In the realm of maintenance and outdoor cleaning, having a clear grasp of your equipment’s anatomy is essential for optimal performance and longevity. Each element plays a critical role in ensuring that tasks are executed efficiently, providing a deeper understanding of how to tackle any challenges that may arise.

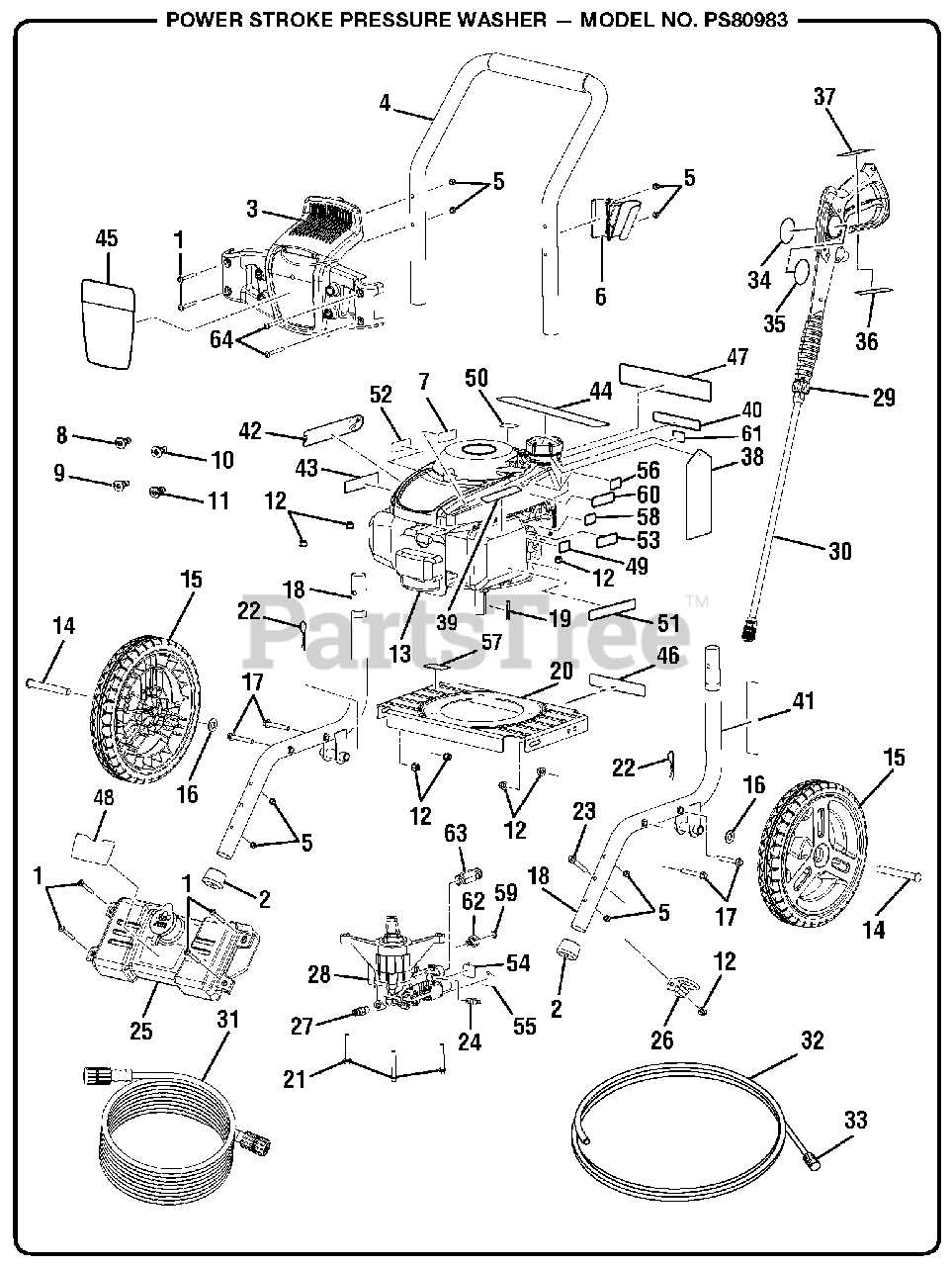

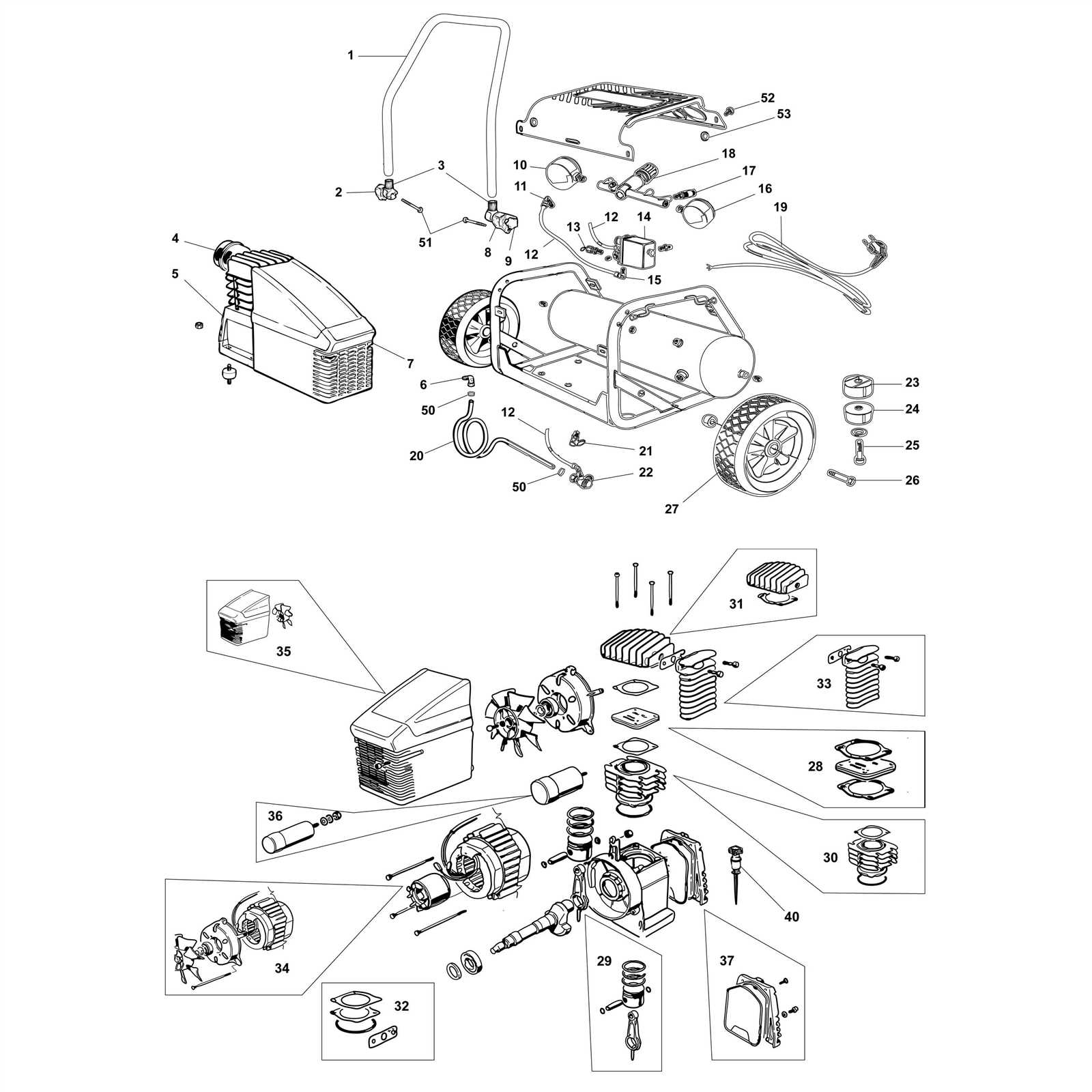

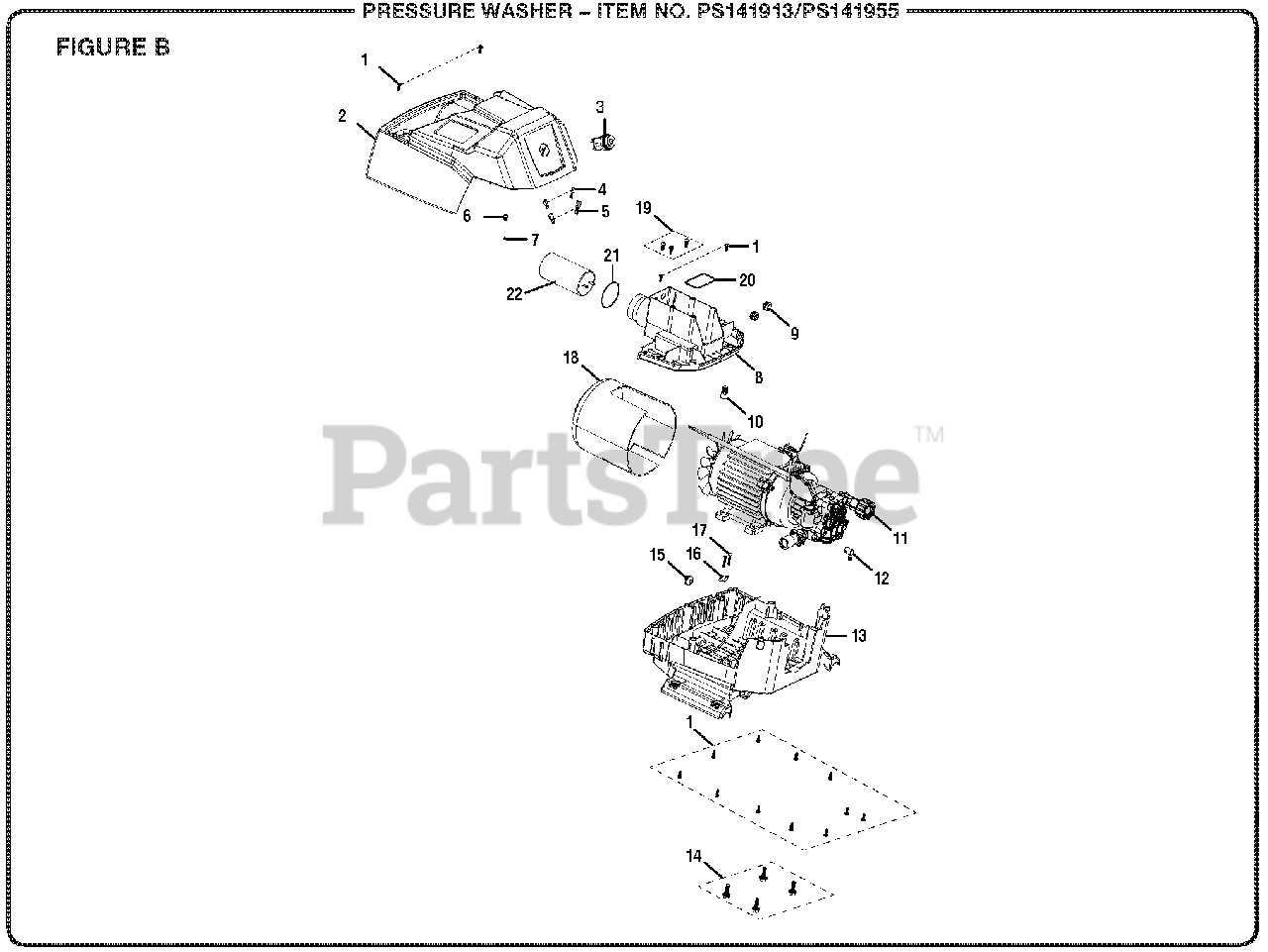

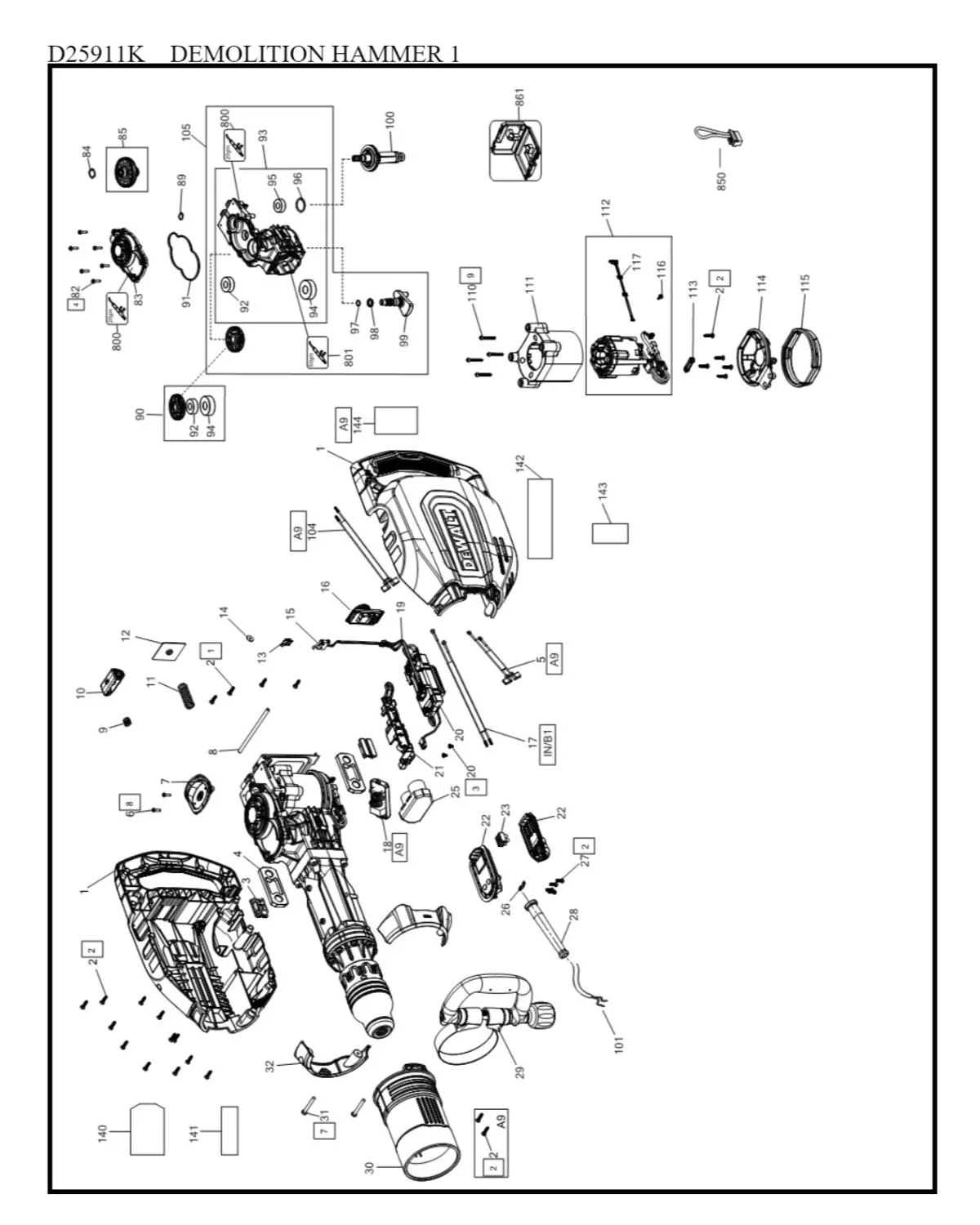

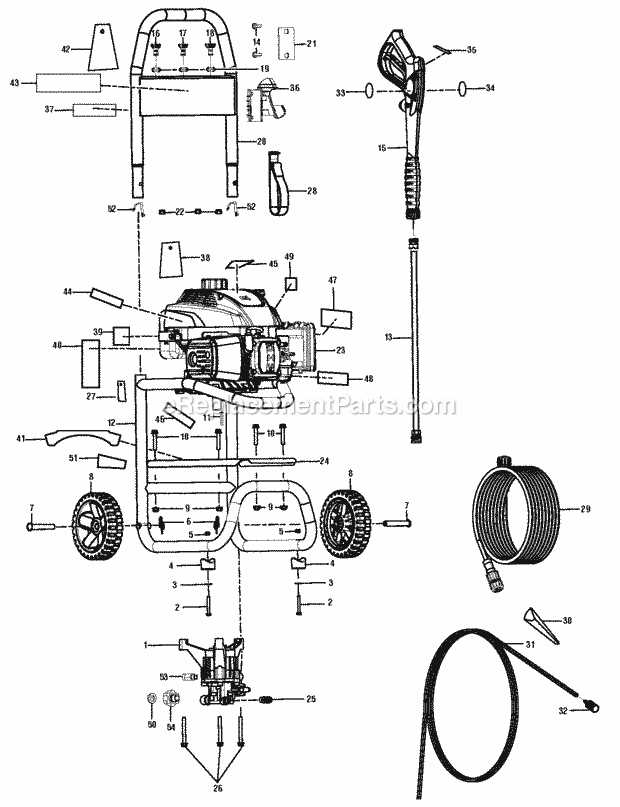

Visual representations of the various components can significantly enhance your ability to identify issues and conduct repairs. By examining these layouts, users can delve into the intricate design of their machines, fostering greater confidence in their maintenance skills.

Ultimately, being well-informed about the essential elements not only aids in troubleshooting but also empowers users to make informed decisions regarding replacements and upgrades. This knowledge paves the way for a smoother and more effective cleaning experience.

