In the world of power equipment, familiarity with each element can significantly enhance performance and maintenance. A clear representation of these components can serve as a vital resource for both professionals and enthusiasts alike. When you grasp the intricacies of your machinery, you set the stage for optimal usage and longevity.

Detailed visuals that outline the various sections of your device not only aid in assembly but also streamline troubleshooting. This knowledge empowers users to tackle repairs with confidence, ensuring that every piece functions harmoniously. With the right information at hand, you can delve into your tool’s workings, unveiling the ultimate potential it has to offer.

Whether you’re a seasoned user or a newcomer, understanding the assembly of your equipment allows for informed decisions regarding upgrades and replacements. By mapping out the relationships between different elements, you can enhance both efficiency and safety. Embracing this knowledge will ultimately lead to a more satisfying experience with your power tool.

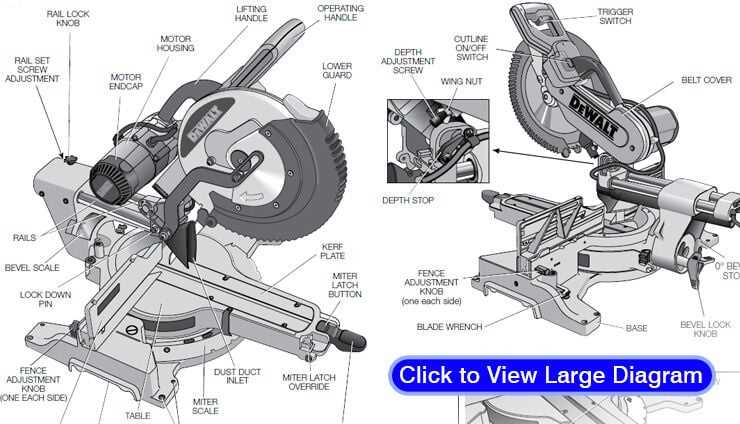

Dws779 Parts Overview

This section provides a comprehensive look at the essential components of a specific cutting tool model, highlighting their functions and interrelationships. Understanding each element is crucial for effective maintenance and optimal performance, ensuring that users can navigate any repairs or upgrades with confidence.

Key Components

The primary elements of the tool include the motor, blade assembly, and base. Each plays a vital role in the overall functionality, contributing to precision and efficiency. The motor powers the device, while the blade assembly ensures clean cuts, and the base provides stability during operation.

Maintenance Considerations

Key Components Explained

Understanding the essential elements of any tool is crucial for effective usage and maintenance. This section will explore the primary features that contribute to the functionality and efficiency of the device, providing insights into their roles and importance.

Motor: The heart of the machine, responsible for powering the tool and ensuring it operates smoothly under various conditions.

Blade: A critical component that determines the quality of cuts, available in various types to suit different applications.

Base Plate: This provides stability and accuracy during use, allowing for precise adjustments and secure positioning.

Guard: Essential for safety, this feature protects the user from debris and potential accidents while operating the device.

Adjustment Mechanism: Facilitates easy modifications to settings, enabling users to tailor the performance to their specific needs.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in various fields, enabling users to understand complex information efficiently. These illustrations serve as essential tools for communication, offering insights that textual descriptions alone may fail to convey. Accurate depictions ensure that every component and its relationship to others are easily discernible, facilitating smoother interactions and operations.

Enhancing Clarity: When visual aids are meticulously crafted, they reduce the chances of misinterpretation. This clarity is vital in technical environments, where details matter significantly. By providing an organized view of intricate systems, these visuals help users grasp functionality and interdependencies with ease.

Supporting Maintenance: Properly constructed visuals are indispensable for maintenance and troubleshooting. They allow technicians to quickly identify issues and locate necessary elements, saving time and minimizing errors. This efficiency is especially important in high-pressure situations where swift resolutions are required.

Facilitating Learning: For learners and new users, well-designed visuals serve as valuable educational resources. They simplify complex ideas and processes, making it easier to absorb and retain information. This foundational understanding paves the way for more advanced learning and proficiency.

