The efficient operation of any machinery relies heavily on its internal structure and functionality. Knowledge of how various elements interconnect can greatly enhance maintenance practices and repair efforts. By familiarizing oneself with the layout of crucial components, users can ensure optimal performance and longevity of their equipment.

In this section, we will explore the essential features of a specific device. Each segment plays a vital role in overall functionality, and understanding their arrangement is key for troubleshooting and enhancements. A thorough examination of these features will provide valuable insights into the workings of the machinery.

By delving into the intricacies of these essential elements, individuals can better appreciate the significance of each component and their contributions to the entire system. This knowledge empowers users to make informed decisions regarding upkeep and improvements, ultimately leading to a more efficient and reliable operation.

This section aims to provide a comprehensive understanding of the different components and mechanisms involved in these powerful tools. By examining the various elements that contribute to their functionality, readers will gain insights into how these devices operate and the importance of each segment.

Key Components of the Device

- Power Source: This element is crucial for generating the necessary energy to drive the system.

- Pressure Regulator: Responsible for maintaining the desired pressure levels within the unit.

- Tank: Serves as a reservoir for storing compressed resources, ensuring consistent output.

- Valves: These components control the flow and direction of the resources as needed.

- Hoses and Connectors: Facilitate the transfer of the medium to various tools and accessories.

Functionality and Maintenance

- Regular Inspection: Routine checks are essential for identifying wear and tear in critical components.

- Cleaning: Keeping the exterior and interior parts free from debris enhances performance.

- Lubrication: Applying appropriate lubricants ensures smooth operation and prolongs lifespan.

- Replacement of Worn Parts: Timely substitution of damaged segments is vital for optimal performance.