Understanding Powerstroke Pressure Washers

When it comes to tackling tough cleaning tasks, having a reliable machine is essential. These powerful devices are designed to deliver high efficiency, making it easier to remove dirt, grime, and stains from various surfaces. By harnessing the strength of pressurized water, they offer a practical solution for both residential and commercial needs.

Familiarity with the components of such equipment can greatly enhance your cleaning experience. Each element plays a crucial role in the overall functionality, ensuring optimal performance. From the motor that drives the system to the nozzle that directs the flow, understanding how these pieces work together will empower users to maintain and troubleshoot their machines effectively.

In addition, knowing how to adjust settings based on specific cleaning tasks can lead to better results. Different surfaces and levels of dirtiness require varied approaches, and a well-informed operator can make adjustments for maximum impact. This adaptability not only improves efficiency but also prolongs the lifespan of the equipment.

Ultimately, mastering the operation and maintenance of these devices transforms them into invaluable allies in any cleaning endeavor. With the right knowledge, users can ensure that their machines remain in peak condition, ready to tackle any challenge that arises.

Key Components of Pressure Washers

Understanding the essential elements of cleaning machines is crucial for optimal performance and maintenance. These components work in harmony to deliver efficient cleaning solutions, ensuring thorough removal of dirt and grime from various surfaces.

Motor: This is the powerhouse of the equipment, providing the necessary energy to drive the pump. A reliable motor is vital for sustained operation.

