In modern automotive engineering, the role of hydraulic assistance systems is crucial for enhancing vehicle control and maneuverability. These intricate assemblies not only improve driving comfort but also play a significant role in overall safety. A thorough examination of their components provides valuable insights into their functionality and maintenance.

By exploring the various elements that constitute these systems, one can appreciate how they work in harmony to facilitate smooth operation. Each component, from the reservoir to the actuators, contributes to the effective transfer of force, enabling effortless handling. Understanding the arrangement and interaction of these elements is essential for anyone involved in vehicle maintenance or repair.

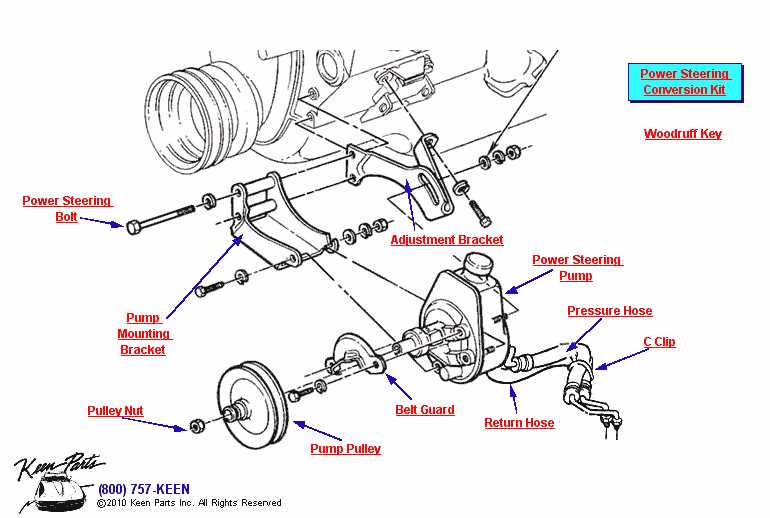

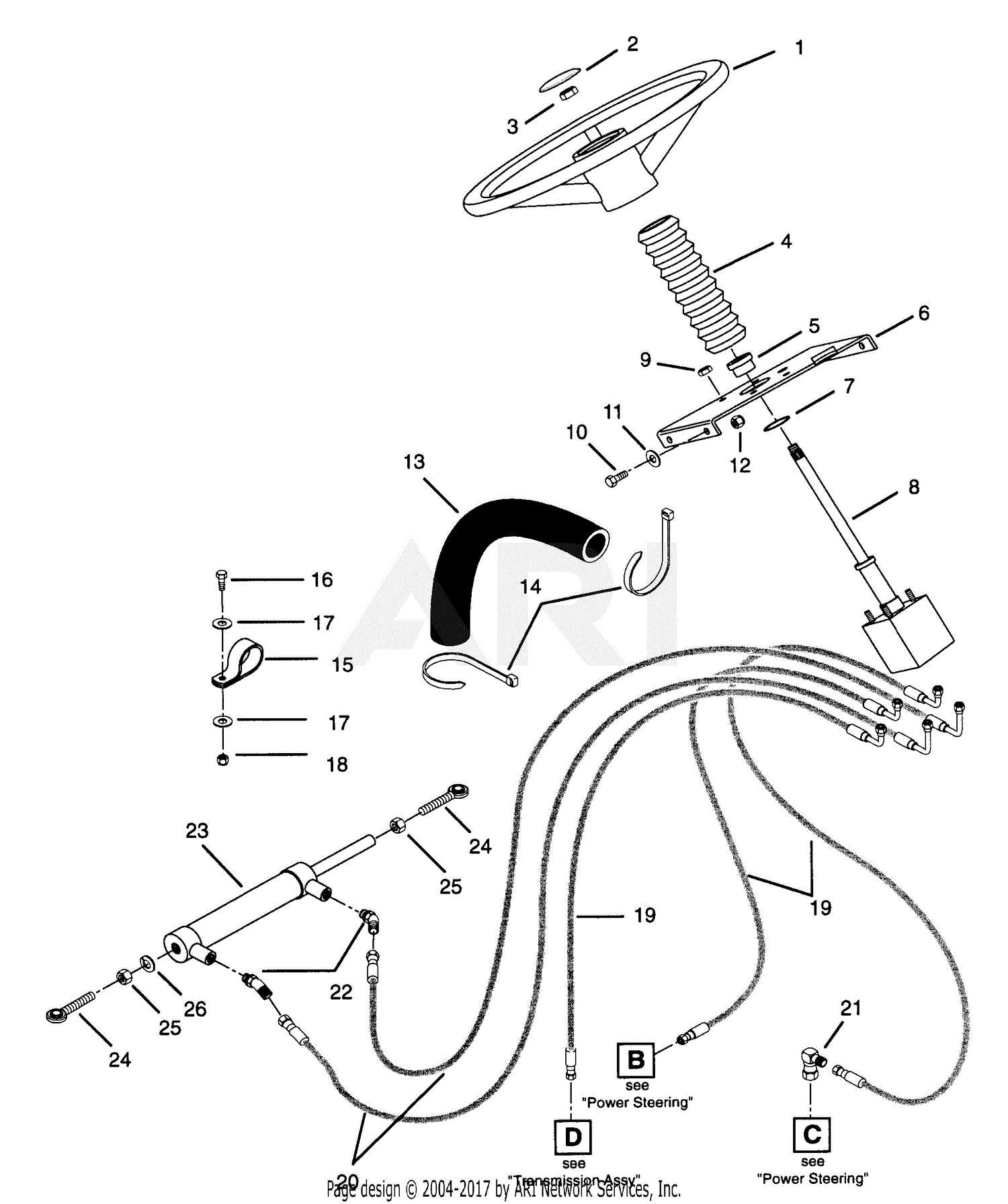

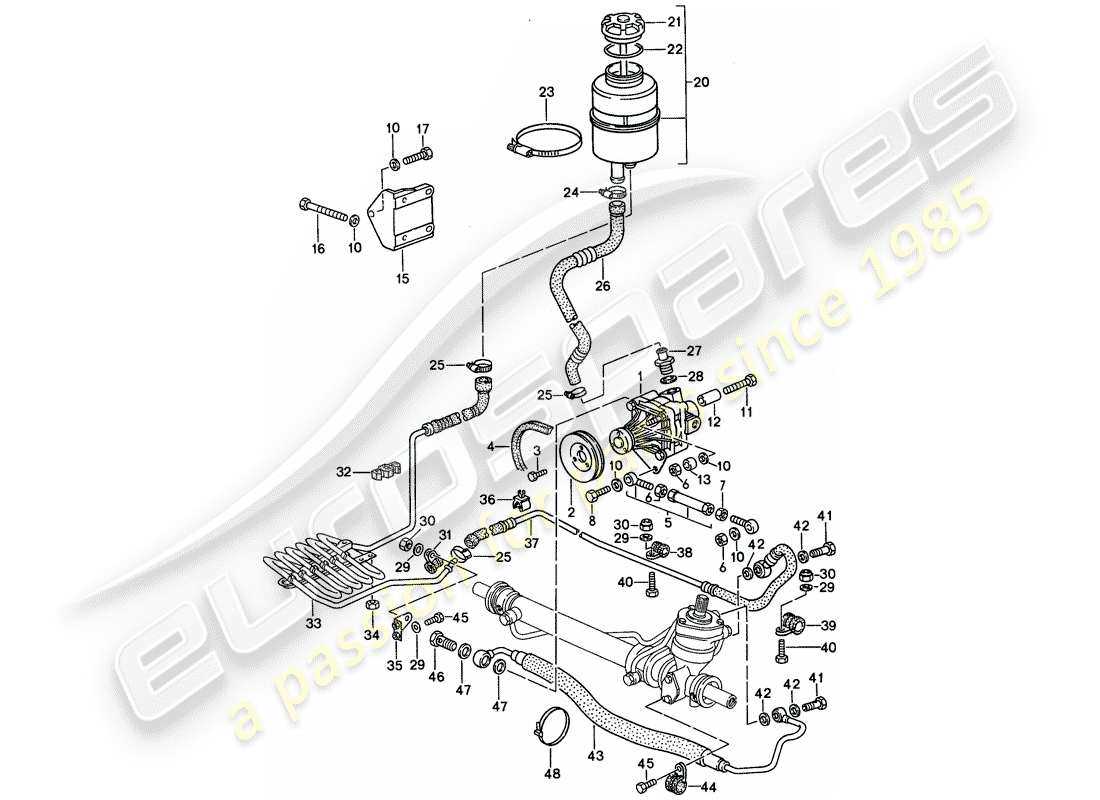

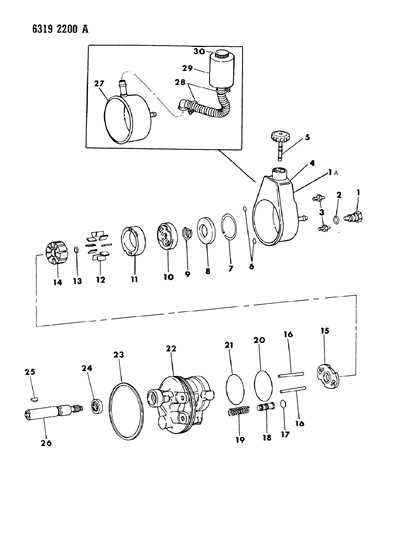

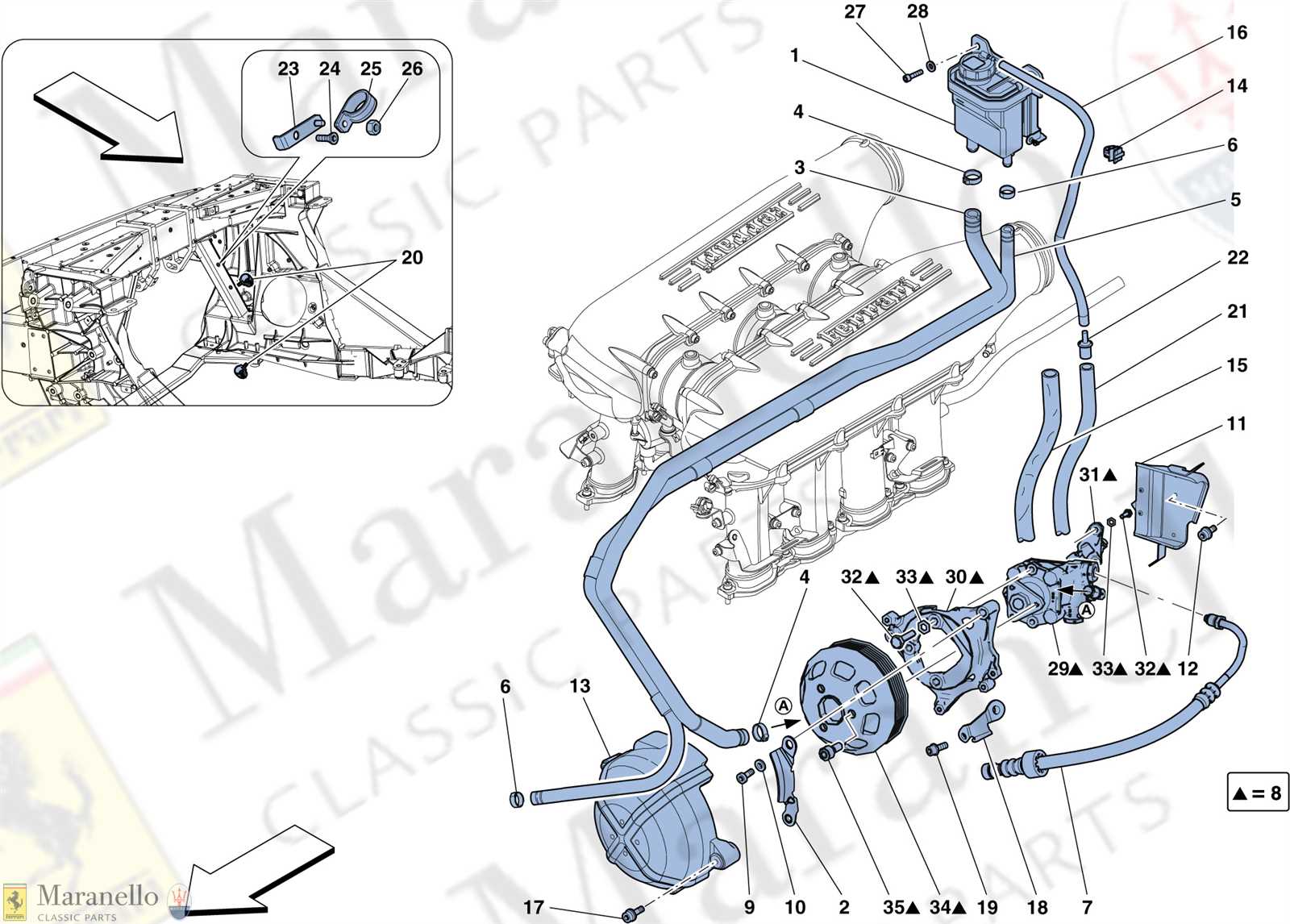

This discussion delves into the intricacies of these systems, offering a visual representation that clarifies the layout and relationships among the components. By familiarizing oneself with these details, automotive enthusiasts and professionals alike can enhance their knowledge and improve their diagnostic capabilities.

