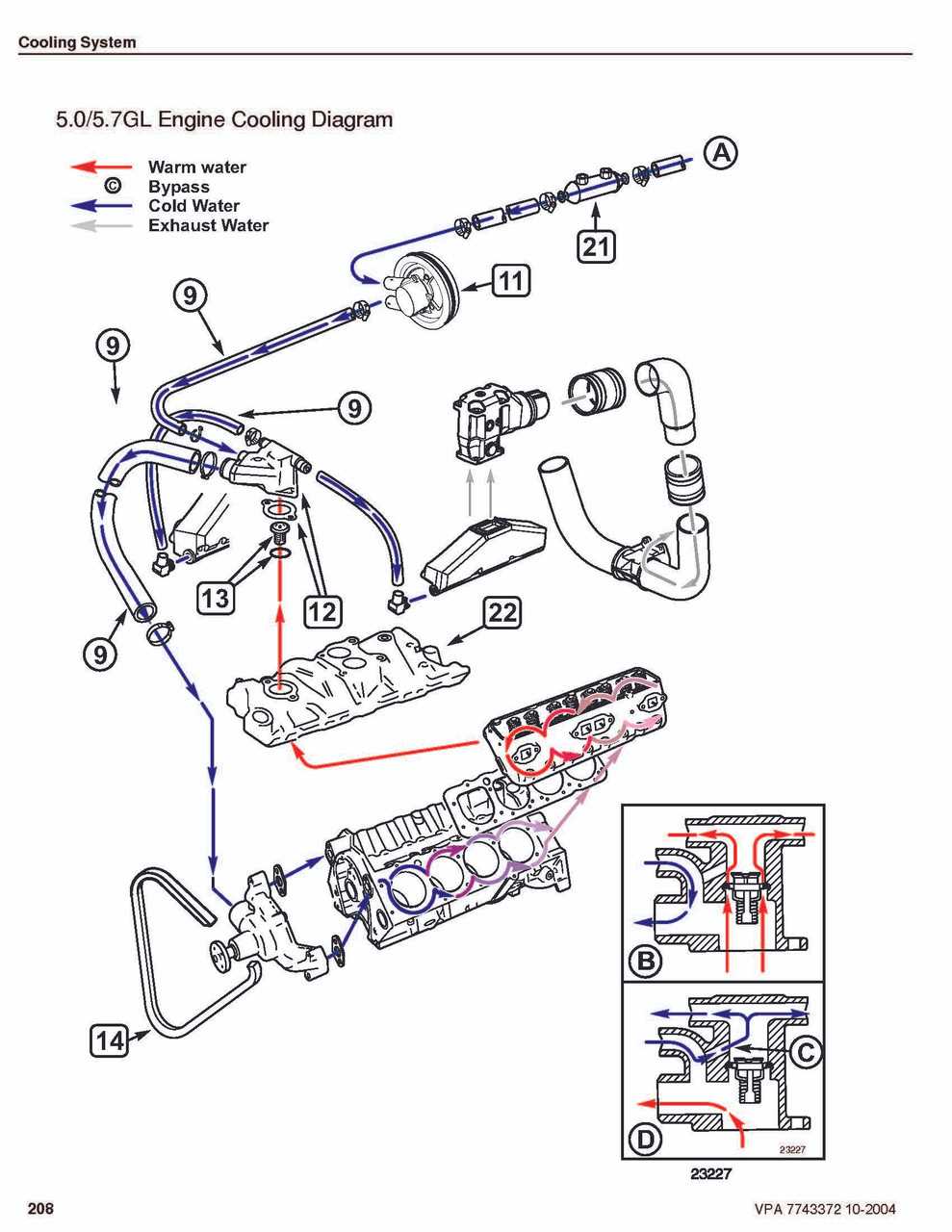

Supporting Systems

Supporting systems like the fuel injection system and cooling system are equally important. The former ensures optimal fuel delivery, while the latter prevents overheating, maintaining the engine’s performance under various conditions.