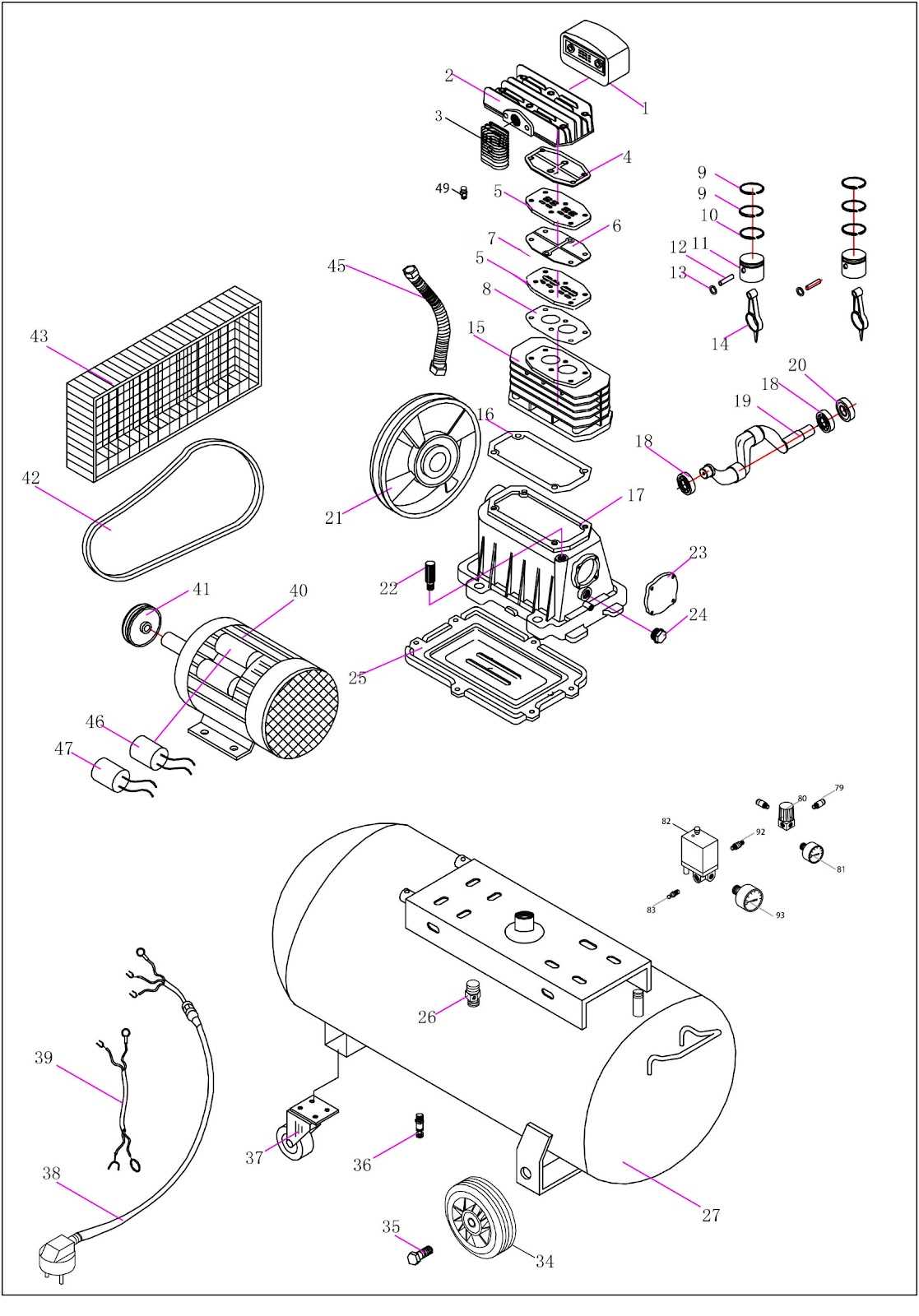

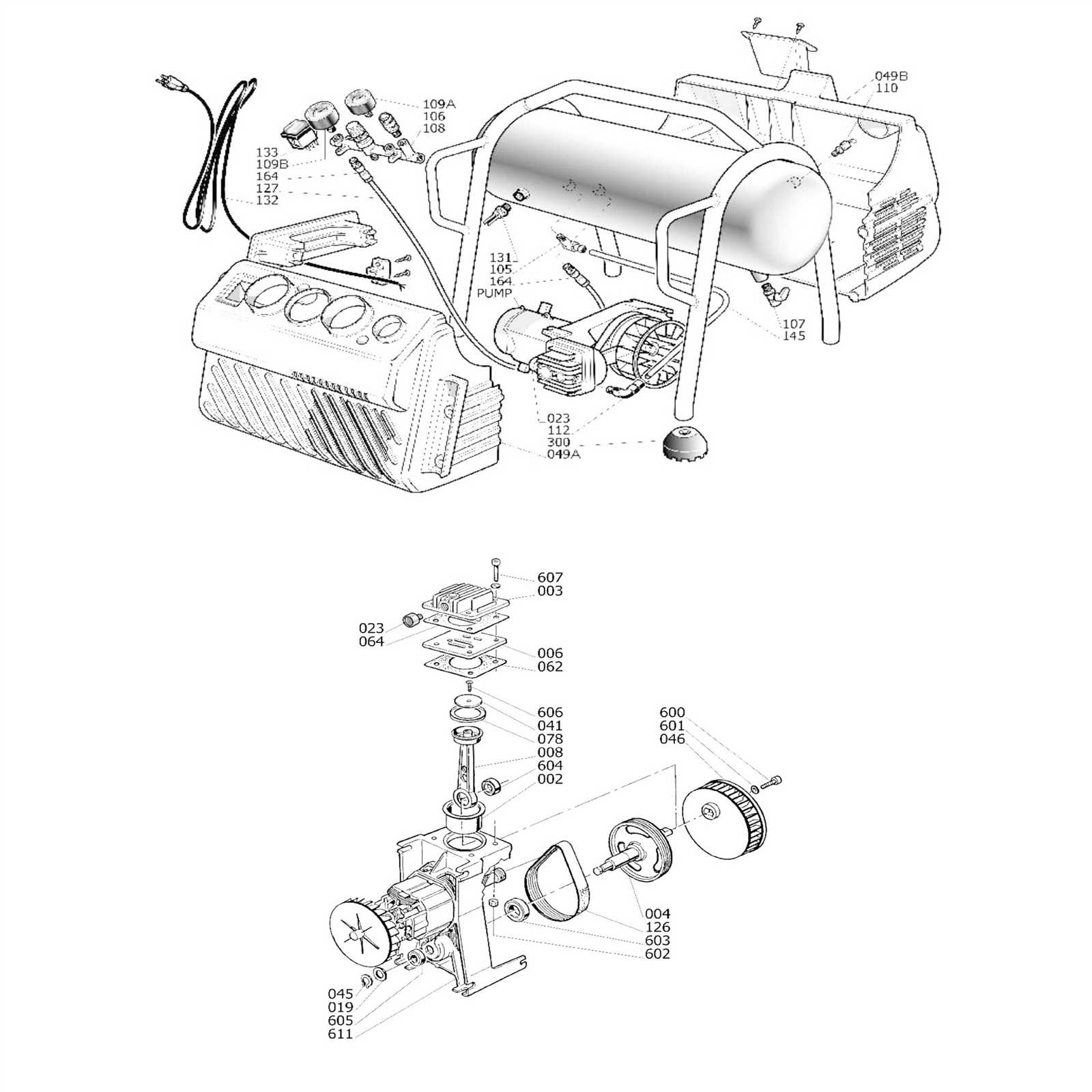

Key Components of Air Compressors

Understanding the fundamental elements that contribute to the functionality of these machines is essential for effective operation and maintenance. Each component plays a crucial role in ensuring optimal performance and reliability, facilitating a variety of tasks across different industries.

Power Source

The power source serves as the backbone, supplying the necessary energy to initiate the system’s operations. It can vary from electric motors to gasoline engines, depending on the model and intended usage. The efficiency and type of the power source significantly influence the overall performance and portability of the device.

Storage Tank

The storage tank acts as a reservoir for the compressed medium, providing a consistent supply during operation. Its capacity determines how long the system can run before needing to replenish its contents. A well-designed tank minimizes fluctuations in pressure, contributing to smoother and more effective functioning.

Understanding Compressor Functionality

The operation of a device designed to increase the pressure of a gas involves several key components and mechanisms. Each element plays a crucial role in ensuring efficiency and effectiveness during the compression process. This section explores the fundamental aspects of how these devices work, providing insight into their inner workings and the significance of each component.