Understanding Power Steering Pump Functionality

The mechanism responsible for assisting in the direction control of a vehicle plays a crucial role in enhancing driving comfort and safety. This system allows for smoother navigation, especially at lower speeds, by reducing the effort required to turn the wheel. An in-depth exploration of its components and operation reveals how it contributes to overall vehicle performance.

Key Components and Their Roles

At the heart of this system is a mechanical device that generates hydraulic pressure. This pressure facilitates the movement of fluid within the system, which is essential for achieving the desired level of assistance. Among the key elements are the reservoir, where the fluid is stored, and the valves that regulate flow based on driver input.

Operational Mechanics

The functionality of this system is based on the principles of hydraulics. When the driver applies force to the wheel, the system activates, allowing fluid to flow through designated pathways. This action not only amplifies the input force but also enhances responsiveness, resulting in improved handling. Understanding these operational dynamics can aid in troubleshooting and maintenance, ensuring longevity and reliability.

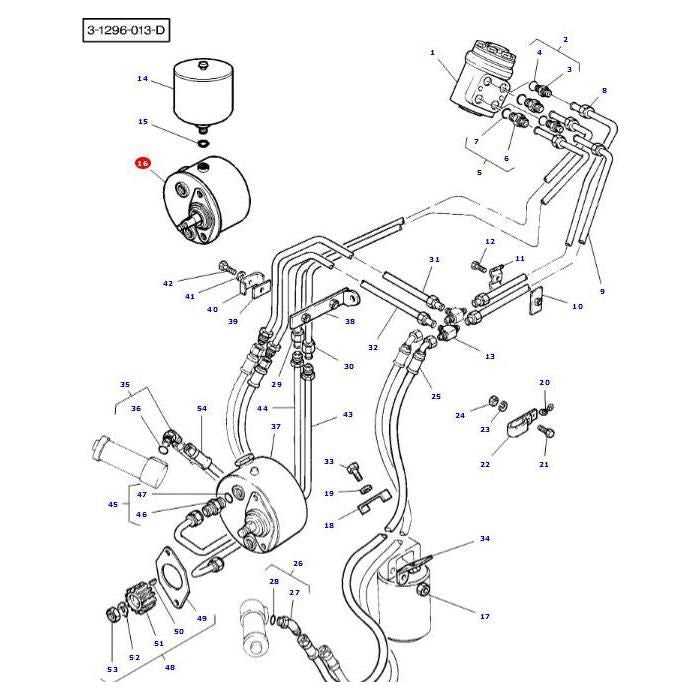

Components of Power Steering Systems

In modern vehicles, the mechanism that assists with maneuverability consists of several integral components that work in harmony. Each element plays a vital role in enhancing the ease of handling, ensuring that drivers can navigate with minimal effort. Understanding these components is essential for grasping how this system functions effectively and efficiently.

Essential Elements

At the core of this assistance mechanism lies the hydraulic unit, which generates the necessary force to aid in turning the wheels. Connected to this unit are various hoses that transport the fluid essential for operation. Additionally, a reservoir stores the hydraulic fluid, ensuring a consistent supply during operation. The interaction of these elements allows for smooth and responsive handling.

Control and Feedback

The system also includes sensors and control units that monitor the vehicle’s movements and adjust the assistance accordingly. These components enhance driver feedback and contribute to the overall safety and performance of the vehicle. Together, they create a seamless experience that greatly improves maneuverability, making driving more enjoyable.