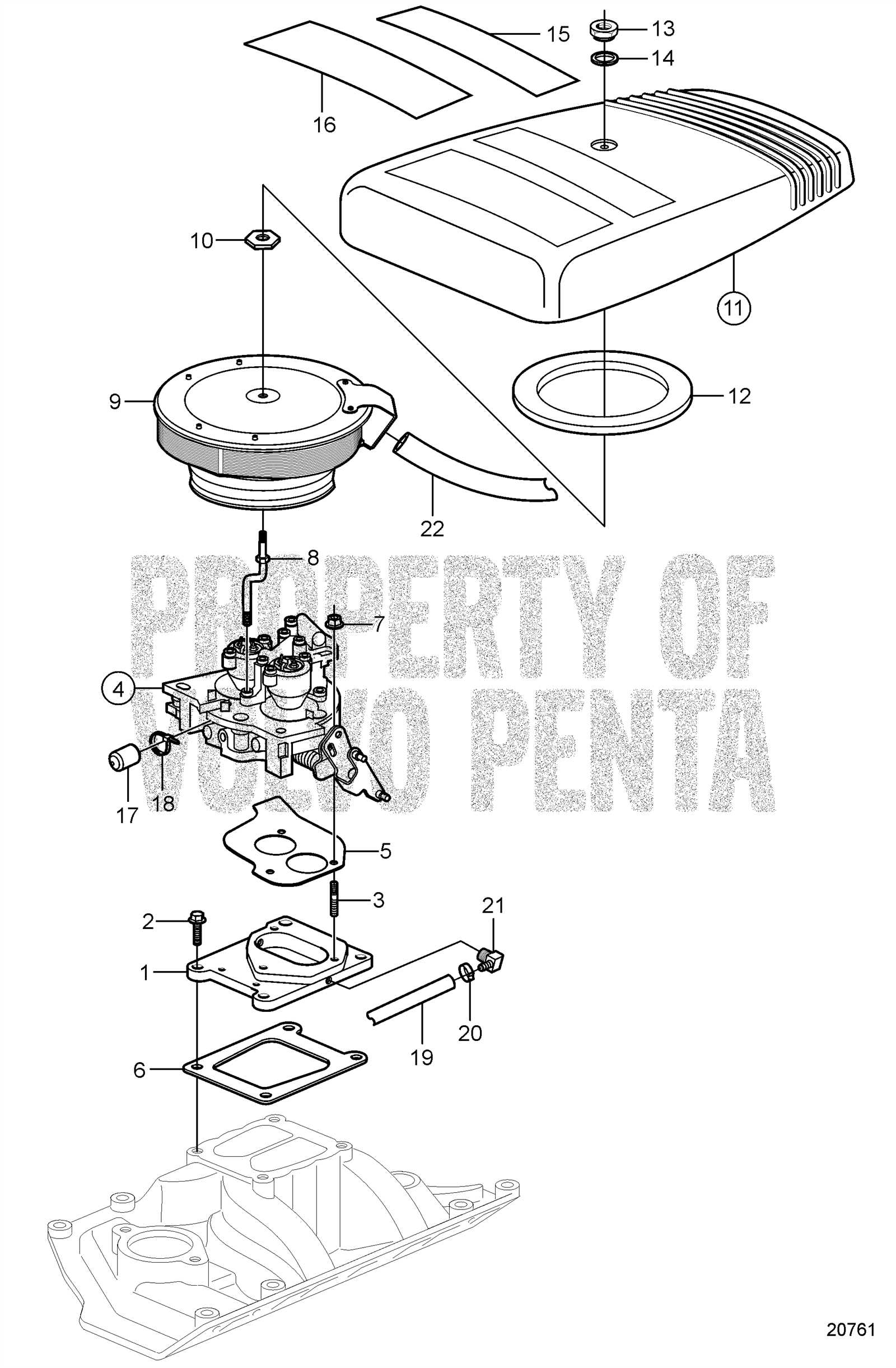

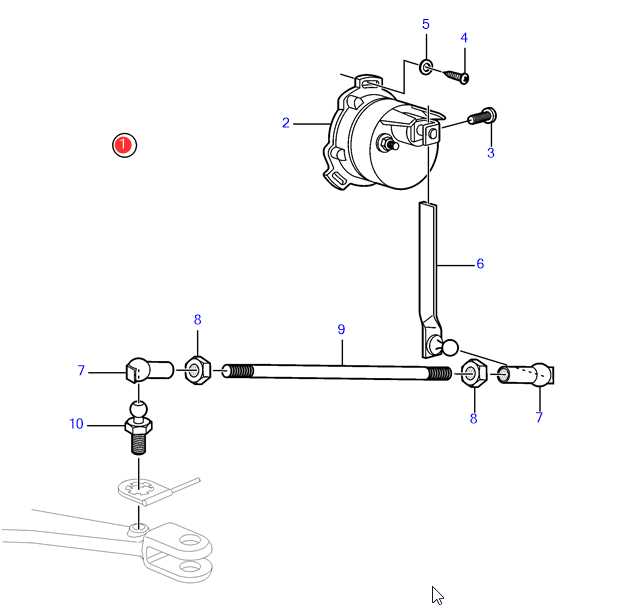

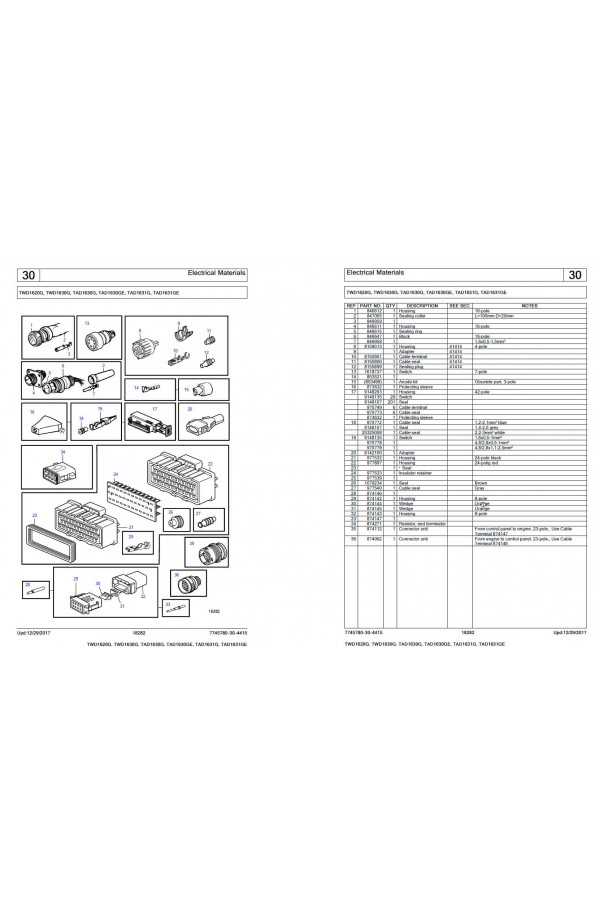

Understanding the Parts Diagram

A comprehensive illustration of components is essential for anyone looking to grasp the intricacies of a specific engine system. Such a visual representation aids in identifying various elements, their functions, and how they interconnect within the overall assembly. By studying this illustration, users can enhance their maintenance skills and troubleshooting abilities.

Key Elements of the Illustration

The illustration typically includes several important features that facilitate understanding:

- Labels: Each component is usually marked with a clear identifier.

- Connections: Lines or arrows often depict how parts interact with one another.

- Section Views: Some diagrams may include cutaway views to show internal structures.

Benefits of Utilizing the Illustration

Engaging with such visual resources offers numerous advantages:

- Improved Clarity: Visual aids simplify complex ideas.

- Enhanced Troubleshooting: Quick identification of faulty components becomes easier.