At the heart of this system lies the mechanism responsible for the intake and compression of gas, transforming it from a lower-pressure state to a higher-pressure state. Understanding these processes helps in recognizing the importance of maintenance and troubleshooting for optimal performance.

| Component | Function |

|---|---|

| Motor | Drives the unit, providing the necessary energy to compress the gas. |

| Pump | Compresses the gas by reducing its volume, increasing its pressure. |

| Tank | Stores the high-pressure gas for later use, ensuring a steady supply. |

| Regulator | Controls the pressure of the gas being released, maintaining safety and efficiency. |

| Hoses | Facilitate the movement of gas from the tank to various applications. |

Common Issues in Air Compressors

Understanding the frequent problems that can arise in pressure systems is essential for maintaining efficiency and extending the lifespan of the equipment. By recognizing these challenges, operators can take proactive measures to ensure smooth operation and minimize downtime.

Frequent Malfunctions

Several typical malfunctions may occur, impacting the performance of the machinery. Identifying these issues early can help in addressing them promptly.

| Issue | Description | Potential Solutions |

|---|---|---|

| Leakage | Unintended escape of fluid from connections or hoses. | Inspect seals and fittings; replace worn components. |

| Noisy Operation | Excessive noise during functioning can indicate underlying problems. | Check for loose parts; lubricate moving components. |

| Insufficient Pressure | Failure to achieve desired pressure levels for effective operation. | Examine intake filters; verify power supply connections. |

| Overheating | High temperatures can lead to damage and decreased efficiency. | Ensure proper ventilation; clean cooling fins and filters. |

Maintenance Tips

Regular upkeep is crucial to prevent issues from escalating. Implementing a consistent maintenance schedule will help keep the system functioning optimally.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your equipment, regular upkeep is essential. Implementing a consistent maintenance routine can significantly enhance functionality and prevent potential breakdowns. This section provides crucial insights into maintaining your device for peak operation.

Start by routinely checking and replacing filters. Clogged filters can impede airflow, leading to decreased efficiency. Additionally, keep the exterior clean to prevent dust and debris from entering sensitive components. Regular lubrication of moving parts is also vital, as it minimizes friction and wear.

Monitor pressure levels and ensure they align with manufacturer specifications. Over-pressurization can cause stress on components, leading to premature failure. Furthermore, inspect hoses and connections for leaks or damage, as these can adversely affect performance.

Lastly, consult the manufacturer’s guidelines for specific maintenance schedules and procedures. Adhering to these recommendations will help maintain optimal performance and extend the lifespan of your equipment.