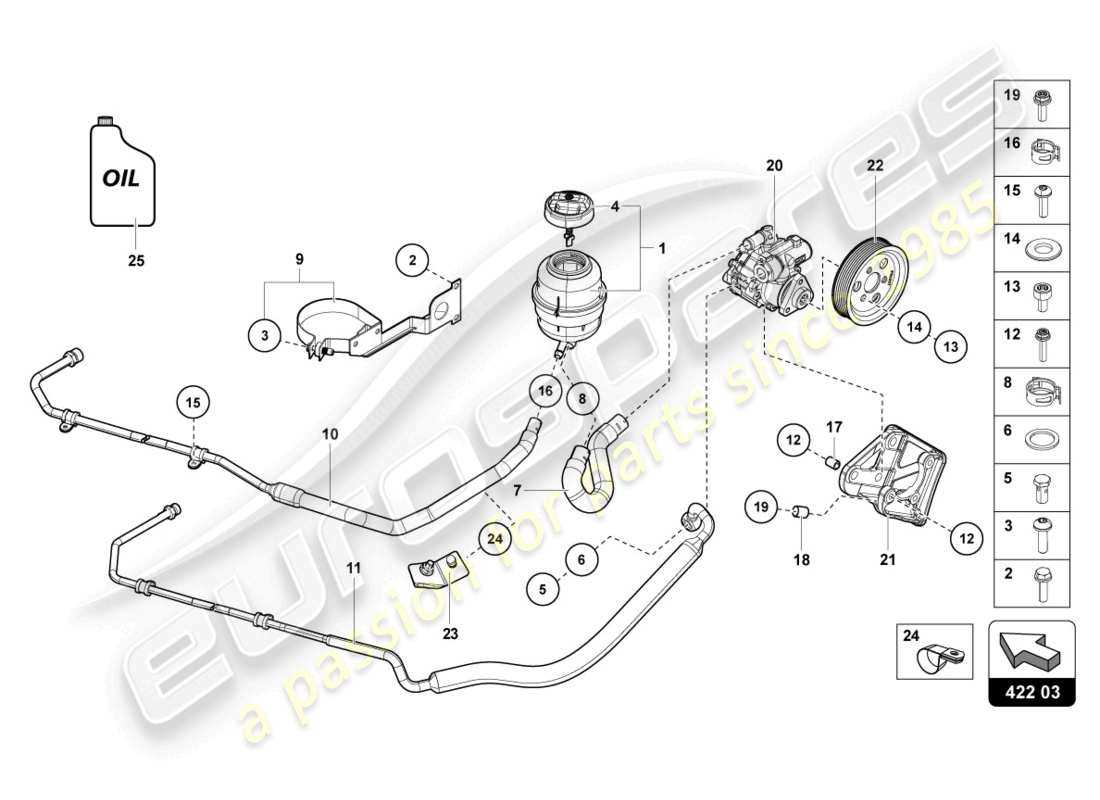

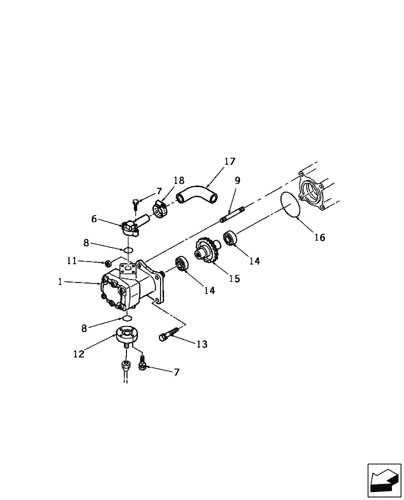

How Power Steering Pumps Operate

Understanding the functionality of hydraulic assist systems is crucial for grasping how vehicles enhance maneuverability. These mechanisms utilize fluid dynamics to reduce the effort needed for turning and navigating, ensuring a smoother driving experience.

Core Components

- Reservoir: Stores the hydraulic fluid, ensuring a steady supply.

- Motor: Drives the mechanism, creating pressure in the fluid.

- Hoses: Facilitate the flow of fluid between various components.

- Valves: Control the distribution and pressure of the hydraulic fluid.

Operational Process

- The motor activates, drawing fluid from the reservoir.

- As the fluid is compressed, it builds pressure.

- This pressurized fluid is directed through hoses to the assistance mechanism.

- Valves adjust the flow based on the driver’s input, ensuring optimal responsiveness.

- When the desired maneuver is achieved, the system returns to equilibrium.

Through this intricate interplay of components, the system provides the necessary assistance, allowing for effortless control while maintaining safety and precision on the road.