Pump: Serving as the heart of the system, this component elevates water pressure, allowing for effective cleaning. It transforms ordinary water flow into a forceful stream.

Hose: This flexible conduit transports water from the pump to the nozzle. A durable hose is essential to withstand high pressures while maintaining flexibility.

Nozzle: This piece controls the direction and intensity of the water flow, enabling users to tailor the cleaning experience to various surfaces and tasks.

Cleaning Solution Tank: Some units include a reservoir for detergents, enhancing the cleaning process by allowing for the application of specialized solutions.

Familiarity with these key components helps users make informed decisions about maintenance and upgrades, ultimately leading to more effective cleaning experiences.

Importance of Pressure Washer Maintenance

Regular upkeep of cleaning equipment is essential for ensuring optimal performance and longevity. Neglecting this aspect can lead to decreased efficiency and potential breakdowns, which can be both inconvenient and costly. By implementing a routine maintenance schedule, users can safeguard their investment and enhance the effectiveness of their tools.

Timely maintenance not only prevents malfunctions but also improves safety during operation. When machines are clean and well-functioning, the risk of accidents or injuries diminishes significantly. Regular inspections allow for early detection of issues, ensuring that repairs are addressed promptly.

Moreover, proper care contributes to better cleaning results. A well-maintained unit operates at peak efficiency, allowing for quicker and more thorough tasks. Users can enjoy enhanced performance and cleaner surfaces, leading to higher satisfaction with their cleaning endeavors.

In summary, investing time and effort into the maintenance of cleaning equipment is crucial. It not only prolongs the life of the machinery but also ensures safety and optimal performance, making every cleaning job more effective.