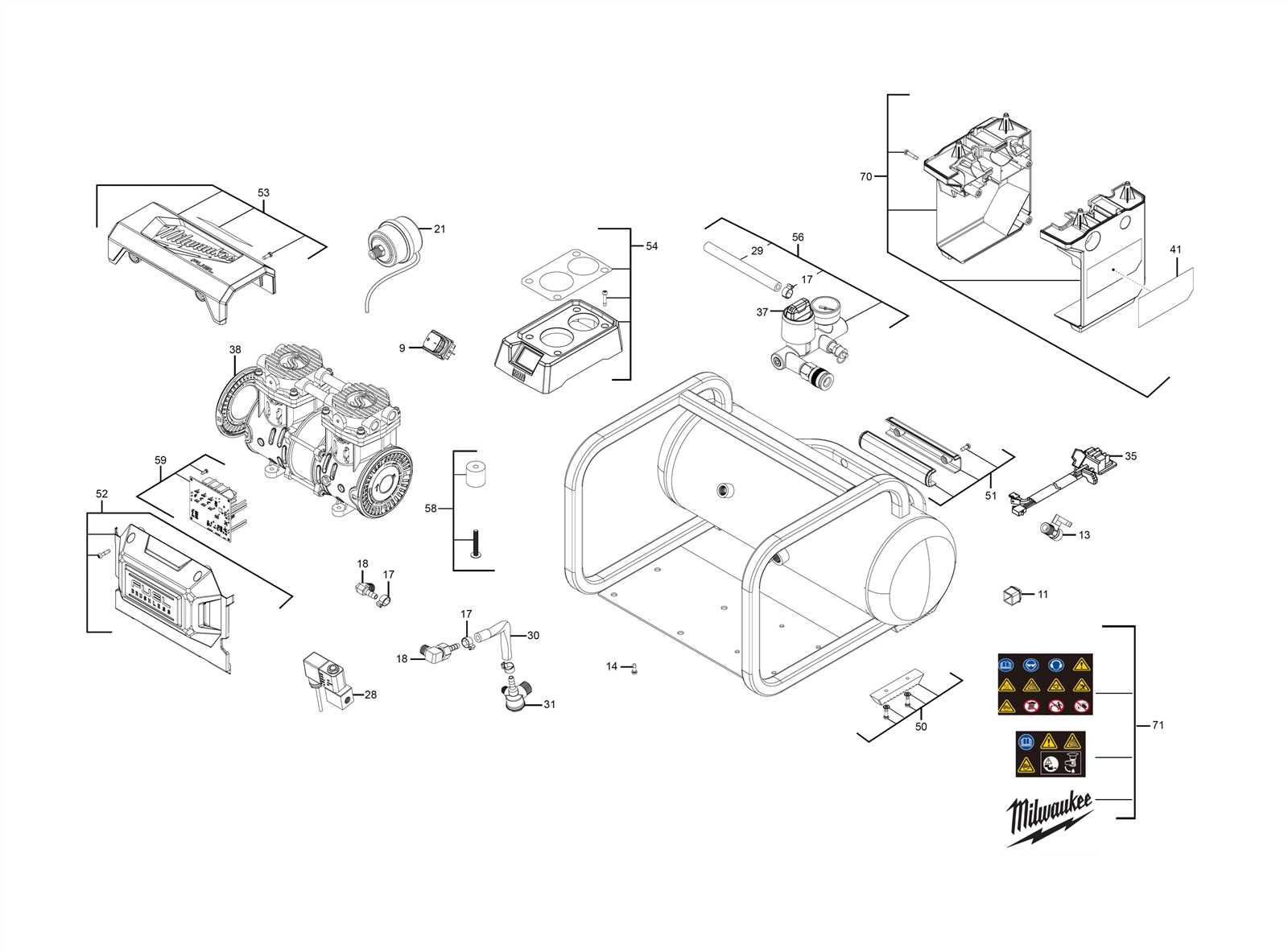

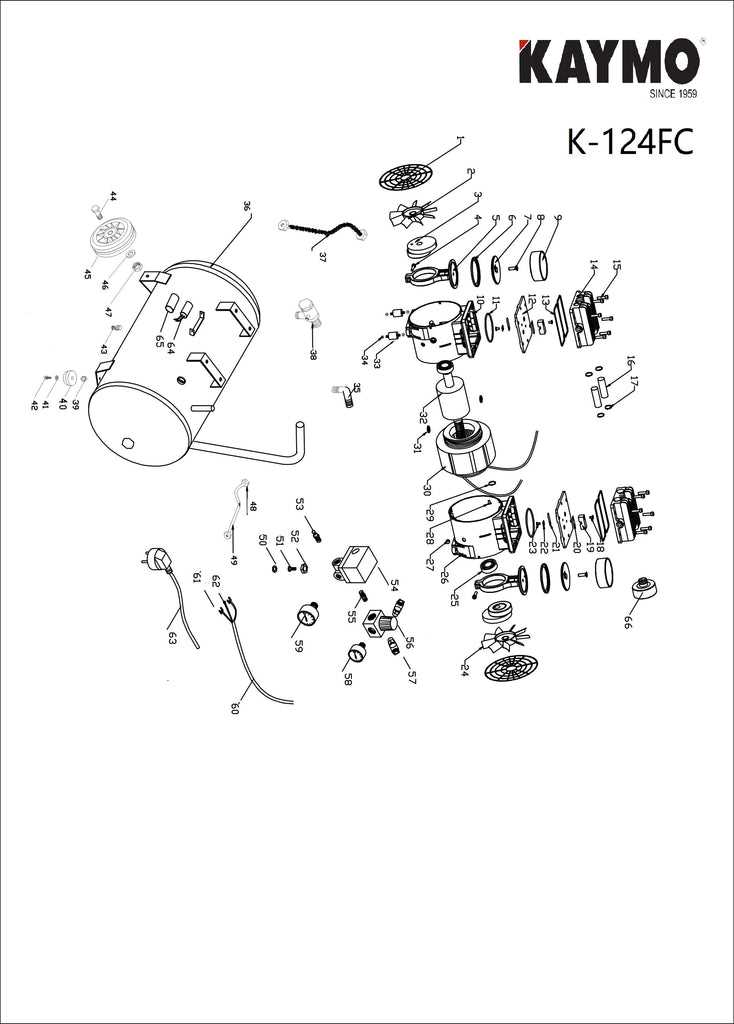

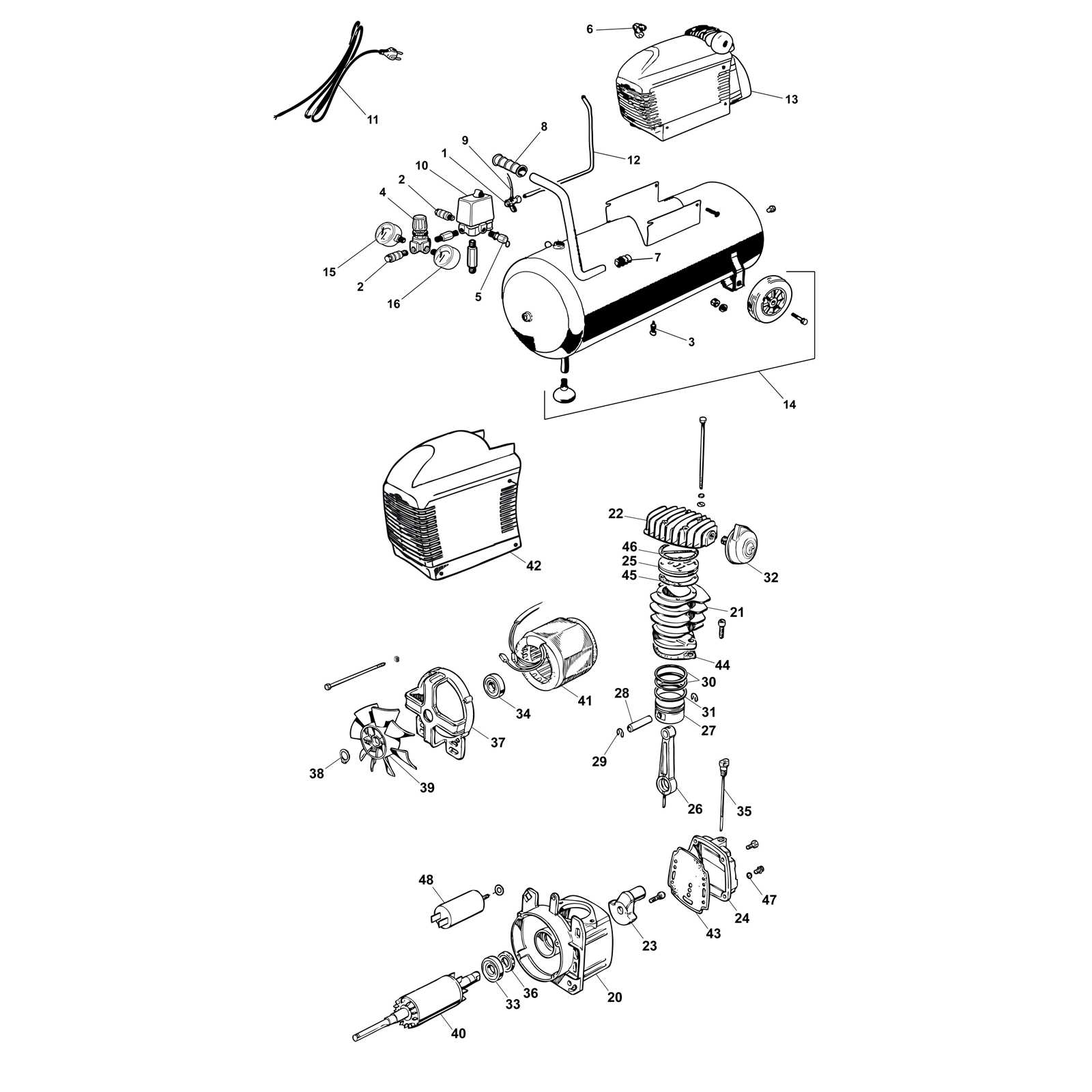

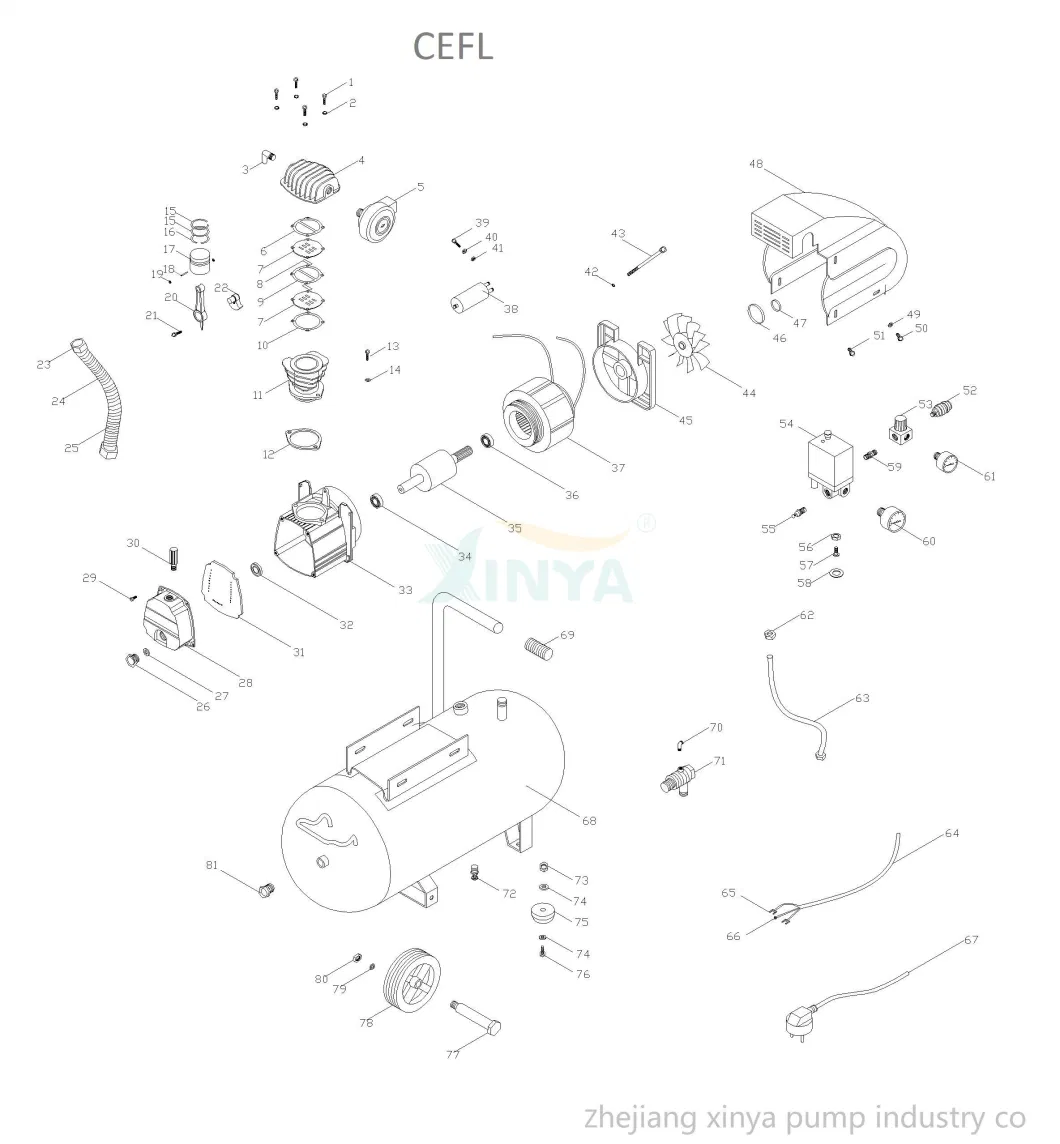