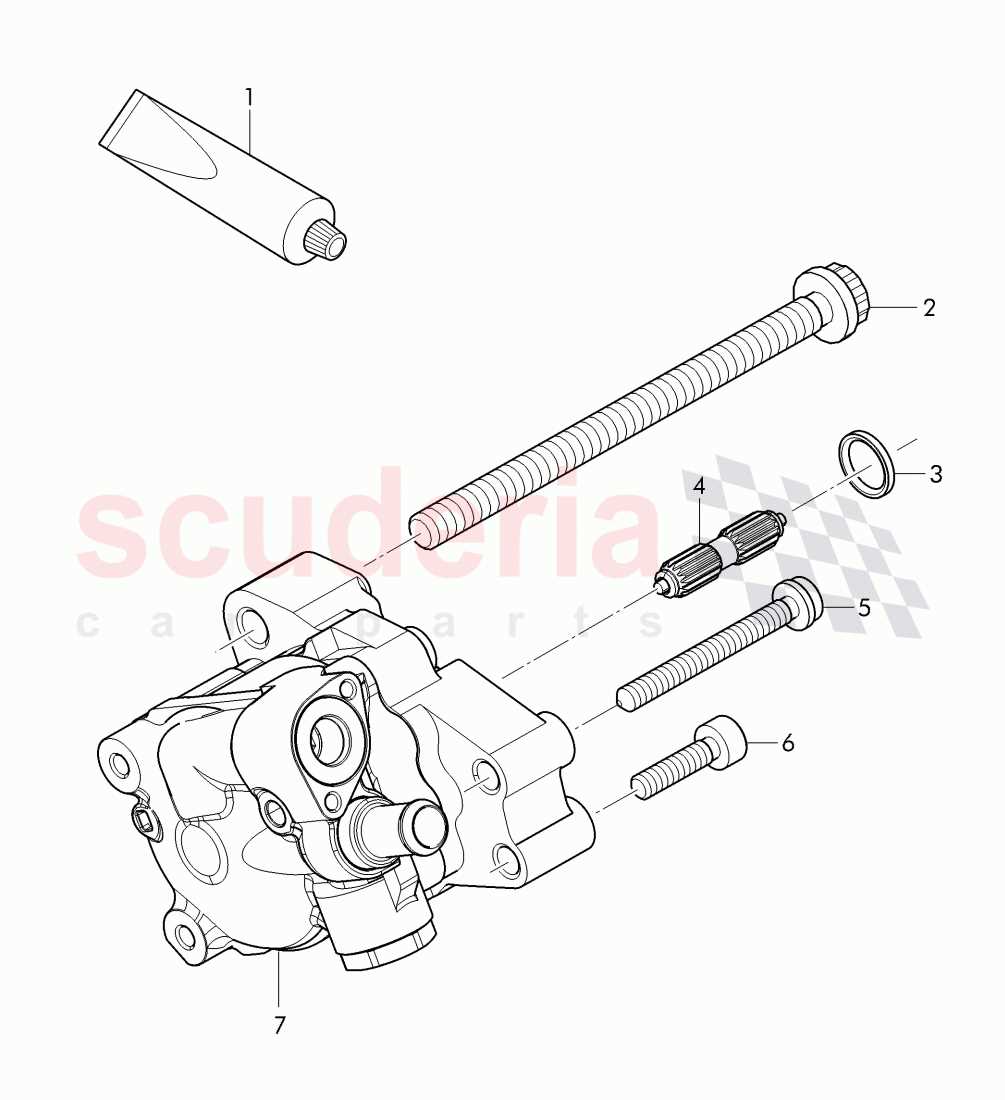

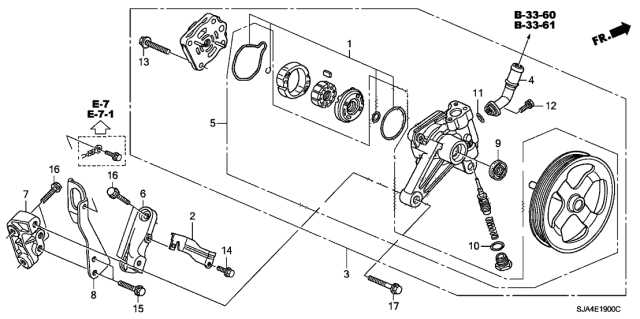

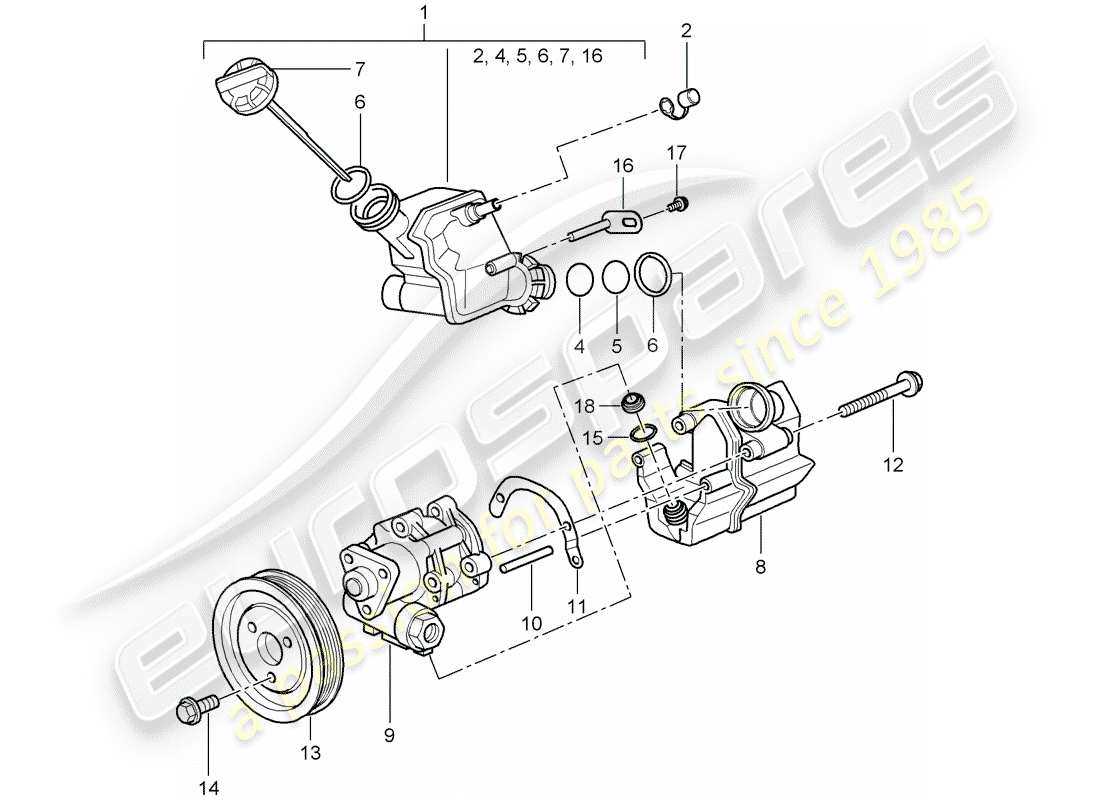

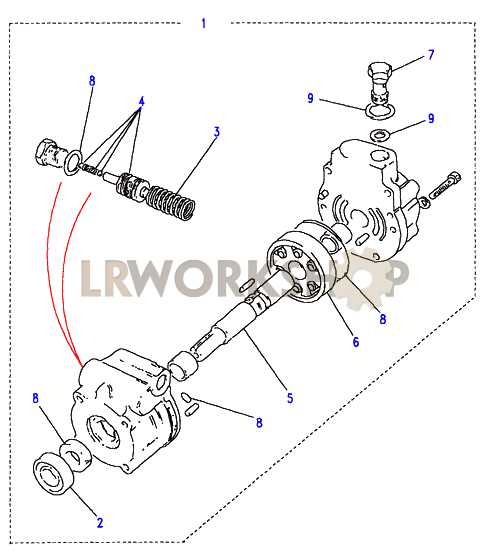

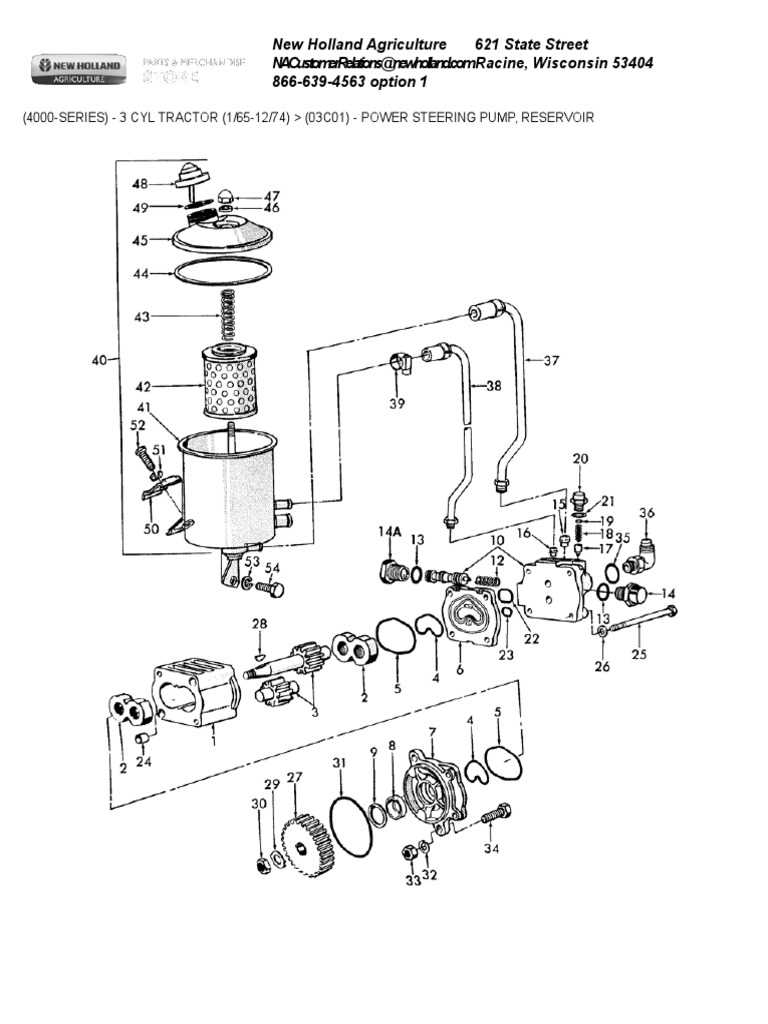

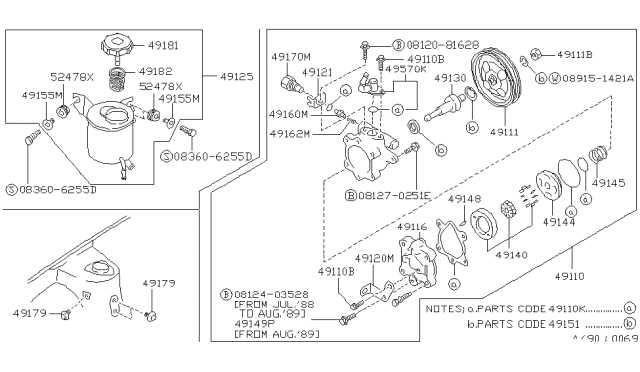

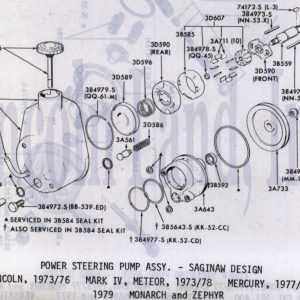

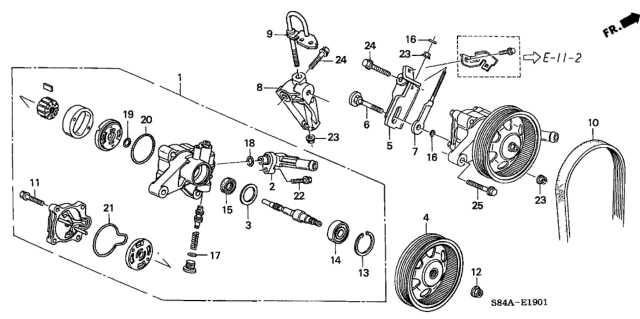

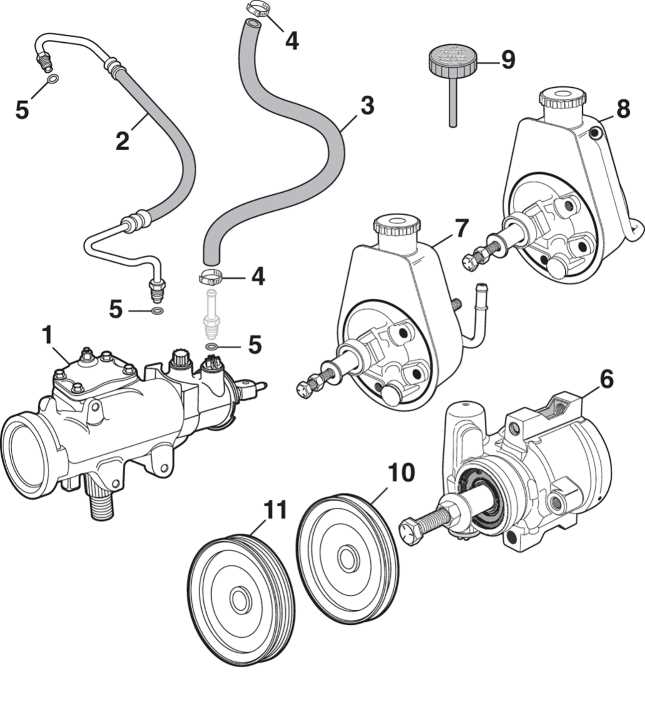

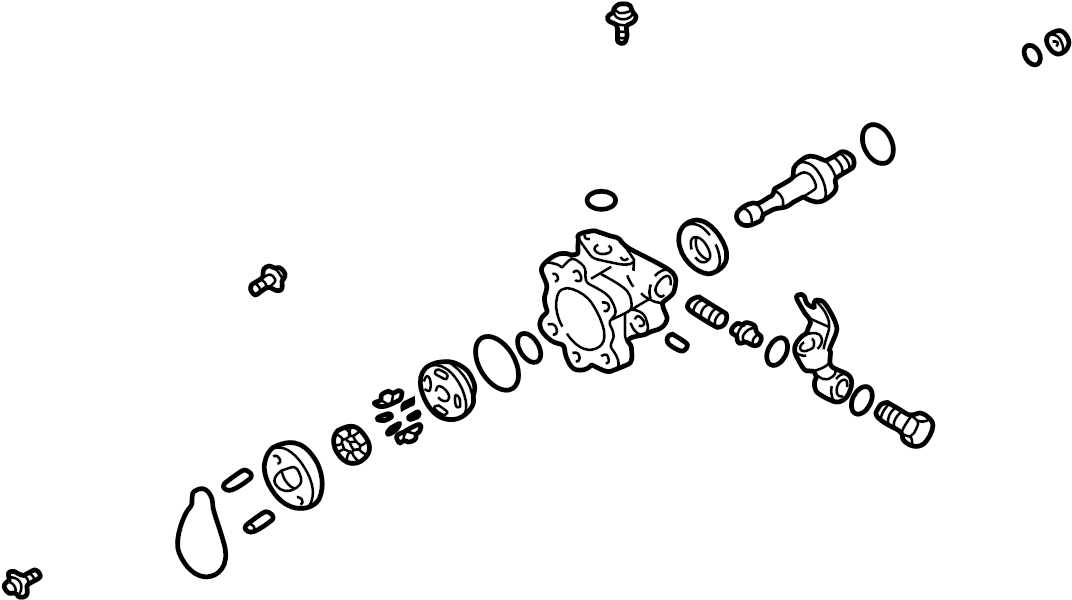

Key Parts of the Pump Assembly

The assembly responsible for fluid management consists of several critical components that work in unison to ensure efficient operation. Understanding these elements is essential for maintenance and troubleshooting, as each plays a vital role in overall functionality.

| Component | Description |

|---|---|

| Reservoir | This container holds the hydraulic fluid, allowing for easy access and replenishment. |

| Rotor | The rotating element creates the necessary pressure to move the fluid through the system. |

| Vane | These slidable pieces help to create the seal necessary for pressure generation within the assembly. |

| Cover | This component seals the assembly, protecting the internal elements from contaminants. |

| Drive Shaft | The shaft connects to the engine, converting rotational energy into fluid motion. |

Hydraulic Fluid and Its Role

In hydraulic systems, a vital component ensures smooth operation and effective transmission of force. This fluid acts as a medium, enabling various mechanical elements to work together seamlessly. Its properties are crucial for achieving the desired performance and longevity of the entire system.