How to Identify Replacement Parts

Identifying the necessary components for your cleaning machine can seem daunting, but with the right approach, it becomes a manageable task. Understanding the specific requirements and functionalities of each element will help ensure a seamless replacement process. This guide will provide you with essential tips to simplify the identification of required items.

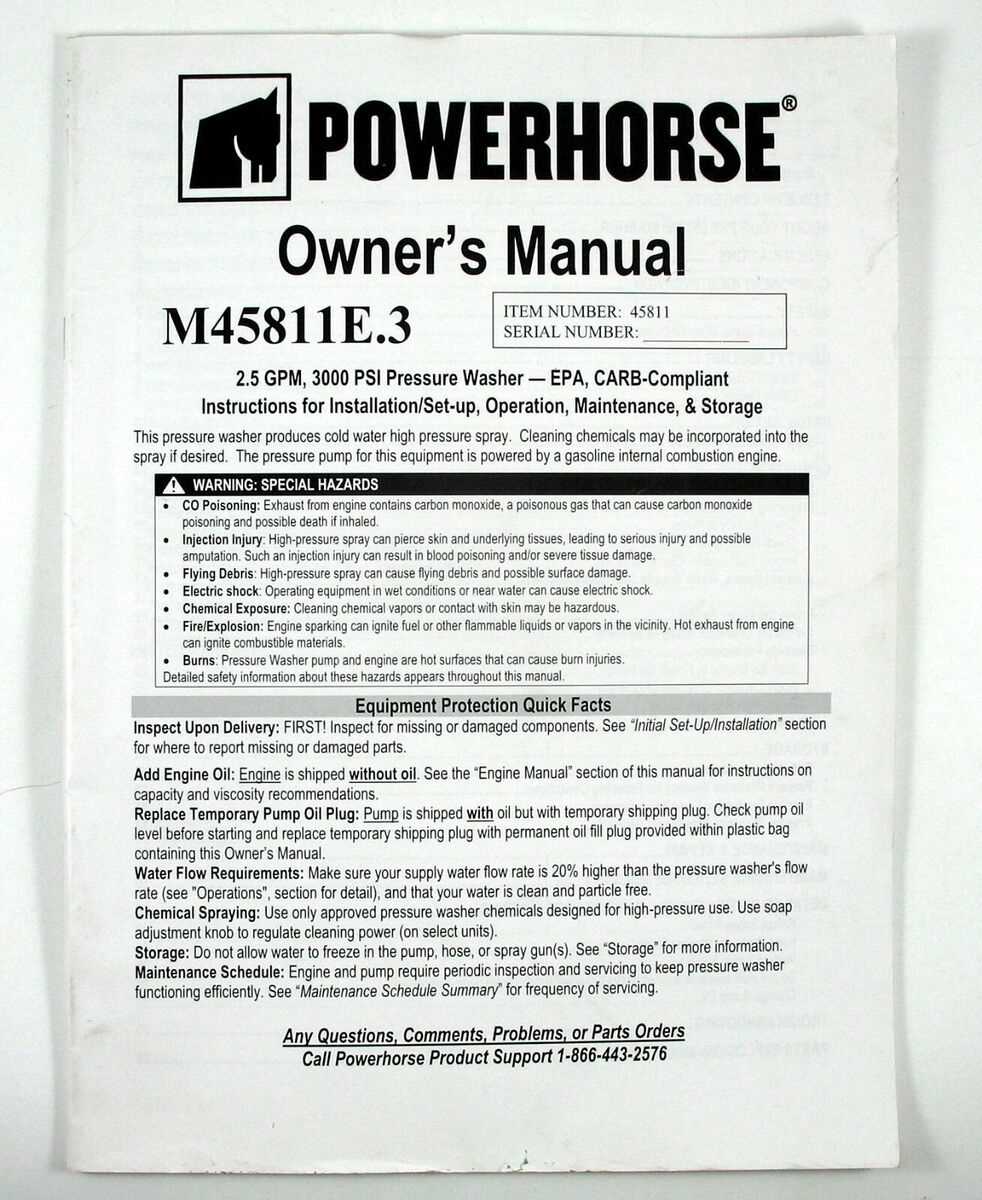

Start by consulting the user manual that came with your device. It typically contains detailed information about each component, including their functions and specifications. If the manual is unavailable, online resources or manufacturer websites can be invaluable for finding the needed details.