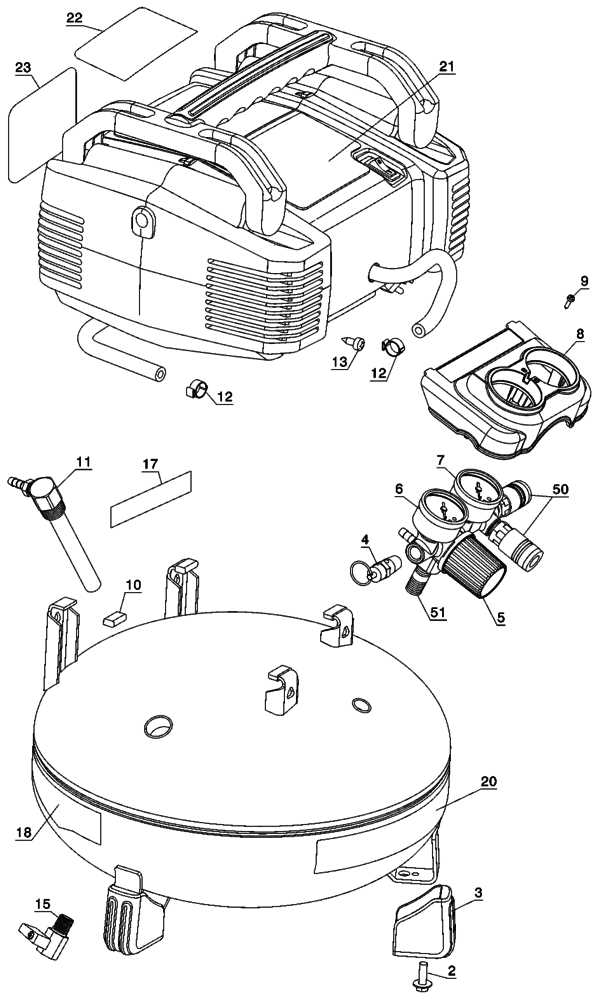

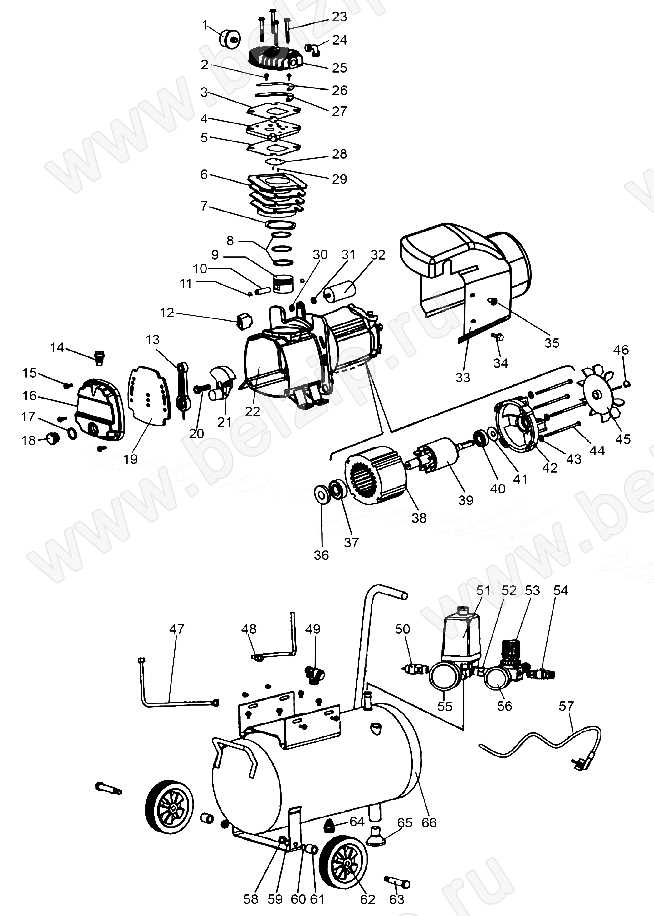

How to Identify Parts Easily

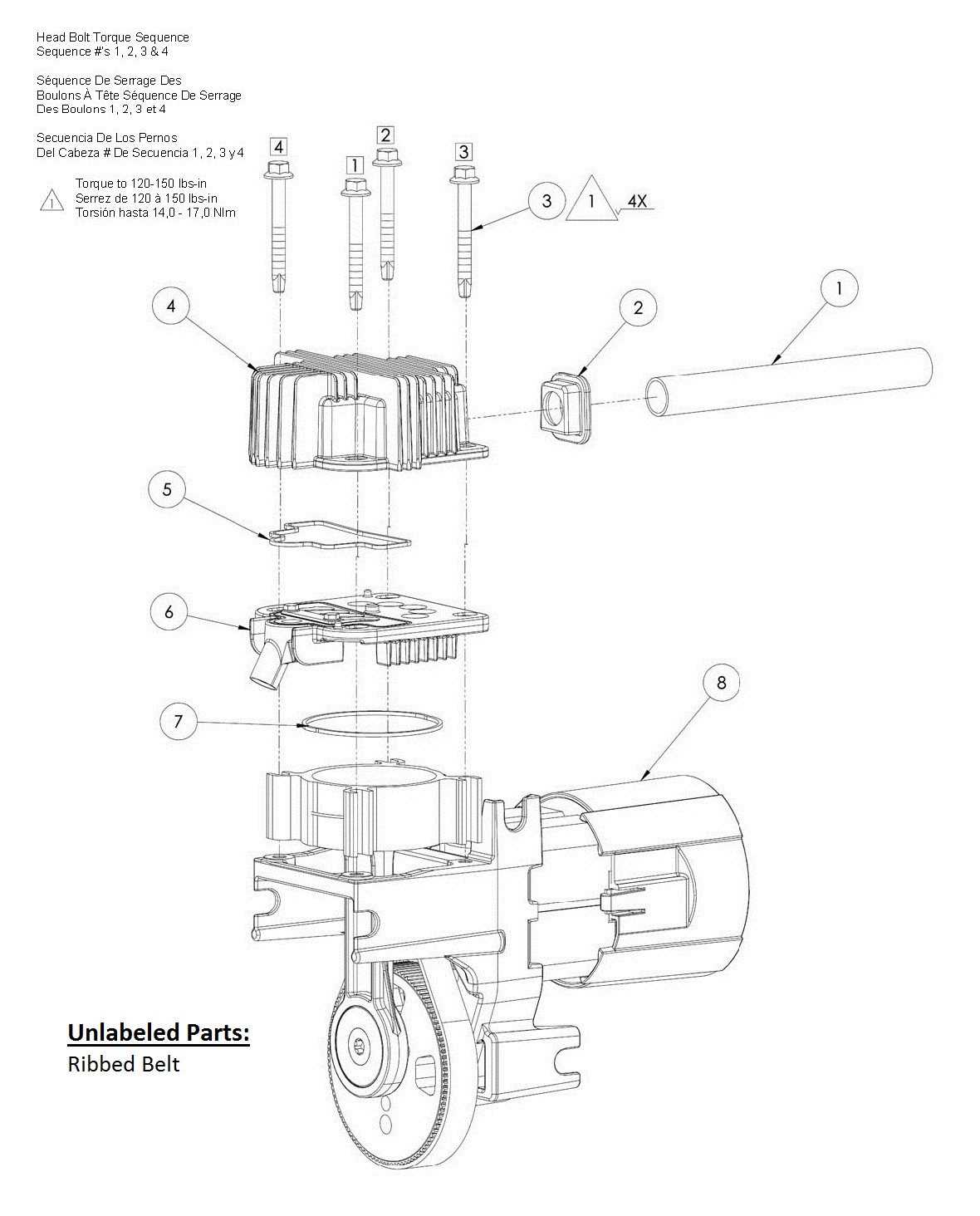