Promoting Collaboration: In team settings, accurate representations foster effective collaboration. When everyone can visualize the same concepts, discussions become more productive, and decision-making is enhanced. A shared understanding of the system at hand creates a more cohesive working environment.

Ultimately, the significance of precise illustrations cannot be overstated. They are not just supplementary materials but essential components that enhance functionality, learning, and collaboration in any technical endeavor.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective assembly and maintenance. These illustrations provide valuable insights into the relationships between different elements, helping users identify each piece’s role and function within a larger system.

Breaking Down the Visuals

To fully grasp the information presented, focus on key aspects such as labels, numbers, and the layout. Each component is usually marked with unique identifiers that correlate with corresponding descriptions in the documentation.

Utilizing Reference Tables

Reference tables enhance comprehension by linking visual cues to detailed specifications. Here’s an example of how a simple table might look:

| Identifier | Description | Quantity |

|---|---|---|

| A1 | Main housing | 1 |

| B2 | Power switch | 1 |

| C3 | Blade assembly | 2 |

By methodically analyzing these illustrations alongside their accompanying reference materials, one can effectively navigate and understand complex assembly processes.

Common Issues with Dws779

When working with high-performance tools, users often encounter a variety of challenges that can affect efficiency and accuracy. Understanding these common problems can help in troubleshooting and maintaining optimal functionality. This section highlights prevalent concerns and offers insights into potential solutions.

Frequent Problems

Users may experience issues such as inconsistent cutting performance, excessive noise, or mechanical failures. Identifying these symptoms early can prevent further complications and ensure safety during operation.

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent Cuts | Worn or damaged blades | Replace blades regularly |

| Excessive Noise | Loose components | Tighten screws and bolts |

| Overheating | Insufficient lubrication | Apply appropriate lubricant |

Maintenance Tips

Regular maintenance is crucial for prolonging the lifespan of your equipment. Ensuring that all components are properly aligned and lubricated can significantly reduce the risk of encountering these issues. Additionally, following the manufacturer’s guidelines will help in maintaining optimal performance.

Finding Replacement Parts

When it comes to maintaining your tools, locating the correct components is essential for ensuring optimal performance and longevity. Whether you are replacing worn-out elements or upgrading your equipment, having access to accurate information can streamline the process and prevent unnecessary downtime.

There are several strategies to effectively source the necessary items. Start by consulting the manufacturer’s documentation, which often includes detailed information about compatible components and their specifications. Online resources can also provide a wealth of knowledge, allowing you to cross-reference models and identify the right options for your specific needs.

| Source | Description |

|---|---|

| Manufacturer’s Website | Official source for specifications and recommended components. |

| Online Retailers | Variety of options and competitive pricing for various items. |

| Local Hardware Stores | Personal assistance and immediate availability of common items. |

| Forums and Communities | Advice and recommendations from fellow users with similar needs. |

By utilizing these resources, you can ensure that you find the right components for your tool, helping to maintain its efficiency and functionality over time.

Tools Needed for Repairs

When undertaking repairs on equipment, having the right instruments is essential for efficient and effective work. Proper tools not only streamline the repair process but also ensure that the job is done safely and to a high standard. Here’s a breakdown of essential tools that can facilitate your repair tasks.

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers, including flathead and Phillips, for removing and securing screws. |

| Wrench Set | Different sizes of wrenches to tighten or loosen nuts and bolts. |

| Pliers | Used for gripping, twisting, or cutting wires and small parts. |

| Allen Keys | Essential for working with hex screws and fittings commonly found in machinery. |

| Multimeter | A tool for measuring voltage, current, and resistance to troubleshoot electrical issues. |

| Safety Gear | Protective equipment such as gloves, goggles, and masks to ensure safety during repairs. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any equipment. By implementing a few straightforward practices, users can extend the life of their tools, enhance performance, and reduce the likelihood of unexpected failures. This section outlines key strategies to keep your machinery in optimal condition.