Functionality of the Fluid

The primary role of hydraulic fluid is to transfer energy from one part of the mechanism to another. By exerting pressure, it facilitates movement and allows for the controlled operation of various functions. Moreover, it aids in lubricating components, minimizing wear and tear, and enhancing overall efficiency.

Types and Characteristics

Different formulations of hydraulic fluids exist, each designed for specific applications. Viscosity, temperature stability, and chemical composition are key characteristics that determine their effectiveness. Selecting the right type is essential to ensure optimal performance and reliability in various operating conditions.

Common Issues in Power Steering Pumps

Understanding the frequent complications associated with hydraulic assistance mechanisms is essential for maintaining vehicle performance. Various factors can contribute to these problems, affecting the system’s efficiency and overall functionality.

- Fluid Leaks: One of the most prevalent issues involves the escape of hydraulic fluid. This can stem from worn seals or damaged hoses, leading to insufficient fluid levels and poor operation.

- Noise: Unusual sounds, such as whining or grinding, often indicate mechanical failures or low fluid levels. These noises should be addressed promptly to prevent further damage.

- Overheating: Excessive temperatures can result from a malfunctioning cooling system or insufficient fluid circulation, potentially damaging internal components.

- Contamination: Debris and contaminants in the hydraulic fluid can lead to clogs and inefficient functioning. Regular fluid changes and system maintenance are crucial.

- Pressure Issues: Irregular pressure can affect responsiveness. This may be caused by a faulty control valve or worn internal parts.

Regular inspections and timely maintenance can help mitigate these complications, ensuring smooth operation and longevity of the hydraulic assistance system.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your vehicle’s essential components requires regular attention and care. By adopting simple maintenance practices, you can significantly enhance the lifespan of these critical systems.

- Regular Fluid Checks: Monitor the hydraulic fluid levels frequently to avoid low fluid conditions that could lead to premature wear.

- Leak Detection: Inspect for any signs of leaks or drips around the system, as even small leaks can escalate into larger issues.

- Routine Cleaning: Keep the area surrounding the components clean to prevent dirt and debris from entering the system.

In addition to these fundamental practices, consider the following recommendations:

- Schedule Professional Inspections: Have a qualified technician examine the system periodically to identify potential problems early.

- Avoid Overloading: Be mindful of the weight and load your vehicle carries, as excessive strain can compromise component integrity.

- Replace Worn Components: Address any signs of wear or damage promptly to maintain overall functionality.