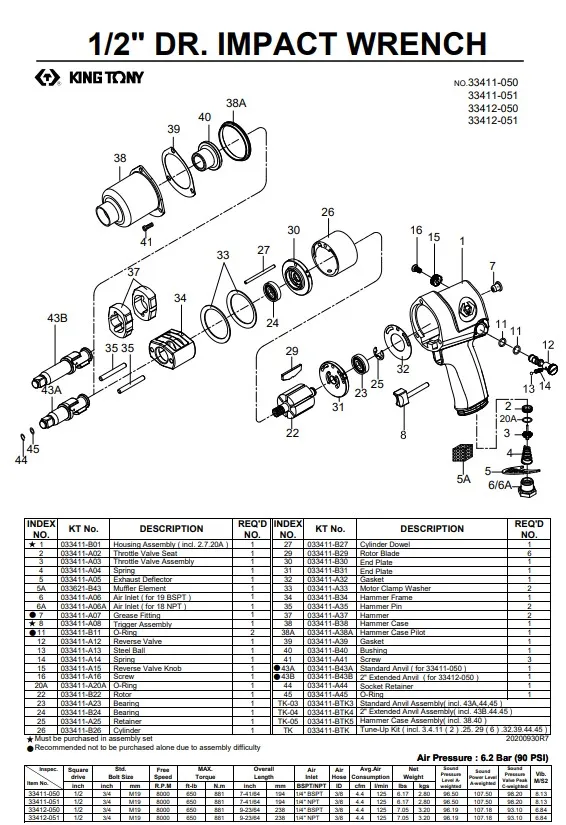

Understanding the components of your machinery can enhance efficiency and maintenance. Recognizing each element’s function and location allows for quicker repairs and better performance. This guide will provide methods to simplify the identification process, ensuring you can locate the necessary elements with ease.