- Efficient Maintenance: Understanding layout allows for more effective repairs and part replacements.

Common Issues and Solutions

When dealing with marine engines, various challenges can arise that may affect performance and reliability. Understanding these common problems and their corresponding solutions is crucial for maintaining optimal functionality and longevity of the engine. Below are some prevalent issues encountered and recommended approaches to resolve them.

| Issue | Description | Solution |

|---|---|---|

| Overheating | This can occur due to insufficient coolant flow or blocked passages. | Inspect the cooling system, check for obstructions, and ensure proper fluid levels. |

| Rough Idling | Irregular engine operation can indicate fuel or air intake problems. | Examine the fuel filter and air intake; replace or clean as necessary. |

| Starting Issues | Difficulty in starting may result from battery or ignition system failures. | Test the battery voltage and inspect ignition components for wear. |

| Excessive Vibration | Unusual vibrations can signal misalignment or worn mounts. | Check alignment of the engine and propeller; replace any damaged mounts. |

| Fuel Leaks | Leaking fuel can lead to hazardous conditions and decreased efficiency. | Inspect fuel lines and connections for wear; replace any damaged parts immediately. |

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your marine engine requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of crucial components. Adopting a proactive approach will help prevent potential issues and keep your equipment running smoothly.

Here are some essential maintenance tips to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Regularly replacing engine oil helps remove contaminants and lubricate moving parts effectively. |

| Filter Replacement | Every 200 hours | Changing the oil and fuel filters ensures optimal performance and prevents clogging. |

| Cooling System Check | Seasonally | Inspect and clean the cooling system to prevent overheating and maintain efficiency. |

| Fuel System Inspection | Every season | Examine fuel lines and connections for leaks or wear to avoid operational disruptions. |

| Belt and Hose Inspection | Monthly | Check belts and hoses for cracks or wear to ensure reliable operation and prevent breakdowns. |

| Battery Maintenance | Monthly | Clean terminals and check fluid levels to keep your power supply reliable and strong. |

By adhering to these practices, you can maximize the performance and reliability of your marine engine, ensuring many years of enjoyable use.

Replacement Parts Availability

When it comes to maintaining marine engines, ensuring access to essential components is crucial for optimal performance and longevity. The market offers a wide variety of options for those seeking to replace worn or damaged items. Understanding the availability of these components can greatly enhance your maintenance strategy.

Sources for Component Acquisition

- Authorized Dealers: Official vendors often stock genuine components, ensuring compatibility and reliability.

- Aftermarket Suppliers: Numerous companies provide quality alternatives at competitive prices.

- Online Marketplaces: E-commerce platforms can offer a broad selection, often with user reviews to guide your choices.

Considerations for Selection

- Quality Assurance: Opt for components that meet industry standards to avoid performance issues.

- Compatibility: Ensure that the selected items are designed for your specific engine model.

- Warranty: Check if the replacement components come with a warranty for added peace of mind.

Installation Guidelines for Components

This section provides essential instructions for the proper assembly and installation of various elements within a marine engine system. Adhering to these guidelines ensures optimal performance and longevity of the machinery.

| Component | Installation Steps |

|---|---|

| Water Pump | Ensure the surface is clean, align the pump with the mounting points, and securely fasten with the recommended torque. |

| Exhaust Manifold | Use a new gasket, position the manifold carefully, and tighten bolts in a crisscross pattern for even distribution. |

| Intake System | Check all seals, position the intake assembly, and ensure all connections are snug to prevent leaks. |

| Fuel Filter | Replace the old filter with a new one, ensuring the flow direction matches the indicated arrows. |

Compatibility with Other Models

Understanding the interrelationship between different engine types can greatly enhance maintenance and replacement processes. This section explores how certain components can be utilized across various models, offering insights into potential cross-compatibility.

Cross-Model Compatibility

Many engine systems share similar components, allowing parts designed for one model to be effectively used in another. This not only simplifies repairs but also broadens the availability of replacement options.