| Identification Method | Description |

|---|---|

| Visual Inspection | Examine the components for any visible wear or damage that could indicate the need for replacement. |

| Model Number | Locate the model number on the device. This information is crucial for finding compatible replacements. |

| Online Forums | Participate in discussion boards or communities where users share their experiences and solutions regarding similar issues. |

| Retailer Assistance | Consult with retailers or service centers that specialize in these machines for expert advice and part identification. |

By following these steps and utilizing available resources, you will be well-equipped to identify the components needed to restore your cleaning equipment to optimal functionality.

Common Issues with Pressure Washers

Various problems can arise when using cleaning machines, impacting their efficiency and effectiveness. Understanding these common challenges can help users troubleshoot and maintain their equipment properly, ensuring a longer lifespan and optimal performance.

Frequent Problems

- Insufficient Cleaning Power: This can be caused by clogged nozzles, low water supply, or improper detergent usage.

- Engine Starting Issues: Often related to fuel quality, spark plug malfunctions, or air filter blockages.

- Leaking Hoses: Wear and tear, improper connections, or damage can lead to water leaks.

- Unusual Noises: Rattling or grinding sounds may indicate internal issues or loose components.

Troubleshooting Tips

- Check and clean nozzles regularly to maintain optimal spray patterns.

- Inspect fuel and spark plugs if the engine fails to start.

- Examine hoses for cracks or wear, replacing them as needed.

- Listen for sounds that deviate from normal operation and address any loose parts immediately.

Reading Parts Diagrams Effectively

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide a clear roadmap, allowing users to identify and locate each element swiftly, thus facilitating a smoother restoration process.

Familiarize Yourself with Symbols

Before diving into the visuals, take time to learn the symbols and notations used. Each graphic often employs specific icons to represent various elements, which can significantly enhance comprehension and prevent confusion during the identification of components.

Follow the Flow of Assembly

When examining the illustration, start from one end and progress through to the other, tracing the assembly sequence. This approach not only clarifies how components interact but also reveals any dependencies that may exist, ensuring a thorough understanding of the entire system.

Finding OEM vs. Aftermarket Parts

When seeking components for your equipment, understanding the distinction between original and alternative options is crucial. Each type offers unique advantages, and making an informed choice can enhance performance and longevity.

Original Equipment Manufacturer (OEM)

OEM components are crafted by the original manufacturer, ensuring compatibility and adherence to quality standards. Choosing these items often guarantees optimal performance, as they are designed specifically for your machine.

Aftermarket Alternatives

Aftermarket options can provide cost savings and sometimes improved features. However, they may vary in quality, so thorough research and reviews are essential before making a purchase. Weighing the benefits of both can lead to the ultimate decision for your needs.

Tips for DIY Repairs

Engaging in do-it-yourself fixes can be both rewarding and cost-effective. With a little preparation and the right approach, anyone can tackle maintenance tasks with confidence. Understanding the components involved and their functions is essential to ensure successful outcomes.

Begin by gathering the necessary tools and supplies. A well-organized workspace makes it easier to locate items and keeps you focused. Familiarize yourself with the various elements that need attention, and consult reliable resources to gain insights into their operation.

Before starting any repairs, always disconnect the equipment from its power source. Safety should be your top priority. Additionally, take notes and photographs during disassembly to simplify reassembly later. If you encounter challenges, don’t hesitate to seek advice from online forums or instructional videos.

Finally, after completing the repairs, conduct a thorough test to ensure everything functions correctly. This final step confirms that your efforts have paid off and that the equipment is ready for use once again.

Tools Needed for Maintenance Tasks

Effective upkeep of equipment requires a variety of essential instruments that facilitate efficient performance. Having the right tools not only streamlines the process but also enhances the longevity of the machinery. Below is a compilation of necessary tools for routine maintenance tasks.