Utilizing Reference Manuals

One effective approach is to consult reference manuals that outline the various elements of your equipment. These documents often contain detailed descriptions and images that can aid in pinpointing specific items. Familiarizing yourself with these resources can save time during maintenance tasks and ensure you have a clear understanding of how everything fits together.

Visual Inspection Techniques

Conducting a thorough visual inspection is another helpful strategy. Start by examining the overall assembly and noting the placement of each component. Taking photographs during disassembly can also provide valuable visual aids for reassembly. This method allows you to track each section and its corresponding function, making it easier to identify them in the future.

Replacing Worn-out Components

Over time, certain elements of a mechanical system can deteriorate due to regular usage, leading to inefficiencies or even failures. Addressing these issues promptly is crucial for maintaining optimal functionality. This section provides guidance on how to identify and replace these aged elements effectively, ensuring the unit continues to operate smoothly.

Regular maintenance checks are essential to detect signs of wear. Common indicators include unusual noises, reduced performance, and leaks. Once you identify a compromised component, follow the steps below for replacement:

| Step | Description |

|---|---|

| 1 | Turn off the machine and disconnect from the power source to ensure safety during repairs. |

| 2 | Carefully inspect the unit to locate the worn component, noting any visible damage. |

| 3 | Remove the damaged part using appropriate tools, taking care not to disturb surrounding components. |

| 4 | Install the new component, ensuring it is secured properly and aligned with existing parts. |

| 5 | Reconnect the power source and conduct a test run to verify that the replacement has restored proper function. |

By replacing worn elements as needed, you can significantly extend the lifespan of the system and enhance its overall performance.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right tools is essential for efficiency and effectiveness. Proper equipment not only streamlines the process but also ensures safety and accuracy during repairs.

Below is a list of essential tools you should gather before beginning any repair work:

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for different types of screws.

- Socket Set: A set of sockets for dealing with different bolt sizes.

- Pliers: For gripping, bending, and cutting wires or small components.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Multimeter: For testing electrical connections and diagnosing issues.

- Safety Gear: Gloves, goggles, and other protective equipment to ensure safety during repairs.

Collecting these tools in advance will help you tackle repairs with confidence and precision, minimizing delays and potential setbacks.

Safety Precautions During Maintenance

Proper maintenance of equipment is crucial to ensure safe and efficient operation. Following essential safety measures during servicing can prevent accidents and prolong the lifespan of the machinery. Awareness of potential hazards and proactive steps can significantly mitigate risks.

Essential Guidelines

- Always disconnect the power supply before beginning any maintenance work.

- Use personal protective equipment (PPE) such as gloves, goggles, and ear protection to safeguard against injuries.

- Ensure the work area is well-ventilated to avoid inhalation of harmful fumes or dust.

- Keep the workspace tidy and organized to prevent trips and falls.

Regular Inspections

- Examine all components for wear and damage before starting maintenance.

- Check for leaks or irregularities in the system, addressing issues immediately.

- Test safety features regularly to ensure they are functioning correctly.

Benefits of Genuine Replacement Parts

Utilizing authentic components in machinery repair and maintenance ensures optimal functionality and longevity. These original elements are designed specifically for the equipment, providing a seamless fit and reliable performance that imitators cannot replicate.

Enhanced Performance

Original components enhance the overall efficiency of your device. They are crafted to meet the precise specifications of the manufacturer, ensuring that every function operates smoothly. This leads to improved output and reduced risk of breakdowns, ultimately saving time and resources.

Increased Reliability

When using genuine elements, users can trust in their durability and quality. These components undergo rigorous testing and adhere to strict standards, resulting in dependable operation. Investing in authentic replacements minimizes the chances of malfunction and extends the lifespan of the equipment.

Resources for Further Assistance

When dealing with mechanical equipment, having access to reliable sources of information can greatly enhance your understanding and troubleshooting abilities. Whether you are seeking guidance for maintenance, repairs, or upgrades, there are numerous resources available to help you navigate the complexities of your device.

Online Forums and Communities

Engaging with online forums can provide invaluable insights and support. Enthusiasts and professionals often share their experiences and solutions, fostering a collaborative environment. Below is a table highlighting some popular platforms:

| Platform | Description | Link |

|---|---|---|

| A wide variety of subreddits focused on machinery and DIY repairs. | Visit Reddit | |

| Stack Exchange | A Q&A platform where experts provide detailed answers to technical queries. | Visit Stack Exchange |

| Facebook Groups | Community-driven groups for sharing tips and advice among members. | Visit Facebook |

Manufacturer’s Support

Another essential resource is the support provided by manufacturers. Official websites often feature comprehensive guides, FAQs, and customer service contacts that can assist you with specific queries regarding your equipment.