By implementing these strategies, you can ensure that your vehicle operates smoothly and remains reliable for years to come.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration in a hydraulic system is crucial for maintaining optimal performance. Various symptoms can point to issues that require immediate attention to avoid further complications and ensure longevity. Being proactive in identifying these signs can save both time and resources.

| Sign | Description |

|---|---|

| Noisy Operation | Unusual sounds such as whining or grinding can indicate low fluid levels or damaged components. |

| Fluid Leaks | Visible fluid spots under the vehicle suggest potential leaks that may lead to a lack of necessary lubrication. |

| Difficulty in Maneuvering | Increased effort required to turn the wheel may signal that the system is struggling to assist as intended. |

| Unresponsive Steering | A delayed response when turning could indicate a failing system that needs immediate inspection. |

| Overheating | Excessive heat can damage internal components, often caused by low fluid or blockages in the system. |

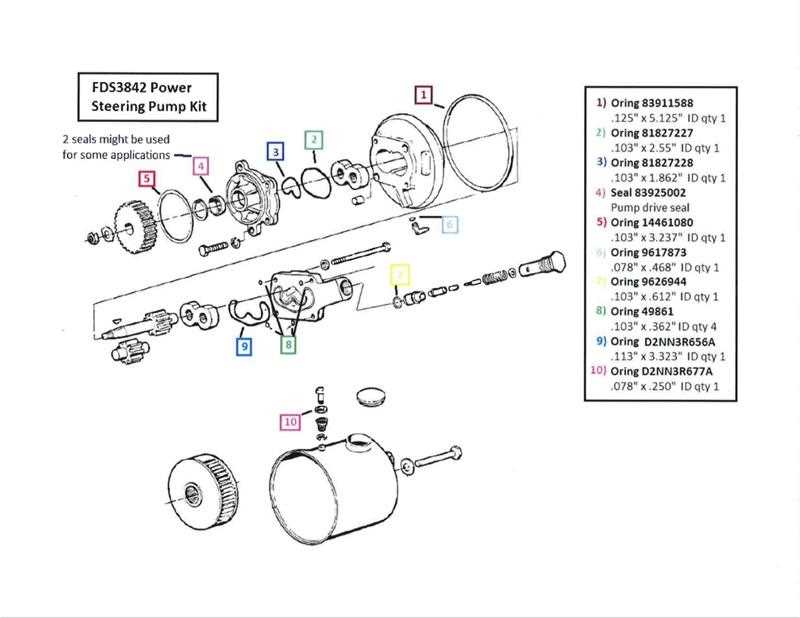

Power Steering Pump Installation Guide

Installing a hydraulic assist system can significantly enhance vehicle handling. This guide outlines the essential steps and considerations for a successful installation, ensuring that the system functions effectively and reliably.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Ensure that the vehicle is parked on a flat surface and the engine is turned off. Disconnect the battery to prevent any electrical issues during the process. Familiarize yourself with the specific model requirements, as variations can exist between different vehicles.

Installation Procedure

Follow these steps to install the hydraulic assist system:

| Step | Action |

|---|---|

| 1 | Remove the old unit by disconnecting the hoses and unbolting it from the mounting bracket. |

| 2 | Install the new unit, ensuring it is properly aligned with the mounting points. |

| 3 | Reconnect the hoses, making sure they are secured and free from leaks. |

| 4 | Refill the system with the appropriate fluid as per the manufacturer’s specifications. |

| 5 | Reconnect the battery and start the engine, allowing it to run for a few minutes to circulate the fluid. |

| 6 | Check for any leaks and ensure the system operates smoothly by turning the wheel from lock to lock. |

By following these steps, you can ensure a successful installation and improve your vehicle’s handling performance.

Tools Required for Replacement

When it comes to swapping out essential components in your vehicle’s system, having the right equipment is crucial for a successful and efficient process. A well-prepared toolkit ensures that you can handle the task with ease, minimizing the risk of damage to surrounding elements.

Here’s a list of tools you will need:

- Wrenches (various sizes)

- Sockets and ratchet set

- Torque wrench

- Hose clamps and pliers

- Fluid catch container

- Replacement fluids

- Sealant or gasket maker

- Rags or towels for cleanup

- Safety goggles and gloves

Each of these tools plays a vital role in ensuring that the replacement process is carried out smoothly and safely. Be sure to gather everything before starting your project to streamline your workflow and avoid interruptions.

Benefits of Upgrading Your System

Enhancing your vehicle’s assistance mechanism can lead to significant improvements in overall performance and driving experience. By investing in advanced technologies, you not only elevate the responsiveness of your controls but also contribute to better handling and comfort. Such upgrades can transform the way you interact with your vehicle, making every drive smoother and more enjoyable.

Improved Efficiency

One of the primary advantages of modernizing your assistance system is the increased efficiency it offers. Newer technologies often feature optimized designs that reduce energy consumption, allowing your vehicle to perform better without straining other components. This results in lower wear and tear, ultimately extending the lifespan of your machinery.

Enhanced Comfort and Control

Upgrading can also lead to a noticeable enhancement in comfort and control. Advanced systems often include features that adapt to driving conditions, providing a more intuitive and responsive feel. With improved feedback and precision, you’ll find yourself navigating corners and making maneuvers with greater confidence. This level of control not only makes driving more pleasurable but can also enhance safety on the road.

Understanding Different Pump Types

In the realm of automotive systems, various mechanisms are utilized to enhance the efficiency and responsiveness of vehicle control. Each type serves a unique function and operates under distinct principles. Grasping the differences between these mechanisms is essential for understanding their roles in vehicle performance.

Types of Hydraulic Mechanisms

Hydraulic systems can be classified into several categories based on their operation and design. The most common types include gear, vane, and piston systems. Gear mechanisms employ interlocking gears to create flow, making them reliable for consistent performance. Vane systems utilize sliding vanes within a rotor, offering efficiency in compact spaces. Meanwhile, piston mechanisms harness the movement of pistons to generate high pressure, suitable for demanding applications.

Choosing the Right System

Selecting an appropriate mechanism depends on various factors, including the desired flow rate, pressure requirements, and space constraints. Understanding the unique characteristics of each type can aid in making informed decisions, ensuring optimal functionality and longevity in automotive applications. Ultimately, the right choice contributes significantly to the overall driving experience.