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten or loosen fasteners and fittings. |

| Screwdriver Set | For adjusting and securing screws in different applications. |

| Multimeter | To check electrical connections and troubleshoot issues. |

| Cleaning Supplies | For maintaining cleanliness and preventing buildup of debris. |

| Safety Gear | To ensure protection during maintenance tasks. |

Safety Precautions During Repairs

When undertaking maintenance on any machinery, prioritizing safety is essential. Adhering to proper precautions not only protects the individual performing the task but also ensures the equipment operates efficiently post-repair. Recognizing potential hazards and implementing measures to mitigate them can prevent accidents and injuries.

Wear Appropriate Personal Protective Equipment (PPE): Always use suitable gear, such as gloves, goggles, and sturdy footwear, to shield against potential injuries. This equipment acts as your first line of defense against harmful substances and mechanical risks.

Disconnect Power Sources: Before starting any repair, ensure that the device is completely powered down and unplugged. This simple step can significantly reduce the risk of electric shock or accidental activation.

Work in a Well-Ventilated Area: Many repair tasks may involve fumes or dust. Ensuring proper airflow can help prevent respiratory issues and maintain a safer working environment.

Keep the Workspace Organized: A clutter-free area minimizes the chance of tripping hazards or misplacing tools. Regularly tidy your workspace to maintain a safe and efficient environment.

Read the Manual: Familiarize yourself with the equipment’s manual. Understanding the manufacturer’s recommendations and safety guidelines will help you perform repairs correctly and safely.

Have a First Aid Kit Accessible: Accidents can happen, even with precautions in place. Having a well-stocked first aid kit nearby ensures prompt treatment in case of minor injuries.

By following these safety guidelines, you can significantly reduce the risk associated with maintenance tasks, leading to a more effective and secure repair process.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components of cleaning equipment, providing clarity for users seeking guidance on maintenance and replacements.

- What are the signs that a component needs to be replaced?

Indicators include unusual noises, leaks, reduced performance, or visible damage.

- How do I identify the correct replacement component?

Refer to the user manual or product specifications to ensure compatibility with your equipment.

- Can I use generic components instead of original ones?

While some generic options may fit, using original components is often recommended for optimal performance.

- Where can I purchase quality components?

Authorized dealers, reputable online retailers, and local hardware stores are good sources.

- How often should I check my equipment for wear and tear?

Regular inspections before and after use can help catch issues early and prolong the lifespan of your device.

Where to Buy Replacement Parts

Finding the right components for your cleaning equipment is essential for maintaining its performance and longevity. Numerous avenues exist for sourcing these crucial elements, ensuring you can restore your device to its ultimate efficiency.

Online Retailers: E-commerce platforms provide a vast selection, often featuring user reviews to guide your purchase decisions. Websites like Amazon and eBay are great starting points.

Specialty Stores: Local shops that focus on outdoor equipment or home maintenance can offer expert advice and a hands-on experience when selecting the necessary components.

Manufacturer’s Website: Directly visiting the official site can lead you to authentic replacements, ensuring compatibility and quality.

Second-Hand Options: Consider thrift stores or online classifieds for budget-friendly alternatives, but verify the condition and compatibility of the items.

Upgrading Your Pressure Washer Components

Enhancing the efficiency and performance of your cleaning equipment can lead to remarkable improvements in your cleaning tasks. By selecting high-quality upgrades, you can achieve better results, save time, and extend the lifespan of your machine.

When considering enhancements, focus on the following areas:

- Hoses: Upgrading to a more durable and flexible hose can improve mobility and reduce kinks.

- Nozzles: Different nozzle types provide varied spray patterns, allowing for tailored cleaning based on the task.

- Detergent Injectors: A more efficient injector can optimize soap application, improving the overall cleaning process.

- Pumps: Investing in a higher-performance pump can boost water flow and pressure, enhancing cleaning power.

Each component plays a crucial role in the functionality of your equipment. Here are some steps to guide you through the upgrade process:

- Assess your current setup to identify areas for improvement.

- Research compatible upgrades that suit your specific model.

- Purchase high-quality components from reputable suppliers.

- Follow installation instructions carefully or seek professional help if needed.

- Test the upgraded equipment to ensure optimal performance.

By strategically upgrading components, you can transform your cleaning experience, making it more efficient and effective.