Routine Cleaning

Keeping your tools clean is vital for preventing the accumulation of dust and debris, which can hinder performance. Make it a habit to wipe down surfaces after each use and periodically inspect for any buildup in hard-to-reach areas. A clean machine not only operates more efficiently but also reduces wear and tear.

Regular Inspections

Conducting regular inspections allows you to identify potential issues before they escalate. Check for any signs of damage, wear, or loose components. Addressing these concerns promptly can save time and money in the long run.

| Maintenance Task | Frequency |

|---|---|

| Cleaning | After each use |

| Inspection | Weekly |

| Lubrication | Monthly |

| Replacement of worn parts | As needed |

Safety Precautions During Repair

Ensuring safety while performing maintenance tasks is crucial for both the technician and the equipment. Proper precautions can prevent accidents and damage, leading to a smoother repair process. Familiarity with the tools and understanding potential hazards can greatly enhance overall safety.

Use Personal Protective Equipment

Always wear appropriate personal protective gear such as gloves, goggles, and hearing protection. This equipment serves as a barrier against various risks, including sharp objects, chemicals, and loud noises, thereby safeguarding your well-being during the repair.

Maintain a Clean Workspace

A tidy work area is essential to minimize the risk of accidents. Remove any unnecessary items and ensure that tools are organized. A clutter-free environment allows for better focus and reduces the chances of mishaps while working on the machinery.

Upgrading Your Dws779

Enhancing the performance and functionality of your tool can significantly improve your woodworking projects. Whether you aim for precision cuts or increased efficiency, upgrading components can make a noticeable difference. This guide will explore various enhancements that can help you get the most out of your equipment.

Key Upgrades to Consider

- Blade Selection: Investing in high-quality blades can improve cut quality and prolong the tool’s life.

- Motor Upgrades: If applicable, consider options that provide greater power and efficiency for demanding tasks.

- Dust Collection Systems: Adding or improving dust extraction can create a cleaner workspace and enhance visibility.

- Fences and Stops: Upgrading to more precise fences can ensure accurate measurements and repeatability.

Installation Tips

- Always refer to the manufacturer’s guidelines when replacing any components.

- Use the proper tools and safety equipment during the installation process.

- Test the equipment after making upgrades to ensure everything functions correctly.

- Regular maintenance post-upgrade is crucial to keep the tool in optimal condition.

By selecting the right enhancements and following installation best practices, you can take your projects to the next level and achieve professional results.

Expert Recommendations for Parts

When it comes to enhancing the longevity and performance of your equipment, understanding the components involved is essential. Professionals in the field emphasize the importance of selecting high-quality replacements and maintaining them regularly to ensure optimal functionality.

Quality Matters

Investing in durable and reliable elements can significantly impact your machinery’s efficiency. Experts suggest prioritizing brands known for their robust construction and excellent performance history, as this can save both time and money in the long run.

Regular Maintenance

Frequent checks and upkeep are crucial. By routinely assessing the condition of your equipment and its components, you can prevent unexpected failures and enhance overall productivity. Always refer to reliable sources for guidance on best practices and care recommendations.

Where to Source Quality Components

Finding reliable and high-quality elements for your tools can greatly enhance performance and longevity. Understanding the best sources can save time and ensure you are investing in durable materials that meet your needs.

Top Sources for Quality Parts

- Manufacturer Websites: Directly purchasing from the original manufacturers ensures authenticity and quality.

- Authorized Dealers: Look for dealers that are certified to sell genuine components.

- Specialty Stores: Local hardware or specialty shops often carry reliable items tailored to specific requirements.

Online Marketplaces

- Reputable E-commerce Platforms: Websites like Amazon or eBay can be useful, but always check seller ratings.

- Dedicated Parts Retailers: Platforms that focus solely on tool components often have a wider selection and expert support.

- Forums and Community Recommendations: Engaging with online communities can provide insights into trustworthy sources.