Compatibility Table

| Model | Compatible Components |

|---|---|

| Model A | Fuel Pump, Ignition Coil |

| Model B | Starter Motor, Water Pump |

| Model C | Oil Filter, Alternator |

Benefits of Using Genuine Parts

Choosing authentic components for your engine maintenance is crucial for ensuring optimal performance and longevity. Genuine items are designed to meet specific standards, providing reliability and peace of mind for operators.

Quality Assurance

One of the primary advantages of using original components is the assurance of quality. Authentic products are:

- Manufactured to exact specifications

- Subjected to rigorous testing

- Made from high-quality materials

Enhanced Performance

Utilizing certified components contributes significantly to the overall efficiency of the engine. Benefits include:

- Improved fuel efficiency

- Better compatibility with existing systems

- Reduced likelihood of malfunctions

In summary, opting for genuine components not only supports the integrity of your machinery but also ensures a smoother operation and fewer repairs over time.

Upgrading Your Engine Performance

Enhancing the capabilities of your marine engine can lead to improved efficiency, responsiveness, and overall enjoyment on the water. By exploring various modifications and upgrades, you can unlock greater power and achieve the ultimate performance for your vessel.

Key Upgrades to Consider

Focus on components such as exhaust systems, intake manifolds, and fuel delivery systems. Upgrading these parts can significantly enhance airflow and fuel combustion, leading to increased horsepower and torque. Additionally, consider upgrading the ignition system for better timing and efficiency.

Regular Maintenance for Optimal Performance

Alongside upgrades, maintaining your engine is crucial. Regular checks and timely replacements of wear-and-tear items ensure that your modifications deliver their full potential. Clean fuel filters and fresh oil can make a substantial difference in how well your engine performs.

Resources for Troubleshooting Problems

When facing challenges with marine engines, having access to the right materials and references is crucial. Various tools and resources can assist in diagnosing issues effectively, ensuring a smoother resolution process. Understanding where to look can save both time and effort in maintaining optimal performance.

Technical Manuals: Comprehensive guides provide essential information on specifications, component locations, and troubleshooting procedures. These manuals often include step-by-step instructions that help pinpoint the source of problems.

Online Forums and Communities: Engaging with fellow enthusiasts and experts can be invaluable. Many forums feature discussions on common issues and solutions, offering practical insights from those with firsthand experience.

Video Tutorials: Visual learners may benefit from watching instructional videos. These resources often demonstrate troubleshooting techniques and repairs, making complex tasks more accessible.

Manufacturer Support: Direct assistance from the manufacturer can be a reliable resource. Official support channels provide expert guidance and may have specific recommendations based on common concerns.

Diagnostic Tools: Utilizing specialized equipment, such as multimeters and pressure gauges, allows for precise identification of engine issues. These tools can reveal underlying problems that may not be immediately apparent.

By leveraging these resources, individuals can enhance their troubleshooting capabilities and ensure their marine engines function at their best.

Insights from Volvo Penta Experts

In the realm of marine propulsion systems, expertise and experience play a crucial role in maintaining optimal performance and longevity. Specialists in this field often emphasize the importance of understanding the intricacies of engine components and their interrelations. By delving into the knowledge shared by seasoned professionals, boat owners can make informed decisions that enhance their vessels’ efficiency and reliability.

Common Challenges and Solutions

Experts frequently encounter a variety of challenges, ranging from mechanical failures to maintenance oversights. Common issues such as overheating, poor fuel efficiency, and unusual noises can often be traced back to specific components. Professionals recommend regular inspections and preventive maintenance to catch potential problems early. Additionally, utilizing high-quality replacements can significantly improve the overall functionality of the propulsion system.

Importance of Proper Maintenance

Adhering to a structured maintenance routine is paramount for any marine engine. Experts advise keeping meticulous records of service history and following manufacturer guidelines. This not only ensures optimal performance but also extends the life of the machinery. Engaging with knowledgeable technicians and utilizing resources for proper upkeep can save time and costs in the long run.